Device for removing dioxin through catalytic oxidation for waste gas treatment and using method of device

A catalytic oxidation and waste gas treatment technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of low dioxin oxidation effect and poor dioxin mixing effect, so as to avoid oxidation effect and reduce The effect of overall running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

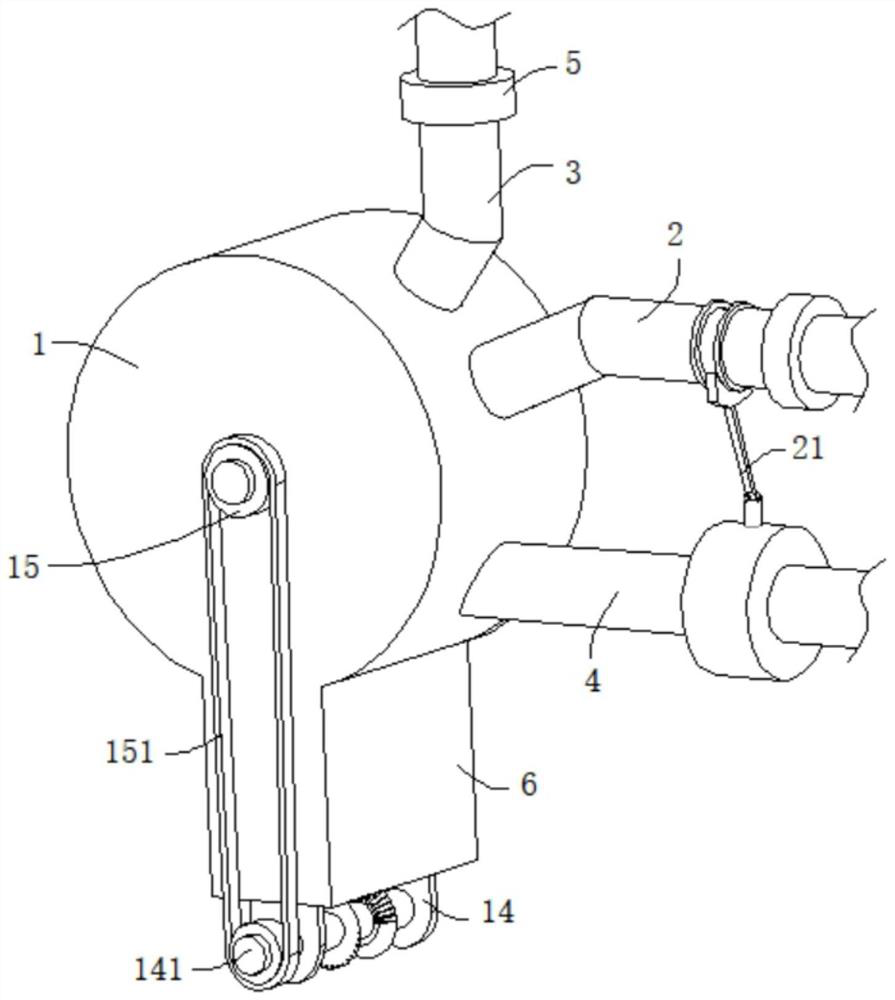

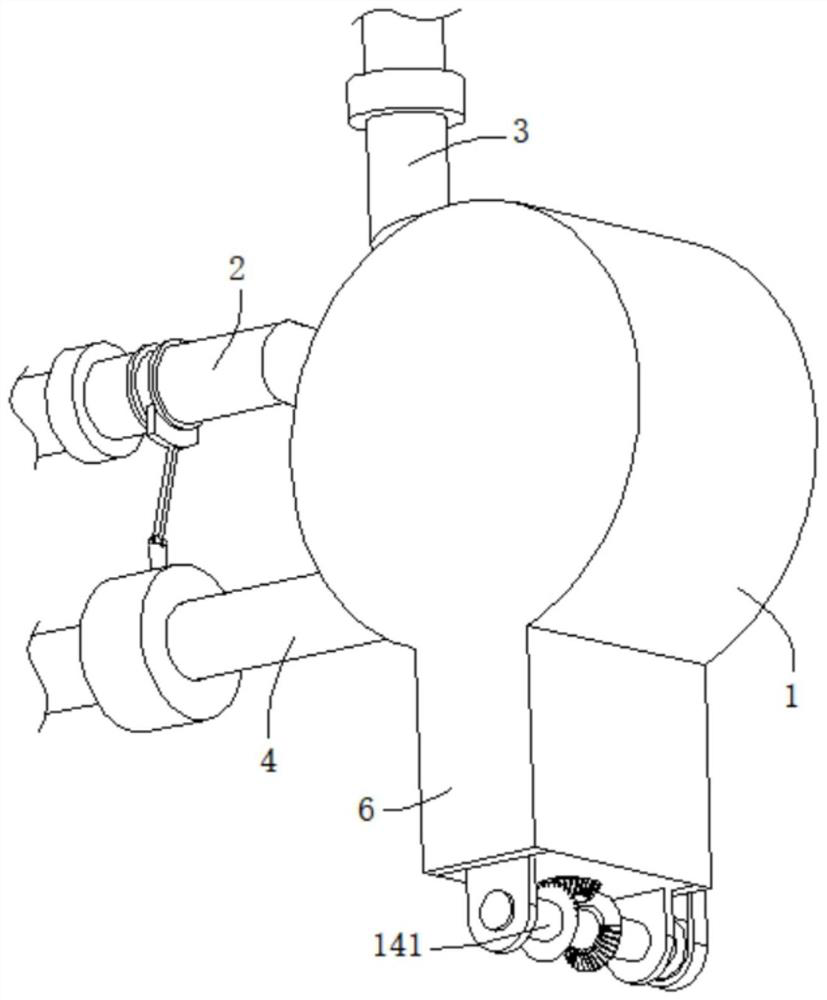

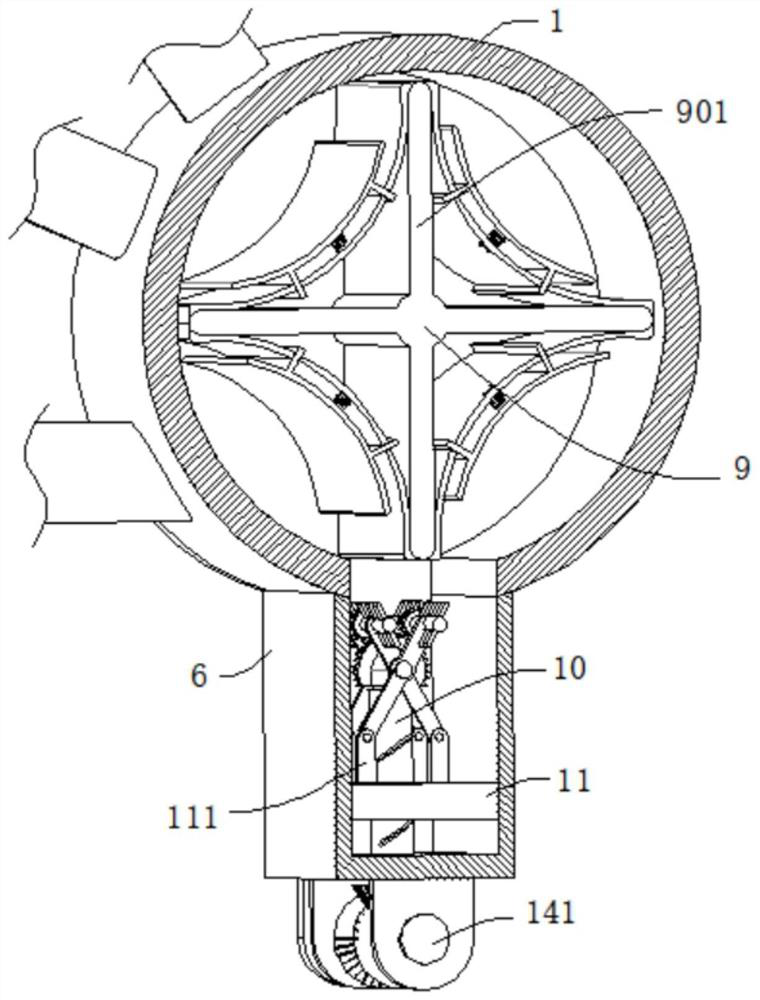

[0040] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 and Figure 10 , a device for removing dioxins by catalytic oxidation for waste gas treatment, comprising a mixing container 1, the two sides of the outer wall of the mixing container 1 are respectively provided with an inlet flue 2 and an outlet flue 4 for transporting flue gas, and the outer wall of the mixing container 1 is also The ozone delivery pipe 3 is connected, the inlet flue 2 and the outer wall of the ozone delivery pipe 3 are fixed with a regulating valve 5, the mixing container 1 is provided with a gas mixing mechanism, and the bottom of the mixing container 1 is connected with a housing 6, and the housing 6 and the mixing The containers 1 communicate with each other, the casing 6 is provided with a secondary mixing mechanism matched with the gas mixing mechanism, the outlet flue 4 is provided with a catalyst layer 7, and the outlet flue 4 is also connected with a spray pipe 8 for transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com