Efficient carbon fiber supported catalyst and preparation method thereof

A technology of supporting catalysts and carbon fibers, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low catalyst adhesion, loss of catalytic effect of carbon fibers, and easy falling off of catalysts, etc., to ensure adsorption and catalytic efficiency, shortened drying time, and high loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

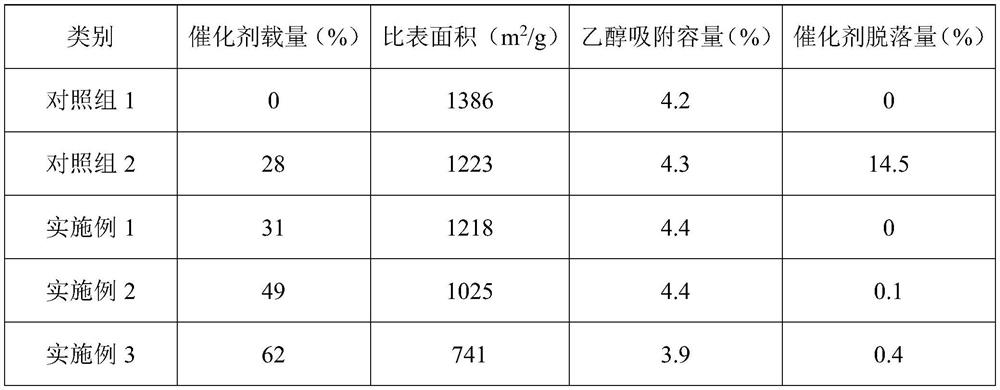

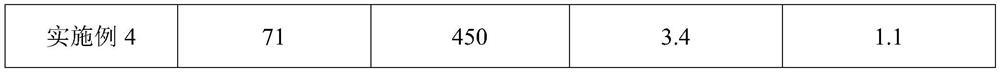

Embodiment 1

[0027] This embodiment provides a high-efficiency carbon fiber supported catalyst, the preparation method of which comprises the following steps:

[0028] Step 1, dissolve manganese nitrate, copper nitrate and nickel nitrate in deionized water to form an aqueous solution of nitrate; slowly add ethanol or glycerol dropwise in the aqueous solution of nitrate to form a precursor alcohol solution of nitrate; manganese nitrate is Manganese nitrate tetrahydrate, copper nitrate is copper nitrate trihydrate, nickel nitrate is nickel nitrate hexahydrate; in the precursor alcohol solution, the molar ratio of manganese nitrate tetrahydrate, copper nitrate trihydrate and nickel nitrate hexahydrate is 6:3:1 .

[0029] The precursor alcohol solution was stirred at 90°C until a viscous thick gel was formed. After the thick gel was dried at 150°C for 1.5 hours, it was calcined in a muffle furnace at 650°C for 3 hours to form a catalyst powder at room temperature. The main component of the ca...

Embodiment 2

[0034] This example provides a high-efficiency carbon fiber-supported catalyst, the preparation method of which is basically the same as that of Example 1, the only difference being that in step 3, after the carbon fiber is cured and dried, it is repeatedly placed in the mixed impregnating solution for loading, and two co-impregnation Second-rate.

Embodiment 3

[0036] This example provides a high-efficiency carbon fiber-supported catalyst, the preparation method of which is basically the same as that of Example 1, the only difference being that in step 3, after the carbon fiber is cured and dried, it is placed in the mixed impregnating solution for two times of loading. Dipping three times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com