Compound thermal insulation plate for thermal insulation of wall body and preparation method and using method thereof

A composite heat preservation and thermal insulation technology, which is applied in the direction of heat preservation, building components, covering/lining, etc., can solve the problems of increasing project cost, difficulty in firmness and durability, difficulty in durability and life expectancy, etc., so as to reduce engineering cost. The effect of low cost, convenient partial renovation, and saving curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

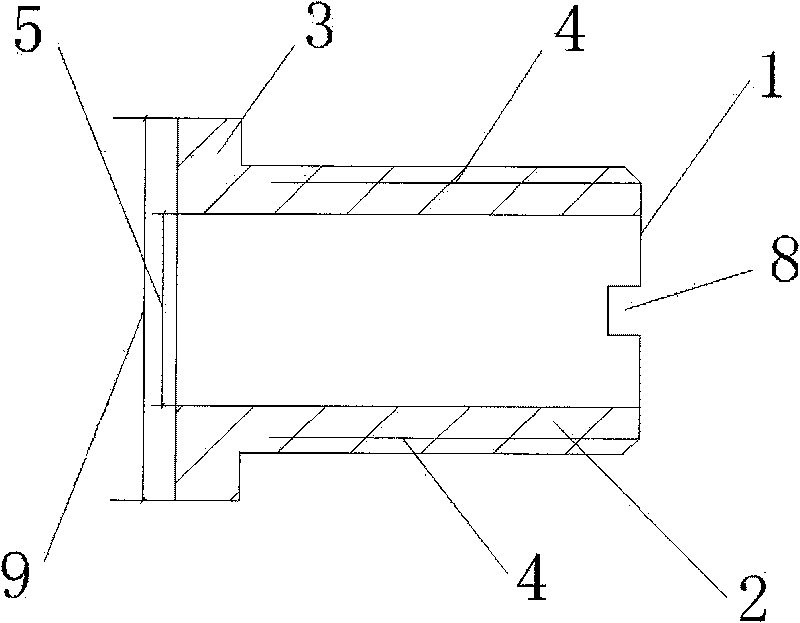

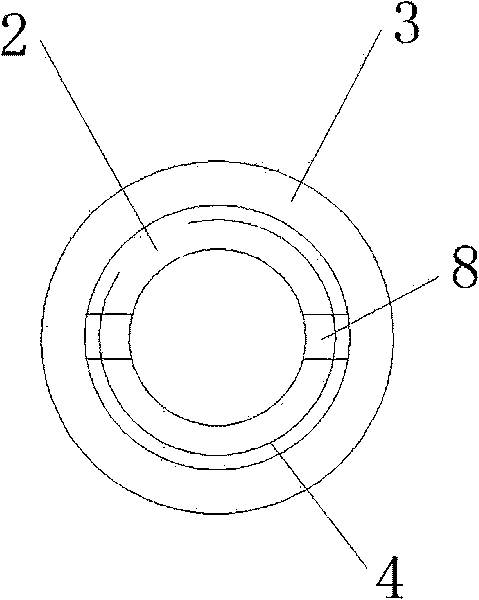

[0049] Technical scheme of the present invention figure 1 , figure 2 The inner sleeve 1 of the combined fixed sleeve is composed of the inner sleeve hollow cylinder 2, the inner sleeve flanging 3, and the thread 4 on the inner sleeve hollow cylinder 2. The inner diameter 5 of the inner sleeve hollow cylinder 2 is larger than the outer diameter 7 of the expansion sleeve of the bolt 6. The hollow cylinder 2 of the inner sleeve is provided with a groove 8, and the diameter of the flange 3 of the inner sleeve or the distance 9 between two vertices is less than or equal to the outer diameter 12 of the hollow cylinder 11 of the outer sleeve 10 of the combined fixed sleeve.

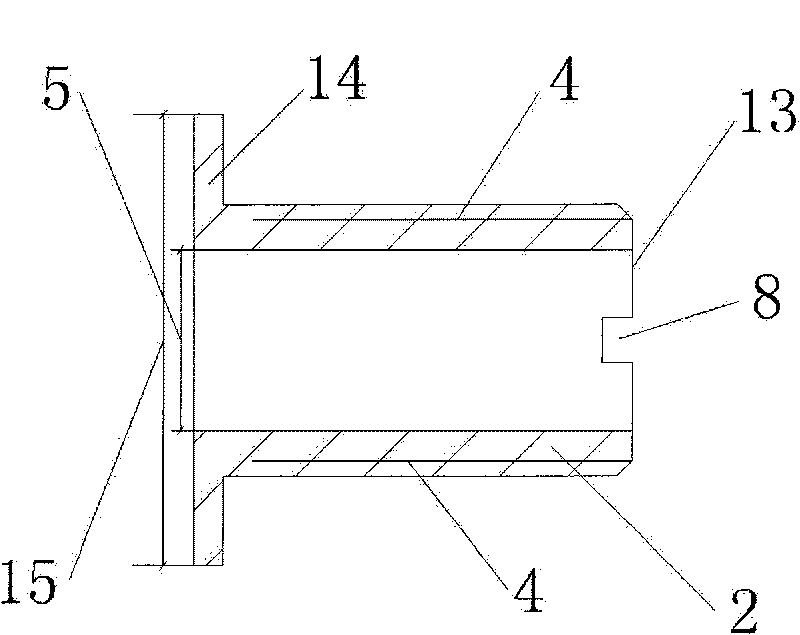

[0050] Technical scheme of the present invention image 3 , Figure 4 The diameter of the flanging 14 of the inner sleeve 13 of the combined fixed sleeve or the distance 15 between two vertices is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com