Embedded system operated digitalization soft switch inversion arc welder

An embedded system and soft switching technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficulty in achieving high integration and miniaturization, reducing the size and weight of the converter, and increasing the loss of switching tubes. , to facilitate fault diagnosis, enhance reliability, and reduce switching voltage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

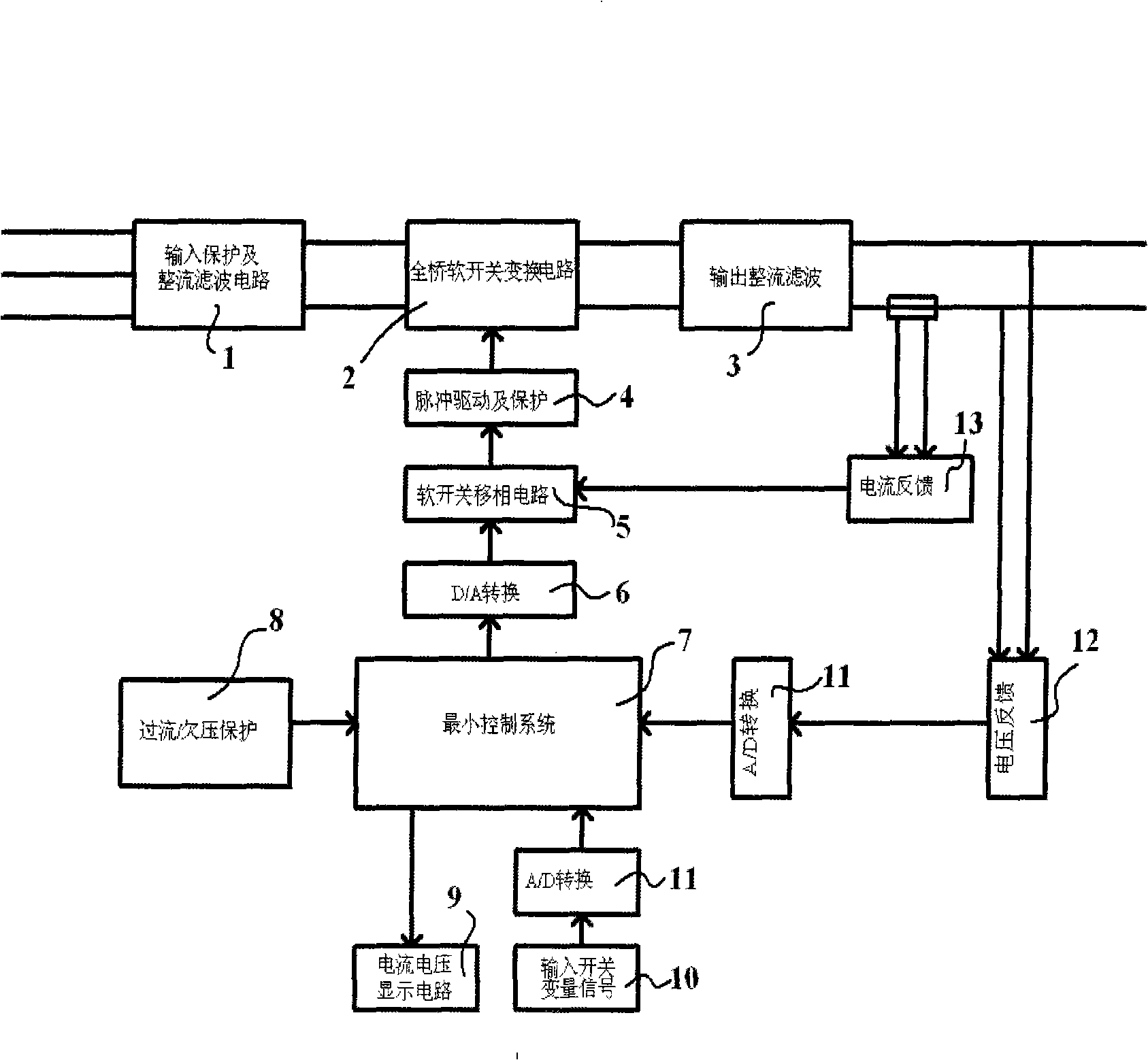

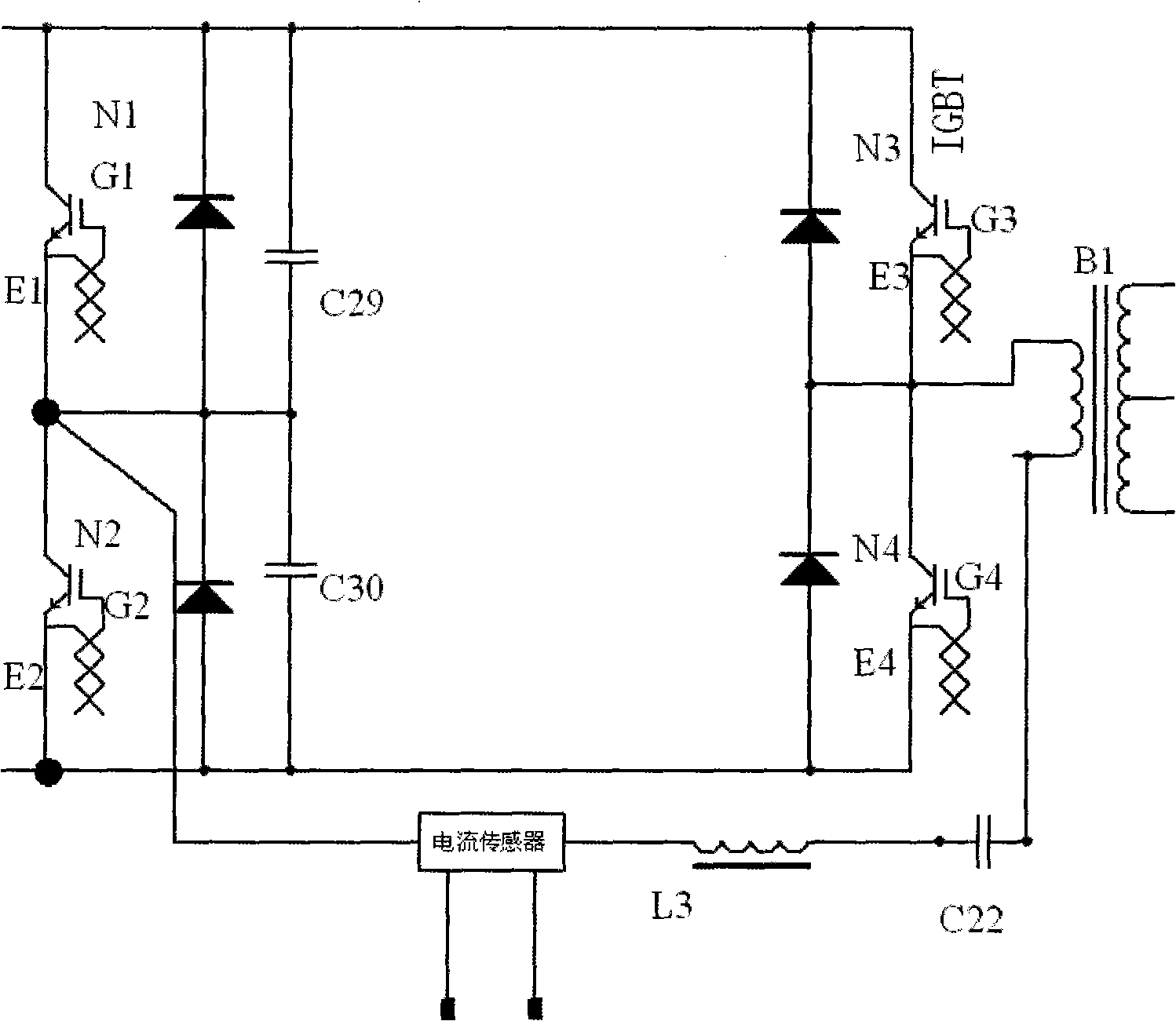

[0032] Depend on Figure 1 to Figure 5 It can be seen that the present invention adopts the IGBT soft-switching inverter technology, and after the power frequency three-phase 380V power input is rectified, the IGBT inverter becomes a high-frequency AC, which is stepped down by a high-frequency transformer and rectified by a rectifier, and the filtered output is suitable for welding of direct current. The circuit design of the control realizes the closed-loop control of the whole machine, so that the welding power source has a good ability to resist power grid fluctuations. It is composed of the following parts: main circuit, program control circuit controlled by single-chip microcomputer 89C51, ZVZCS soft switch full bridge phase shift control circuit composed of special soft switch phase shift chip UCC3895, drive and protection circuit, etc., system block diagram like figure 1 .

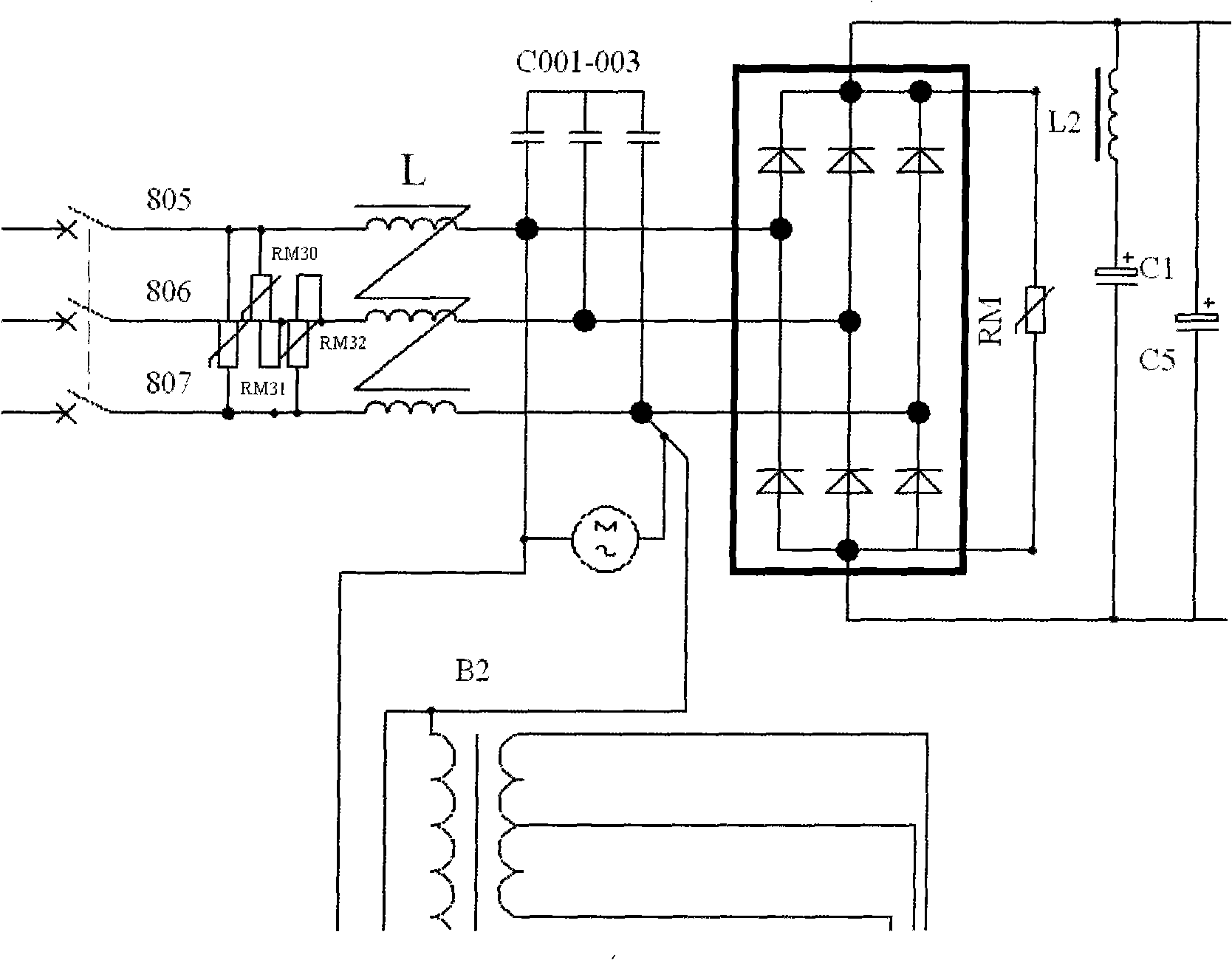

[0033] 1. The main circuit includes:

[0034] (1) Input protection and rectification filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com