Process for treating heavy metal wastewater

A technology for wastewater treatment and heavy metals, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems that the discharge water does not meet the national discharge standards and the time-consuming treatment of heavy metal wastewater, etc. Achieve the effects of short time consumption, enhanced adsorption, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

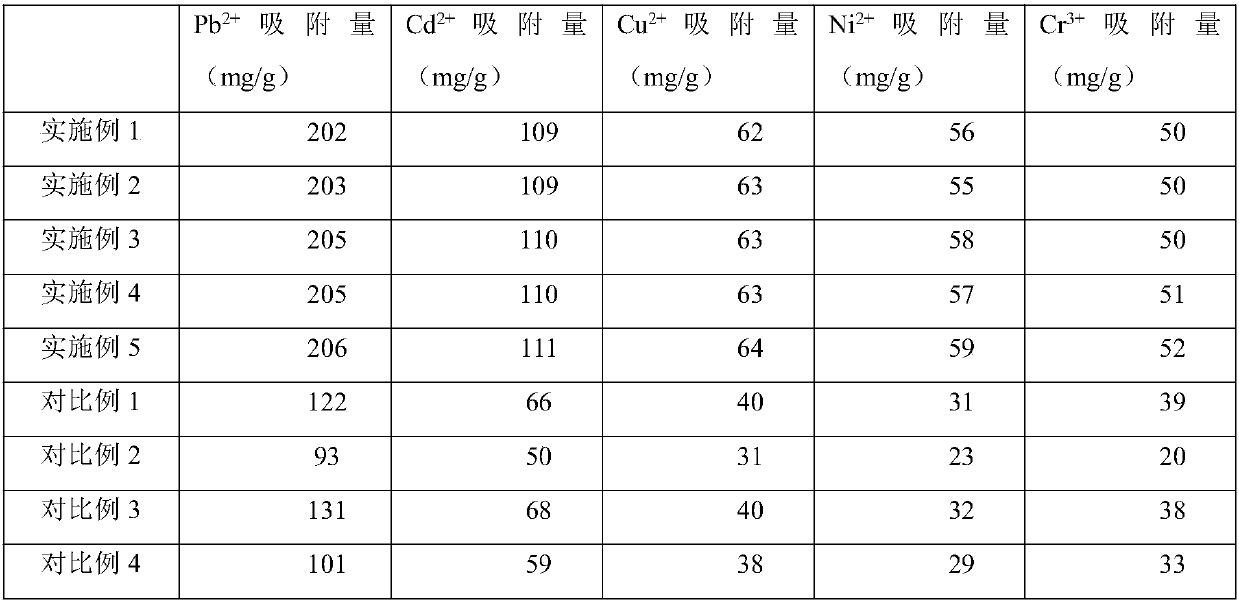

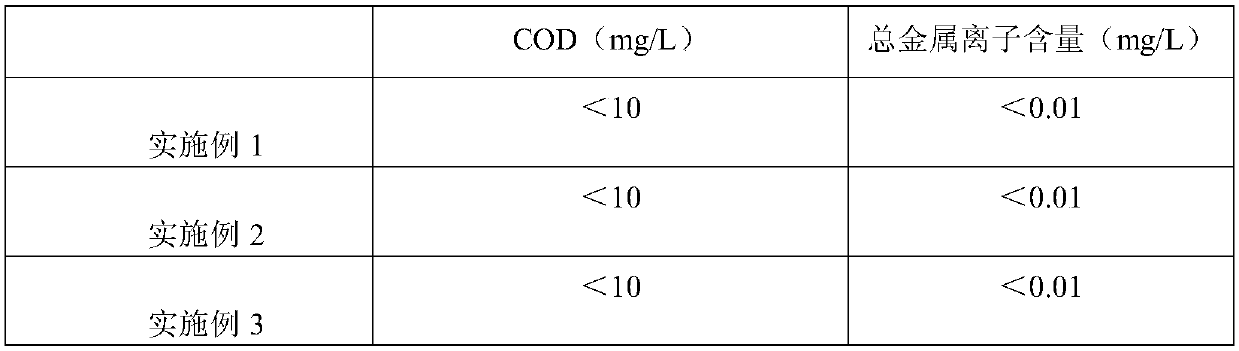

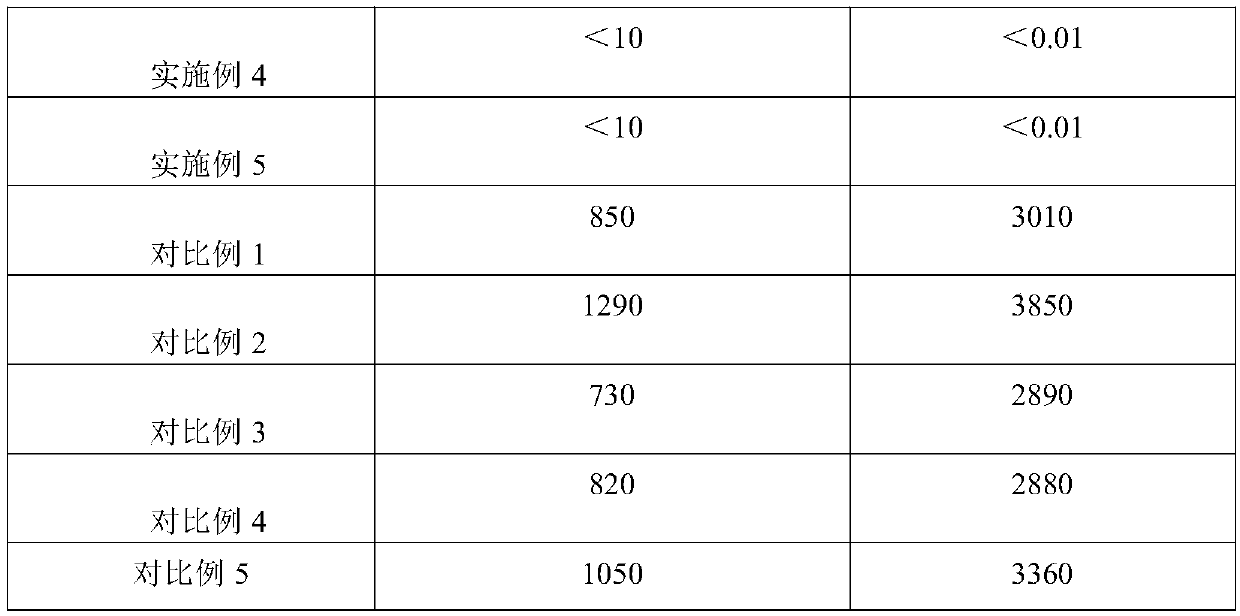

Examples

Embodiment 1

[0029] A heavy metal wastewater treatment process, the specific steps are as follows:

[0030] (1) Preparation of treatment agent: After the corn stalk powder was treated with alkali and organically modified in sequence, it was added to chlorosulfonic acid together with sepiolite powder, and left to stand at 50°C for 2 hours, then cooled to room temperature (25°C). Filter, wash with water until neutral, heat to 1200°C, and sinter for 6 hours to obtain intermediate product I; add intermediate product I to polyvinyl alcohol aqueous solution, then add anionic polyacrylamide, stir at 80°C for 40 minutes, and centrifuge The intermediate product II was obtained; the intermediate product II was added to the iron ion solution, stirred at 500 rpm for 10 minutes, then concentrated ammonia water was added dropwise, and after the addition was completed, it was left to stand for 20 minutes, separated by magnetic separation, washed with water until neutral, Dry at 50°C to constant weight, p...

Embodiment 2

[0042] A heavy metal wastewater treatment process, the specific steps are as follows:

[0043] (1) Preparation of treatment agent: After the corn stalk powder was treated with alkali and organically modified in sequence, it was added to chlorosulfonic acid together with sepiolite powder, and stood at 60°C for 3 hours, then cooled to room temperature (25°C). Filter, wash with water until neutral, heat to 1300°C, and sinter for 8 hours to obtain intermediate product I; add intermediate product I to polyvinyl alcohol aqueous solution, then add anionic polyacrylamide, stir at 90°C for 60 minutes, and centrifuge The intermediate product II was obtained; the intermediate product II was added to the iron ion solution, stirred at 600 rpm for 15 minutes, then concentrated ammonia water was added dropwise, and after the addition was completed, it was left to stand for 25 minutes, separated by magnetic separation, washed with water until neutral, Dry at 60°C to constant weight, pour into...

Embodiment 3

[0055] A heavy metal wastewater treatment process, the specific steps are as follows:

[0056] (1) Preparation of treatment agent: After the corn stalk powder was treated with alkali and organically modified in sequence, it was added to chlorosulfonic acid together with sepiolite powder, left to stand at 50°C for 3 hours, cooled to room temperature (25°C), Filter, wash with water until neutral, heat to 1200°C, and sinter for 8 hours to obtain intermediate product I; add intermediate product I to polyvinyl alcohol aqueous solution, then add anionic polyacrylamide, stir at 80°C for 60 minutes, and centrifuge The intermediate product II was obtained; the intermediate product II was added to the iron ion solution, stirred at 500 rpm for 15 minutes, then concentrated ammonia water was added dropwise, and after the addition was completed, it was left to stand for 20 minutes, separated by magnetic separation, washed with water until neutral, Dry at 60°C to constant weight, pour into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com