Continuous catalysis production method of PBT resin

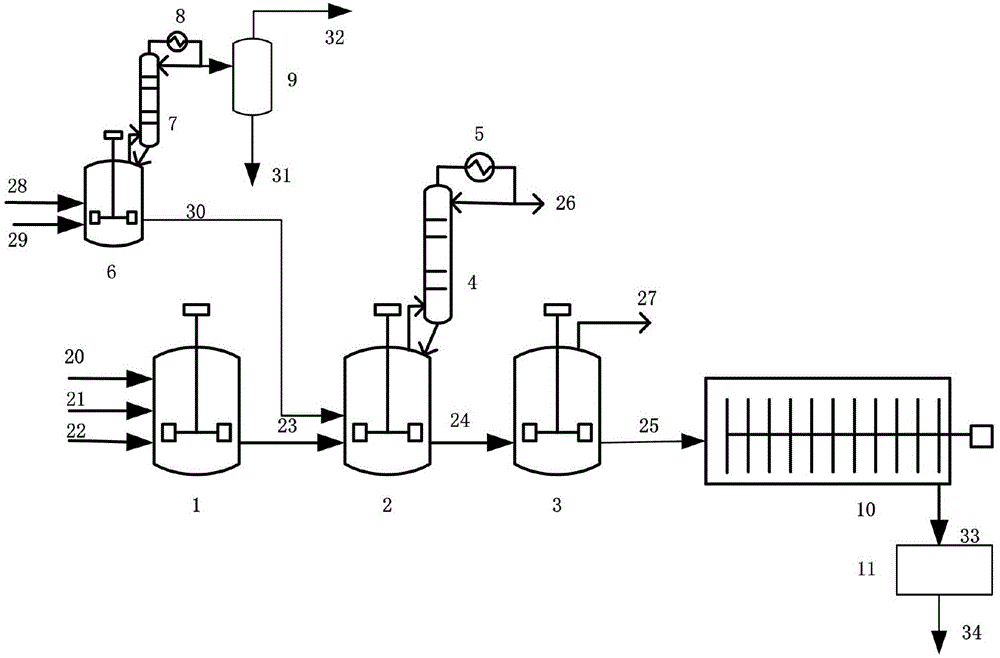

A technology of PBT resin and production method, which is applied in the field of PBT synthesis, can solve the problems of accelerated hydrolysis, complicated post-treatment, and increased waste water treatment burden, etc., and achieves the effects of enhancing hydrolysis resistance, ensuring catalytic efficiency, and inhibiting hydrolysis scaling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1.1 Preparation of catalyst

[0031] Add 15kg / hr of 1,4-butanediol and 1.5kg / hr of tetrabutyl titanate into the catalyst preparation tank. The temperature of the preparation tank is controlled at 90°C, the absolute pressure is controlled at about 10kPa, and the residence time is controlled at 2hr. The butanol collection tank 9 obtains a water-containing butanol solution, and the butanol flow rate is 0.33kg / hr. The catalyst solution is continuously discharged from the catalyst preparation tank 6 .

[0032] 1.2 Catalyst hydrolysis performance evaluation

[0033]The prepared catalyst solution sample and the tetrabutyl titanate catalyst sample were configured with four water concentration (0.5%, 1%, 2% and 3%) samples containing 0.5% titanium (titanium element) respectively, and observed the precipitation of the two, As shown in Table 1, it can be seen that the catalyst prepared in Example 1.1 has better hydrolysis resistance.

[0034] Table 1 Catalyst Hydrolysis Precipi...

Embodiment 2

[0041] Add 1000kg / hr of terephthalic acid and 638kg / hr of 1,4-butanediol into PBT beating tank 1, and stir to make PBT slurry 23. The PBT slurry 23 and 1.5kg / hr tetrabutyl titanate enter the PBT esterification reactor 2, and the esterification reaction is carried out at 200-250°C and 10-100kPa pressure (absolute pressure), and the water and side reactions produced by the reaction The generated THF and evaporated butanediol are separated in the PBT dehydration tower 4, water and THF come out from the top of the tower, and the rising steam is condensed in the top condenser 8, part of which is refluxed, and the rest enters the subsequent separation device for further separation THF and water, butanol flow in water is 0.65kg / hr. The butanediol at the bottom of the dehydration tower is returned to the PBT esterification reactor 2, and the PBT esterification product 24 generated by the esterification reaction enters the PBT pre-shrinkage reactor 3, and is pre-shrinked at 220-255°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com