IGBT module life monitoring method

A life and detection data technology, applied in the field of IGBT modules, can solve the problems of high modeling requirements, high detection circuit response time and precision requirements, and difficult data acquisition, so as to achieve the effect of improving safety and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

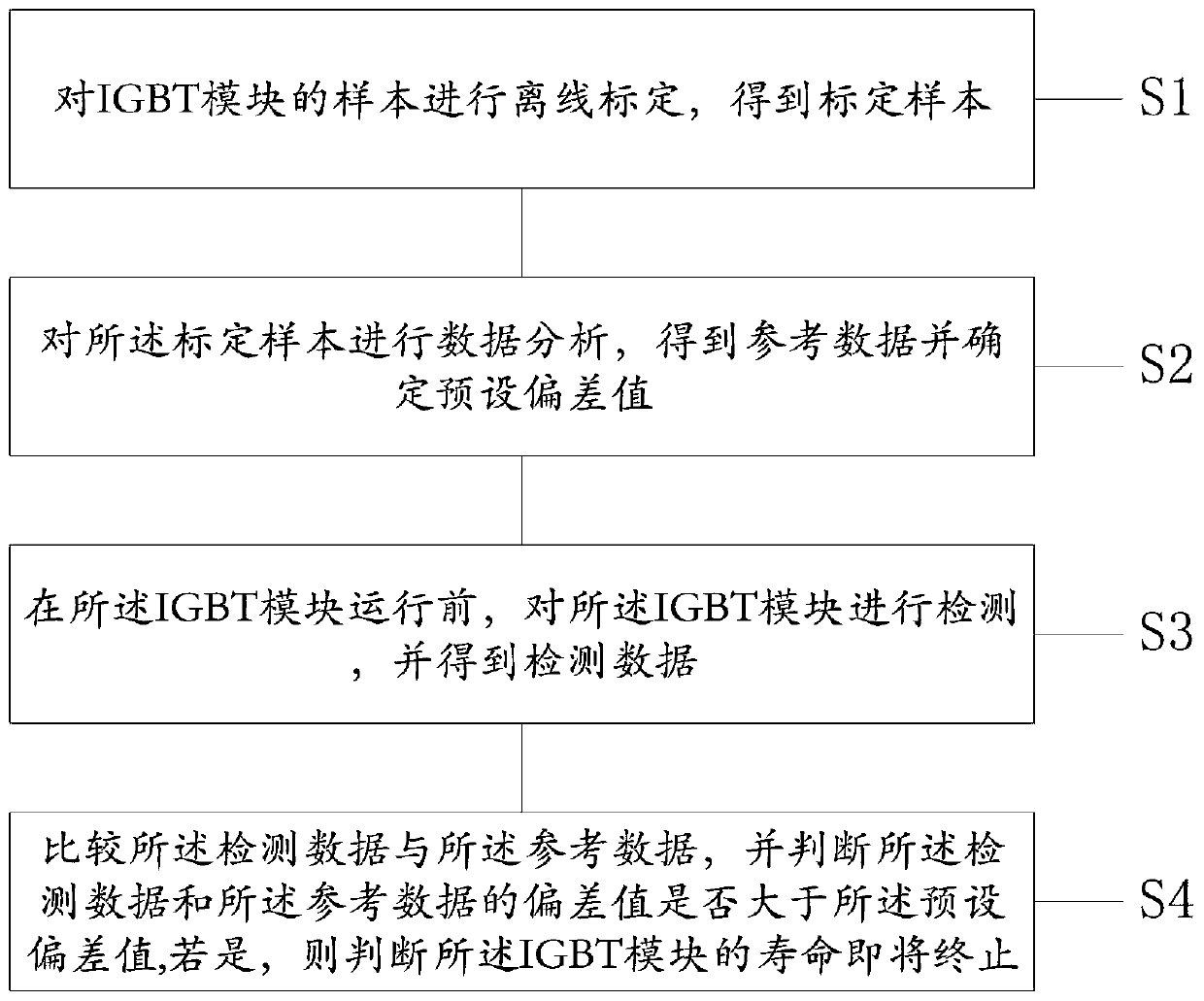

[0020] like figure 1 as shown, figure 1 It is a schematic flow chart of the IGBT module life monitoring method of the present invention; the IGBT module life monitoring method specifically includes the following steps:

[0021] S1 performs offline calibration on samples of IGBT modules to obtain calibration samples; in a preferred embodiment of the present invention, the offline calibration of samples of IGBT modules to obtain calibration samples is specifically: the first saturation of the IGBT module samples Voltage drop V cesat With the first junction temperature T j The change curve of its diode's first forward voltage V f With the first junction temperature T j The change curve of the IGBT module is calibrated off-line, and the calibration curve of the IGBT module sample is obtained as the calibration sample; in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com