Low-internal-resistance solid sulfide electrolyte lithium battery cell, battery and preparation method thereof

A technology of sulfide electrolyte and solid electrolyte, which is applied in battery electrodes, secondary battery manufacturing, electrode manufacturing, etc. It can solve the problems of unstable effect, weakened interface impedance, and limited effect, so as to reduce the internal resistance of the battery and slow down the internal resistance of the battery. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

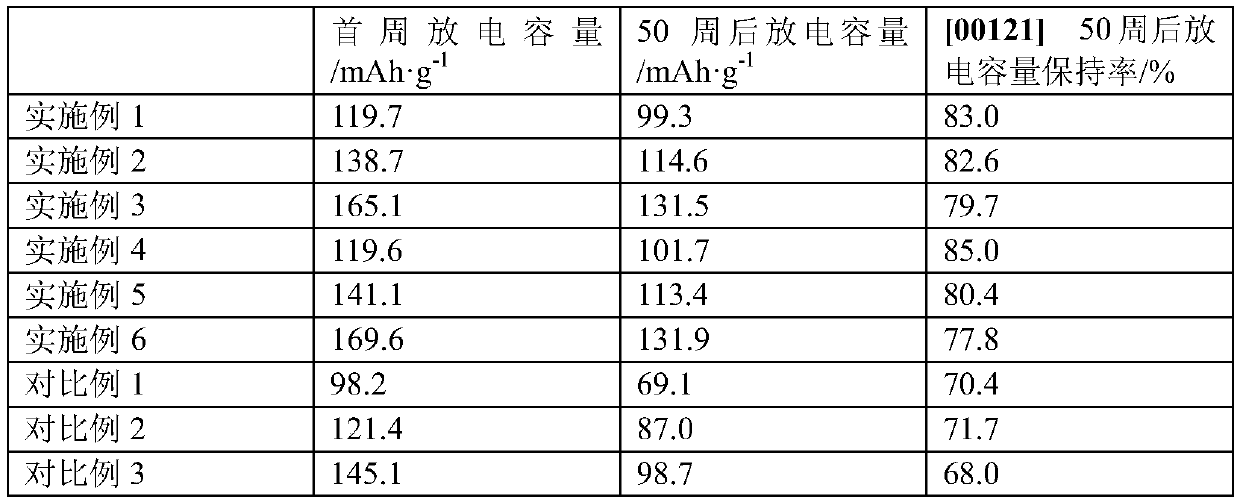

Examples

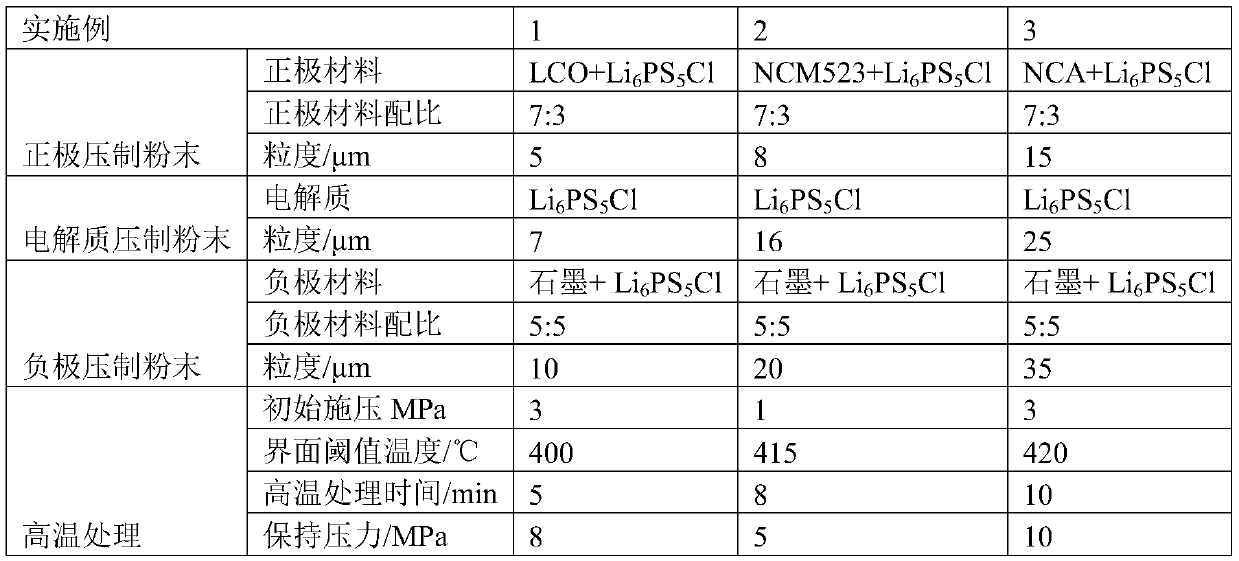

Embodiment 1~3

[0080] A low internal resistance solid sulfide electrolyte lithium battery, comprising a positive electrode layer, an electrolyte layer and a negative electrode layer laminated in sequence.

[0081] The positive electrode layer is formed by pressing the positive electrode pressed powder. The positive electrode pressed powder includes uniformly mixed positive electrode material powder and sulfide solid electrolyte powder, and its particle size is 5-15 μm. The positive electrode material powder is one of lithium cobalt oxide material, nickel-cobalt-manganese ternary material, and nickel-cobalt-aluminum ternary material. The mixing mass ratio of positive electrode material powder and sulfide solid electrolyte powder is 7:3.

[0082] The electrolyte layer is formed by pressing electrolyte pressing powder, which is solid electrolytic powder of sulfide.

[0083] The negative electrode layer is formed by pressing the negative electrode pressed powder. The negative electrode pressed ...

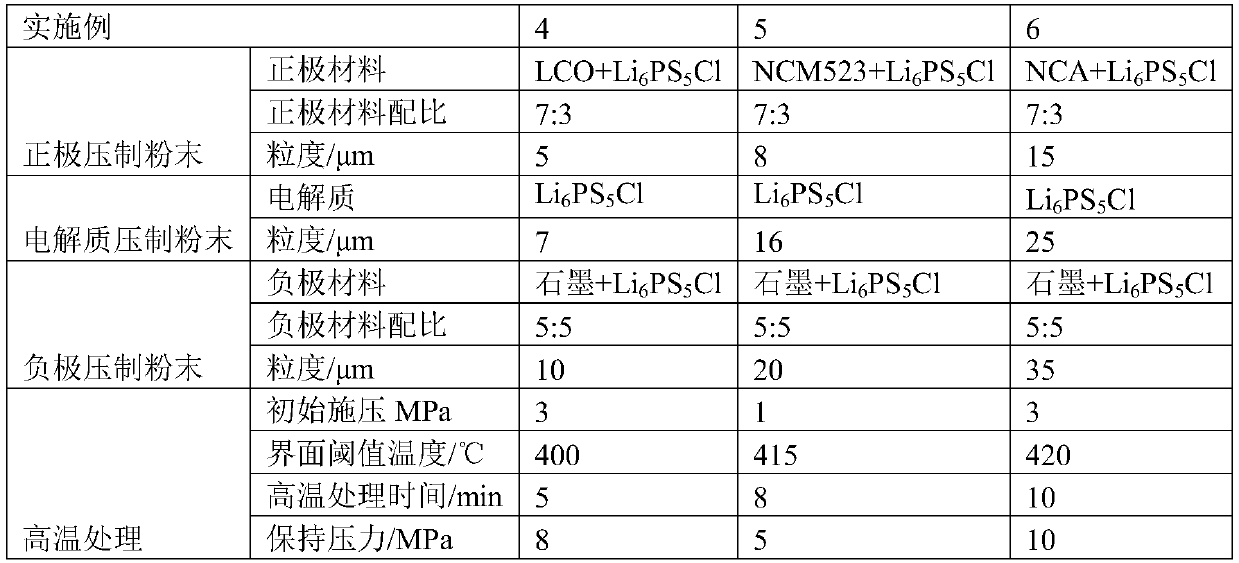

Embodiment 4~6

[0097] A low internal resistance solid sulfide electrolyte lithium battery, based on the basis of Examples 1 to 3, the difference is that the preparation method of the solid sulfide electrolyte lithium battery is as follows:

[0098] A. Put the positive electrode pressed powder uniformly mixed with the positive electrode material powder and the sulfide solid electrolyte powder into the mold for internal cooling and isostatic pressing to form the positive electrode layer. The thickness of the positive electrode layer is 60 μm, and the pressing density is 3.0 g cm -3 ;

[0099] B. Evenly spread a layer of electrolyte pressed powder on the upper surface of the positive electrode layer, and cold isostatic pressing to obtain an integrated positive electrode layer and electrolyte layer. The thickness of the electrolyte layer is 30 μm, and the compacted density is 2.0 g cm -3 ;

[0100] C. Lay a layer of negative electrode pressing powder uniformly mixed with negative electrode mate...

Embodiment 7

[0122] A kind of low internal resistance solid-state sulfide electrolyte lithium battery, it is based on the basis of embodiment 1, and its difference is that its sulfide solid-state electrolyte is Li 2 S-P 2 S 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com