A device for detritating tritiated water and its realization method

A tritium water and heating device technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high energy consumption and cumbersome processes, and achieve simple and simplified processes Process, energy saving and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

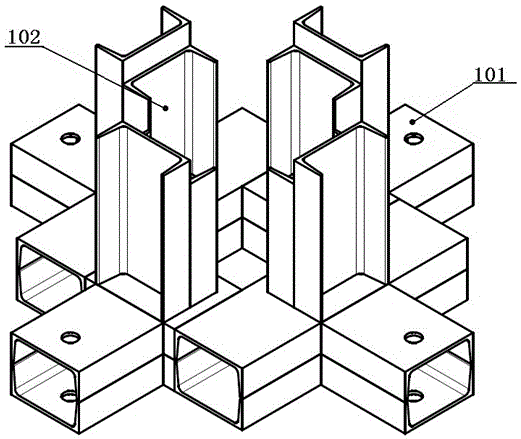

[0037] Such as figure 1 As shown, the present invention is used for isotopic transfer of water and hydrogen under vapor phase conditions to realize the purification treatment of tritium-containing water. The invention includes a raw water storage tank 1, a steam generator 2, a first liquefaction system, a second liquefaction system, a steam heating device 5, a catalytic reaction section 6, a product water collection tank 9 and a base assembly 10. The raw material water storage tank 1 is used to collect tritium-containing water and deliver it to the steam generator 2. The steam generator 2 is used to heat the tritium-containing water to form water vapor, which is then delivered to the water vapor heating device 5 , The water vapor heating device 5, the catalytic reaction section 6 and the second liquefaction system cooperate and pass hydrogen for treatment.

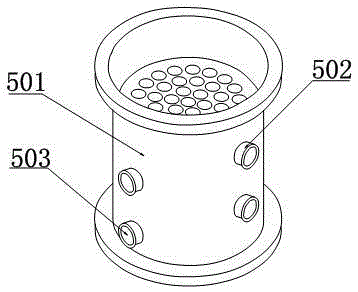

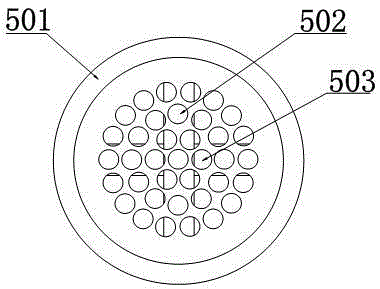

[0038] Such as figure 2 , 3 As shown, the water vapor heating device 5 includes an outer cylinder body 501 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com