Quadripolymer-type corrosion-inhibition scale inhibitor PMAHS and preparation method thereof

A corrosion and scale inhibitor, polymerized technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Good dispersibility, less dosage, and excellent scale inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 80kg of water and put it in the reactor, slowly add 25kg of maleic anhydride, stir, heat to 65℃~85℃, add 5kg of molecular weight regulator isopropanol under stirring conditions; then prepare 10kg of acrylic acid and 10kg of acrylic acid hydroxy The mixed solution of ethyl ester (I) 60~90kg; and the mixed solution of 15kg sodium methallyl sulfonate, 5kg sodium persulfate and 6kg sodium hypophosphite (II) 60~90kg;

[0017] Note: Dissolve sodium methallyl sulfonate and sodium persulfate before adding sodium hypophosphite. Water should not be added all at once, but should be added slowly. Under the condition of continuous stirring, adjust the temperature of the reactor to 65℃~85℃, and add the mixed solution (I) and (II) dropwise at the same time, and control the dropping speed of the mixed solution (I) and (II) to be 0.5~1 The dripping is completed within hours at the same time, kept at a constant temperature for 1 to 5 hours, and cooled to obtain the PMAHS of the present...

Embodiment 2

[0019] Take 60kg of water and place it in the reactor, slowly add 30kg of maleic anhydride, stir, heat to 65℃~85℃, add 10kg of molecular weight regulator isopropanol under stirring conditions; then prepare 15kg of acrylic acid and 5kg of acrylic acid hydroxy The mixed solution of ethyl ester (I) is about 60~90kg; and the mixed solution of 10kg of sodium methallyl sulfonate, 10kg of sodium persulfate and 8kg of sodium hypophosphite (II) is 60~90kg; Methods and steps to operate.

Embodiment 3

[0021] Take 70kg of water and place it in the reactor, slowly add 40kg of maleic anhydride, stir, heat to 65℃~85℃, add 8kg of molecular weight regulator isopropanol under stirring conditions; prepare another 5kg of acrylic acid and 15kg of acrylic acid hydroxy The mixed solution of ethyl ester (I) is about 60 kg; and the mixed solution of 20 kg of sodium methallyl sulfonate, 15 kg of sodium persulfate and 10 kg of sodium hypophosphite (II) is about 60 kg; according to the method and steps of Example 1 above To proceed.

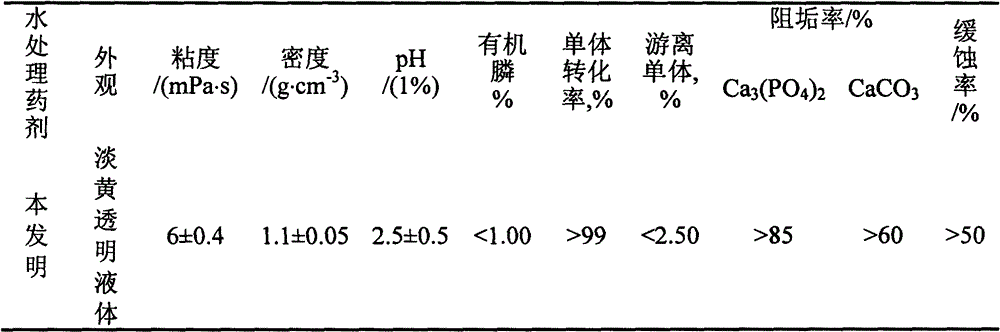

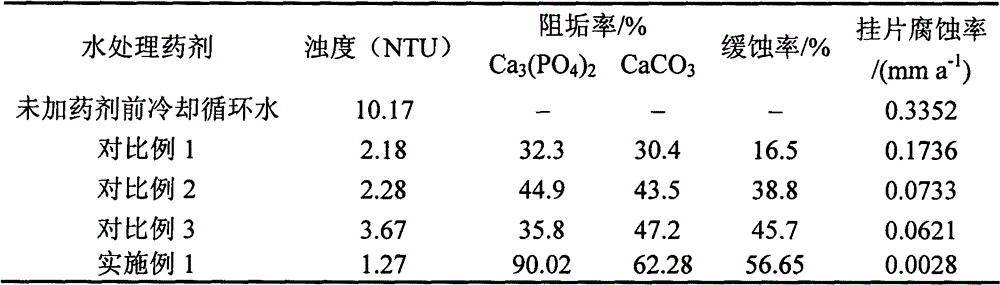

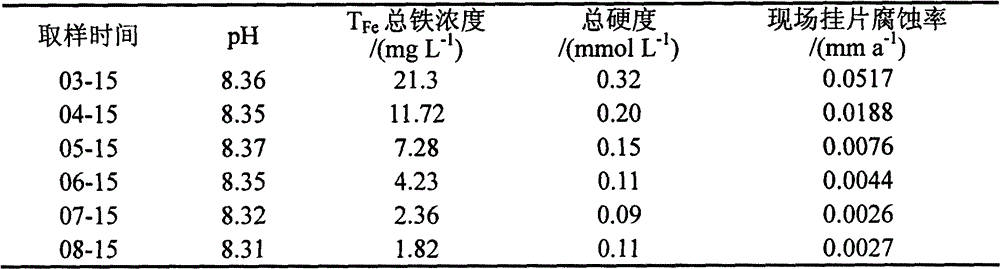

[0022] Specific comparison method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com