an o 3 / Photocatalytic advanced oxidation reaction system and method for high concentration wastewater

A high-concentration wastewater, advanced oxidation technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of preventing the ozone oxidation process, high operating costs, and low treatment efficiency. , to facilitate replacement and recycling, reduce production costs, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

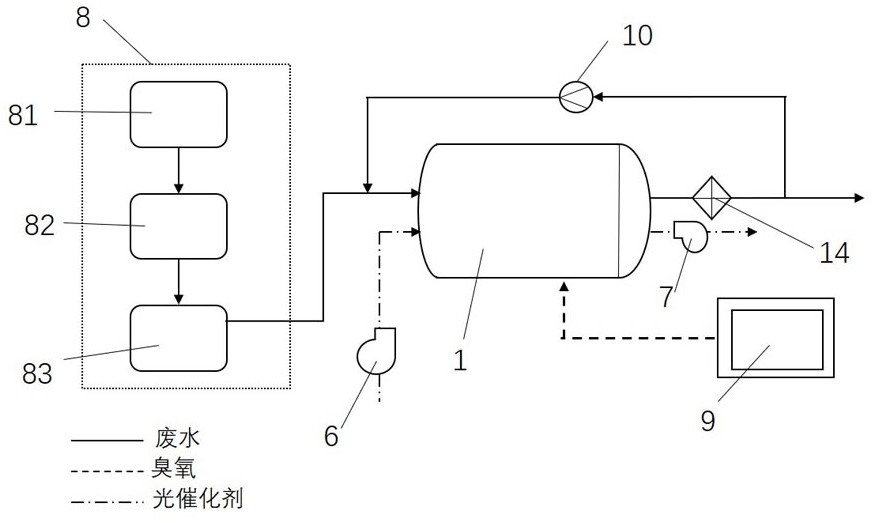

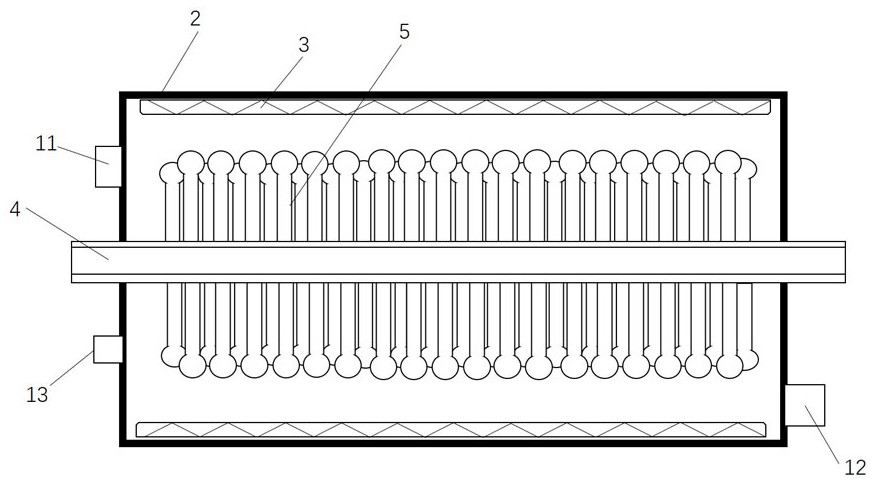

[0045] use figure 1 and figure 2 The reaction device shown treats printing and dyeing wastewater, and the treatment process is as follows:

[0046] 1) The printing and dyeing wastewater to be treated is pretreated in the pretreatment module;

[0047] 2) The pretreated wastewater was passed into the reaction device. The amount of photocatalyst pumped was 10g, the amount of ozone was 90mg / L, and the hydraulic retention time was 120min. After the reaction was stable, the CODCr of the printing and dyeing wastewater at the water outlet was measured. The COD removal rate can reach 73.2%.

Embodiment 2

[0049] use figure 1 and figure 2 The reaction device shown treats printing and dyeing wastewater, and the treatment process is as follows:

[0050] 1) The printing and dyeing wastewater to be treated is pretreated in the pretreatment module;

[0051] 2) The pretreated wastewater was passed into the reaction device. The amount of photocatalyst pumped was 20g, the amount of ozone was 60mg / L, and the hydraulic retention time was 120min. After the reaction was stable, the CODCr of the printing and dyeing wastewater at the water outlet was measured. The COD removal rate can reach 83.4%.

[0052] To sum up, it can be seen from the comparison of the results of the COD removal rate of Example 1 and Example 1 that the removal rate of COD is improved after adding the photocatalyst, which shows that under the same other conditions, the wastewater under the synergistic effect of ozone and photocatalysis Better processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com