Ultralow temperature ash-free antiwear incombustible ester type hydraulic oil, production technology and application thereof

An ultra-low temperature, hydraulic oil technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of poor anti-wear effect, short wear cycle of components and engines, high maintenance costs, and achieve low ash accumulation, excellent low-temperature fluidity, Reduced effect of maintenance and overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

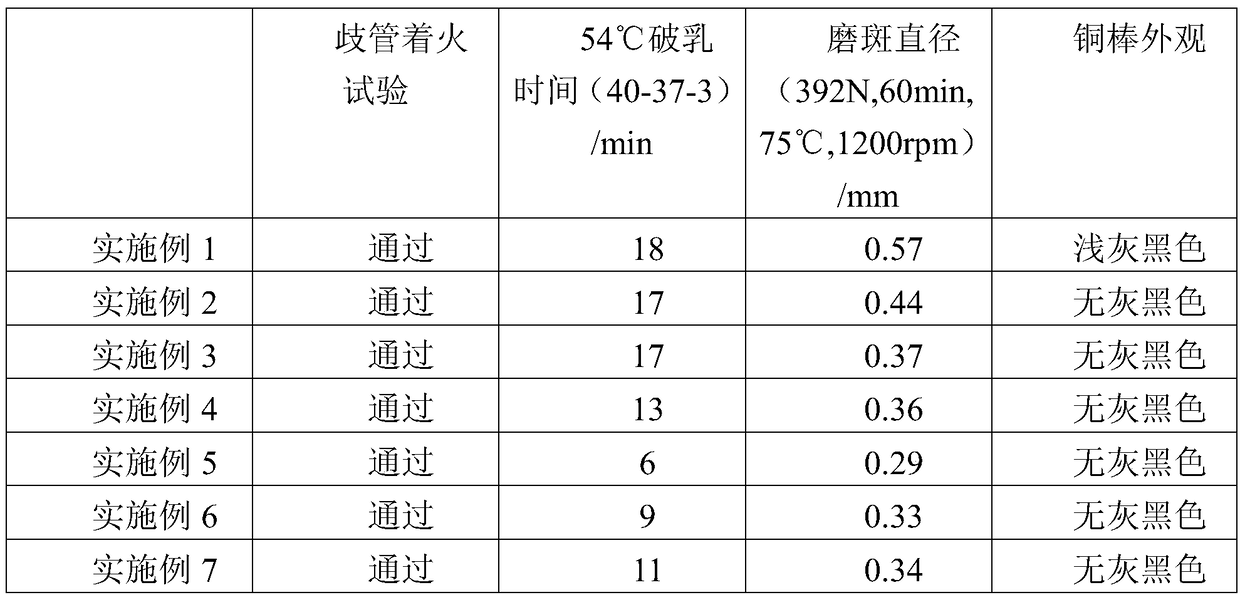

Examples

Embodiment 1

[0070] A kind of ultra-low temperature ashless anti-wear and flame retardant ester type hydraulic oil, comprising the following components by weight:

[0071] 1.5 parts of viscosity index improver, 1.2 parts of pour point depressant, 0.05 part of demulsifier, 0.003 part of defoamer, 0.5 part of ashless detergent and dispersant, 0.4 part of rust inhibitor, 0.03 part of antioxidant, 1 part of flame retardant, 93 parts of base oil.

[0072] The base oil is a mixture of dibutyl phthalate, dioctyl sebacate, diisodecyl adipate, trimethylolpropane trioleate, dibutyl phthalate, dioctyl sebacate The mass ratio of octyl ester, diisodecyl adipate and trimethylolpropane trioleate is 1:1:1:10. The viscosity index improver was butyl methacrylate. The defoamer is simethicone. The ashless detergent dispersant is polyisobutylene succinimide ashless dispersant (manufactured by Xinxiang Ruifeng New Material Co., Ltd., model RF1154). The pour point depressant is polymethacrylate pour point de...

Embodiment 2

[0075] A kind of ultra-low temperature ashless anti-wear and flame retardant ester type hydraulic oil, comprising the following components by weight:

[0076] Viscosity index improver 1.5 parts, pour point depressant 1.2 parts, demulsifier 0.05 parts, defoamer 0.003 parts, extreme pressure antiwear agent 3 parts, ashless detergent 0.5 parts, rust inhibitor 0.4 parts, antioxidant 0.03 parts 1 part, 1 part of flame retardant, 93 parts of base oil.

[0077]The base oil is a mixture of dibutyl phthalate, dioctyl sebacate, diisodecyl adipate, trimethylolpropane trioleate, dibutyl phthalate, dioctyl sebacate The mass ratio of octyl ester, diisodecyl adipate and trimethylolpropane trioleate is 1:1:1:10. The viscosity index improver was butyl methacrylate. The defoamer is simethicone. The ashless detergent dispersant is polyisobutylene succinimide ashless dispersant (manufactured by Xinxiang Ruifeng New Material Co., Ltd., model RF1154). The pour point depressant is polymethacryla...

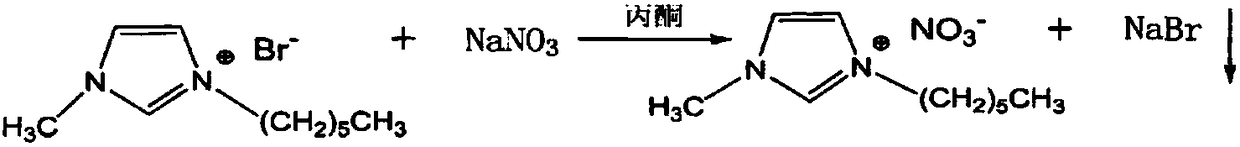

Embodiment 3

[0080] It is basically the same as embodiment 2, the only difference is: in this embodiment 3:

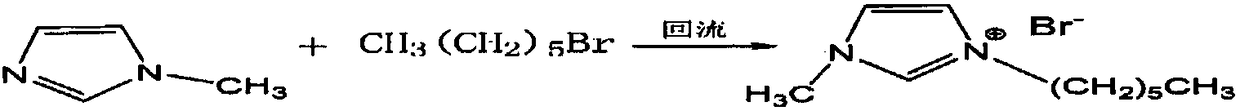

[0081] The extreme pressure antiwear agent is zinc sulfide / graphene oxide compound modified by ionic liquid. The preparation method of the zinc sulfide / graphene oxide composite modified by ionic liquid comprises the following steps: (1) Take 6 g of zinc nitrate hexahydrate and add it into 10 mL of water, stir for 40 minutes at 30 ° C and a speed of 200 rpm, add 10 mL of Ionic liquid, continue to stir under the above conditions for 30 minutes to obtain the mixed solution I for later use, add 3.2 g of thioacetamide to 10 mL of the ionic liquid, and stir for 40 minutes at 30° C. at a speed of 200 rpm to obtain the mixed solution II. Add the mixed solution II to the mixed solution I, stir at 30°C and 200 rpm for 40 minutes, raise the temperature to 65°C, stir at 65°C and 200 rpm for 40 minutes, and stir at 8000 rpm Centrifuge at a high speed for 20 minutes, take the centrifugal precip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com