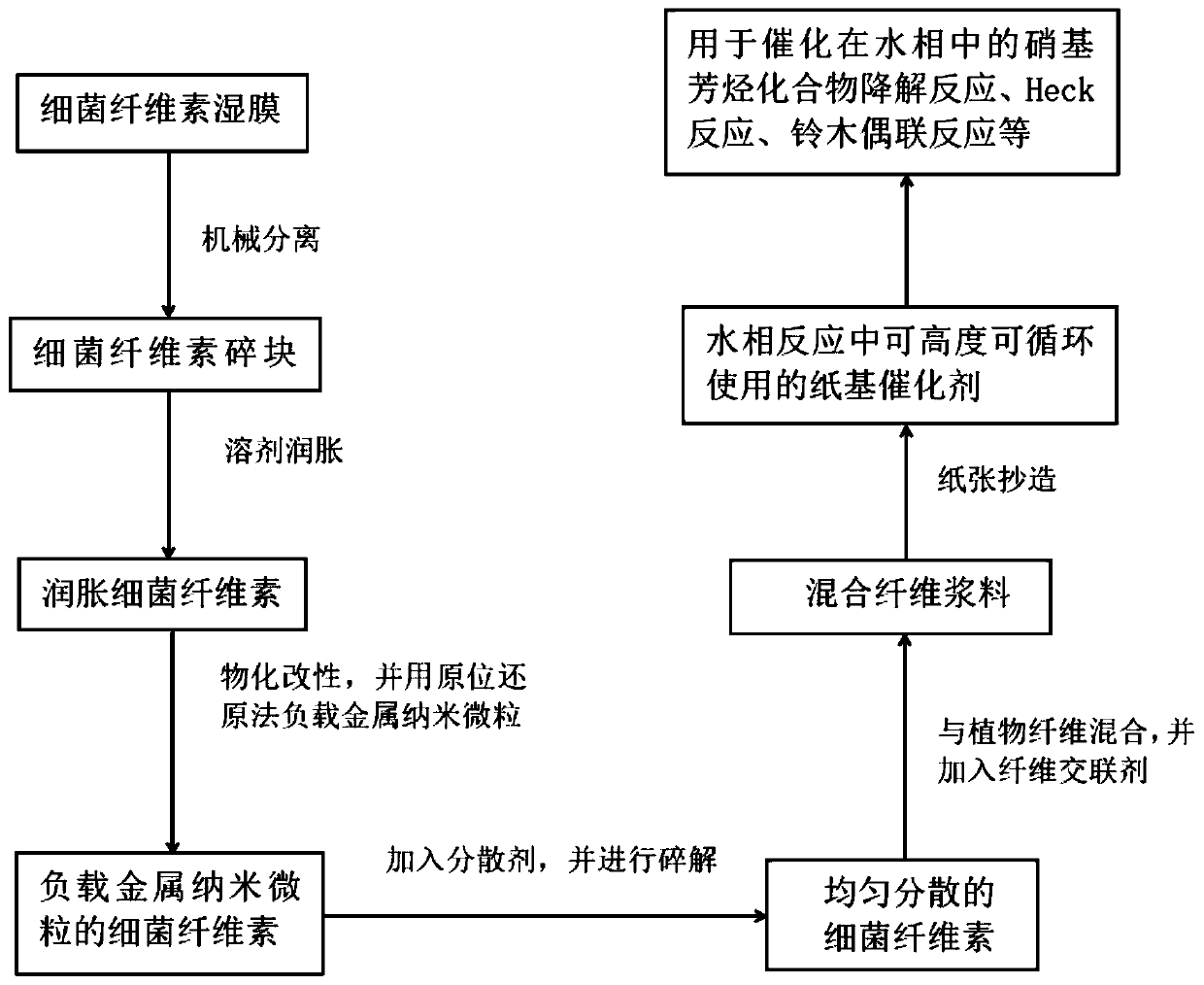

Method for improving water phase reaction recycling capability of bacterial cellulose-plant fiber composite paper-based catalyst

A bacterial cellulose and plant fiber technology, which is applied in catalytic reactions, carbon compound catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of affecting the recycling ability of paper-based catalysts and limiting the use range of paper-based catalysts , dissociation of fiber structure and other issues, to achieve good dispersion and stability, good reaction rate, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

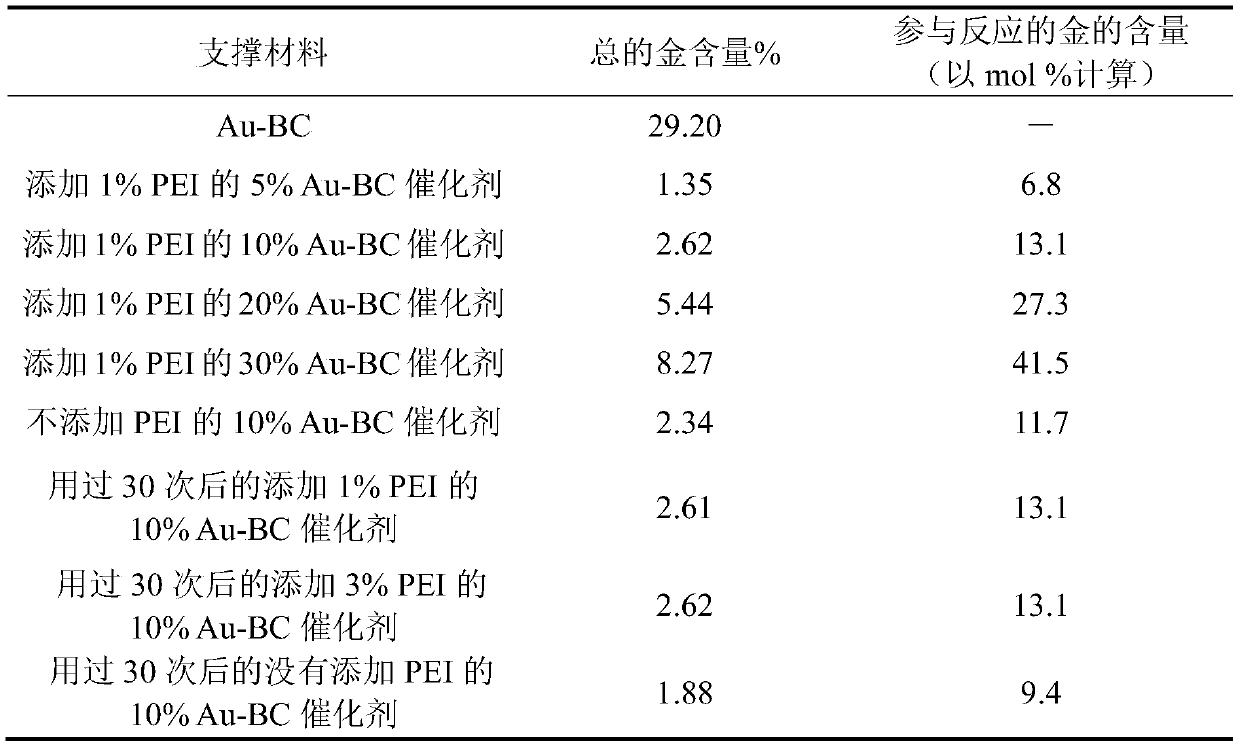

[0032] Cut 30 g of bacterial cellulose (BC) wet film into small pieces of 1 cm × 1 cm × 0.8 mm, and crush it 3 times in the instant mode with a laboratory mixer. The disintegrated BC and 60mL NaOH solution (1M) were mixed and poured into an Erlenmeyer flask, and activated by magnetic stirring at room temperature for 3h. Then acrylonitrile (0.30 mol, 20 mL) was slowly added dropwise under stirring, and the mixture was reacted at room temperature for 12 h. Afterwards, BC was isolated by filtration, washed thoroughly with deionized (DI) water, and then washed with 70% ethanol to obtain cyanoethyl surface-functionalized bacterial cellulose (CEBC). Afterwards the CEBC was dispersed in 50 mL of NaOH / NH 2 In OH·HCl (0.05mol, 1:1mol) aqueous solution, under magnetic stirring state, react at 50°C for 6h. After completing the reaction, separate by filtration and wash with deionized water to obtain amidoxime surface functionalized bacterial cellulose (AOBC).

[0033] HAuCl 4 (0.25 g)...

Embodiment 2

[0040] Cut 30 g of bacterial cellulose (BC) wet film into small pieces of 1 cm × 1 cm × 0.8 mm, and crush it 3 times in the instant mode with a laboratory mixer. Suspend the disintegrated BC in 100 mL of aqueous solution containing 0.48 g of 2,2,6,6-tetramethylpiperidine-nitrogen-oxide (TEMPO) and 3 g of sodium bromide, by adding NaClO (0.30 mol, 20 mL ) to start the reaction, stirred gently at room temperature, added 0.5M NaOH to maintain the pH value of the suspension at 10-10.3, and activated for 5h. The reaction was stopped by adjusting the pH to 7.0 with 0.5M HCl. After completing the reaction, wash with deionized water to obtain oxidized bacterial cellulose (TOBCN).

[0041] HAuCl 4 (0.25 g) was dissolved in 50 mL of deionized water at 4 °C and added to TOBCN, the mixture was stirred and reacted at room temperature for 1 h, then filtered and washed. With 100mL sodium borohydride solution (0.1M) to reduce BC for 1h, the Au 2+ After in situ reduction to Au nanoparticle...

Embodiment 3

[0046] Cut 30 g of bacterial cellulose (BC) wet film into small pieces of 1 cm × 1 cm × 0.8 mm, and crush it 3 times in the instant mode with a laboratory mixer. Soak the disintegrated BC in a mixture containing 40 mL of acetic acid, 25 mL of toluene, and 0.1 mL of 60% perchloric acid, and stir the mixture vigorously for 1 min. Then 60 mL of acetic anhydride was added, the mixture was vigorously stirred for 30 minutes, and the mixture was allowed to stand at room temperature for 1 hour. Then wash and filter with water to obtain acetate-esterified bacterial cellulose.

[0047] Add acetate-esterified bacterial cellulose to 100 mL of 0.2 M CuSO 4 In the solution, the reaction was stirred at room temperature at a speed of 350 rpm for 4 h. The resulting solid product was filtered and washed, and added to 60ml of sodium citrate (5 × 10 -2 In M), react at normal temperature for 1h, and reduce the copper ion loaded. The resulting copper nanoparticles-loaded BC (Cu-BC) was filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com