Patents

Literature

265results about How to "Stable molecular structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

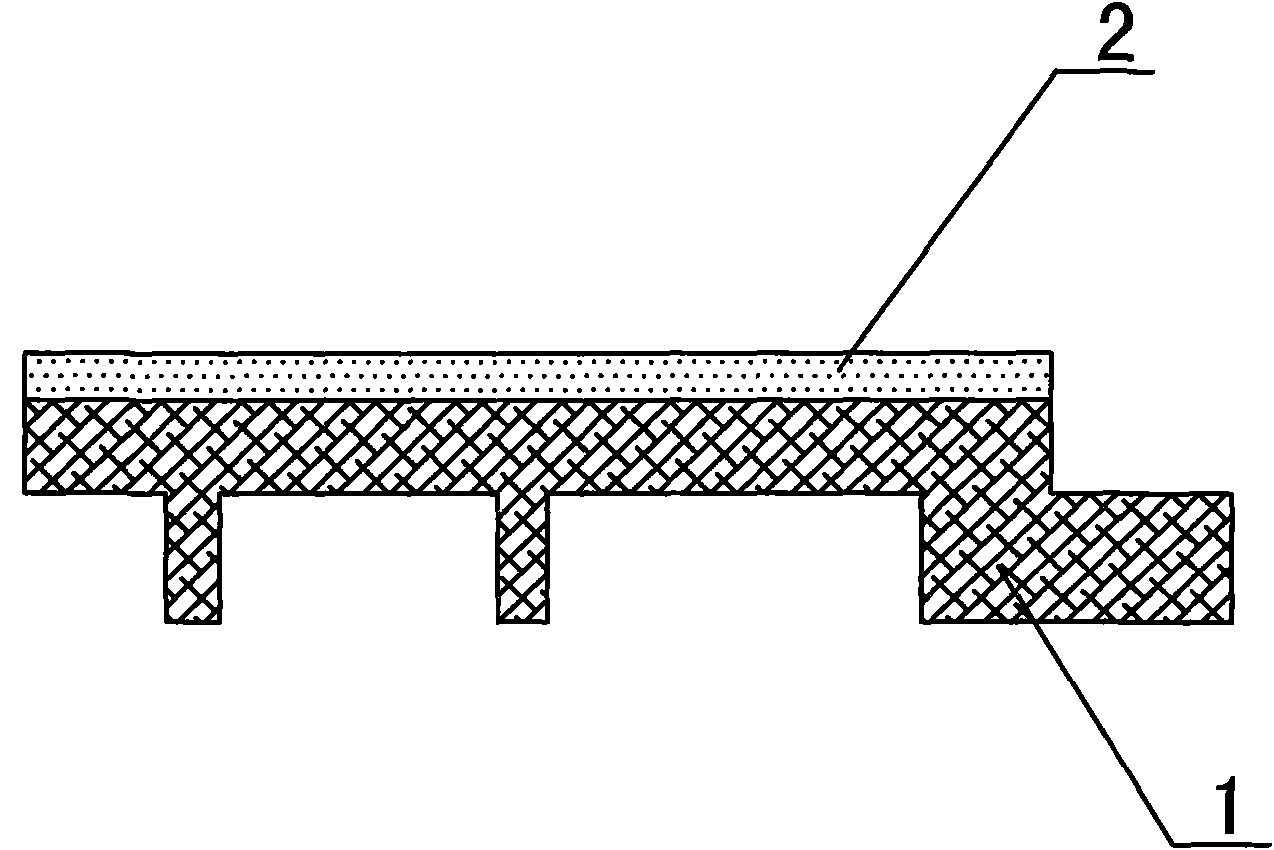

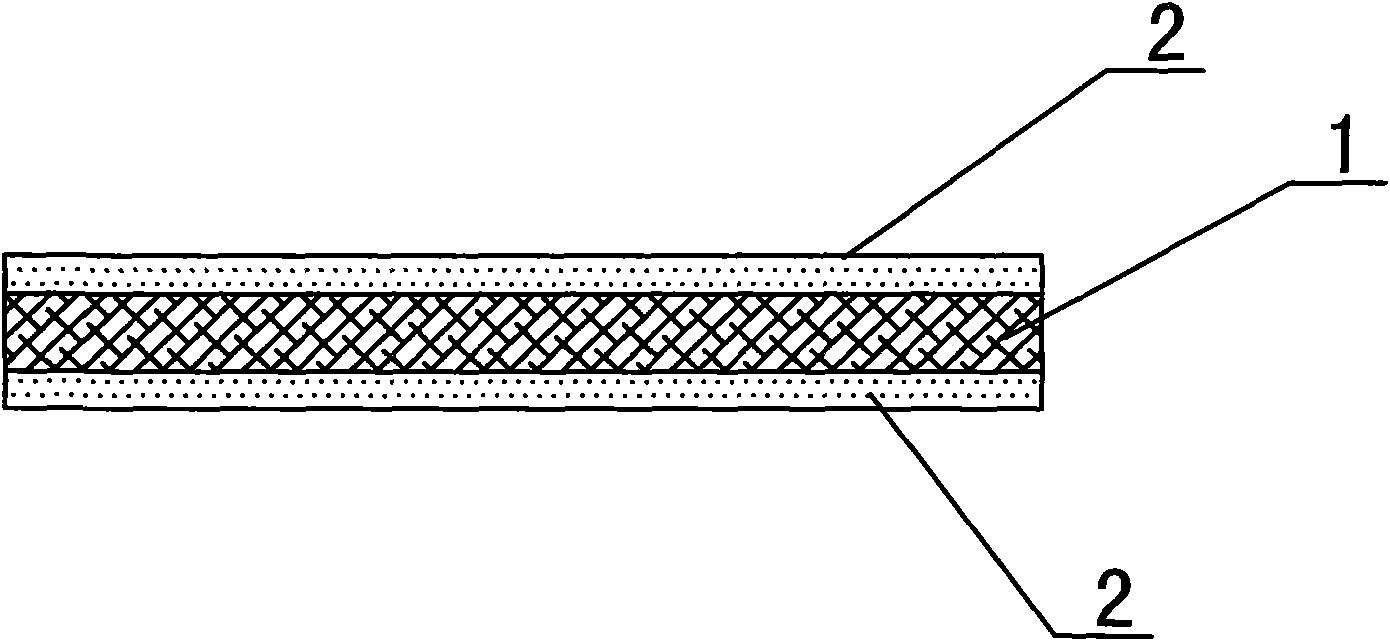

TPU clad net

InactiveCN101225610AExcellent physical mechanism performanceGood mechanical strengthLaminationLamination apparatusCold tolerancePolyester

The invention provides a TPU mesh fabric, which is made by coating a special PU adhesive to a high-strength polyester fiber and then combining with a TPU film. The PU coating steps are: PU-coat arrow dry arrow cool the high-strength polyester fiber; the coating quantity is 180-200g / m2; the coating speed is 20-25m / min; the drying temperature is 110-130 DEG C; the two layers of TPU film (underlayer, face layer) are preheated and fused through the adjustment and change of the heating drum temperature, and then are rolled, cooled and formed with the high-strength polyester mesh fabric after middle-layer preheating through rubber roller and iron roll. The TPU mesh fabric has the advantages of environmental protection, innocuity, high strength, abrasion resistance, high cold tolerance, good color stability, good heat resistance and best PVC-replacing material.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

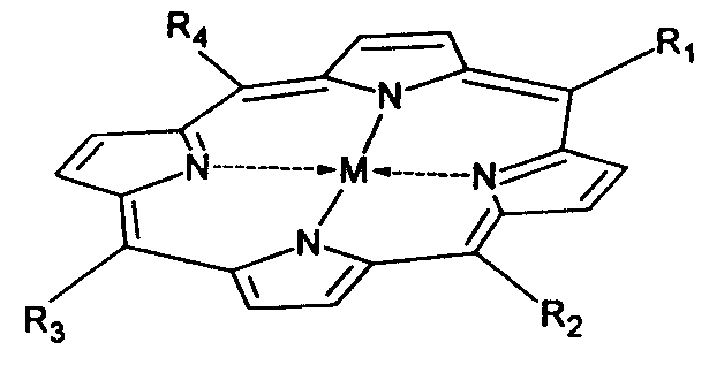

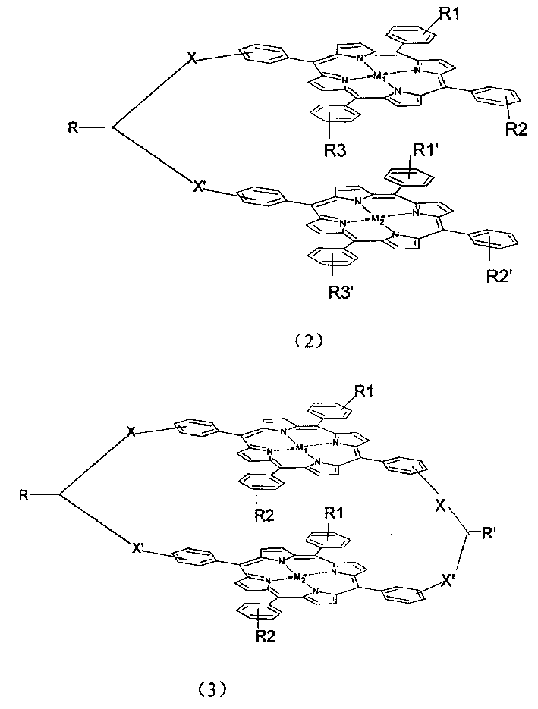

Substituted carbolnie metal complex and application thereof

InactiveCN1472212AHigh selectivityWide pH rangeGroup 8/9/10/18 element organic compoundsGroup 2/12 element organic compoundsEnzymeCathode catalyst

Owner:SHANDONG UNIV OF TECH

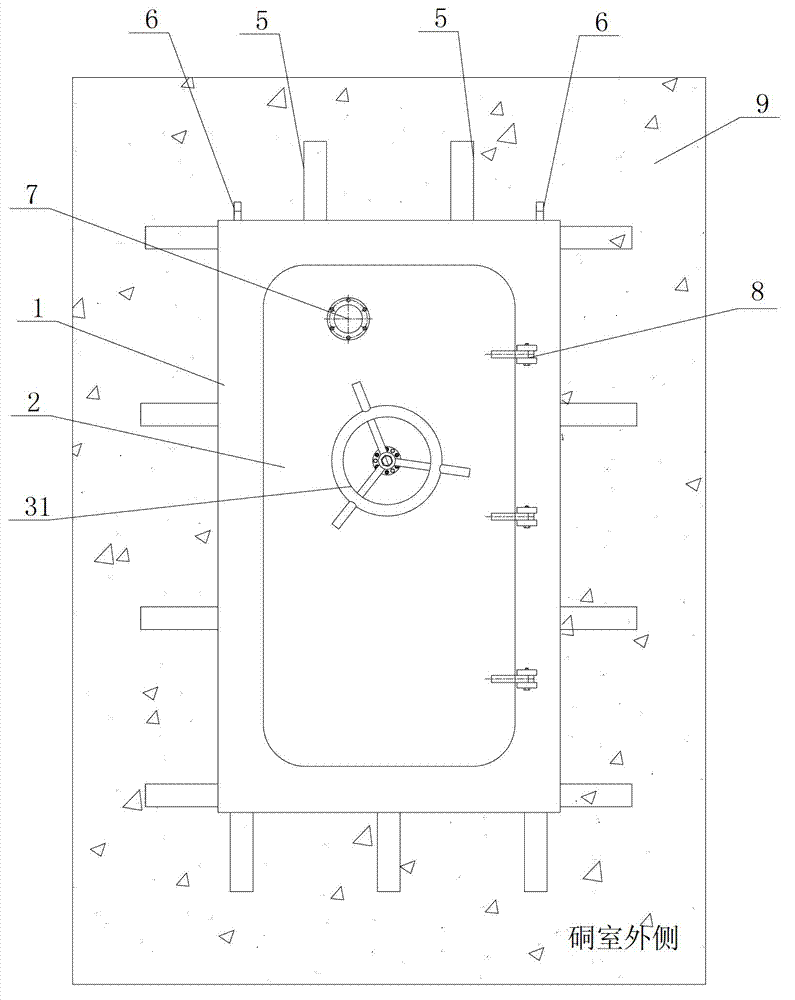

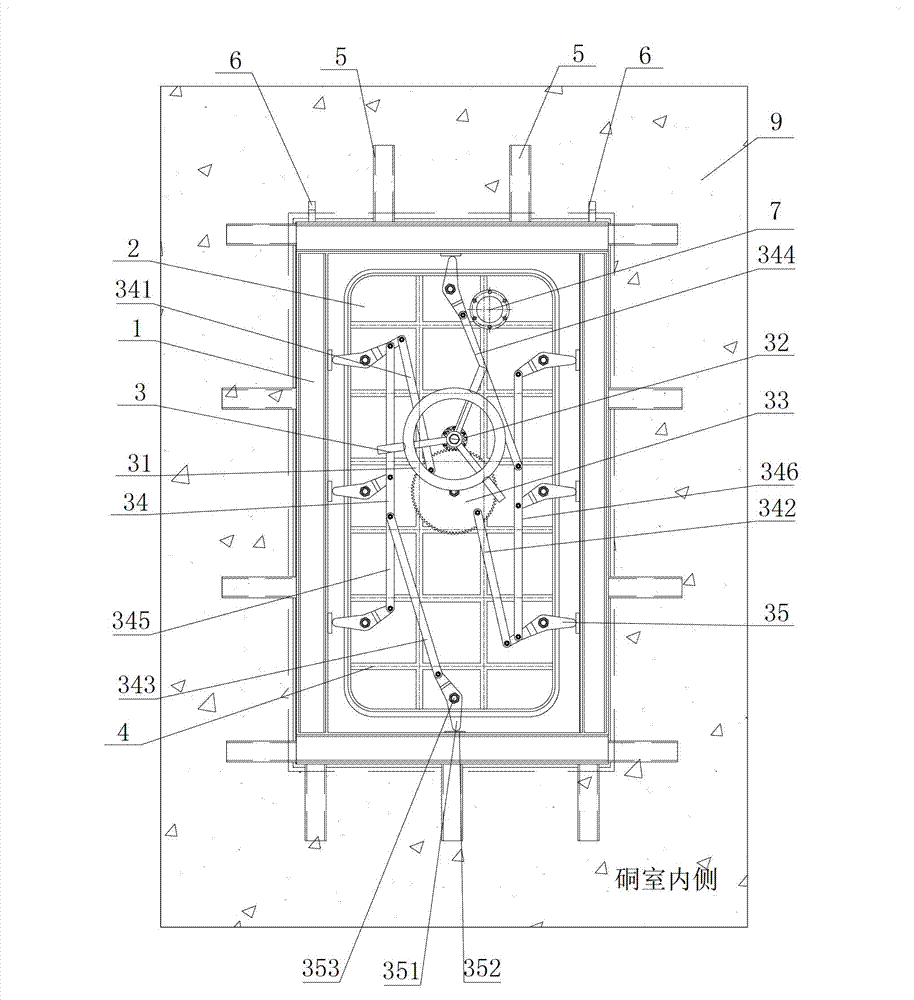

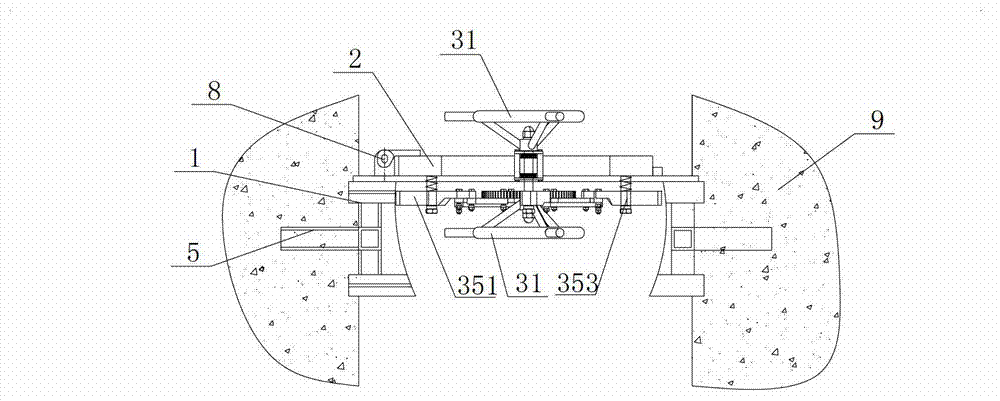

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

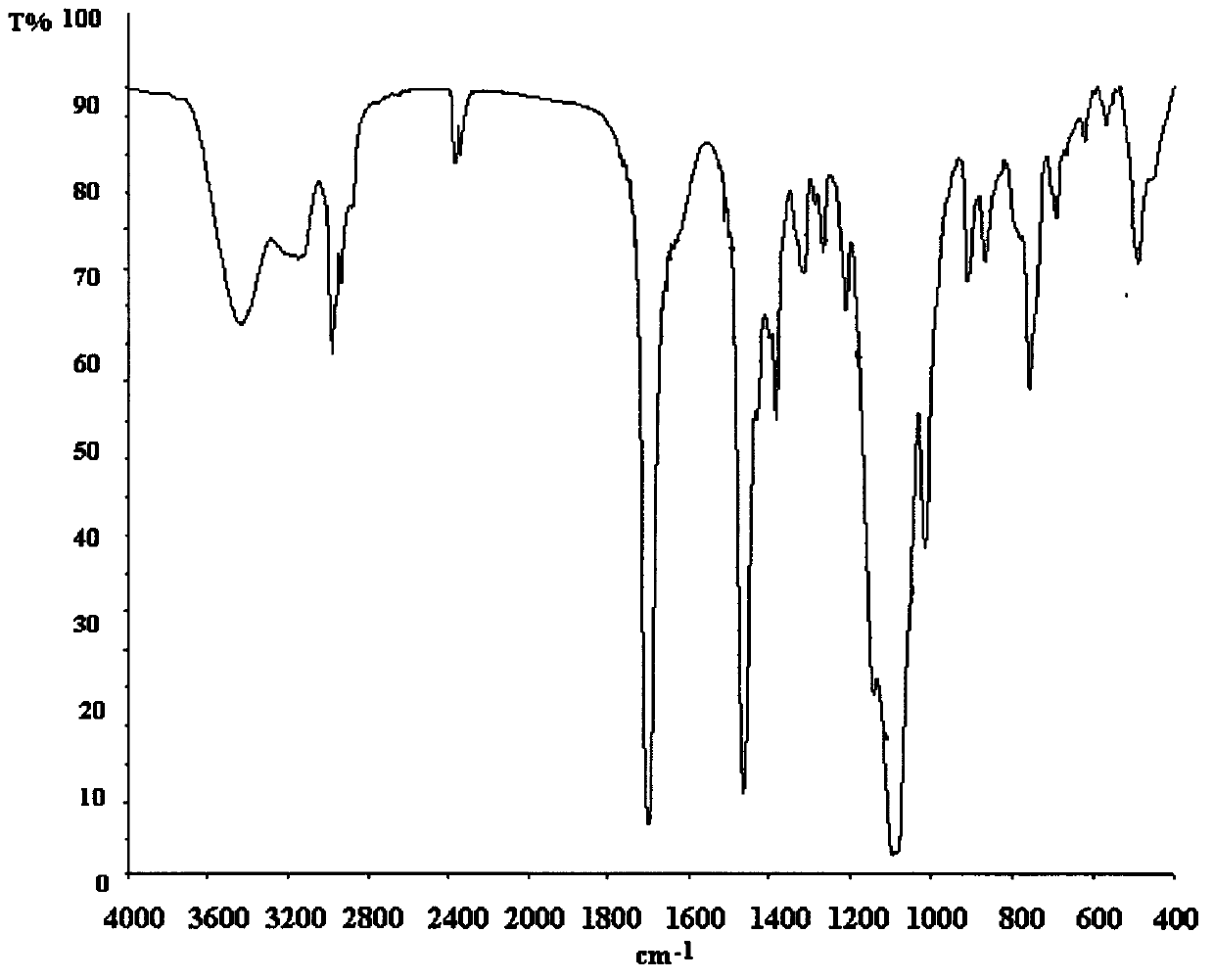

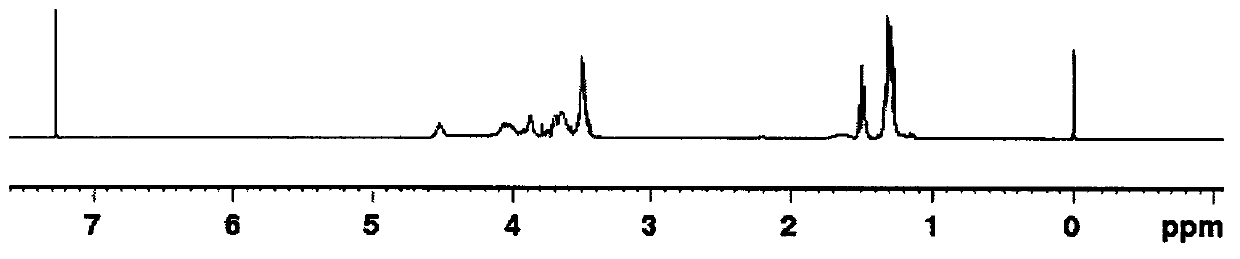

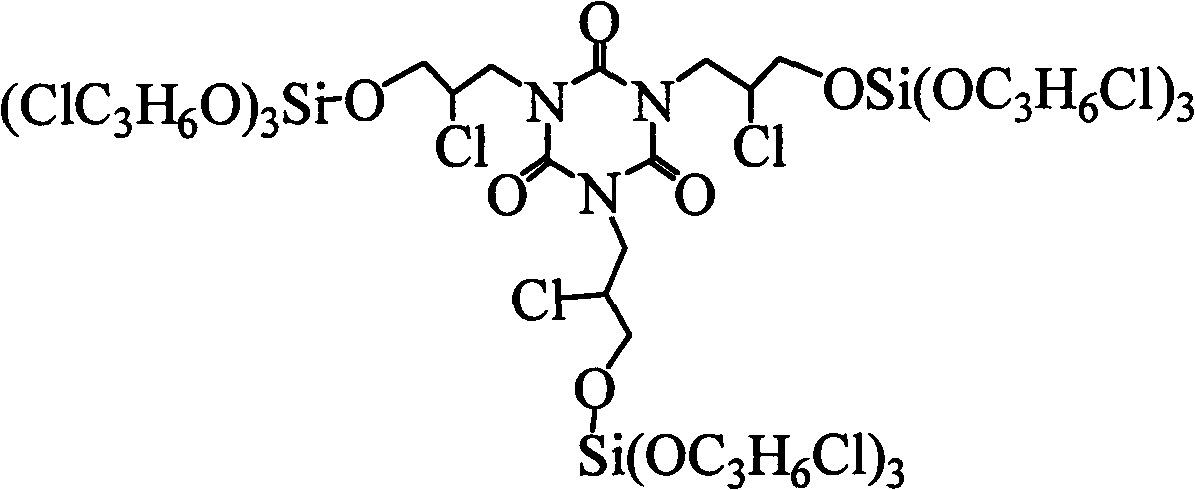

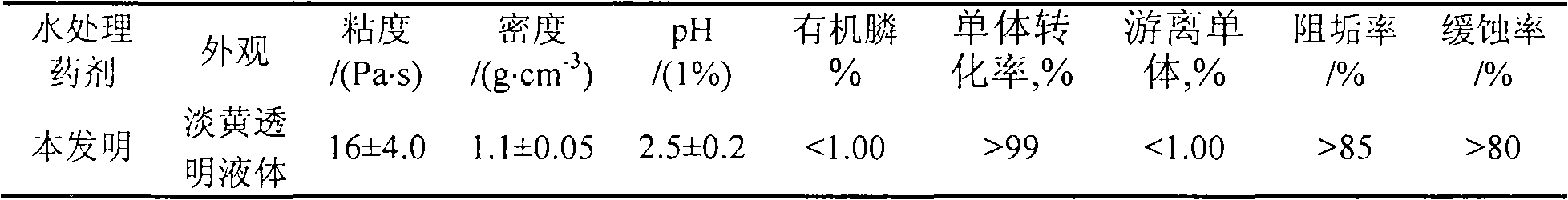

Triazinetri-tri(chloropropyl) silicate compound and preparation method thereof

ActiveCN102731549AGood symmetryStable molecular structureSilicon organic compoundsPlasticizerSilicon tetrachloride

The invention relates to a silicon-halogen synergic flame retardant triazinetri-tri(chloropropyl) silicate compound and a preparation method thereof, in particular to a tri{2-chloro-3-[tri(chloropropoxy)siacryloxy]propyl}isocyanurate compound and a preparation method thereof. The compound has the structural formula shown in the specification, wherein OC3H6Cl is OCH2CHClCH3 or OCH2CH2CH2Cl or OCH(CH3)CH2Cl. The preparation method comprises the following steps of: controlling a certain molar ratio of raw materials; enabling triepoxypropylisocyanurate to react with silicon tetrachloride at 60 DEG C for 4-6 hours in an organic solvent; adding epoxypropane and reacting at 50-60 DEG C for 4-6 hours; and purifying to obtain the product triazinetri-tri(chloropropyl) silicate. The triazinetri-tri(chloropropyl) silicate provided by the invention has good flame-retardant plasticizing property and is suitable to be used as a flame-retardant plasticizer of polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the production technology is simple, the cost is low, and the industrial production is easy to realize.

Owner:张家港市乐余科创园投资发展有限公司

Adsorbent gel ball and preparation method thereof

ActiveCN102258983AImprove adsorption capacityImprove adsorption efficiencyOther chemical processesAlkali metal oxides/hydroxidesHigh absorptionModified carbon

The invention provides a preparation method for an absorptive gel ball. The method provided by the invention comprises the following steps: a) carrying out carboxylation processing on a carbon nano tube by utilizing the mixed solution of concentrated sulfuric acid and concentrated nitric acid to obtain a carboxyl modified carbon nano tube, wherein the weight ratio of the concentrated sulfuric acid to the concentrated nitric acid to the carbon nano tube is (40-90): (30-5): (30-5); b) mixing the carboxyl modified carbon nano tube and water soluble alginate in water to obtain the mixture of the alginate and the carbon nano tube; and c) adding a calcium chloride solution to the mixture to obtain the absorptive gel ball. The invention also provides an absorptive gel ball. The absorptive gel ball provided by the invention comprises multiple micro-gel balls in a core shell structure, wherein the core of the micro-gel ball is the carboxyl modified carbon nano tube; and the shell is a calcium alginate polymer. The absorptive gel ball provided by the invention has high absorption efficiency and is suitable for the processing of decoloration of wastewater in the fields such as textile, printing and dyeing, printing ink, leather, rubber, coking, papermaking, pharmacy and the like.

Owner:HUBEI UNIV

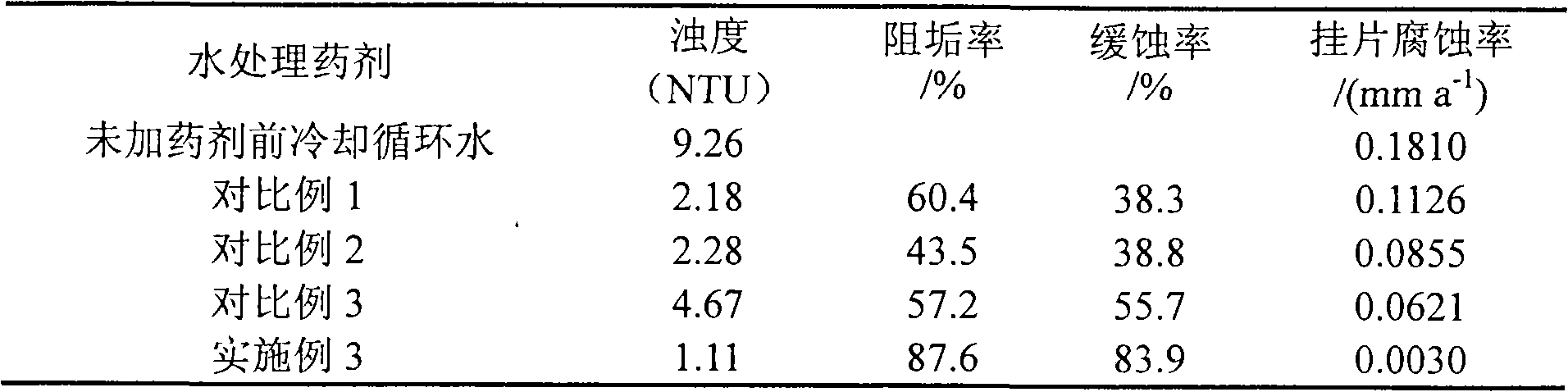

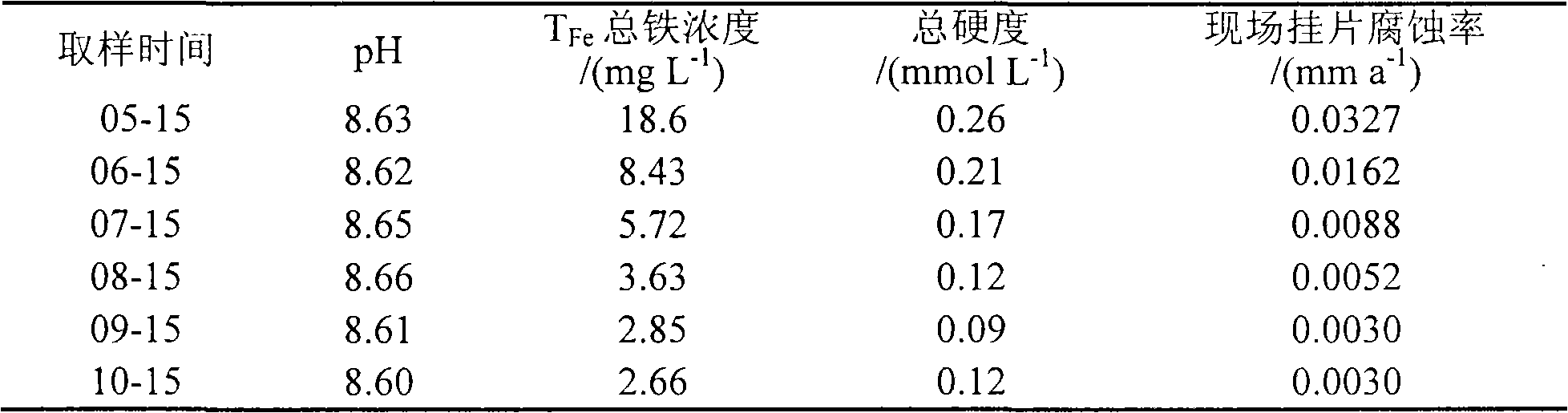

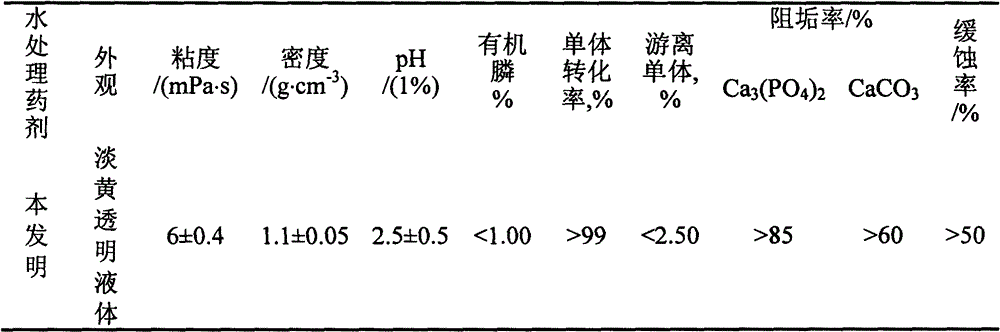

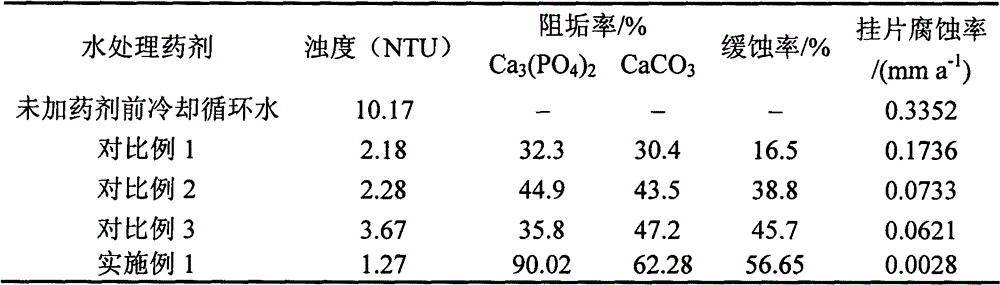

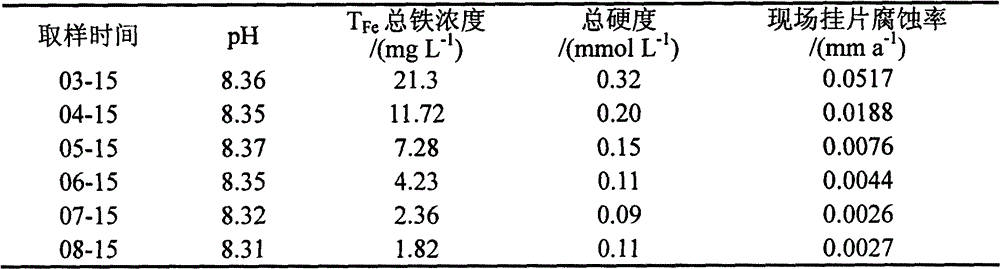

Four-element polymerization type corrosion inhibition antisludging agent and method for preparing same

InactiveCN101289256AAvoid corrosionSimple processTreatment using complexing/solubilising chemicalsPeroxydisulfateNuclear chemistry

The invention discloses a quaternary polymeric form corrosion and scale inhibitor which consists of maleic anhydride, hydroxy-propyl acrylate, acrylic acid, sodium alkyl sulfonate, sodium peroxydisulfate, sodium hypophosphite, isopropyl alcohol and water. The invention also discloses a preparation method of the quaternary polymeric form corrosion and scale inhibitor. The corrosion and scale inhibitor has good performance in inhibiting calcium carbonate scale, calcium sulphate scale, calcium phosphate scale and zinc scale and good dispersing performance for dispersing ferric oxide and is also characterized by corrosion resistance, high temperature resistance, stable molecule structure and low phosphorus content; the whole production process has no emission of 'the three wastes'. The technique of the product of the invention for treating circular cooling water is simple and the product of the invention has the advantages of little dosage, low cost, good effect and good economic benefit and wide social benefit.

Owner:NANJING FORESTRY UNIV

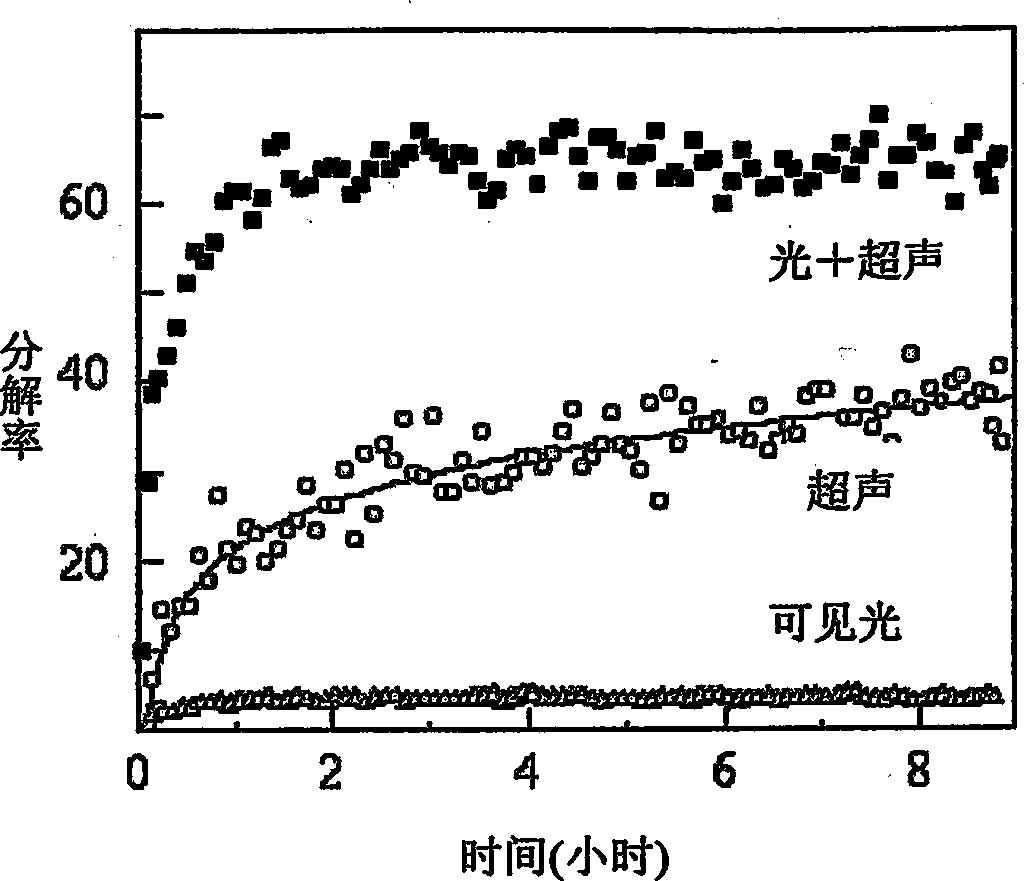

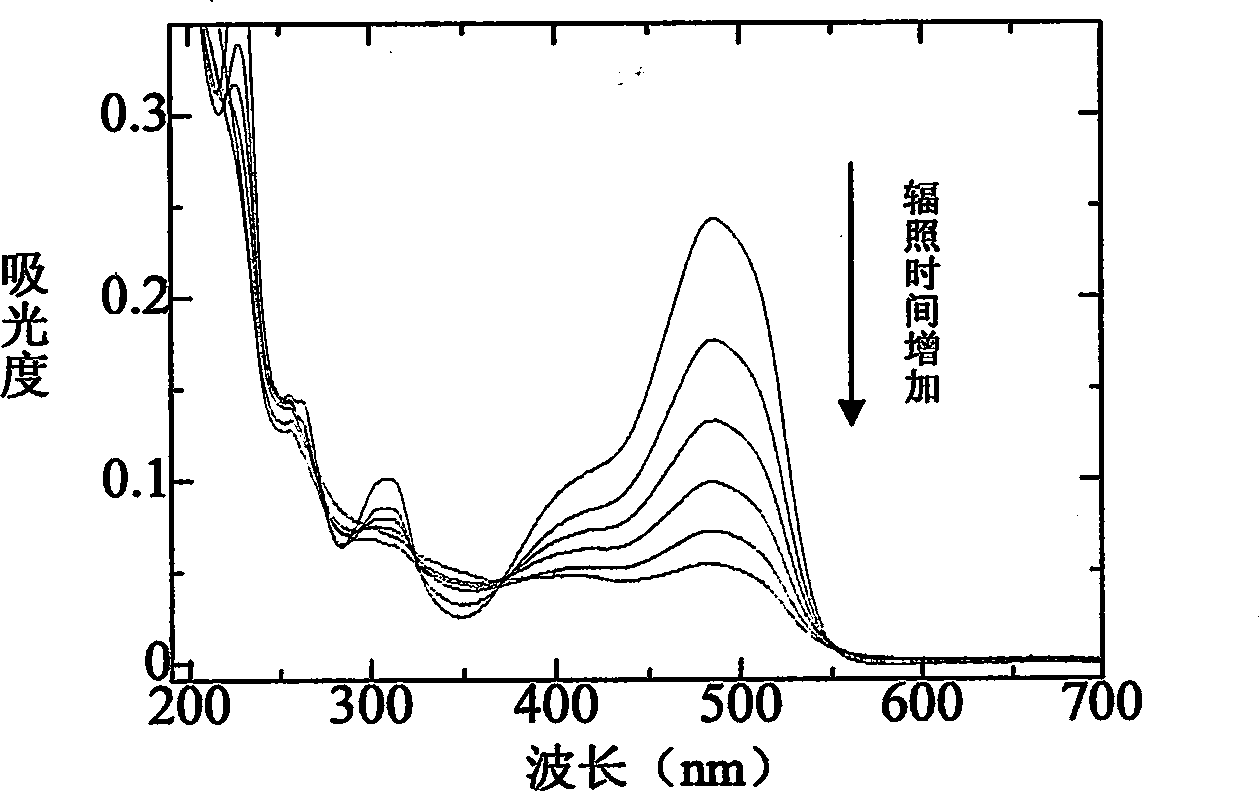

Method for treating wastewater of azo dye

InactiveCN1872712AStable molecular structureNo degradationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsDecompositionCompound (substance)

This invention discloses a method for treating azo-dye wastewater. The method comprises: (1) introducing azo-dye wastewater into a wastewater pool; (2) fixing an ultrasonic wave generator, and a visible light source; (3) opening the ultrasonic wave generator and the visible light source simultaneously, ultrasonicating and irradiating the azo-dye wastewater; (4) examming the dye decomposition result, and terminating the treatment when the decomposition reaches saturation. The method has such advantages as high decomposition rate, no toxic intermediates, low cost, no addition of other chemical substances, no pollution, and adequate utilization of ultrasonic wave energy.

Owner:NANJING UNIV

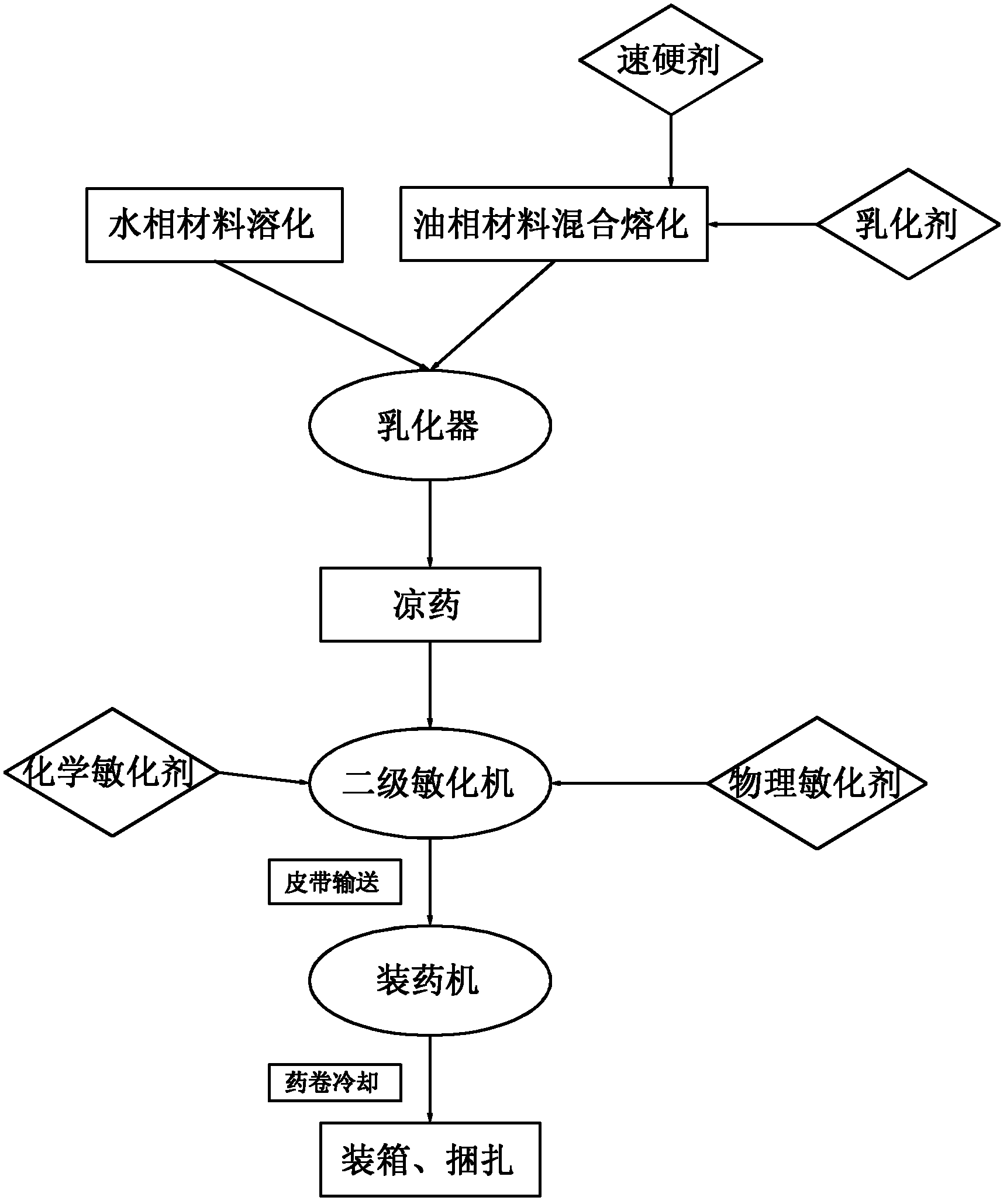

High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

ActiveCN102633580AIncrease the hardness of the outer phaseMolecular chain lengthNon-explosive/non-thermic compositionsEmulsion explosiveHardness

The invention relates to a high-temperature acceleratingly-hardened emulsion explosive, which comprises water-phase materials, oil-phase materials, emulsifier, sensitizer and hardening accelerator, wherein the water-phase materials include wax and / or fatty acid; the sensitizer includes physical sensitizer and chemical sensitizer simultaneously; and the hardening accelerator is selected from silicate and / or alkaline matter. The temperature of the emulsion explosive is higher than 35 DEG C, and the emulsion explosive has a certain hardness and is non-sticky, thereby being applicable to open-air filling operation in hot summer, and being high in explosion performance.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

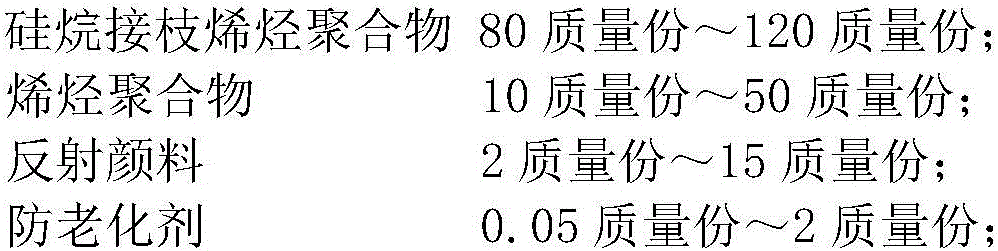

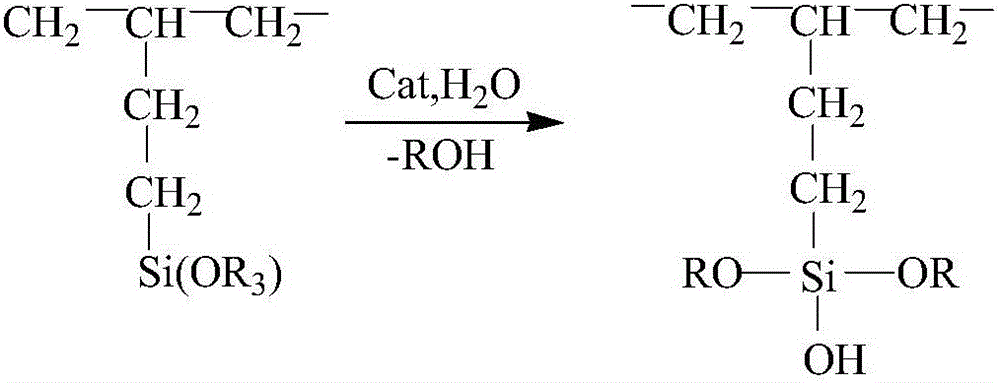

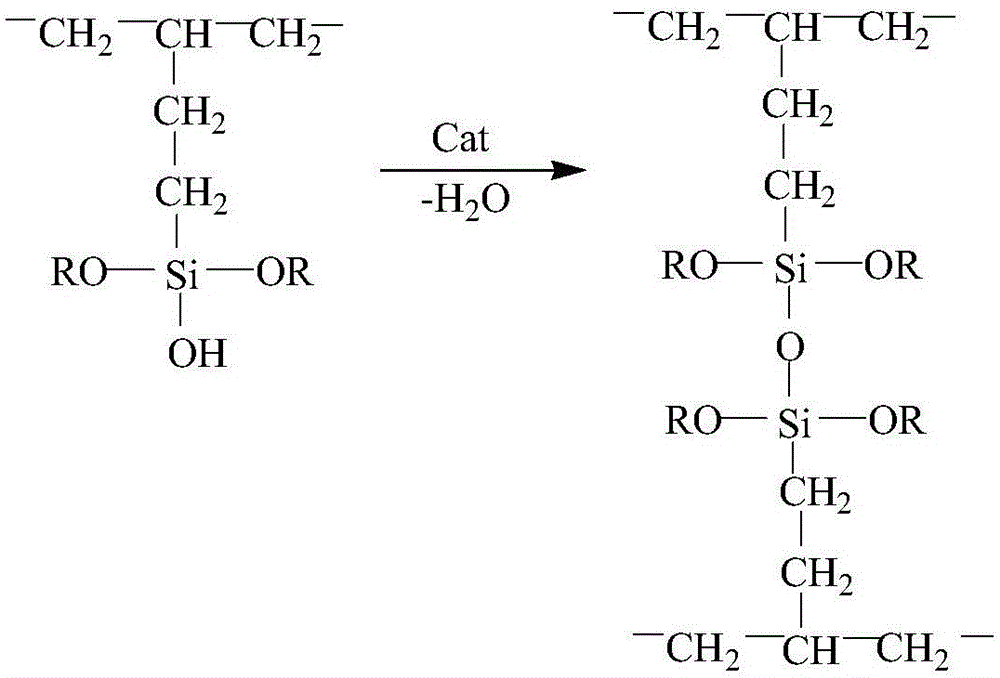

Photovoltaic packaging adhesive film

ActiveCN106366986AImprove reflectivityImprove insulation performanceNon-macromolecular adhesive additivesPhotovoltaic energy generationSilanesAdhesive

The invention provides a photovoltaic packaging adhesive film. The packaging adhesive film has a uniform crosslinking degree which is 5-30%. The packaging adhesive film comprises, by mass, 80-120 parts of silane grafted olefin polymer, 10-50 parts of olefin polymer, 2-15 parts of reflective pigment and 0.05-2 parts of anti-ageing agent, wherein the silane grafting rate of the silane grafted olefin polymer is 0.5-3%. The adhesive film guarantees lamination performance of an assembly and is higher in assembly yield compared with the prior art. The reflectivity of the adhesive film is improved, the anti-ageing performance is better, safety and reliability of the photovoltaic assembly are ensured, bubbles and other defects in the assembly lamination process can be reduced or avoided, and the assembly yield is further increased.

Owner:乐凯胶片股份有限公司

Biporphin metal coordination compound with bridge linking face-face structure and its use

InactiveCN1472211AHigh catalytic activityHigh selectivityGroup 8/9/10/18 element organic compoundsGroup 2/12 element organic compoundsPtru catalystFuel cells

A biporphyrin-metal coordination compound with bridged face-face structure is prepared by simulating biologic enzyme catalyst. It is the nitrogen-contained large-ring metal match with two catalytic activity centers for absorbing both ends of molecular oxygen, and can be used as catalyst of the cathode of methanol fuel battery.

Owner:SHANDONG UNIV OF TECH

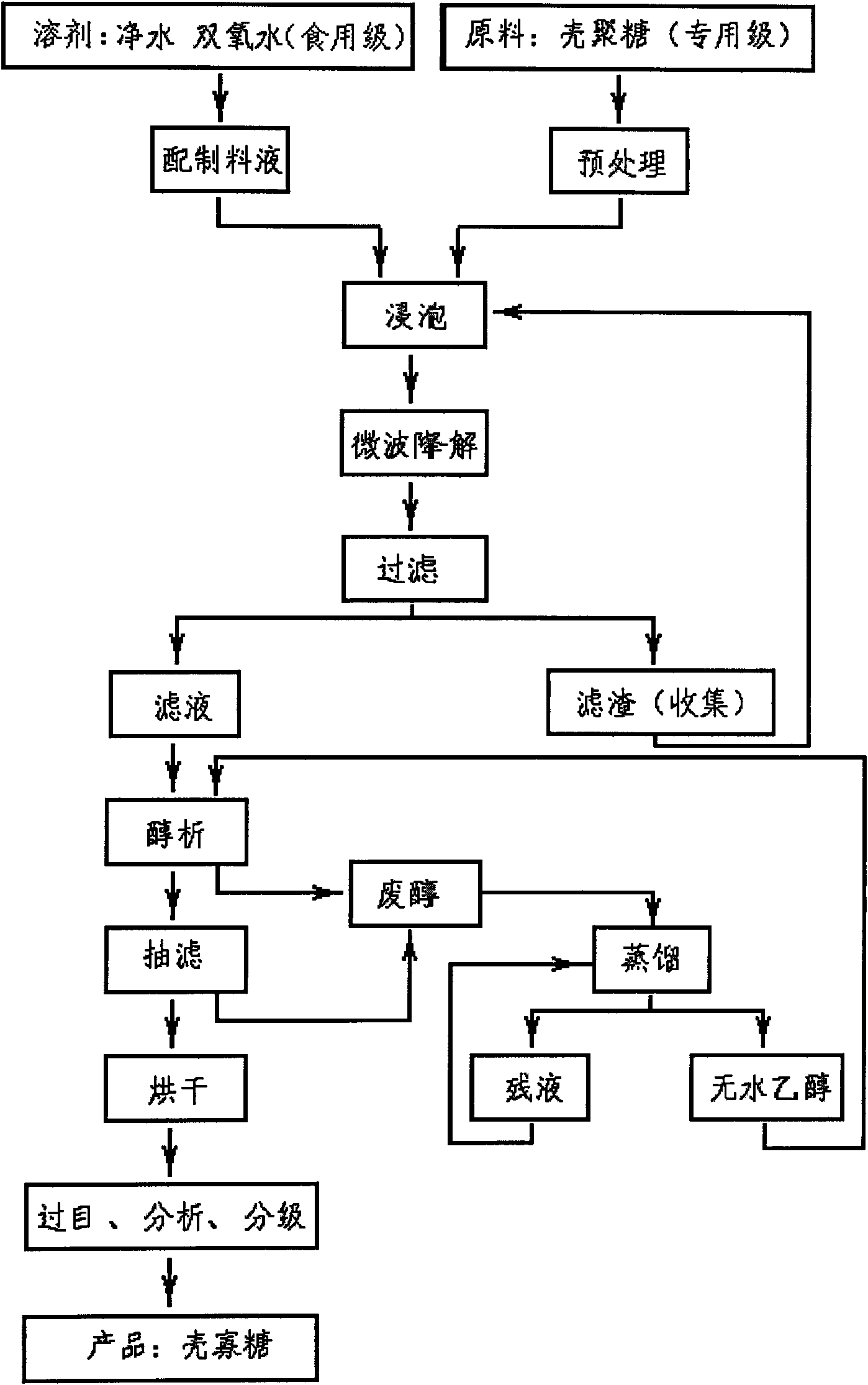

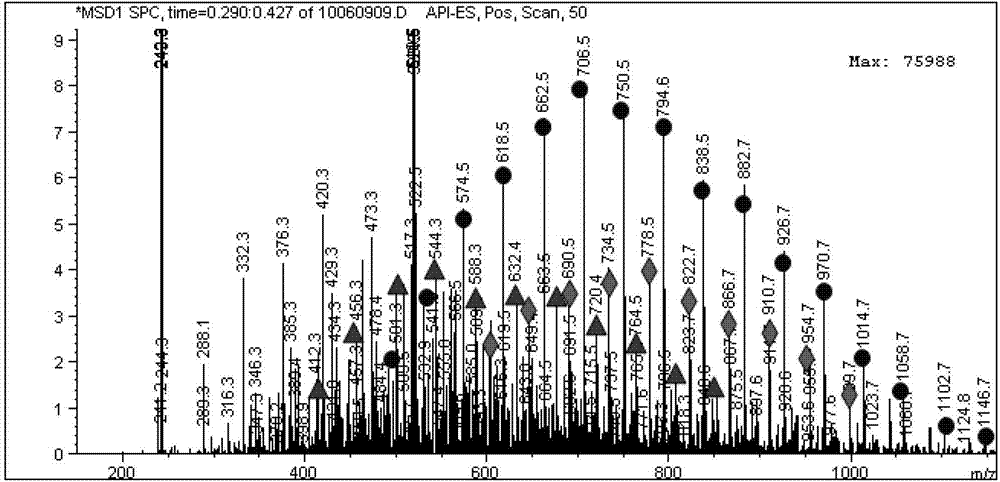

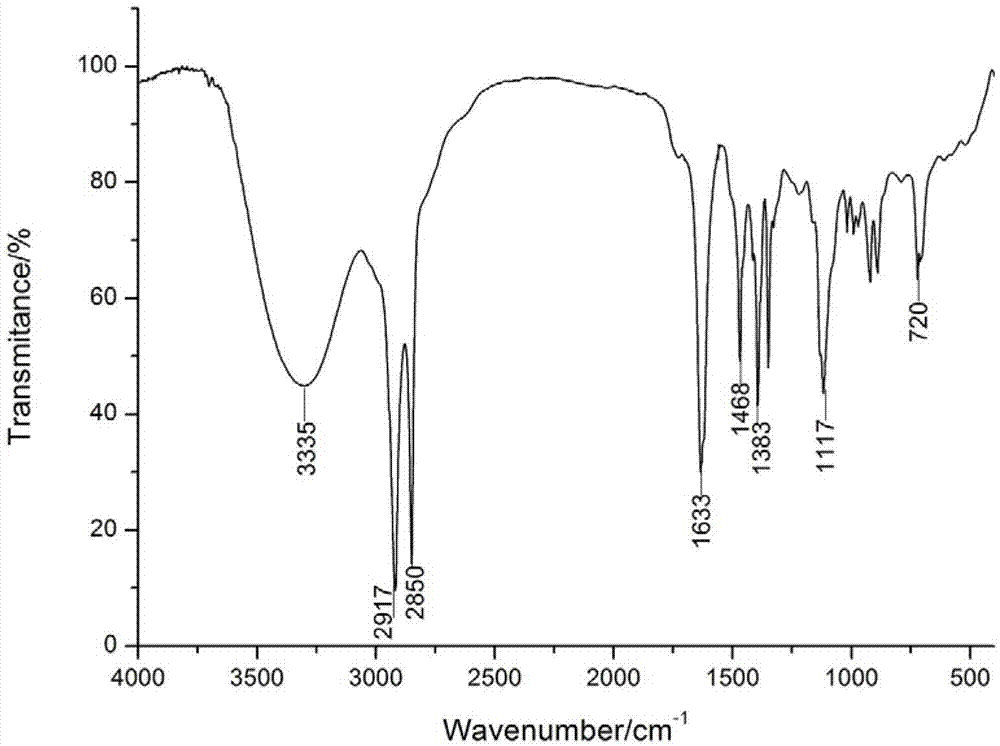

Method for preparing chitosan into water-soluble chitooligo saccharide

The invention relates to a method for preparing chitosan into water-soluble chitooligosaccharide, which comprises the following steps: using chitosan as a raw material, processing the chitosan by rinsing and drying technology, and immersing the chitosan in a material liquid prepared by purified water and edible hydrogen peroxide; carrying out the processing of microwave radiating degradation to form the mixed liquid of low-molecular chitooligo saccharide which can be dissolved in the material liquid and partial undegraded chitosan, and obtaining residual slag of chitosan and a chitooligo saccharide solution by filtration; and sending the chitooligo saccharide solution into absolute ethyl alcohol, and after alcohol precipitation, carrying out sucking filtration and drying to obtain a finished product of water-soluble chitooligo saccharide. The processing technology of microwave radiating degradation is used, and energy is mased by a physical method to degrade high-molecular chitosan into low-molecular water-soluble chitooligo saccharide with a stable structure, thus no other side product of reaction or pollutant is generated in the degrading process. Compared with the preparing method of the prior art, the invention has the advantages of advanced technology, simple procedures, low investment of production facilities, high product purity, stable quality and the like, and developsa wide market application prospect for the chitosan prepared by taking chitin as a raw material.

Owner:赵建发

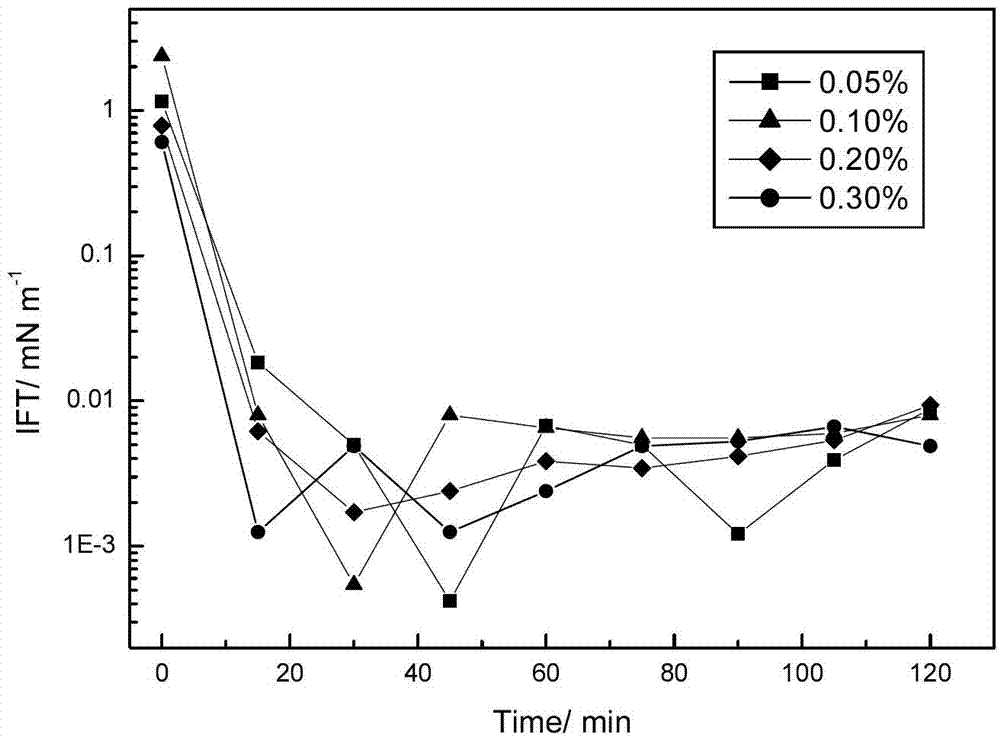

Non-alkali composite flooding compound based on straight-chain fatty alcohol ether carboxylic betaine

ActiveCN102775976AIncrease critical micelle concentrationLower Krafft pointsDrilling compositionBetaineEther

The invention provides a non-alkali composite flooding compound, comprising the following components in percentage by weight: 0.005-0.30% of straight-chain fatty alcohol ether carboxylic betaine amphoteric surfactant, 0.05-0.25% of polymer, and the balance of oilfield injected clear water or return water. According to the invention, the straight-chain fatty alcohol ether carboxylic betaine amphoteric surfactant is used as the essential component of the non-alkali composite flooding compound, to form surfactant / polymer binary system which can reach ultra interfacial tension range with middle-low-temperature middle-low-salt oil deposit and high-temperature high-salt oil deposit, in this way, the requirements on non-alkali composite oil flooding are satisfied.

Owner:PETROCHINA CO LTD

Amnion eye drops for curing cornea alkali burn

ActiveCN101658491AImprove stabilitySolubility temperature increasesSenses disorderPharmaceutical delivery mechanismSide effectIrritation

The invention provides amnion eye drops for curing cornea alkali burn and a preparation method thereof. The preparation method comprises the steps of: taking amnion homogenate supernate as main activeconstituent; and adding with trehalose, hyaluronic acid or salt thereof, heparin or salt thereof, sodium chloride, benzalkonium bromide, vitamin, etc. The eye drops belongs to an ophthalmology drug delivery system, has a good lubrication function, and can provide a conglutination-resistant surface; and the drug delivery system is added with the other pharmacological active constituents, thereby being capable of increasing the viscocity of medical liquid, prolonging the residence time of the drug in eye surface, improving the bioavailability of the drug, reducing the side effect of the drug, reducing the drug irritation, and having a slow release effect. The amnion eye drops is an effective ophthalmology new drug, and has good clinic application foreground.

Owner:HARBIN MEDICAL UNIVERSITY

Medicinal collagen material and its making process

InactiveCN1463984AStable molecular structureGood anti-leakage performanceConnective tissue peptidesPeptide/protein ingredientsEthylene Oxide SterilizationSpinal dura mater

The medical collagen material is made through the processes of chondroitin sulfate crosslinking, high temperature vacuum drying and ethylene oxide. Is has stable molecule structure and better anti-seepage and anti-stick performance, and is used in repairing cerebral dura mater, spinal dura mater and peripheral nerve.

Owner:于海鹰 +1

Plastic wood board with high weather resistance and processing method thereof

ActiveCN101941310AWon't releaseGood physical propertiesRubber layered productsASA-polymerSocial benefits

The invention discloses a plastic wood board with high weather resistance, comprising a plastic wood base board. The plastic wood base board mainly takes wood flour and PVC (Poly Vinyl Chloride) raw material as main raw materials; the surface of the plastic wood base board is provided with an ASA (Acrylonitrile-Styrene-Acrylate) coextrusion layer; and the coverage range of the ASA coextrusion layer is an upper surface of the integral plastic wood board. The plastic wood board with high weather resistance can not only enable the surface of the plastic wood board to be rich in luster and the integral effect to be more attractive by matching with the inherent color of the plastic wood board, but also solve the problem of color fading of the plastic wood board used outdoors and select different models as required and has the advantages of convenient installation, low price and very well social benefit and economic benefit.

Owner:无锡唯景建材科技有限公司

Preparation method for enteric plant cellulose hard hollow capsules

ActiveCN103330695AGuaranteed functionKeep dryPharmaceutical non-active ingredientsCapsule deliveryFiber derivativeFiber

The invention provides a preparation method for hard hollow capsules from enteric plant cellulose derivatives and belongs to the technical field of pharmaceutic adjuvants. Plant cellulose is prepared from plant derivatives such as pine, purified cotton and the like. Colorless and transparent hard hollow capsules, colored hard hollow capsules, shading hard hollow capsules and the like can be prepared though the preparation method. The preparation method comprises steps of mixing of plant cellulose, surfactants, coagulant aids, coloring agents and water, molding, drying, coating and the like. The plant cellulose hard hollow capsules are advantaged by stable performances, low water content, environmental protection and safety. The plant cellulose hard hollow capsules can be filled by all kinds of contents.

Owner:SHAOXING KANGKE CAPSULE

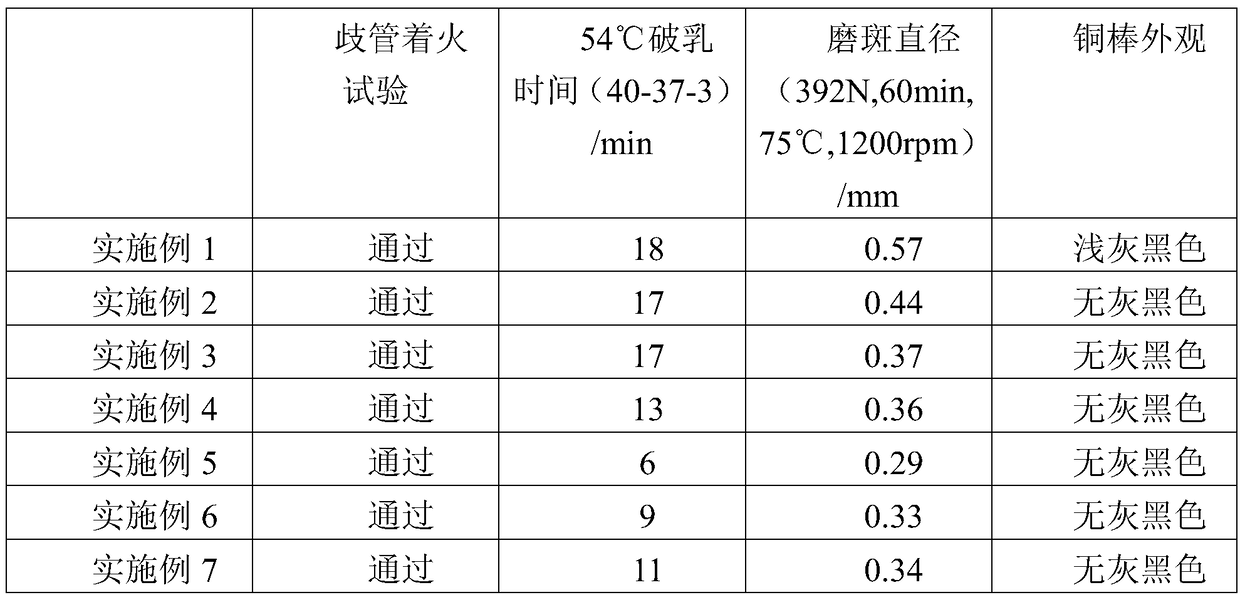

Ultralow temperature ash-free antiwear incombustible ester type hydraulic oil, production technology and application thereof

InactiveCN108641792AImprove oxidation stabilityStable molecular structureLubricant compositionFire retardantLubrication

The invention discloses ultralow temperature ash-free antiwear incombustible ester type hydraulic oil, a production technology and application thereof. The ultralow temperature ash-free antiwear incombustible ester type hydraulic oil is prepared from a viscosity index improver, a pour point reducer, an emulsion breaker, a defoaming agent, an antiwear reagent at extreme pressure, an ash-free detergent dispersant, an antirust agent, an antioxidant, a fire retardant and base oil. The ultralow temperature ash-free antiwear incombustible ester type hydraulic oil has the advantages that firstly, theoil has the extremely stable molecular structure, and the good oxidation stability; secondly, the oil has the extremely good lubricating performance and antiwear performance, and can effectively prolong the life of an engine; thirdly, the oil has the low temperature fluidity so that the engine can be easily started; fourthly, the oil has the good high temperature high shearing performance, the volatile loss at a high temperature is less, and the oil film tenacity and strength of an oil product at the high temperature are ensured; fifthly, the viscocity and the lubrication of the oil can be maintained after a ultralong driving process; sixthly, the oil has the good detergent dispersing performance, and the dust deposition amount is less after the oil is used for a long time; seventhly, theoil has the good biodegradability; and eighthly, the oil has low condensation point and can be widely applied to bad working environments such as low temperature and cold.

Owner:冠仕(上海)新能源科技有限公司

Quadripolymer-type corrosion-inhibition scale inhibitor PMAHS and preparation method thereof

InactiveCN102745823ASimple processGood dispersionScale removal and water softeningTemperature resistanceCorrosion

The invention discloses a quadripolymer-type corrosion-inhibition scale inhibitor PMAHS. The quadripolymer-type corrosion-inhibition scale inhibitor PMAHS comprises maleic anhydride (MA), acrylic acid (AA), hydroxyethyl acrylate (HEA), sodium methallylsulfonate (SMAS), sodium persulfate, sodium hypophosphite, isopropanol and water. The invention also discloses a preparation method of the quadripolymer-type corrosion-inhibition scale inhibitor PMAHS. The quadripolymer-type corrosion-inhibition scale inhibitor PMAHS has excellent effects of inhibiting production of calcium phosphate scales and calcium carbonate scales and especially phosphate scales, has good iron oxide dispersibility, has functions of corrosion inhibition, high temperature resistance and acid and base resistance, and has a stable molecular structure and low phosphorus content. The preparation method does not produce three wastes in production. The quadripolymer-type corrosion-inhibition scale inhibitor PMAHS has the advantages of simple circulating cooling water treatment processes, low use amount, low cost, good effects, good economic benefits and wide social benefits.

Owner:NANJING FORESTRY UNIV

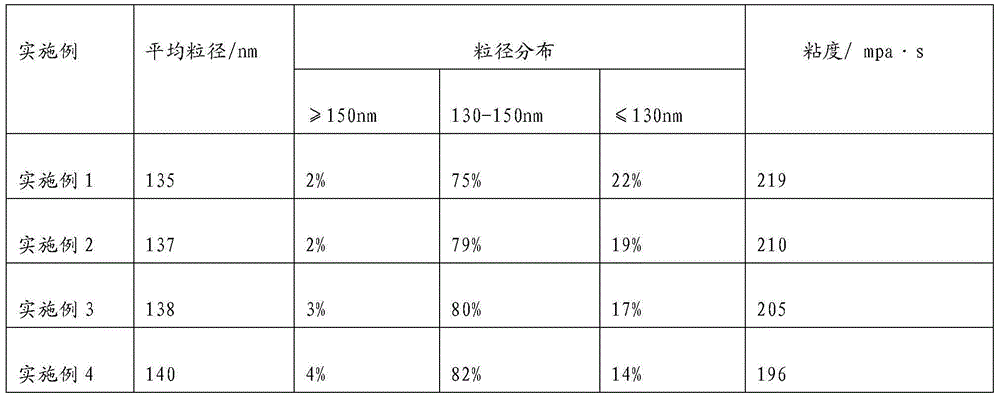

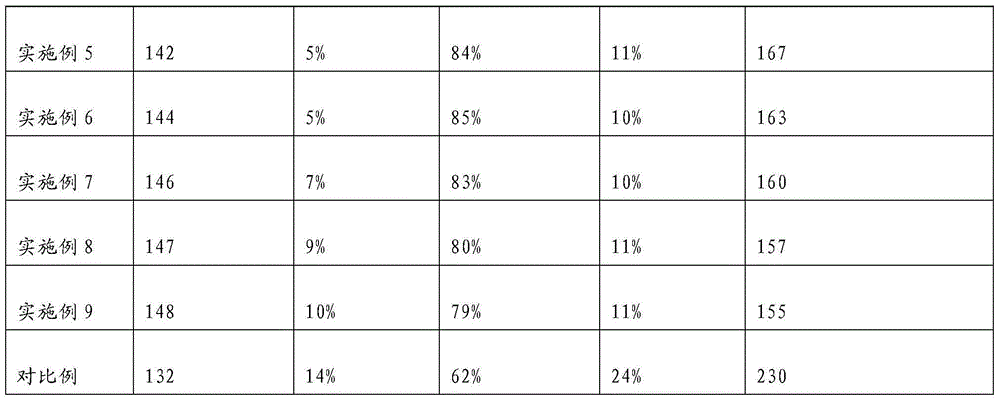

Carboxylated styrene-butadiene latex

ActiveCN104628953AStable molecular structureMolecular weight controllableButadiene-styrene rubberMechanical property

The invention relates to a carboxylated styrene-butadiene latex. High-speed steam is utilized to provide reaction heat energy for the reaction of the carboxylated styrene-butadiene latex, and the cooled steam is converted into high-temperature deionized water; the high-speed steam also drives the liquid in the reaction vessel to rotate, and the liquid in the reaction vessel is dispersed by the steam flow to form abundant micro steam-water combinations so as to push the material in the reaction vessel to quickly flow; and the substances and temperature in the reaction vessel are uniformly distributed, the polymerization reaction is uniform, and thus, the carboxylated styrene-butadiene latex has the advantages of stable molecular structure, controllable molecular weight and more centralized size distribution, has balanced and excellent mechanical properties, and enhances the qualification rate and quality of the product.

Owner:宁波卫山多宝建材有限公司

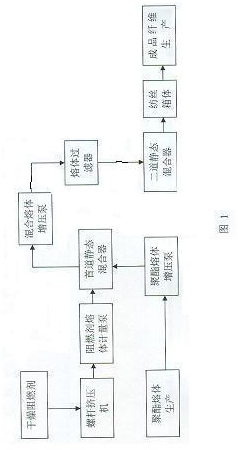

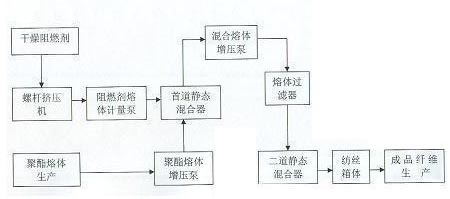

Production method of inflaming retarding hollow polyster fiber

ActiveCN102586907AQuality improvementGood physical propertiesFlame-proof filament manufactureFilament forming substance formingFiberPolymer science

The invention discloses a production method of an inflaming retarding hollow polyster fiber. The production method is characterized by comprising the following process steps of: mixing the polyester raw materials (namely terephthalic acid and ethylene glycol) uniformly in the mole ratio of 1.12:1, conducting esterification and condensation polymerization on the mixture to obtain polyethylene glycol terephthalate melt, and pumping the polyethylene glycol terephthalate melt in a primary-pass static mixer; after a phosphorus flame retardant is heated and dried, pumping by a metering pump an inflaming retarding melt heated and melted in a screw rod extruder into the primary-pass static mixer; mixing the polyethylene glycol terephthalate and the inflaming retarding melt by the primary-pass static mixer to form a mixed melt, processing the mixed melt by a mixed melt boosting pump, pumping the mixed melt by a melt filter and a secondary-pass static mixer in sequence so as to feed the mixed melt in a spinning jet to form small hollow filiform flows, shock-cooling the mixed melt to cure the mixed melt into fibers. The production method has the advantages that the process flow is reasonable, the quality of the fibers can be guaranteed easily, and the inflaming retarding efficiency of the fibers is high.

Owner:JIANGSU DESAI CHEM FIBER

Preparation method of modified polyethylene diaphragm for lithium ion battery

ActiveCN102993452AImprove thermal deformation resistanceGood adhesivenessPolyurea/polyurethane coatingsCell component detailsParticulatesPolyurethane adhesive

The invention discloses a preparation method of a modified polyethylene diaphragm for a lithium ion battery. The preparation method of the modified polyethylene diaphragm is characterized in that a high-temperature resistance coating is uniformly coated on the two surfaces of the polyethylene diaphragm, and the modified polyethylene diaphragm is formed after drying; and the high-temperature resistance coating comprises inorganic particulate matters, a polyurethane adhesive, a dispersing agent and an ethanol solution. The high-temperature resistance coating adopted in the invention has low surface tension and is more environment-friendly by taking an ethanol solution as a solvent; dispersed phases in the high-temperature resistance coating are coated on the two surfaces of the polyethylene diaphragm to form a high-temperature resistance Al2O3 coating which can stop a positive electrode and a negative electrode from directly contacting when a base material melts, slows down the release of heat energy and improves the safety performance of the battery; and the polyurethane adhesive synthesized in the invention increases an interface bonding force between Al2O3 particles and the base material of the polyethylene diaphragm, enhances the adhesion between the Al2O3 particles and the base material, and simultaneously increases the imbibition capacity and heat resistance performance of the modified polyethylene diaphragm.

Owner:CHINA HAISUM ENG

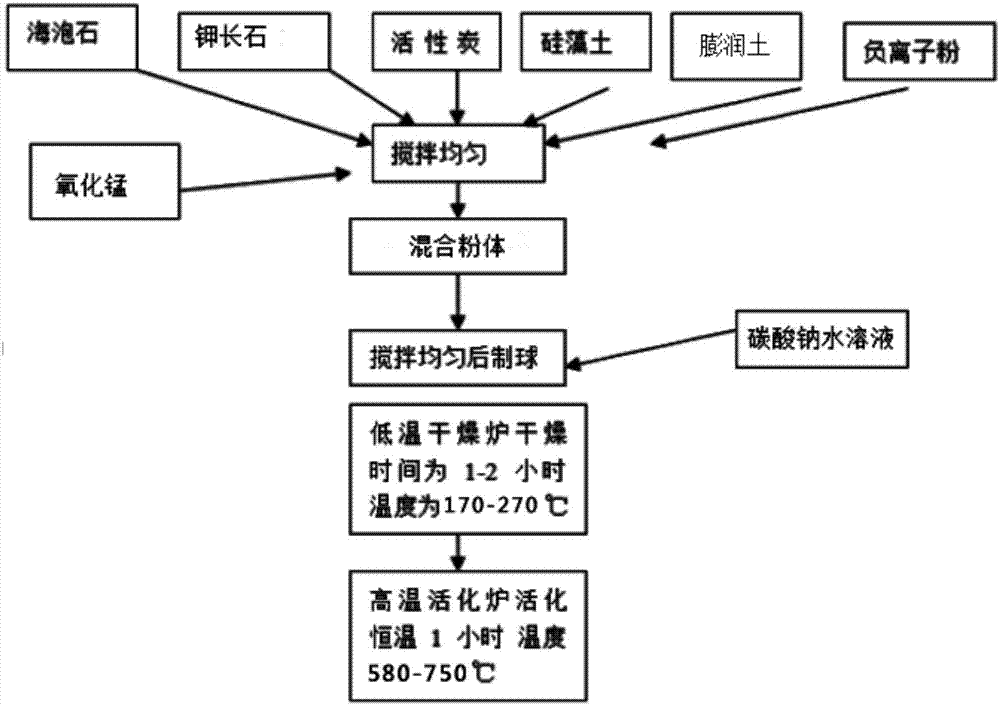

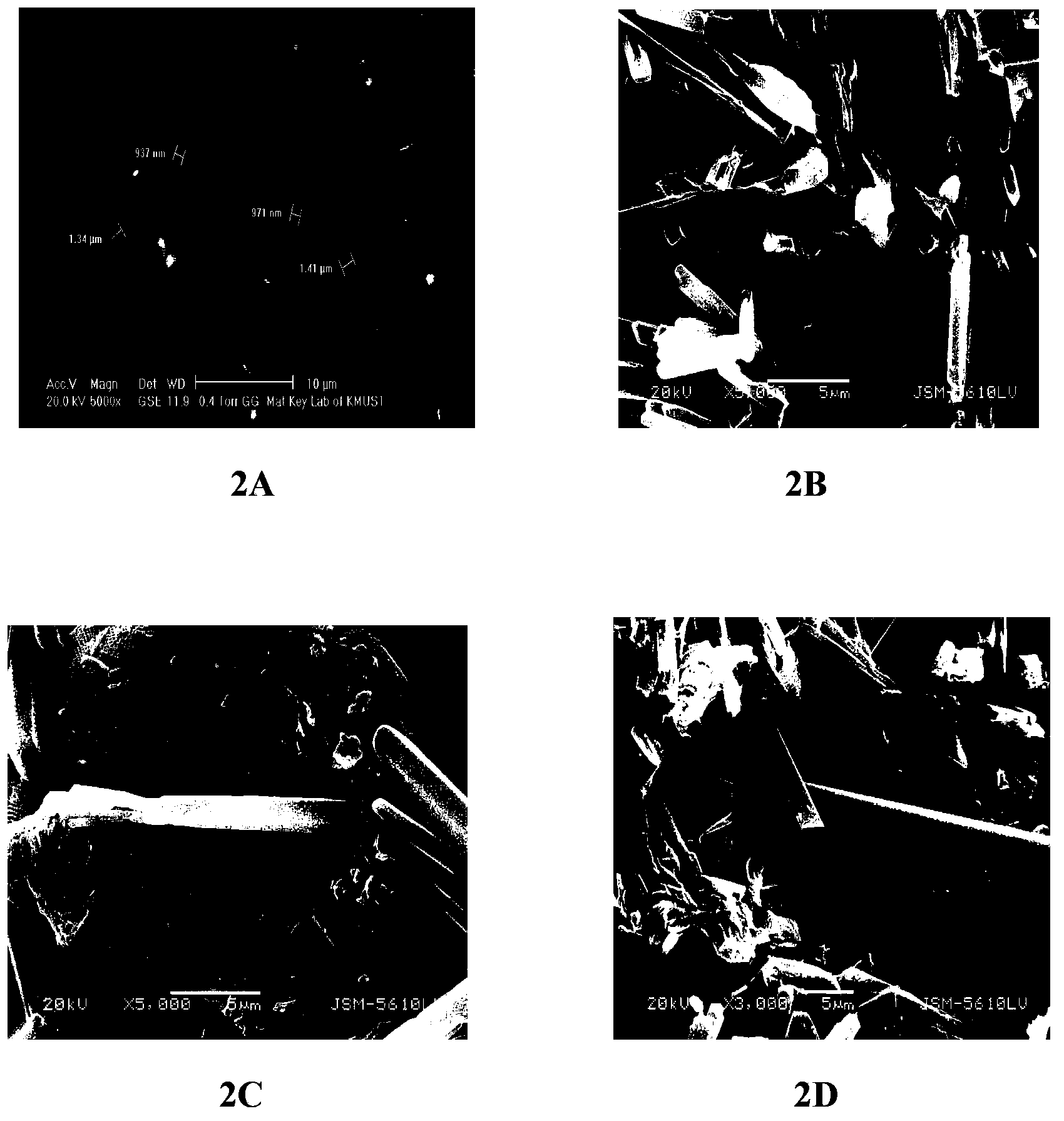

Anion-containing diatom nano mineral crystal particles and preparation method thereof

InactiveCN107349899AGood adhesionIncrease inhalationGas treatmentOther chemical processesActivated carbonBenzene

The invention discloses anion-containing diatom nano mineral crystal particles and a preparation method thereof. The nano mineral crystal particles are prepared from raw materials in parts by weight as follows: 50-70 parts of sepiolite, 0.1-0.5 parts of anion powder, 5-10 parts of attapulgite, 10-20 parts of activated carbon, 5-10 parts of diatomite, 10-15 parts of kaolin and 3-5 parts of manganese oxide. The sieved sepiolite, anion powder, attapulgite, activated carbon, diatomite, kaolin and manganese oxide are weighed and mixed, and a proper quantity of sodium carbonate aqueous solution is added, and spheres are obtained through granulation; the nano mineral crystal particles are prepared after primary drying and activation. The prepared nano mineral crystal purification particles can adsorb formaldehyde, benzene, TVOC and other harmful gases and can play roles in decomposing, removing and releasing anions. Mineral materials such as sepiolite and attapulgite are used for bonding, the pure nature of the product is guaranteed, the preparation steps are simple, and the process is mature and suitable for industrial production.

Owner:文卓齐

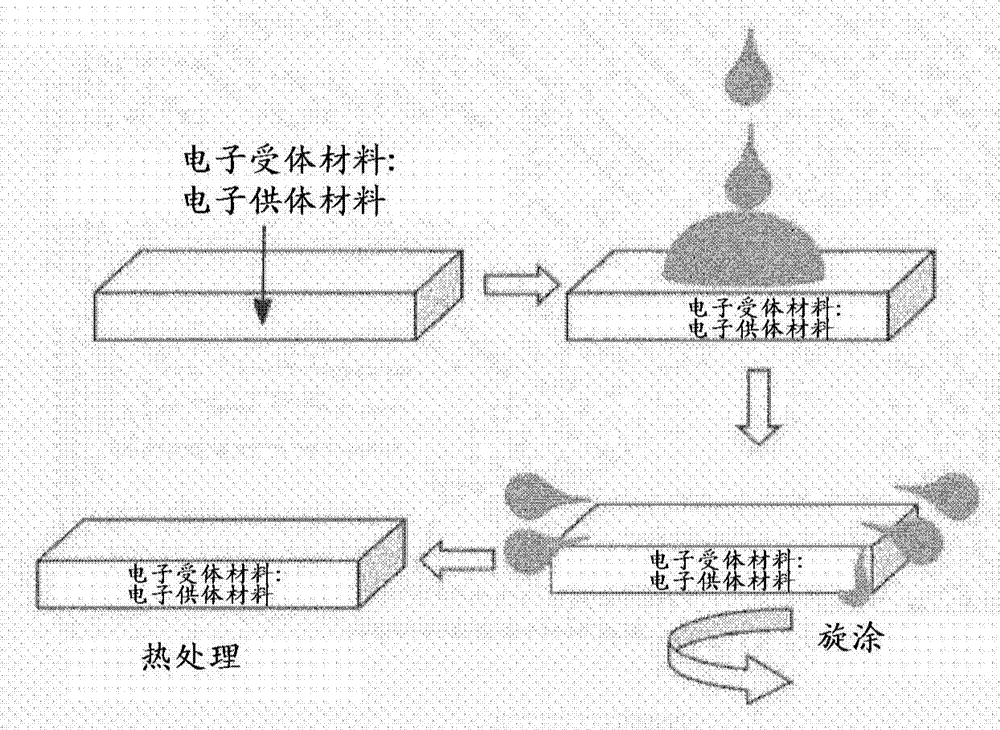

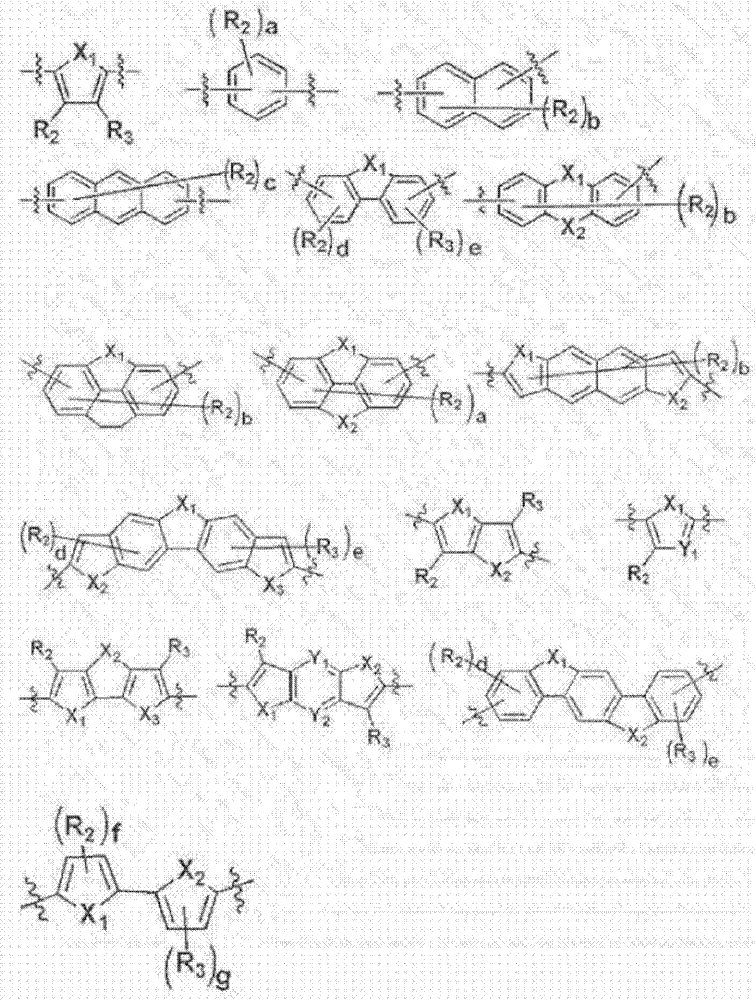

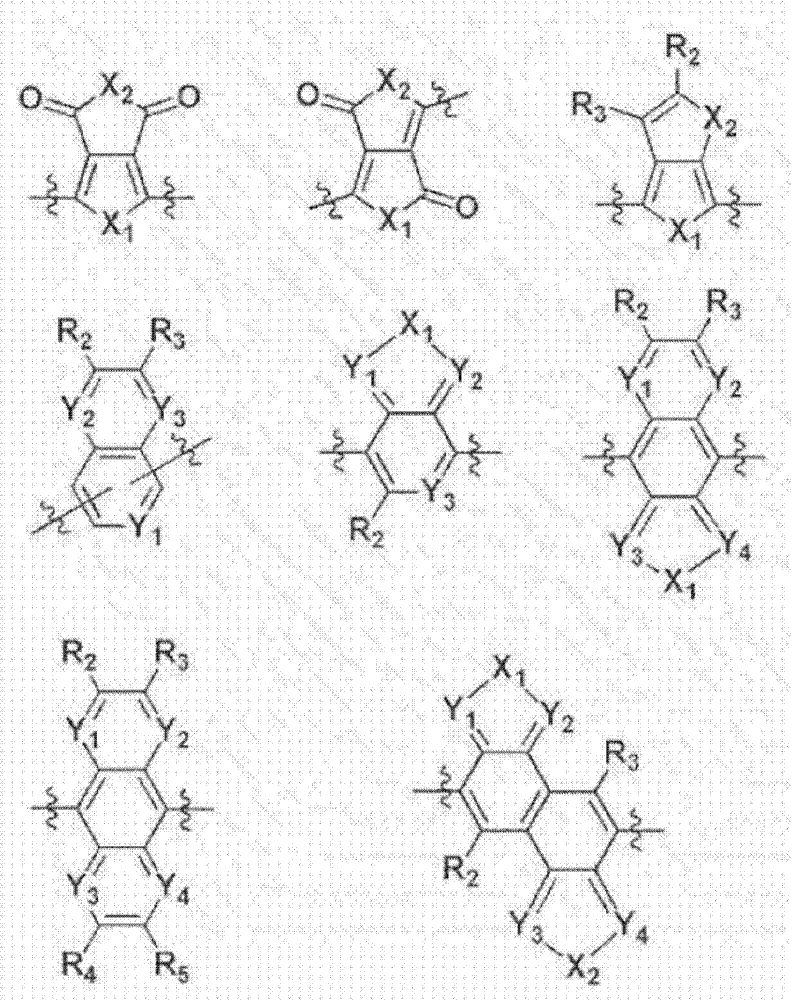

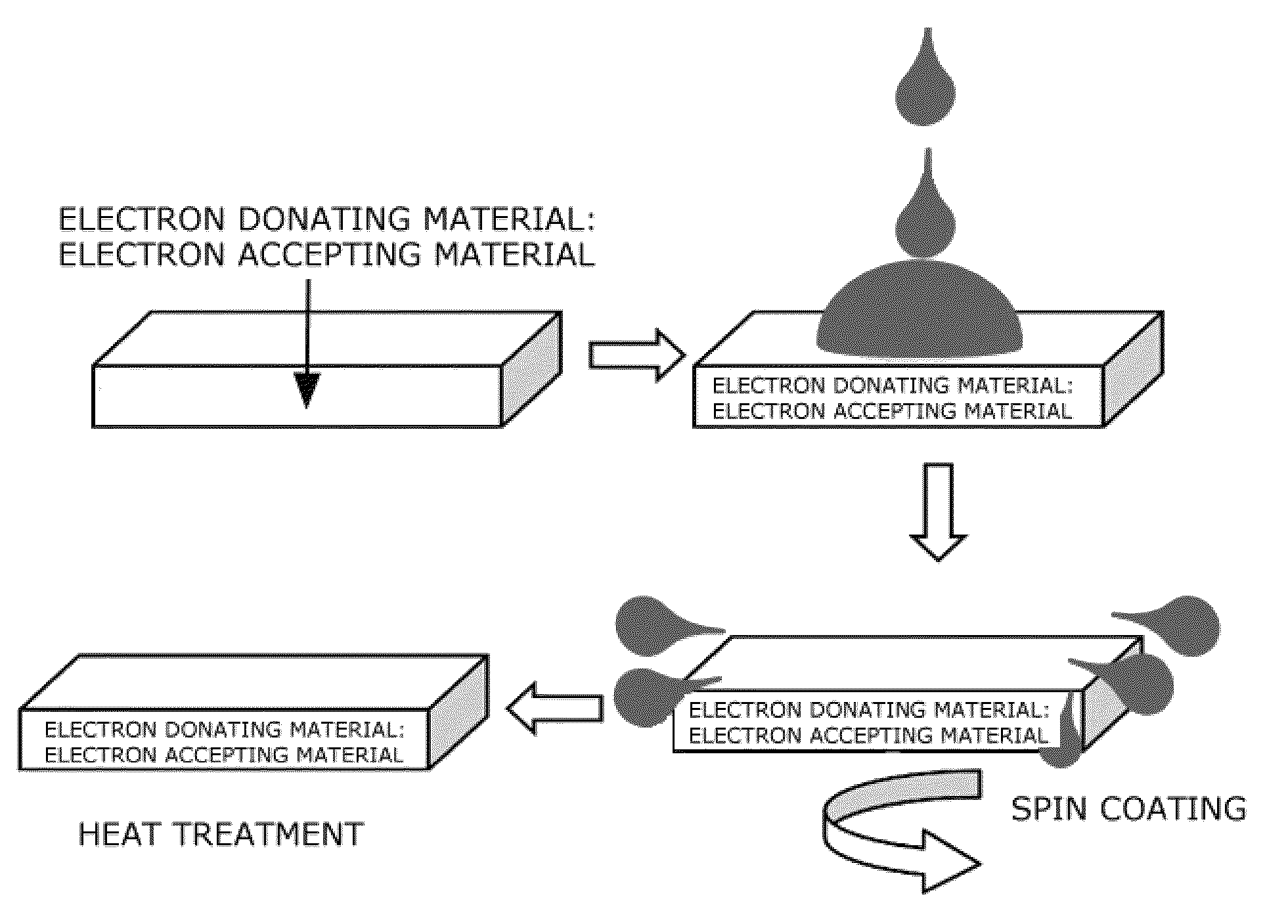

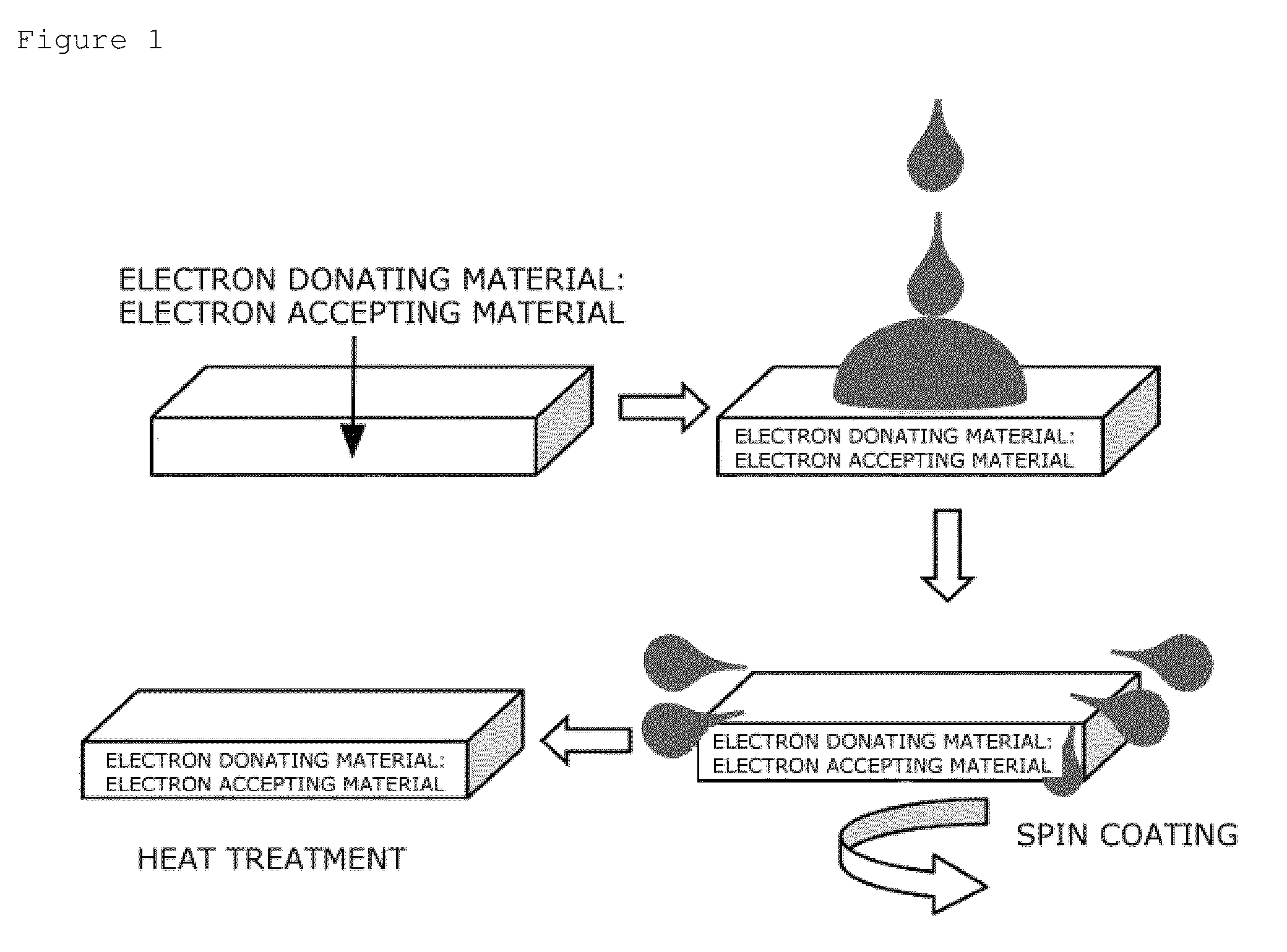

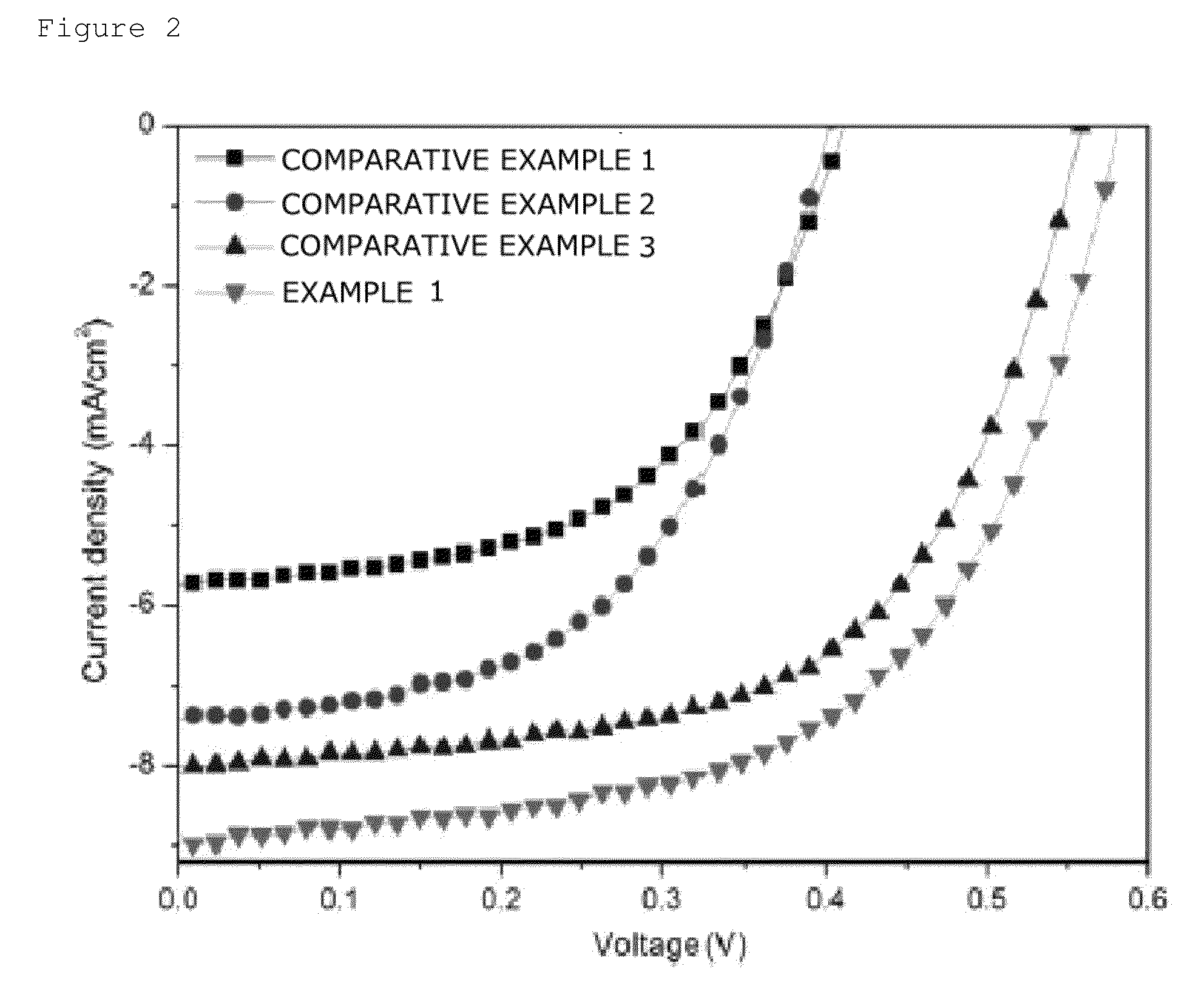

Optically active layer, organic solar cell comprising optically active layer, and method for manufacturing same

ActiveCN104718635AImprove conduction abilityGood light absorptionFinal product manufactureNanoinformaticsNon solventElectron

The present specification provides a photoactive layer including an electron accepting material and an electron donating material, an organic photovoltaic cell including the same, and a method of manufacturing the organic photovoltaic cell, which includes treating the electron accepting material and the electron donating material by a non-solvent.

Owner:LG CHEM LTD

Active layer, organic photovoltaic cell comprising the same and manufacturing method thereof

ActiveUS9299937B2Improve conductivityEasy to handleNanoinformaticsSolid-state devicesNon solventActive layer

Owner:LG CHEM LTD

Preparation method of carboxylic butadiene-styrene latex

ActiveCN104592447AStable molecular structureConcentrated particle size distributionThermal energyMechanical property

The invention relates to a preparation method of a carboxylic butadiene-styrene latex; reaction thermal energy is provided for reaction of the carboxylic butadiene-styrene latex through high-speed water vapour; after being cooled, the water vapour is converted into high-temperature deionized water; furthermore, the high-speed water vapour is also used for driving liquid in a reaction container to rotate; the liquid in the reaction container is dispersed by a water vapour flow to form a lot of tiny steam and water mixtures; a material in the reaction container is driven to flow rapidly; substances and temperature in the reaction container are uniform to distribute; the polymerization reaction is also uniform; therefore, the final product, namely the carboxylic butadiene-styrene latex, is steady in molecular structure, easy in molecular weight control and more centralized in particle diameter distribution; the balanced and good mechanical property can be obtained; and the yield and quality of the product are increased.

Owner:NANTONG TENGLONG CHEM TECH CO LTD

Phthalocyanine-based sulfonic acid-doped polyaniline anticorrosive paint

ActiveCN103849295AStable molecular structureGood water solubilityAnti-corrosive paintsEpoxy resin coatingsAdhesion forceFoaming agent

The invention discloses phthalocyanine-based sulfonic acid-doped polyaniline anticorrosive paint which is prepared by the following method: (1), synthesizing eigenstate polyaniline; (2), synthesizing phthalocyanine-based sulfonic acid-doped polyaniline: taking and sufficiently dissolving the eigenstate polyaniline with N, N-dimethyl formamide, then, adding phthalocyanine-based sulfonic acid liquor, washing by using distilled water until filtrate is colorless after reacting for 10 hours-15 hours at 60 DEG C-70 DEG C, and vacuum-drying solids to obtain the phthalocyanine-based sulfonic acid-doped polyaniline; and (3), preparing polyaniline anticorrosive paint: under the room temperature, mixing the phthalocyanine-based sulfonic acid-doped polyaniline, aqueous epoxy resin liquor, a flatting agent and a de-foaming agent, dispersing for 10 minutes under 1500r / minute, filtering, and adding a curing agent and a diluent for sufficiently mixing to obtain the needed anticorrosive paint. The phthalocyanine-based sulfonic acid-doped polyaniline anticorrosive paint disclosed by the invention can effectively overcome a de-doping phenomenon, is simple to operate, good in adhesion force and excellent in corrosion resistance.

Owner:四川宇涂科技有限公司

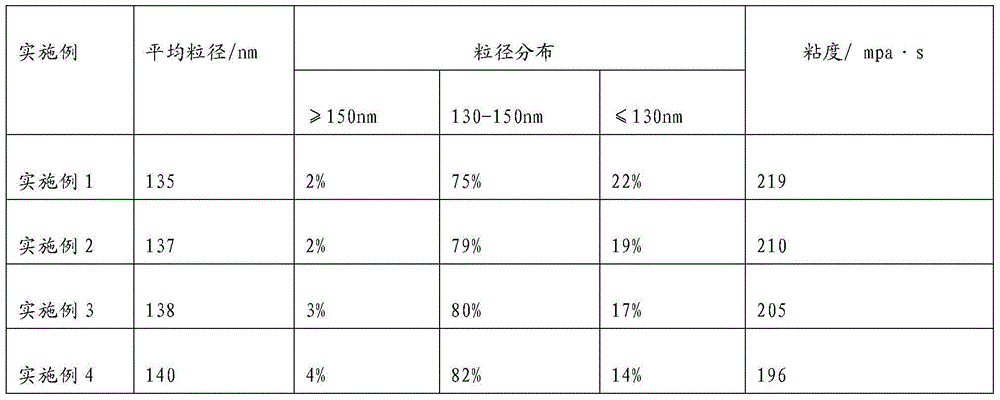

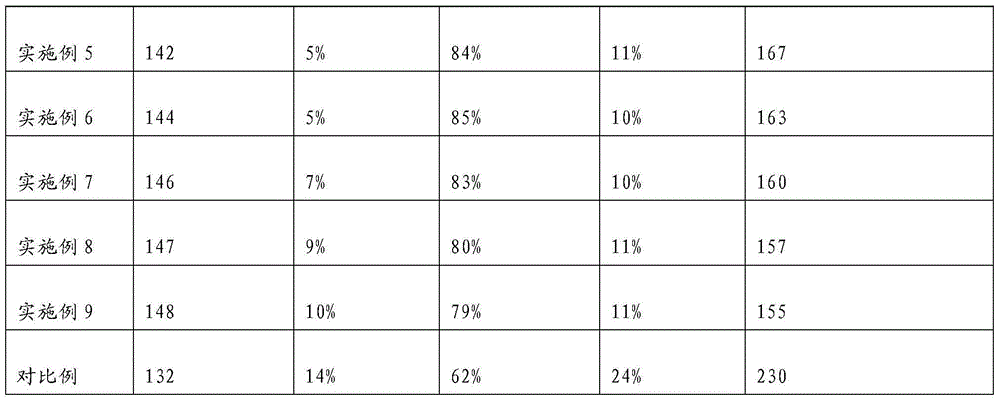

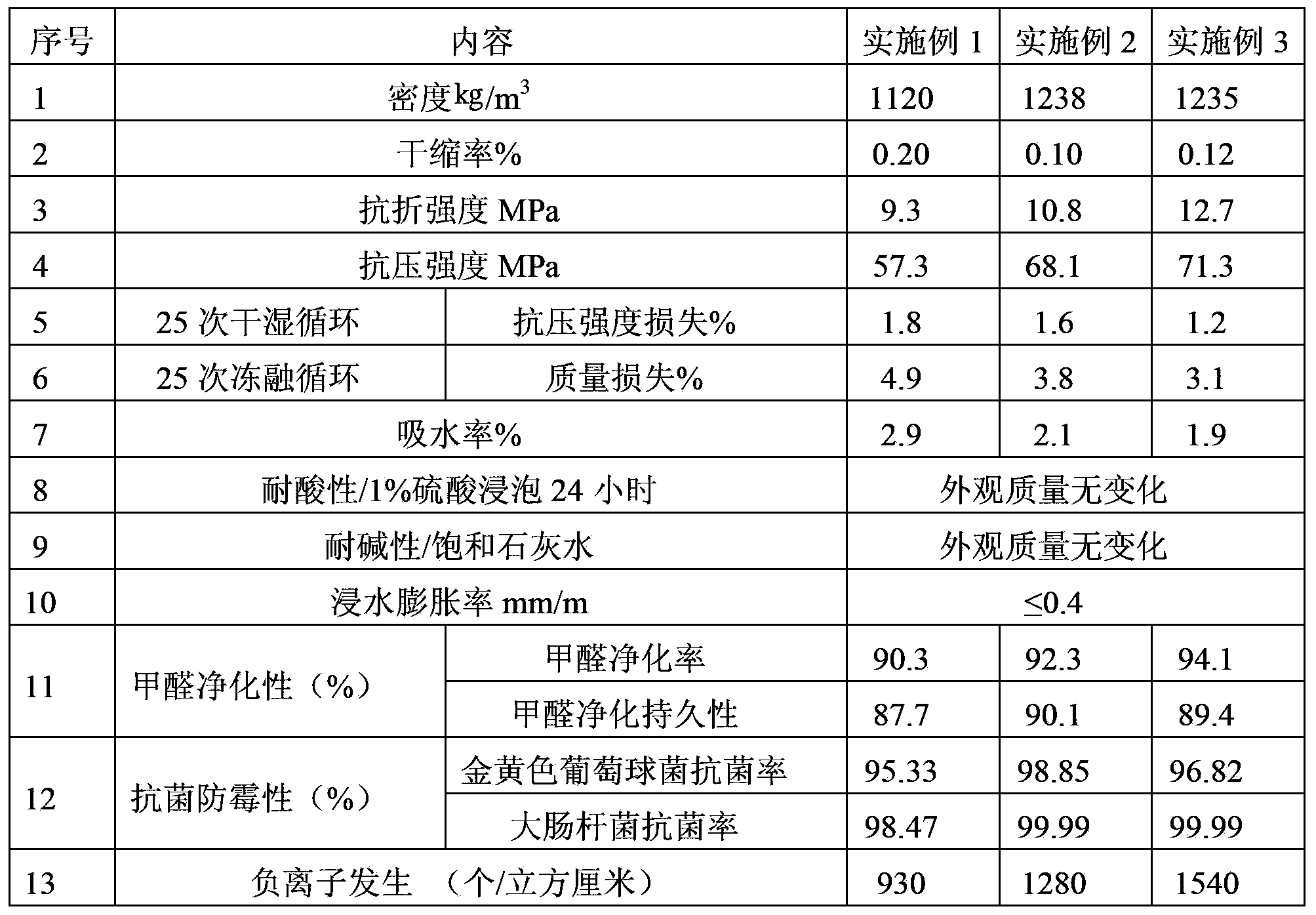

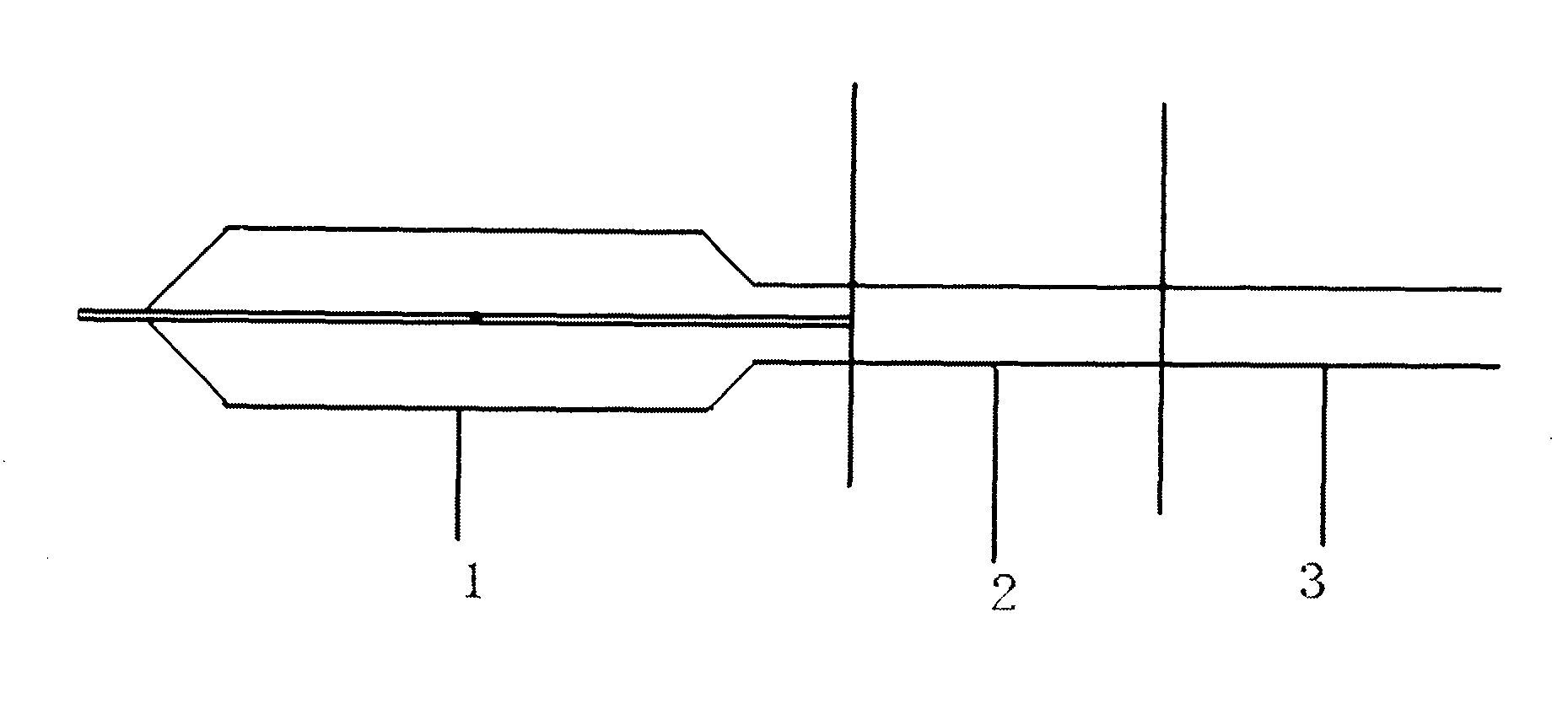

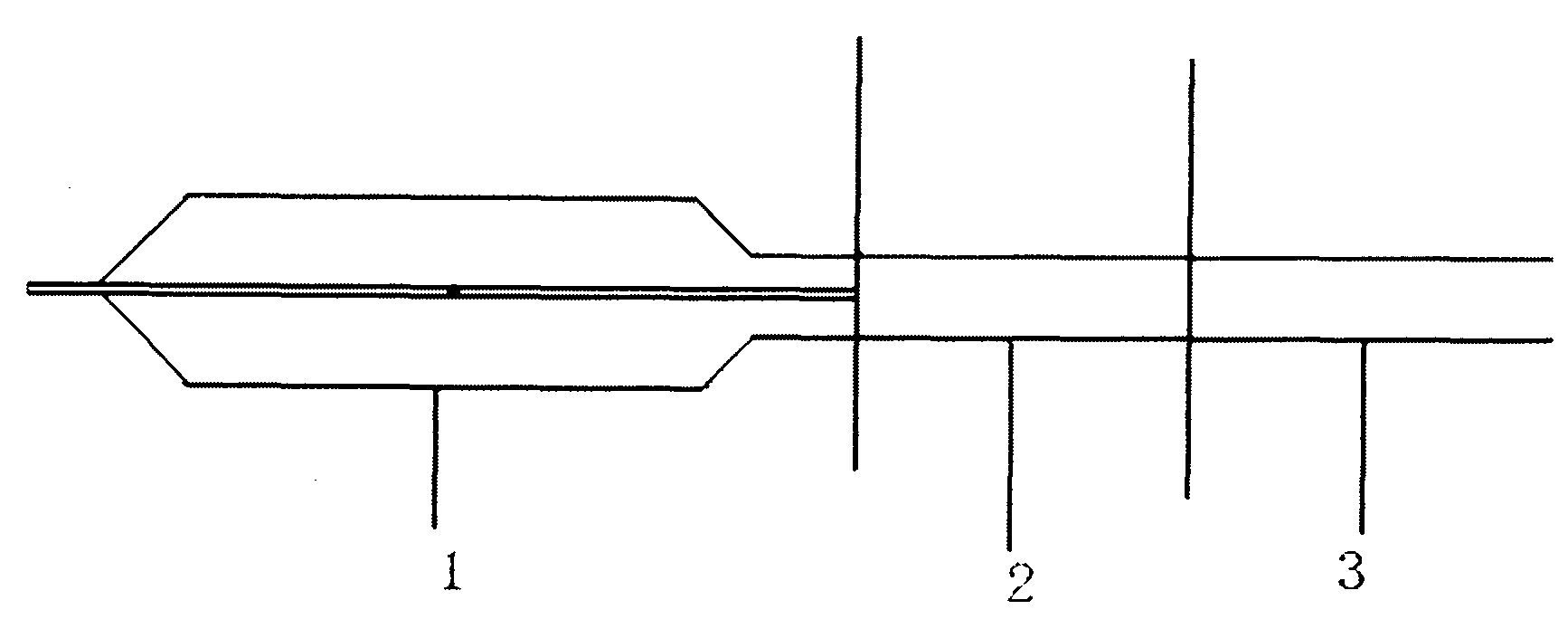

Inorganic ecologic wood, and preparation method and application thereof

The invention provides an inorganic ecologic wood. The inorganic ecologic wood is prepared through using, by weight, 100.0 parts of inorganic gelling powder, 6.0-42.0 parts of a dispersible vegetable fiber, 8.0-25.0 parts of amorphous SiO2 mineralization powder, 0.0-5.5 parts of a modification aid, and 23.5-26.2 parts of a complex formulation solution. The inorganic ecologic wood reserves the good plasticity and environmental protection characteristic of the inorganic material, and has the ecologic functions of formaldehyde cleaning, antibiosis, mildew resistance and negative ion generation. The invention also provides a preparation method of the inorganic ecologic wood, and applications of the inorganic ecologic wood as building materials comprising ecologic board, wood floors, interior and exterior decorative boards or decorative modeling boards and the like.

Owner:HUBEI GREENS NEW BUILDING MATERIALS SCI & TECH YINGCHENG

PEEK (Polyetheretherketone) balloon dilatation catheter

InactiveCN101822867AEliminate induced toxic effectsAvoid damageStentsBalloon catheterBalloon dilatation catheterCell damage

The invention relates to a PEEK balloon dilatation catheter for an intravascular interventional treatment operation, which comprises a balloon, a distal tube and a proximal tube, wherein PEEK (Polyetheretherketone) resin is adopted as the main raw material of the proximal tube, so that the PEEK balloon dilatation catheter not only has good high-temperature resistance, mechanical property, lubricating property and dimensional stability, but also prevents harmful metal ions from entering a human body to induce a toxic effect and generate cell damage and inflammation reactions from a source.

Owner:DONGGUAN DIKAI MEDICAL

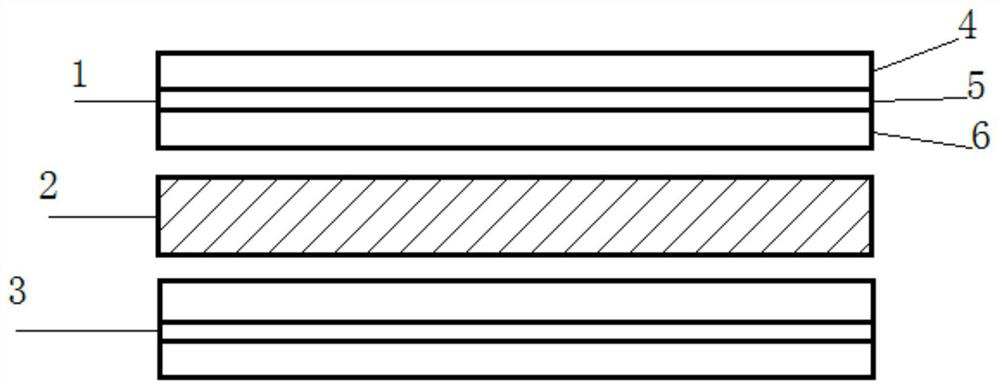

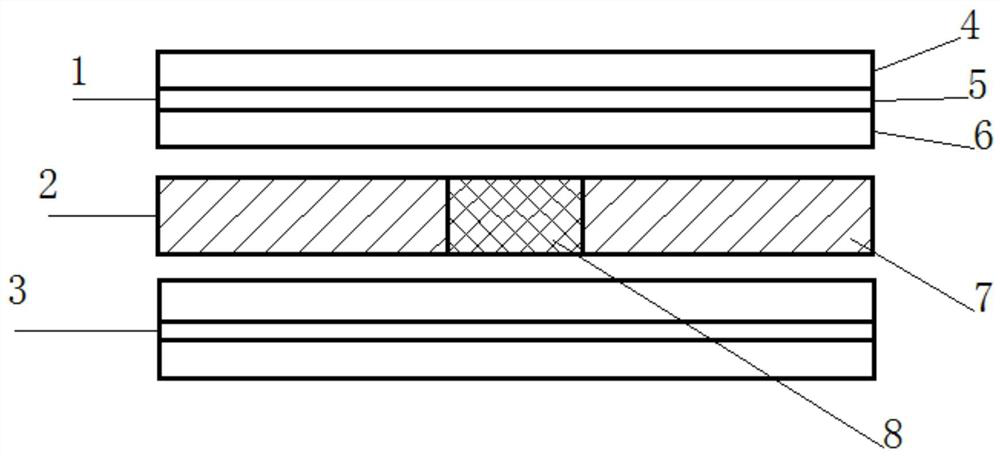

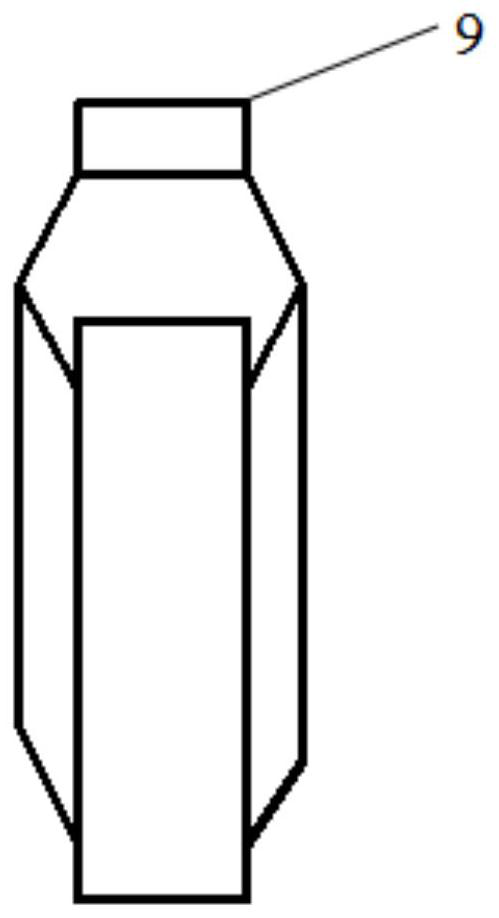

Reinforced aramid honeycomb sandwich plate

InactiveCN111873558AImprove adhesionNot easy to layerSynthetic resin layered productsLaminationAdhesiveHoneycomb

The invention relates to a reinforced aramid honeycomb sandwich plate which is composed of an upper skin layer, a middle aramid honeycomb core layer and a lower skin layer, wherein every two adjacentlayers are bonded through an adhesive. The upper skin and the lower skin are each of a three-layer composite structure, and the middle layers are made of aramid pulp. Concave-convex leftover materialsare reserved on the upper edge and the lower edge of the aramid honeycomb core. The wall thicknesses of the hole grids in the middle aramid fiber honeycomb core are the same; or in a certain direction, the wall thickness of the middle hole grid is large, and the wall thicknesses of the hole grids on the two sides are small. The honeycombs of the aramid fiber honeycomb core are hollow, or hollow columns made of aramid fibers are placed in the honeycombs of the aramid fiber honeycomb core. The concave-convex leftover materials are reserved on the upper edge and the lower edge of the aramid honeycomb core, so that the contact area between the aramid honeycomb core and the upper skin and between the aramid honeycomb core and the lower skin is increased, the bonding strength, the bonding strength and the tearing strength are improved, and the aramid honeycomb sandwich plate is not prone to layering. Meanwhile, the middle layer of the upper skin and the middle layer of the lower skin are controlled to be aramid pulp, so that the impact resistance of the aramid honeycomb sandwich plate is improved.

Owner:DONGHUA UNIV

Glass fibers of grafted temperature-sensitive hydrogel

The invention discloses glass fibers of grafted temperature-sensitive hydrogel and a preparing method. The preparing method mainly includes the steps that surfaces of glass fibers are modified with gamma-methacryloxy propyl trimethoxy silane (MPS); in ethanol water, under the action of cross-linking agent N, N-methylene-bis(acrylamide) (MBAA), initiator potassium peroxodisulfate (KPS) and chiral monomers (AAc-L-Phe), the glass fibers GF-MPS-PNIPAM-AAc-L-Phe of grafted temperature-sensitive hydrogel are prepared through a free radical copolymerization method. The glass fibers have the advantages of being simple in technological method, low in cost, convenient to industrially apply and popularize and capable of being used in the field of biological medicine and having hydrophility and pH responsiveness.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com