Preparation method and application of covalent organic framework compound and open-cage fullerene composite material

A technology of covalent organic framework and composite material, applied in the field of chemical synthesis, can solve problems such as high price, and achieve the effects of simple method, increased conductivity and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

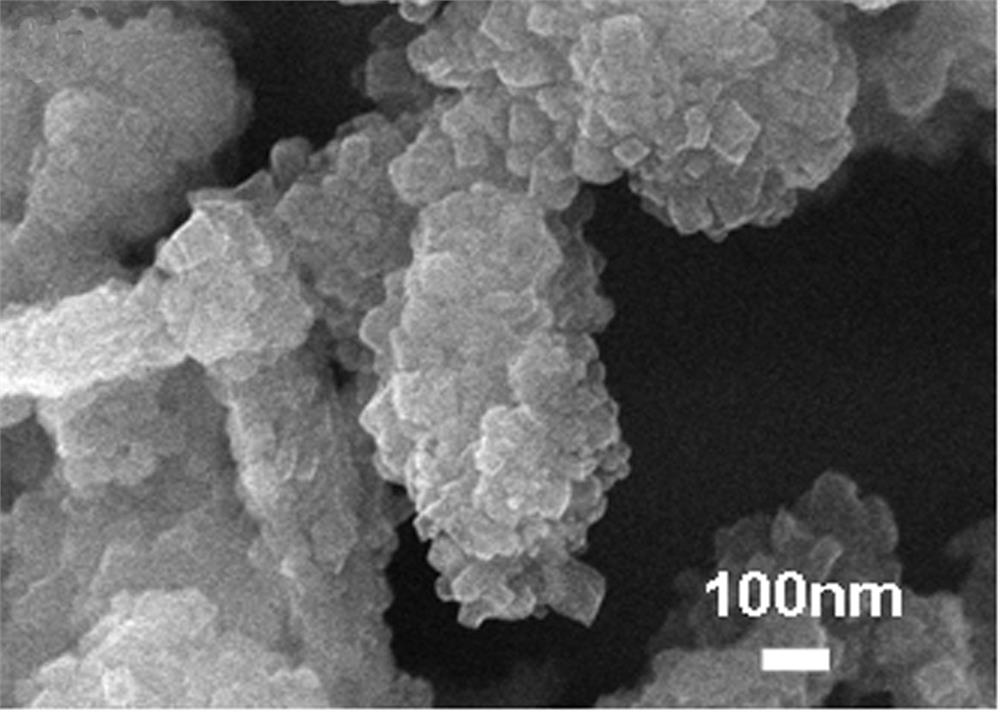

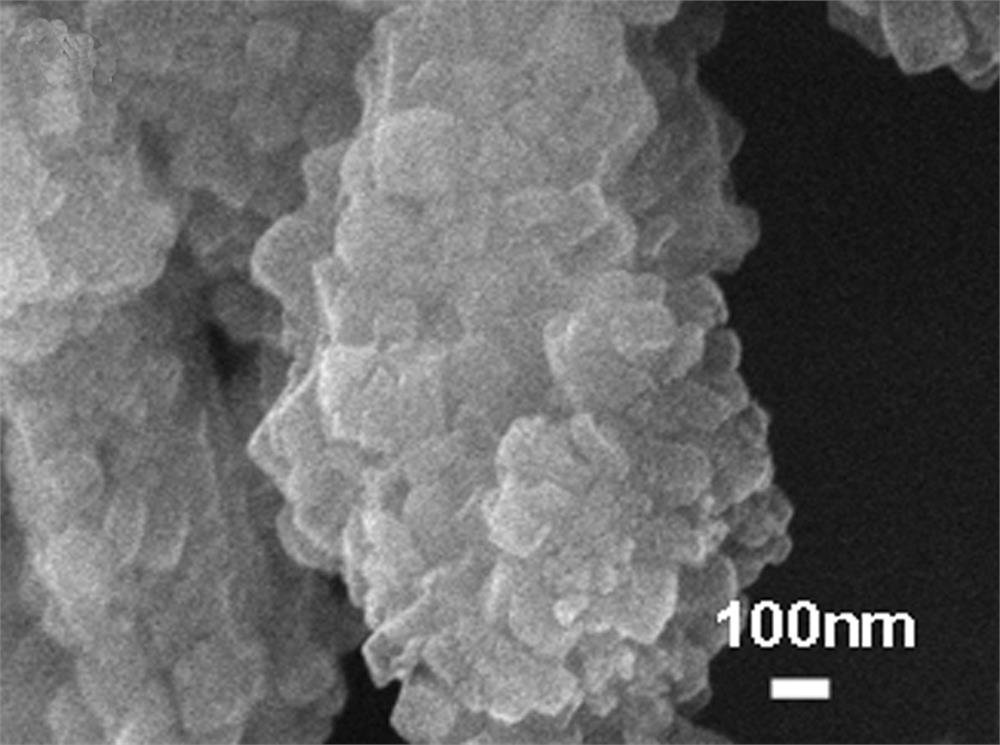

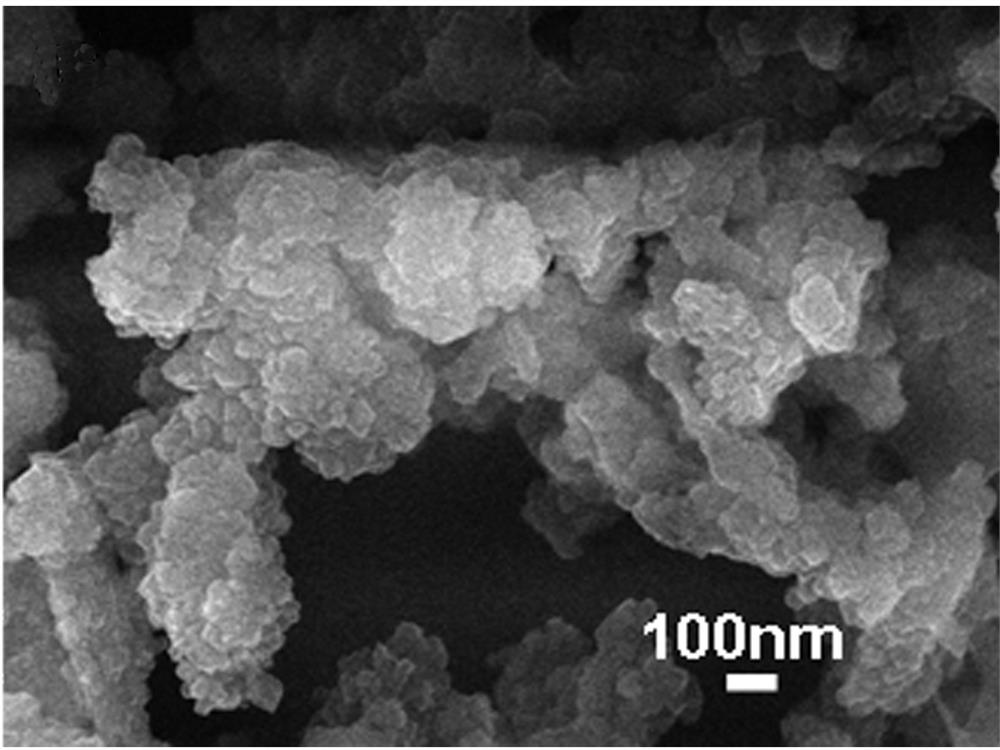

Image

Examples

Embodiment 1

[0063] Embodiment 1 A kind of preparation method of covalent organic framework compound

[0064] This embodiment includes the following steps carried out in sequence:

[0065] S11. Weigh 3.09kg (5mol) of 1,3,6,8-tetrakis(4-formaldehyde phenyl)pyrene and 1.08kg (10mol) of p-phenylenediamine respectively in a container, add o-dichlorobenzene Perform ultrasonication for 30 minutes to assist dissolution to form a homogeneous solution. Add 4.65kg (77.5mol) of acetic acid during the ultrasonication process. After the container is frozen under liquid nitrogen conditions, the container is pumped to remove oxygen, and then the container is degassed. Sealed in the state;

[0066] S12. Heat the sealed container to 250°C at a heating rate of 5°C / h under the condition of 25°C, and react for 48 hours to obtain reactant A;

[0067] S13. The reactant A was washed with acetone, methanol, and dioxane in sequence, then soaked in acetone for 12 hours, and finally vacuum-dried at 80° C. for 12 h...

Embodiment 2-6

[0071] The preparation method of embodiment 2-6 covalent organic framework compound

[0072] Examples 2-6 are respectively a preparation method of a covalent organic framework compound, and their steps are basically the same as in Example 1, the only difference being the amount of raw materials and process parameters, see Table 1 for details:

[0073] List of each technological parameter in the embodiment 2-6 of table 1

[0074]

[0075]

Embodiment 7

[0076] Embodiment 7 A kind of preparation method of open cage fullerene

[0077] This embodiment includes the following steps carried out in sequence:

[0078] S21. Take 3.1kg (10mol) of 3-(2-pyridyl)-5,6-diphenyl-1,2,4-triazine and 3.6kg (5mol) of C60 and dissolve them in 9L of o-dichlorobenzene , heated to reflux at 150°C for 24h, cooled to room temperature, and used CS 2 Carry out silica gel column chromatography directly as the eluent, finally remove unreacted C60, and then use CS 2 Carry out secondary elution with the eluent mixed with ethyl acetate at a volume ratio of 80:1 to obtain reactant B;

[0079] S22. Dissolving 10 g of reactant B in 10 L of CCl 4 In the process, a 150-watt high-pressure mercury lamp was used to irradiate in an oxygen atmosphere for 72 hours, and the solution changed from pink purple to brown; the solution was rotary evaporated, and the residue was subjected to silica gel column chromatography. 2 The solution mixed with ethyl acetate at a vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com