Patents

Literature

117results about How to "Low in phosphorus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

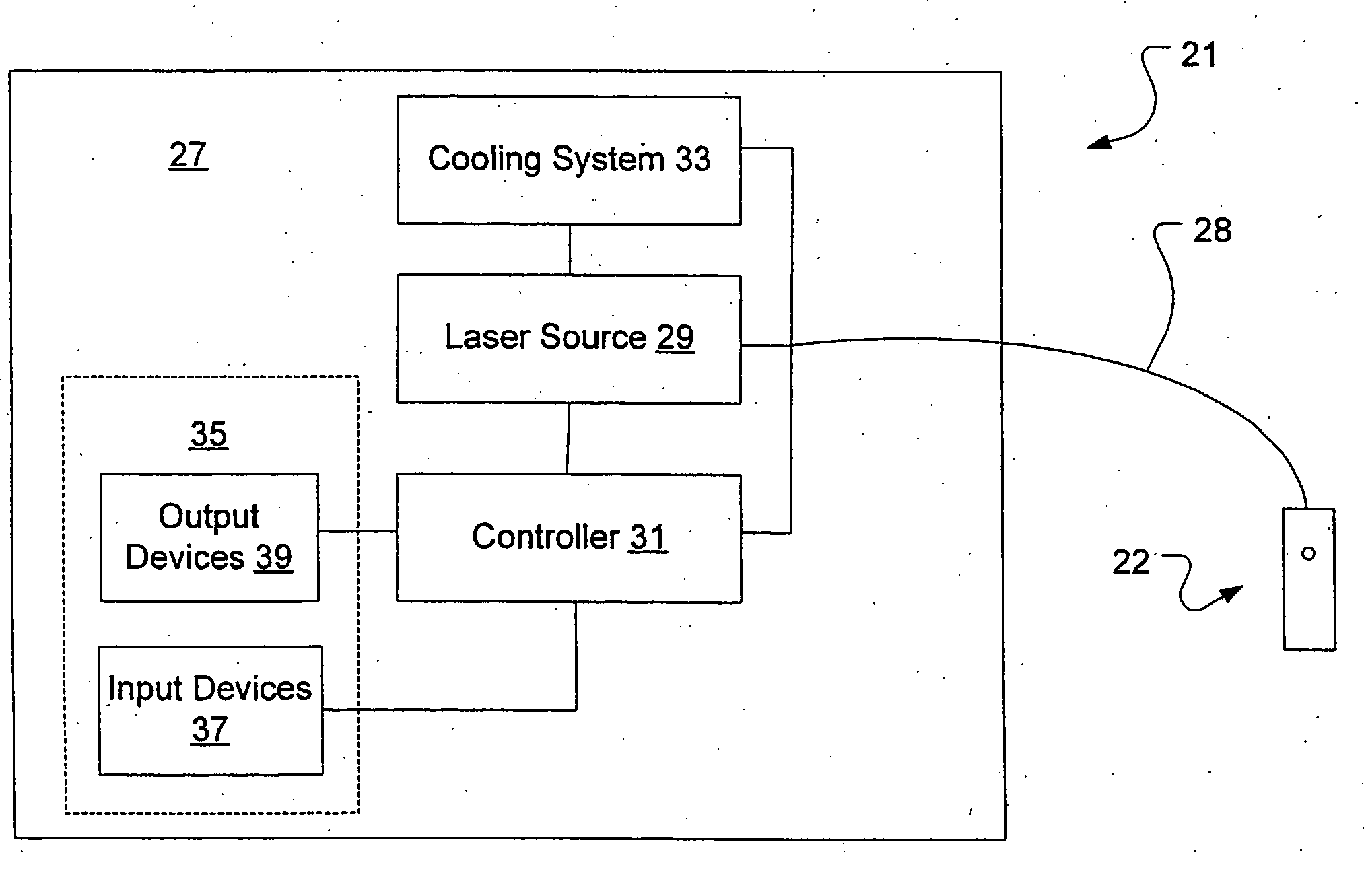

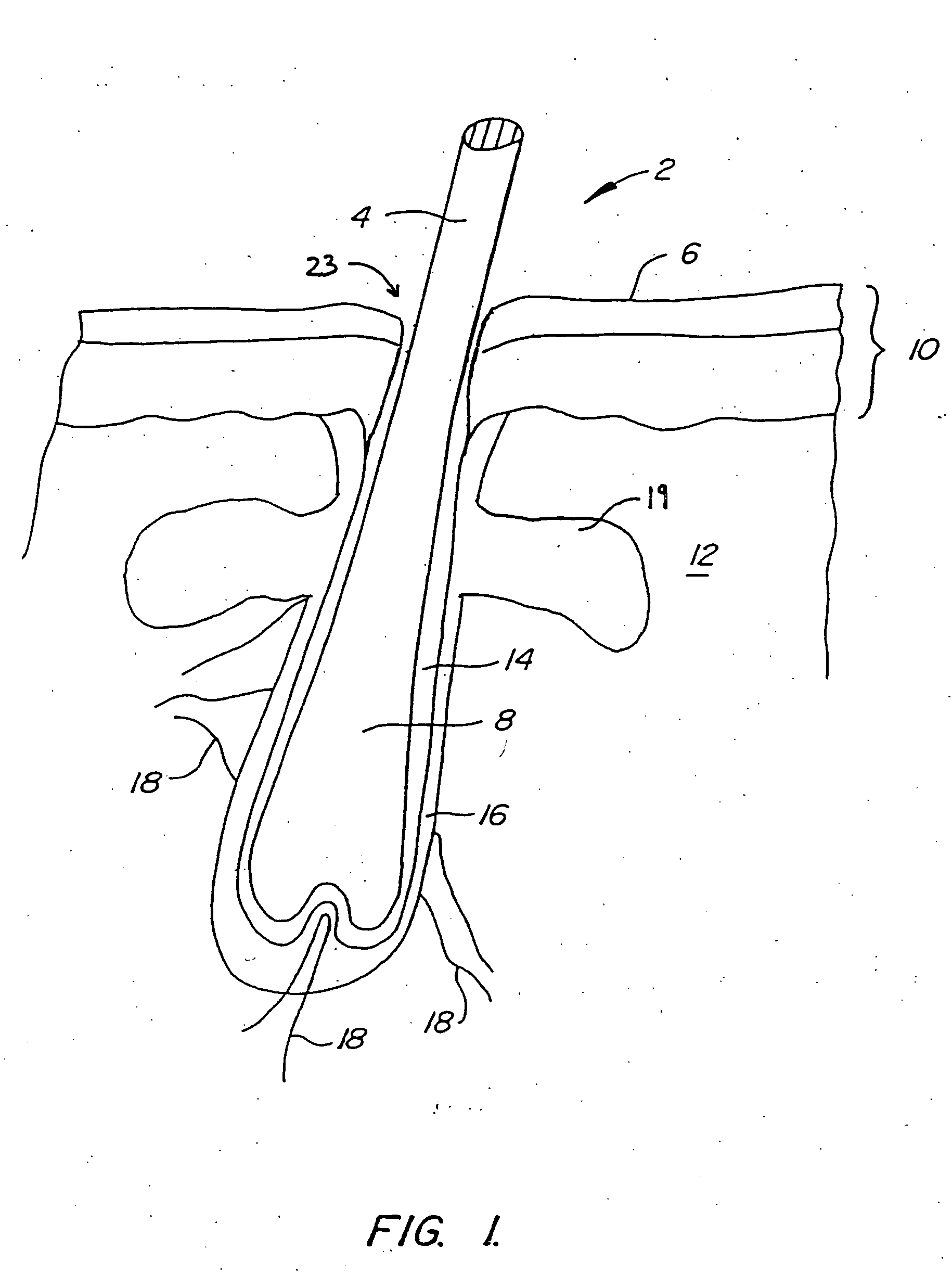

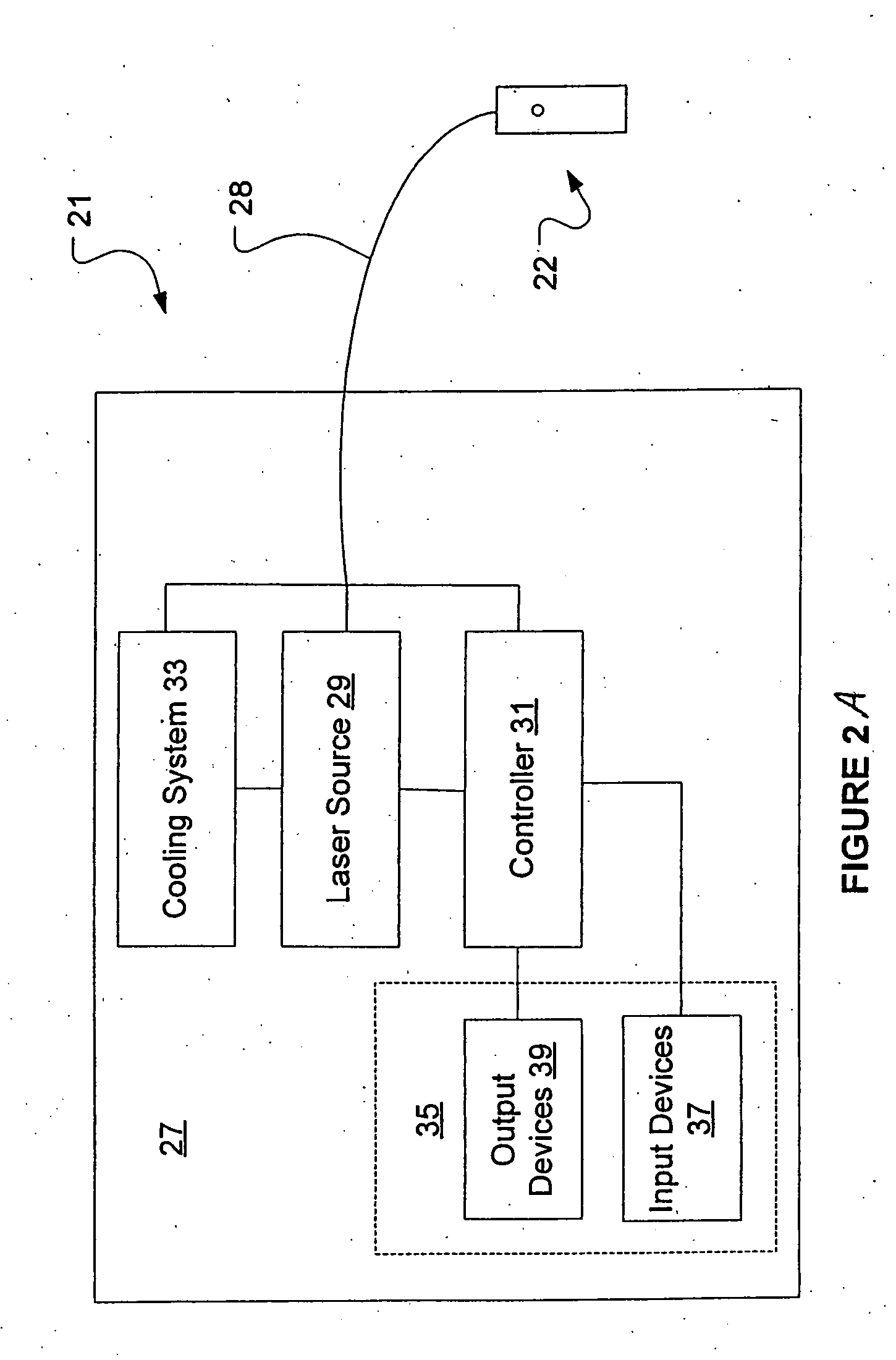

Methods and devices for non-ablative laser treatment of dermatologic conditions

ActiveUS20050107852A1Short pulse operationLarge amount of energyElectrotherapyDiagnosticsWrinkle skinCelsius Degree

The invention comprises a system and method for non-ablative laser treatment of dermatologic conditions. A laser energy is transmitted to an underlying target element in the skin. The target element is heated to a temperature of at least forty degrees Celsius. In some embodiments, a pulsed, near infrared, high peak power laser energy is used. The systems and methods of the present invention may be used to treat acne, smooth wrinkles, remove hair, treat leg veins, treat facial veins, improve skin texture, decrease pore sizes, reduce rosacea, reduce “blush / diffuse redness, reduce striae, reduce scarring, or the like.

Owner:CUTERA

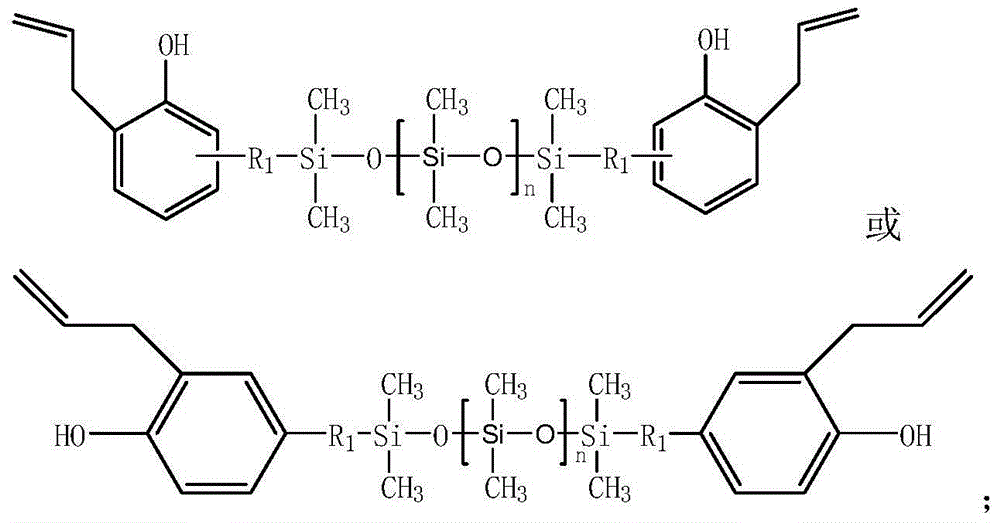

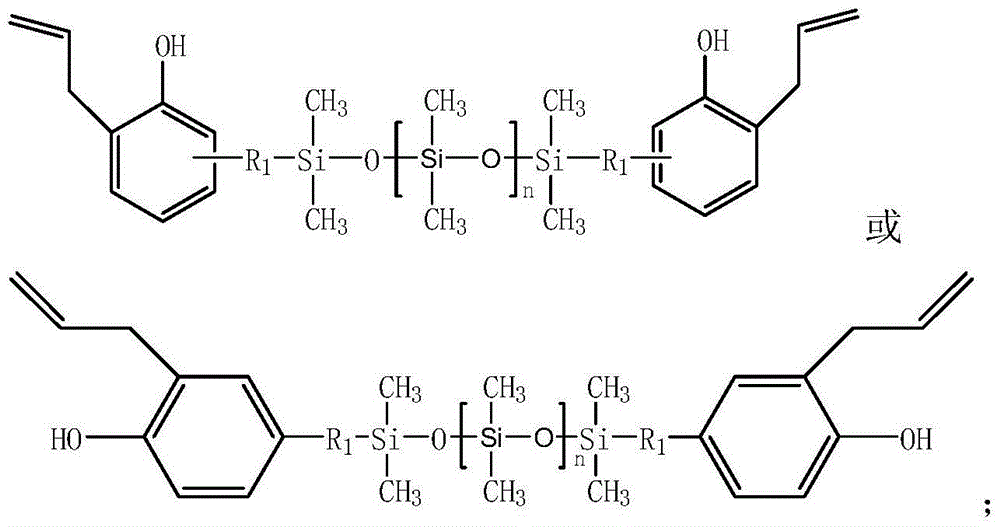

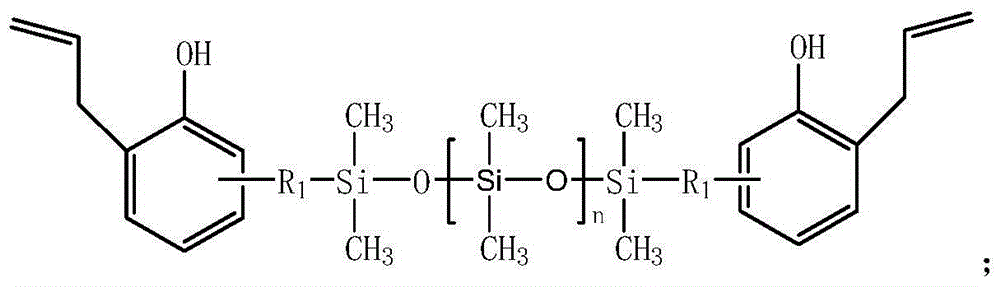

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

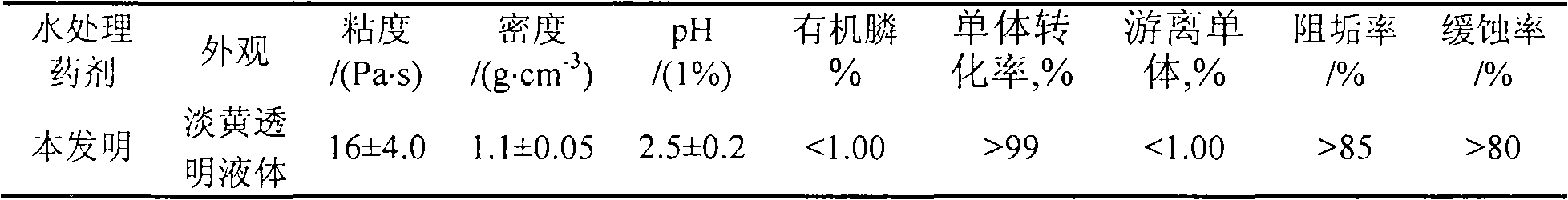

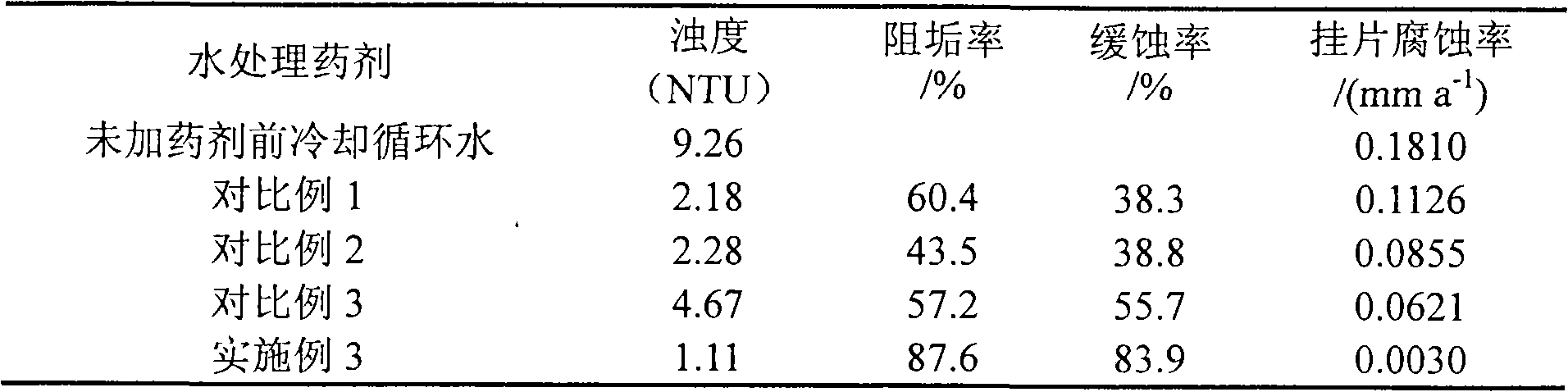

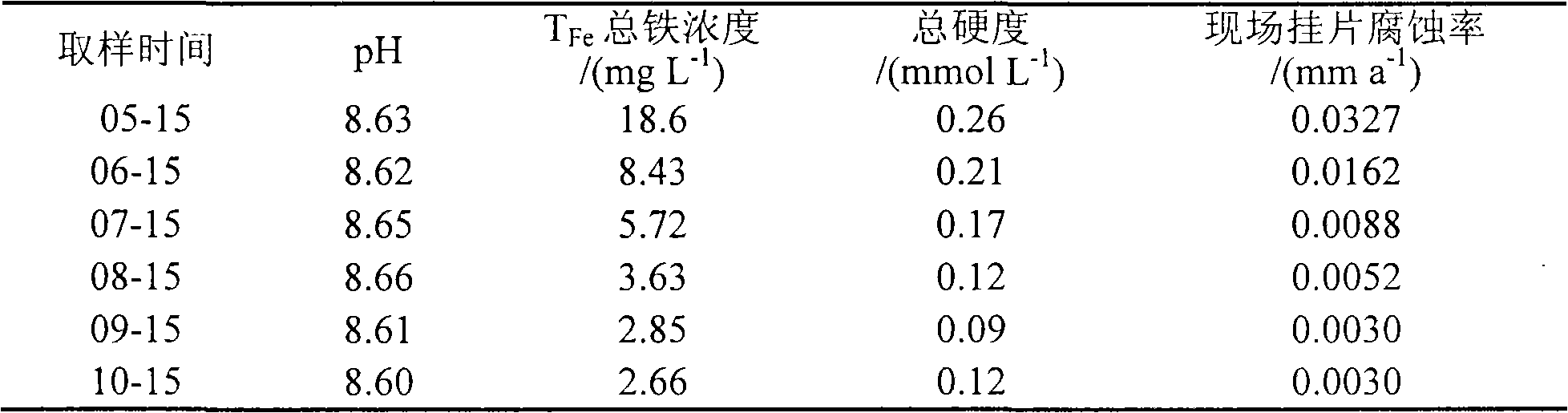

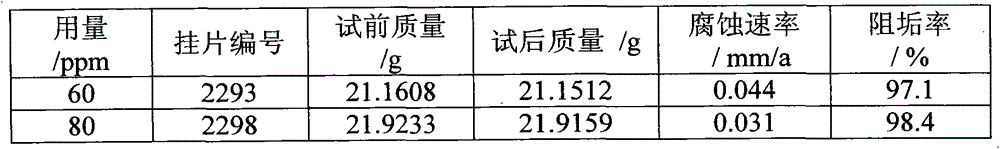

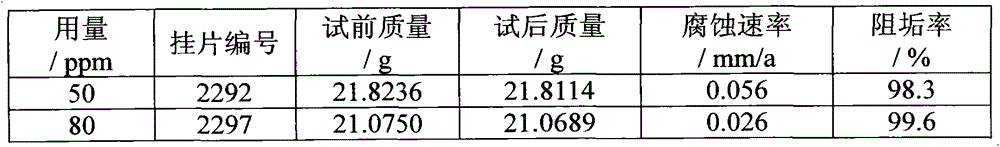

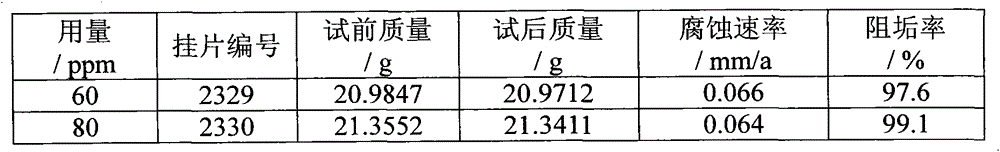

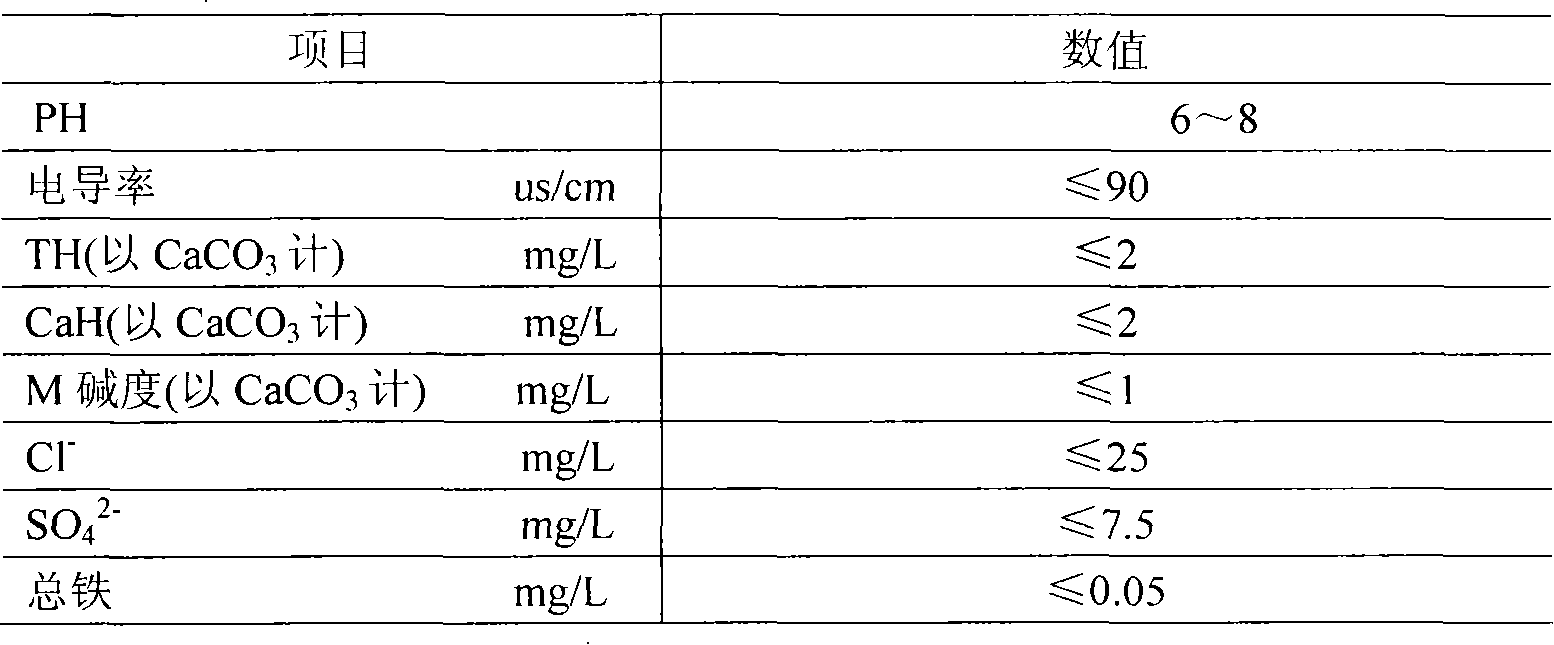

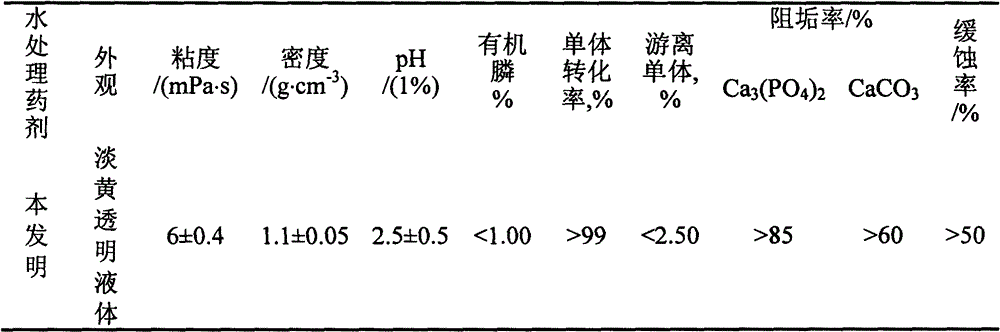

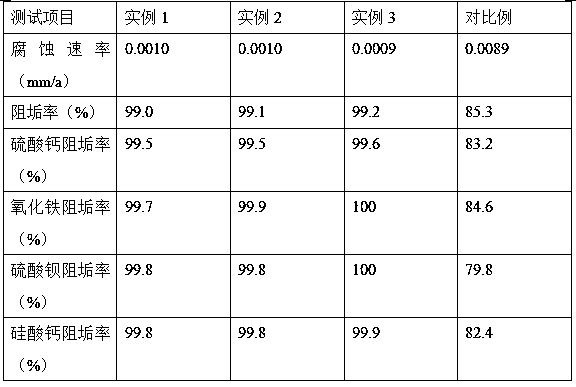

Four-element polymerization type corrosion inhibition antisludging agent and method for preparing same

InactiveCN101289256AAvoid corrosionSimple processTreatment using complexing/solubilising chemicalsPeroxydisulfateNuclear chemistry

The invention discloses a quaternary polymeric form corrosion and scale inhibitor which consists of maleic anhydride, hydroxy-propyl acrylate, acrylic acid, sodium alkyl sulfonate, sodium peroxydisulfate, sodium hypophosphite, isopropyl alcohol and water. The invention also discloses a preparation method of the quaternary polymeric form corrosion and scale inhibitor. The corrosion and scale inhibitor has good performance in inhibiting calcium carbonate scale, calcium sulphate scale, calcium phosphate scale and zinc scale and good dispersing performance for dispersing ferric oxide and is also characterized by corrosion resistance, high temperature resistance, stable molecule structure and low phosphorus content; the whole production process has no emission of 'the three wastes'. The technique of the product of the invention for treating circular cooling water is simple and the product of the invention has the advantages of little dosage, low cost, good effect and good economic benefit and wide social benefit.

Owner:NANJING FORESTRY UNIV

Smelting method of steel for raw material pure iron

The invention relates to a smelting method of steel for raw material pure iron, comprising the following steps of: I, tapping by a converter: tapping when P is less than or equal to 0.006%, S is less than or equal to 0.07% and C is 0.02-0.04% in liquid steel; and binary alkalinity of furnace slag is 3-4; II, primarily dephosphorizing: in the process of tapping by the converter, adding a liquid steel dephosphorizing agent into a steel ladle and powerfully agitating by argon; III, deeply dephosphorizing: adding lime after an LF (Low Frequency) furnace arrives, wherein the binary alkalinity of the furnace slag is 4-5; powerfully agitating by the argon and slagging off; adding the lime by the LF furnace and adjusting the slag by fluorite, wherein the alkalinity is 7-8; raising the temperature and adding aluminum powder to adjust the slag and powerfully agitating by the argon; IV, decarbonizing: conveying the steel ladle to an RH and arriving at the station and vacuumizing oxygen, wherein the vacuum degree is less than or equal to 4 mbar; and decarbonizing at the vacuum degree for 10-15 minutes; and V, desulfurizing: after decarbonizing, making the oxygen content after decarbonizing; adding aluminum according to a constant oxygen amount and adjusting; and adding a desulfurization agent, wherein the mass percentages of components in the liquid steel are as follows: the C is less than or equal to 0.002%, the S is less than or equal to 0.005%, the P is less than or equal to 0.002% and Al is less than or equal to 0.03%; and the others are Fe and unavoidable impurities. The smelting method of the steel for the raw material pure iron improves the purity of the liquid steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

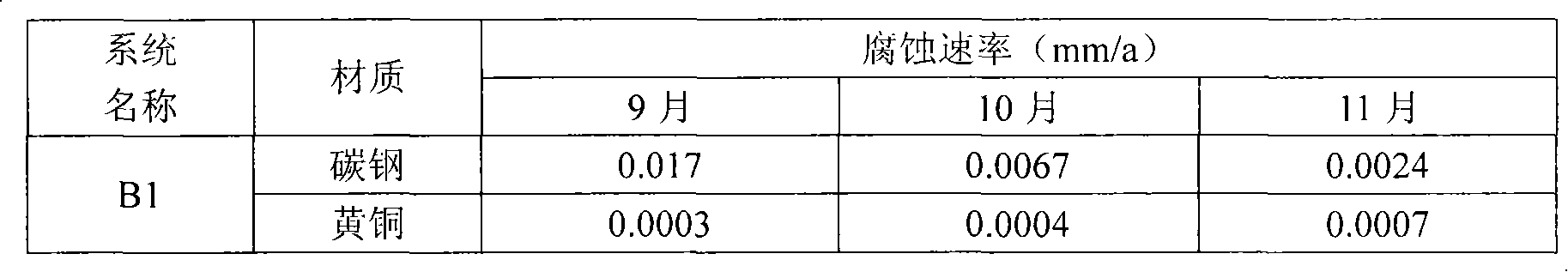

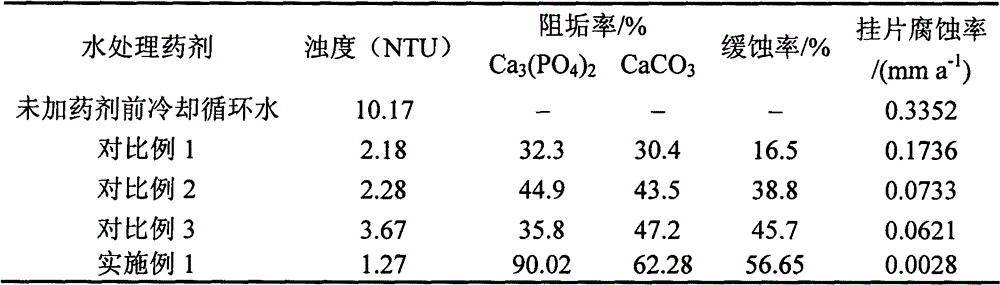

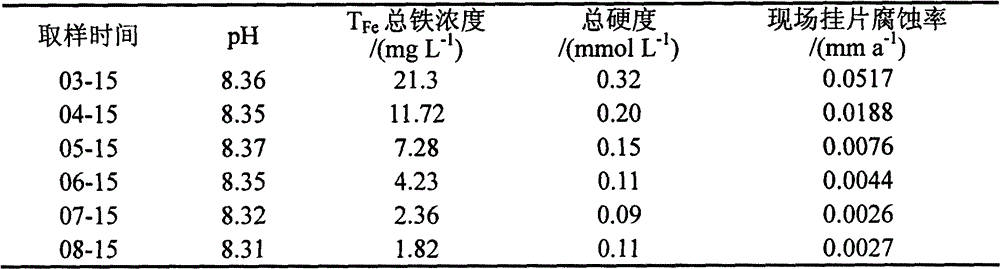

Multi-component corrosion and scale inhibitor

ActiveCN104609579AReduce phosphorus contentReduce dosageScale removal and water softeningOrganic solventMolybdate

The invention relates to a corrosion and scale inhibitor, which comprises a component A and a component B, wherein the component A comprises an organic phosphine compound, a multipolymer dispersant and deionized water; the component B comprises polyphosphate, inorganic zinc salt and molybdate, wherein the mass ratio of the component A to component B is 2:1-1:2. The corrosion and scale inhibitor also comprises a component C, wherein the component C comprises an azole compound, a hydroxide, an organic solvent and deionized water. Compared with a traditional single liquid corrosion and scale inhibitor, the corrosion and scale inhibitor of the invention has strong composite formula adaptability, ratio and dilution times can be timely adjusted according to client on-site water quality; for the terminal clients, storage space is saved, transport cost is reduced, and usage cost of its agent is reduced simultaneously.

Owner:OCHEMATE MATERIAL TECH CO LTD

Puffing expression method for producing oil with low oil-containing oil-bearing material

InactiveCN101245284AImprove product qualityAvoid excessive denaturationFatty-oils/fats productionPress cakeImpurity

The invention relates to a method for extracting oil by swelling and pressing low oil content oil seeds and is characterized by comprising the following steps: 1) clearing: impurities are removed from the oil seeds; 2) quality-adjusting: the temperatures and water contents are adjusted for the oil seeds; 3) the oil seeds are pressed and swelled; 4) enzyme killing and drying are carried out for the pressed and swelled oil seeds; 5) most of the oil is pressed from the dried oil seeds; the oil seeds can be crushed and then the quality adjusting can be done after the clearing of the step 1); after the step 2) of quality-adjusting, the bloom rolling can be done to the oil seeds and then the pressing and swelling can be done. The method adds the procedures of pressing and swelling before the traditional one time pressing and obtains pure physical pressed oil with high quality and pressed cakes which can be directly used for feed processing, which increases the processing amount of a press and reduces the power consumption and wearing. The method is mainly used for producing small-scale pressed oil and pressed cakes with good qualities and raw materials of low oil content oil seeds such as soybeans and rice bran.

Owner:中机康元粮油装备(北京)有限公司

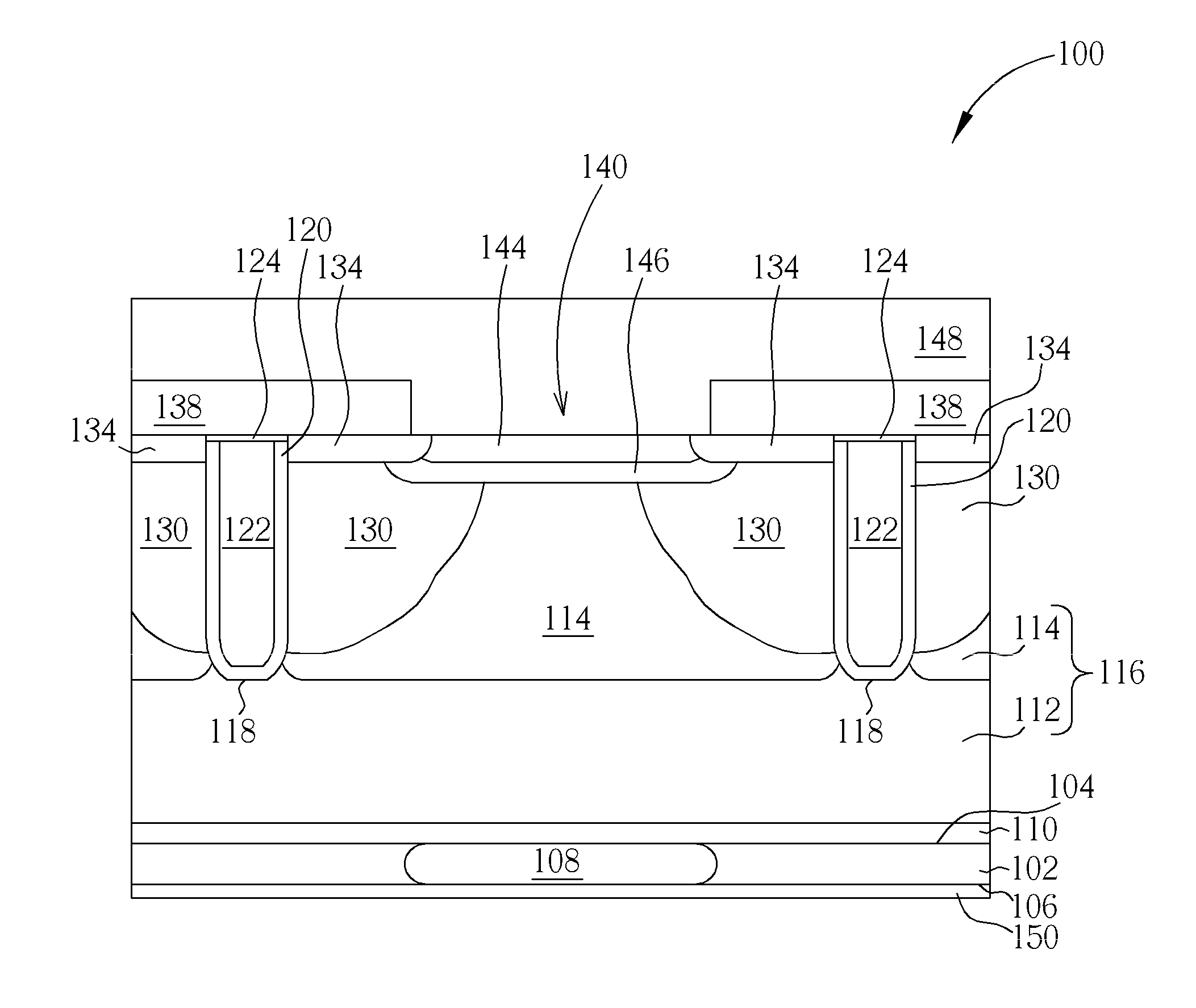

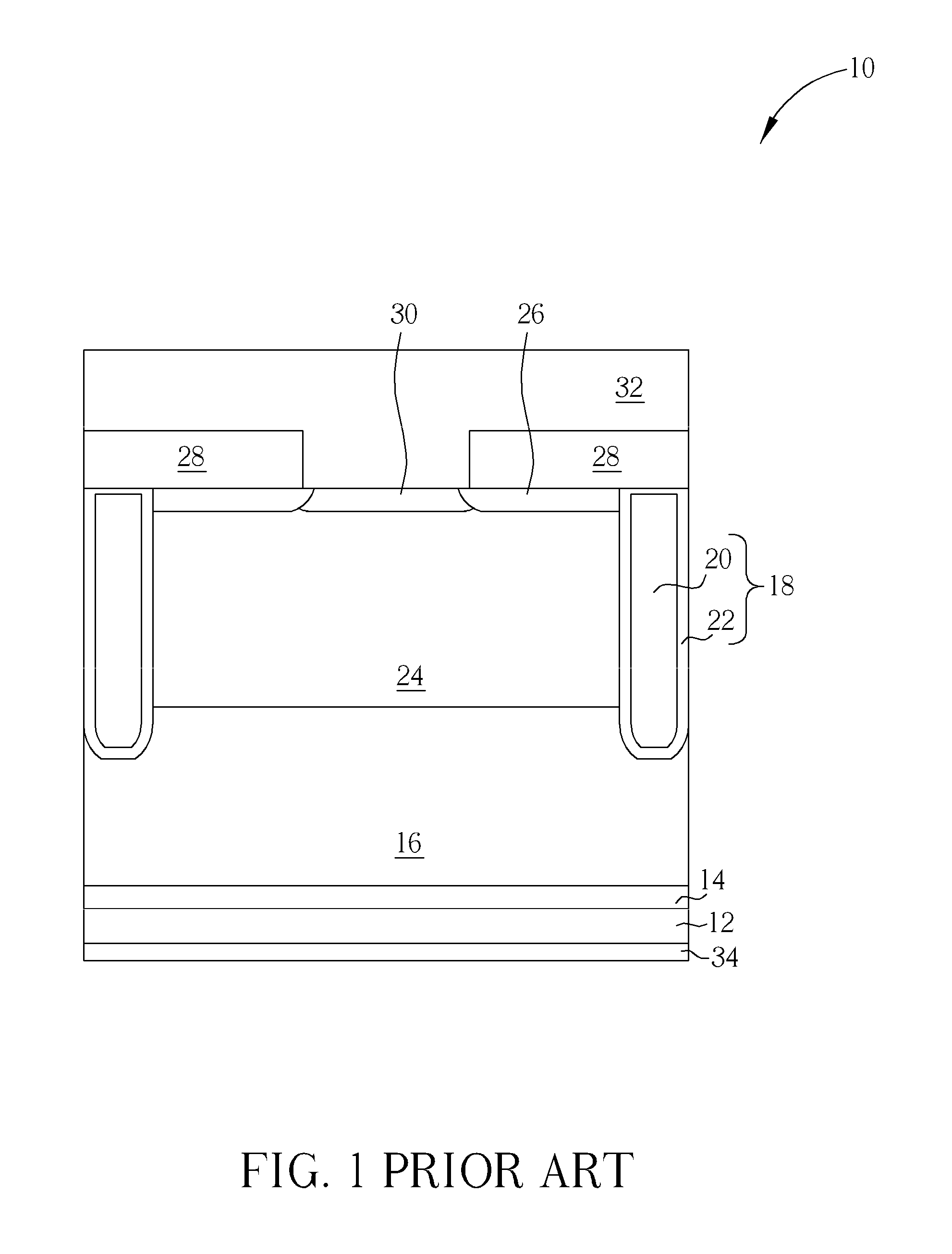

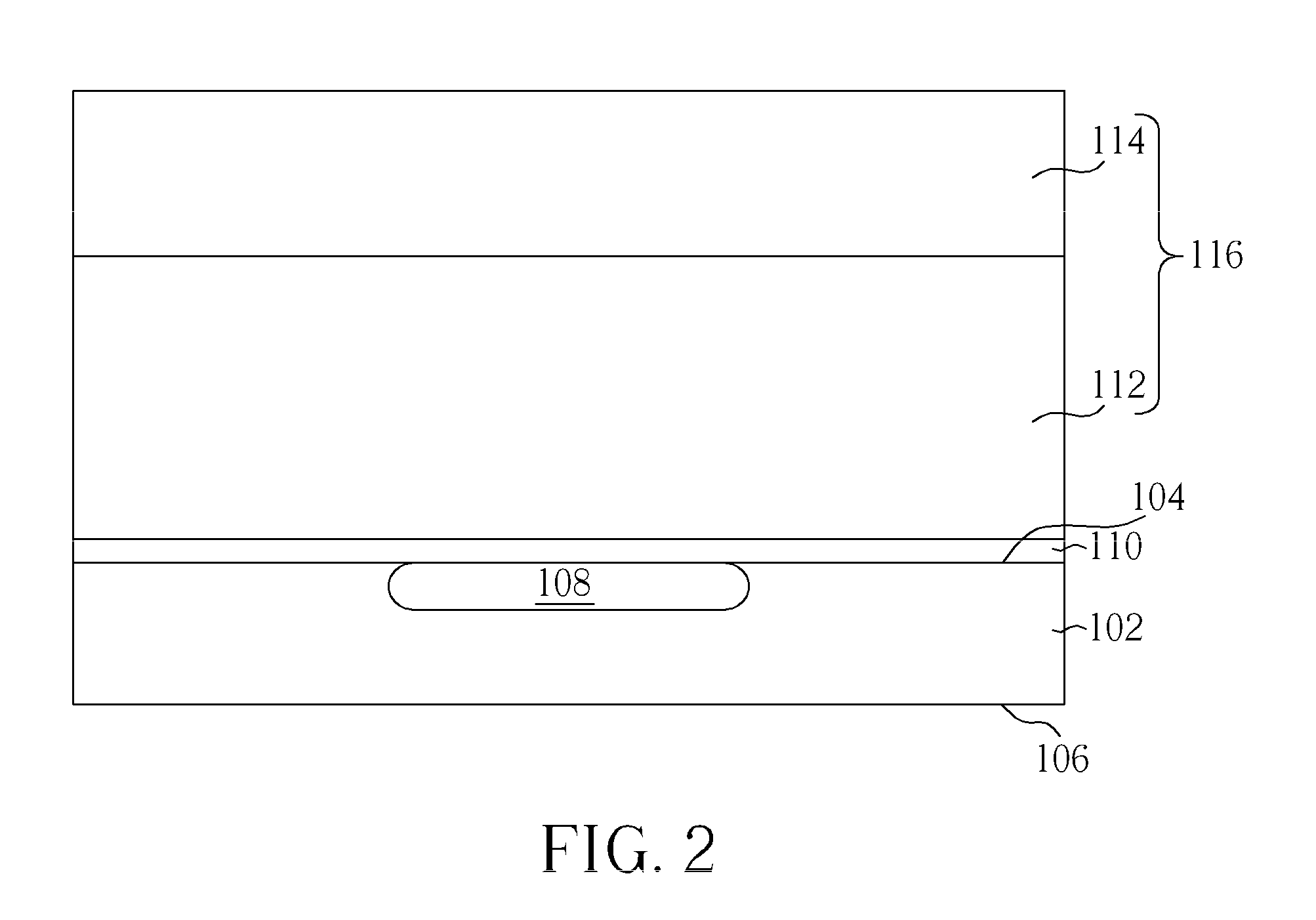

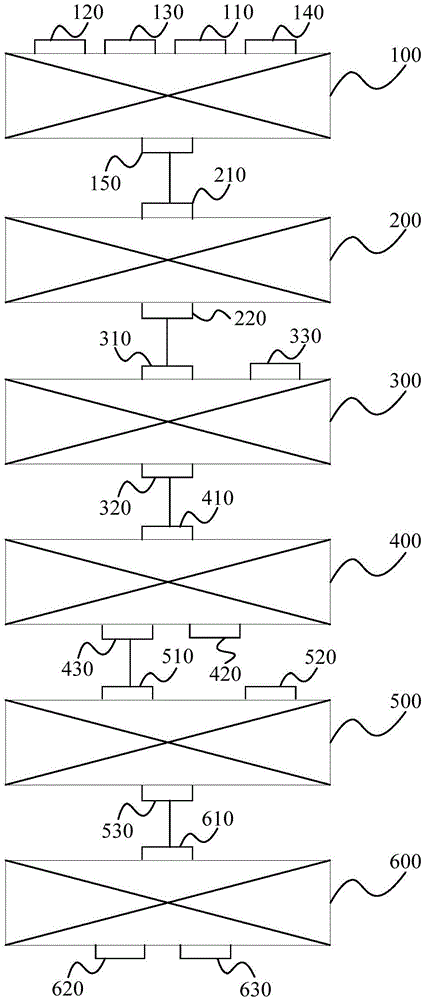

IGBT with fast reverse recovery time rectifier and manufacturing method thereof

InactiveUS20110079819A1Accelerate switchingDecrease areaSemiconductor/solid-state device manufacturingSemiconductor devicesReverse recoveryEngineering

An IGBT with a fast reverse recovery time rectifier includes an N-type drift epitaxial layer, a gate, a gate insulating layer, a P-type doped base region, an N-type doped source region, a P-type doped contact region, and a P-type lightly doped region. The P-type doped base region is disposed in the N-type drift epitaxial layer, and the P-type doped contact region is disposed in the N-type drift epitaxial layer. The P-type lightly doped region is disposed between the P-type contact doped region and the N-type drift epitaxial layer, and is in contact with the N-type drift epitaxial layer.

Owner:ANPEC ELECTRONICS CORPORATION

Corrosion inhibitor

InactiveCN101607765AImprove corrosion inhibition effectLow toxicityScale removal and water softeningCorrosion inhibitorAzole

The invention discloses a corrosion inhibitor, which is prepared from sodium nitrite, borate, organic phosphonate compounds, organic amine, aromatic azole compounds, AA / AMPS terpolymer, solid alkali and water. The corrosion inhibitor improves the corrosion inhibition effect by compounding the sodium nitrite and other substances and by means of the synergy of the compositions; and the dosage of nitrite (calculated by NO2) is reduced to between 50 and 60 mg / L from between 400 and 500 mg / L so as to greatly reduce the dosage of the toxic sodium nitrite and reduce influence on environment and processing cost. Due to good synergy, the corrosion inhibitor has better corrosion inhibition performance.

Owner:SHANGHAI WEILAI ENTERPRISE

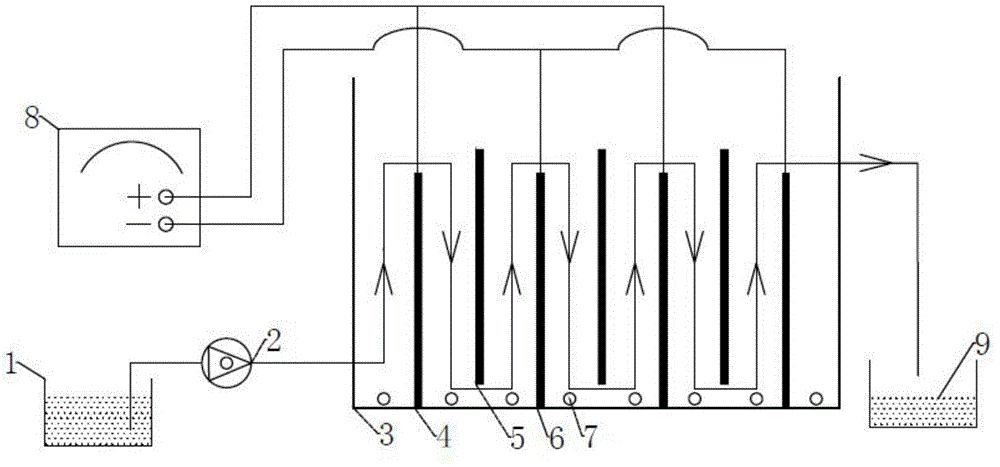

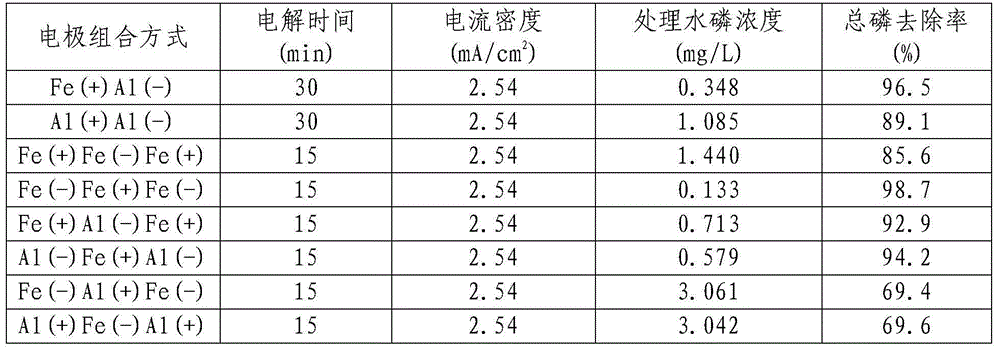

Method and device for treating phosphorus wastewater by adopting multi-electrode baffling electric flocculation process

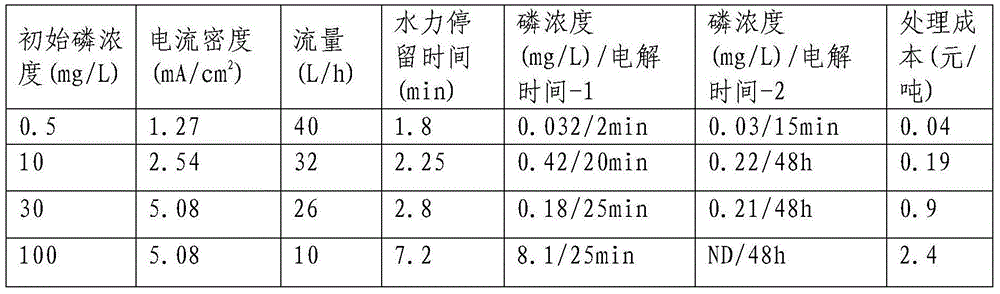

ActiveCN104787859AReduce processing costsSimple processWater/sewage treatmentPeristaltic pumpElectrochemistry

The invention belongs to the technical field of sewage treatment in environmental engineering, and particularly relates to a method and a device for treating phosphorus wastewater by adopting a multi-electrode baffling electric flocculation process. The PH value of wastewater is regulated with alkaline liquor to 7.0-8.0; the regulated wastewater is pumped into an electric flocculation tank through a peristaltic pump, is subjected to electrolytic flocculation treatment through the baffling of a multi-electrode under the condition of aeration, and then is discharged through an overflow launder, the discharged water is collected and left to stand for 30 minutes, a liquid supernatant is discharged, a floc is recycled; a power supply of the electric flocculation tank is a direct current power supply, the current density is 1.27-5.08mA / cm<2>, and the electrolysis time is 2 minutes to 48 hours. The technical characteristics are as follows: the wastewater baffles along the multi-electrode, then the short stream of the wastewater is avoided, the chance of enabling a pollutant in the wastewater to be in contact with a high-concentration flocculating agent in an electrolysis plate is increased, the flocculent precipitation is promoted, so that the pollutant treatment effect is improved. The multi-electrode baffling electric flocculation process is suitable for treating inorganic phosphorus wastewater at medium and low concentrations, needed equipment is simple, easy in operation and low in cost, and runs stably, so that the process is an electrochemistry phosphorous removal process having a high potential.

Owner:中国中化股份有限公司 +2

Quadripolymer-type corrosion-inhibition scale inhibitor PMAHS and preparation method thereof

InactiveCN102745823ASimple processGood dispersionScale removal and water softeningTemperature resistanceCorrosion

The invention discloses a quadripolymer-type corrosion-inhibition scale inhibitor PMAHS. The quadripolymer-type corrosion-inhibition scale inhibitor PMAHS comprises maleic anhydride (MA), acrylic acid (AA), hydroxyethyl acrylate (HEA), sodium methallylsulfonate (SMAS), sodium persulfate, sodium hypophosphite, isopropanol and water. The invention also discloses a preparation method of the quadripolymer-type corrosion-inhibition scale inhibitor PMAHS. The quadripolymer-type corrosion-inhibition scale inhibitor PMAHS has excellent effects of inhibiting production of calcium phosphate scales and calcium carbonate scales and especially phosphate scales, has good iron oxide dispersibility, has functions of corrosion inhibition, high temperature resistance and acid and base resistance, and has a stable molecular structure and low phosphorus content. The preparation method does not produce three wastes in production. The quadripolymer-type corrosion-inhibition scale inhibitor PMAHS has the advantages of simple circulating cooling water treatment processes, low use amount, low cost, good effects, good economic benefits and wide social benefits.

Owner:NANJING FORESTRY UNIV

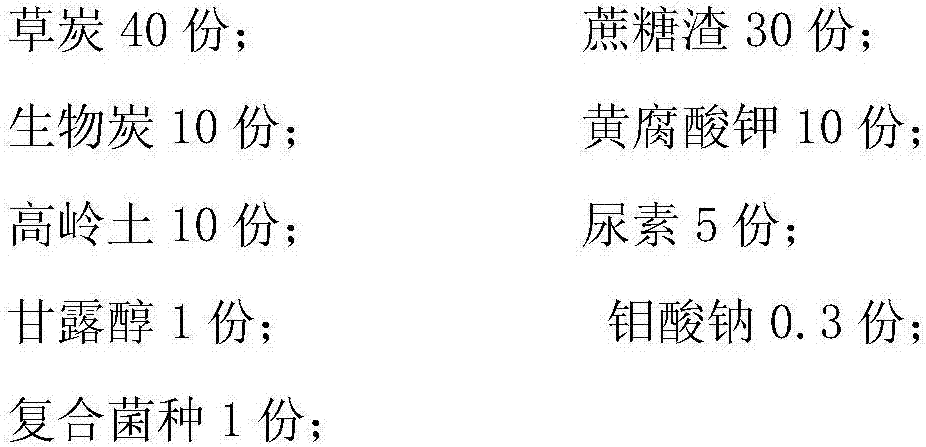

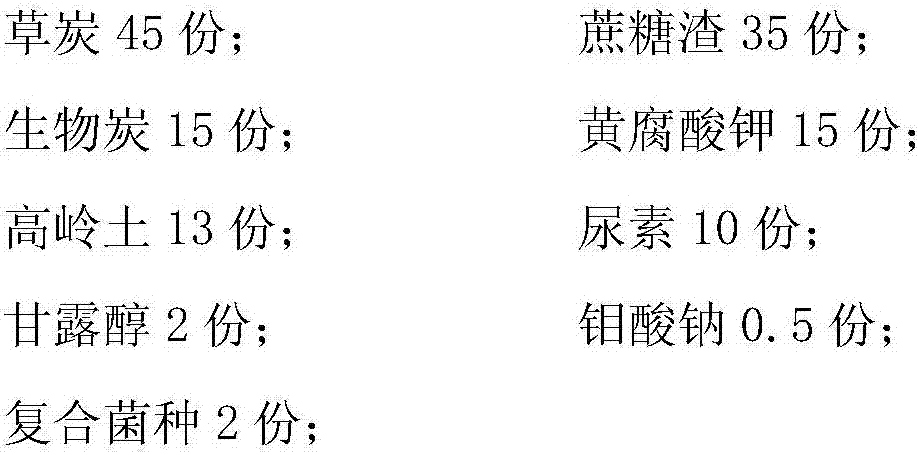

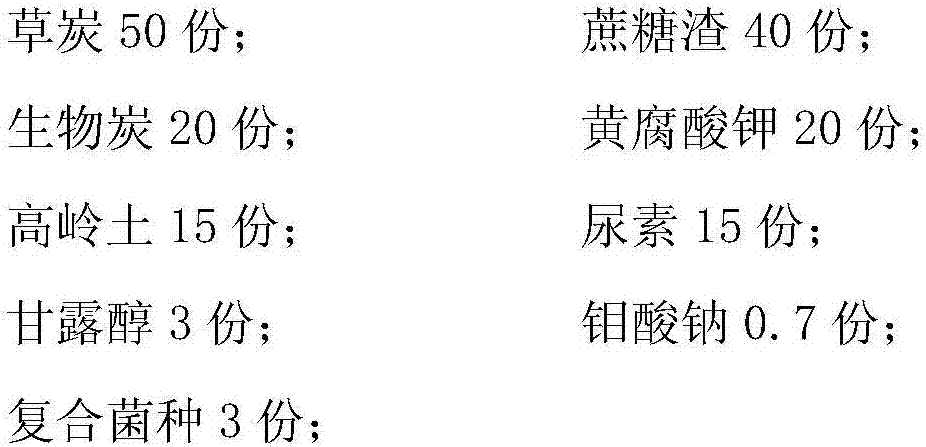

Fertilizer for sweet potatoes and preparation method of fertilizer

InactiveCN107188750ANutritious and comprehensivePromote growthBioloigcal waste fertilisersUrea compound fertilisersSucroseMannitol

The invention belongs to the technical field of fertilizer, and particularly discloses a fertilizer for sweet potatoes and a preparation method of the fertilizer. The fertilizer for the sweet potatoes is mainly prepared from 40-50 parts of turf, 30-40 parts of sugar cane bagasse, 10-20 parts of biochar, 10-20 parts of potassium fulvic acid, 10-15 kaolin, 5-15 parts of urea, 1-3 parts of mannitol, 0.3-0.7 part of sodium molybdate and 1-3 parts of compound strains through mixed fermentation and granulation, wherein the compound strains contain bacillus mucilaginosus, pseudomonas alealigenes, rhizobia and sterptomyces kasugaensis. The fertilizer for the sweet potatoes has the advantages of being long acting, capable of increasing the yield and free of residue and pollution, the preparation method is simple, implementation is easy, the cost is low, and a good application and popularization prospect is achieved.

Owner:覃淑兰

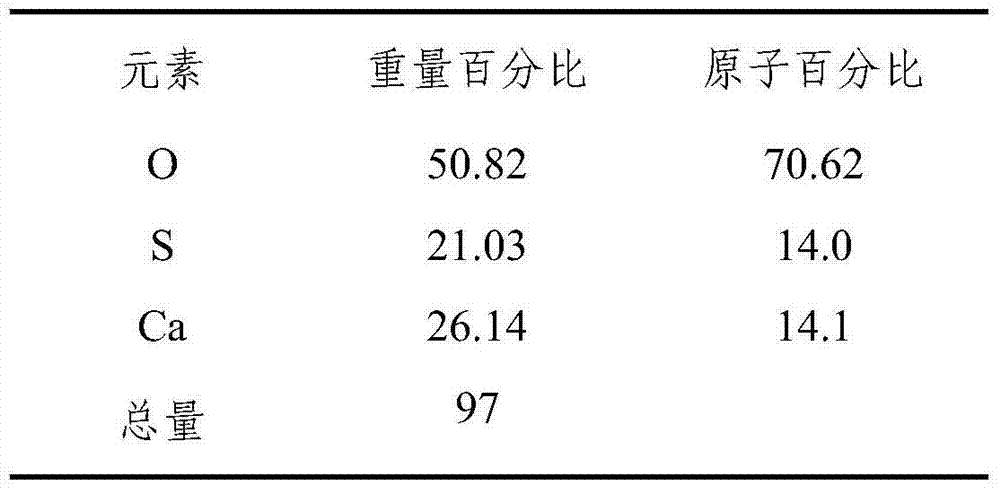

Method for improving by-product phosphogypsum quality during phosphoric acid production process

ActiveCN103496729ALow in phosphorusImprove qualityCalcium/strontium/barium sulfatesPhosphoric acidProcess engineeringCALCIUM DIHYDROGEN PHOSPHATE

The invention discloses a method for improving the by-product phosphogypsum quality during a phosphoric acid production process. The method comprises the steps that: (1) phosphoric acid is subjected to a reaction with phosphate concentrate; filtering is carried out, such that a filtrate containing calcium dihydrogen phosphate, calcium hydrogen phosphate, and phosphoric acid is obtained; and the filtrate is delivered to an extraction tank; (2) the filtrate is subjected to an extraction reaction in the extraction tank by using sulfuric acid with calcium dihydrogen phosphate and calcium hydrogen phosphate, and an obtained extract liquid is dilute phosphoric acid containing phosphogypsum; during the process, through analyzing filtrate calcium content, sulfuric acid theoretical dose is calculated according to a phosphoric acid extraction reaction formula, and sulfuric acid addition amount is determined; and (3) the extraction liquid is filtered by using a filtering machine, such that dilute phosphoric acid and phosphogypsum comprising 97% of dehydrate are obtained. In the phosphogypsum provided by the invention, dihydrate gypsum content is greatly higher than that of prior art, phosphorus content is substantially reduced, and phosphogypsum quality is greatly improved. Therefore, good raw material is provided for downstream phosphogypsum construction material manufacturing, and a basis is provided for sufficient utilization of phosphogypsum. The method is suitable for wet-method phosphoric acid production enterprises intending to utilize phosphogypsum.

Owner:GUIZHOU JINLIN CHEM

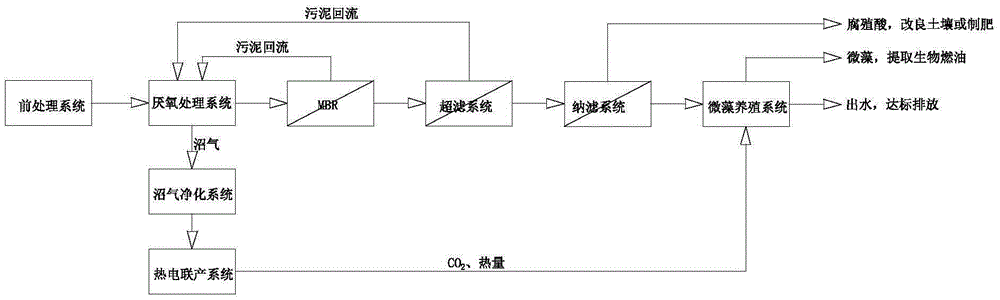

Novel livestock wastewater treatment process

ActiveCN105417877AReduce ammonia nitrogenLow in phosphorusWaste water treatment from animal husbandryWaste based fuelUltrafiltrationWater quality

The invention discloses a novel livestock wastewater treatment process. According to the novel process, after being subjected to solid-liquid separation through a pretreatment system, livestock wastewater sequentially enters an efficient anaerobic treatment system, an MBR, an ultrafiltration system and a nanofiltration system to be treated, then effluent flowing out of the nanofiltration system enters a microalgae cultivation system for microalgae cultivation, and effluent flowing out of the microalgae cultivation system can meet discharge standards and is discharged. Through the novel livestock wastewater treatment process, ammonia nitrogen, phosphorus and COD in wastewater can be effectively removed to improve the effluent quality, and meanwhile, by-products with economic values such as biogas, humic acid and microalgae are obtained.

Owner:SUZHOU CLEAR IND CO LTD

Fullerene, boron and nitrogen containing lubricant and preparation method thereof

ActiveCN105062618AImprove the lubrication effectImprove wear resistanceAdditivesSolubilityFriction reduction

The invention discloses a fullerene, boron and nitrogen containing lubricant and a preparation method thereof. An additive is prepared from polar modified fullerene C60, methyl laurate and nitrogen-containing borate, wherein a weight ratio of polar modified fullerene C60 to methyl laurate to nitrogen-containing borate is 1: (2-3): (20-25). The polar modified fullerene C60 is prepared from fullerene C60, concentrated sulfuric acid, concentrated hydrochloric acid and tall oil acid through reaction. The additive is the fullerene, boron and nitrogen containing lubricant, serves as a friction modifier, an anti-wear agent and an antioxidant of lubricating oil especially lubricating oil for an internal combustion engine, has remarkable friction reduction and oil saving effects, and further has the advantages of energy saving and environment protection due to absence of sulfur, phosphorus and chlorine; a production method is simple, the cost is low, oil solubility is good, and the yield is high.

Owner:王严绪

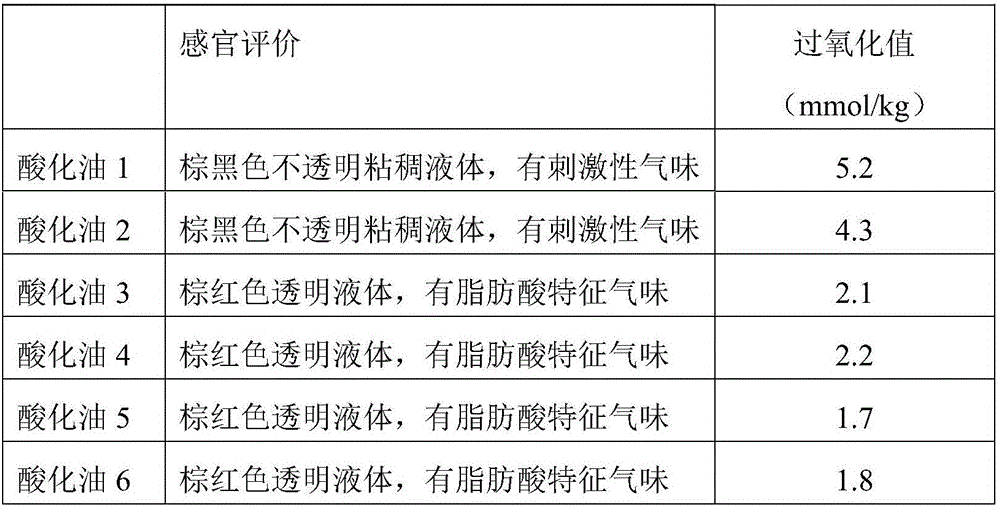

Grease refining method based on enzymatic degumming technology

InactiveCN105907466ALow in phospholipidsQuality improvementFatty-oils/fats refiningPhospholipidChemistry

The invention discloses a grease refining method based on the enzymatic degumming technology. Grease is subjected to acid reaction, then enzymatic degumming is conducted, and degummed oil is obtained through colloid separation, wherein the phosphorus content of the degummed oil is not higher than 30 mg / kg; the degummed oil is subjected to alkali refining to obtain desaponification oil, the desaponification oil is subjected to decoloration and deodorizing, and refined oil is prepared. The method reduces the phospholipid content in soapstock and improves quality of acidic oil; the desaponification oil with lower phosphorus content can be obtained; phospholipid in grease is separated independently, and high-value application is further facilitated.

Owner:SOUTH CHINA UNIV OF TECH

Processing method for rice bran oil

InactiveCN103409233AImprove oil yieldGood decolorization effectFatty-oils/fats refiningFatty-oils/fats productionFiltrationRice Bran Extract

The invention discloses a processing method for rice bran oil. A finished rice bran oil product is obtained by successively subjecting rice bran to puffing, leaching, pretreatment of mixed rice bran crude oil, degumming, decoloring, de-waxing and physical deacidification. In the procedure of leaching, a leaching solvent--isopropanol is added into the rice bran having undergone puffing, and oil yield of the rice bran oil is improved through optimization of the leaching procedure; in the procedure of pretreatment of the mixed rice bran crude oil, the mixed rice bran crude oil is subjected to filtration so as to control impurity content to be less than 0.2%; in the procedure of degumming, the temperature of the rice bran crude oil having undergone removal of impurities is adjusted to 42 to 45 DEG C, 20 to 25% of an aqueous oxalic acid solution is added under stirring, heating is carried out during stirring until the temperature is 62 to 64 DEG C, and the solution is stood for 1 to 2 h so as to obtain oxalic acid degummed oil; and then the oxalic acid degummed oil is subjected to water processing so as to obtain degummed oil. The processing method for the rice bran oil provided by the invention has the advantages of low energy consumption, high oil yield and a good decoloring effect.

Owner:湖南灯塔米业有限公司

Preparation method of iron phosphate

InactiveCN107032316ASimple processIncrease energy consumption and laborPhosphorus compoundsBrown iron oxideIron phosphate

The invention relates to the technical field of energy materials, and in particular relates to a preparation method of iron phosphate. Relatively pure iron and a small amount of iron oxide are used as raw materials to react with phosphoric acid to obtain iron phosphate which is then water-washed and oven-dried to obtain an iron phosphate product with uniform particle size and excellent tap density. The preparation method of iron phosphate, provided by the invention, dispenses with the treatment of the byproduct salts generated during iron phosphate production from phosphate and an iron salt; the preparation method controls the properties of iron phosphate through a high pressure oxidation process, so as to effectively improve the tap density and other properties; and the preparation method effectively reduces material loss, reduces the phosphorus content in sewage and reduces the difficulty of sewage treatment through rectification, purification and reuse of phosphoric acid, thus achieving the purpose of green production.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Method for recovering simple-substance phosphorus from sludge phosphorus via terminal membrane microfiltration and application for same

ActiveCN103213958AHigh recovery rateShort production processPhosphorus purificationSludgePhosphorite

The invention discloses a method for recovering simple-substance phosphorus from sludge phosphorus via terminal membrane microfiltration, which is remarkably increased in the recovery rate of simple-substance phosphorus compared with the existing method. The method for recovering simple-substance phosphorus from sludge phosphorus via terminal membrane microfiltration disclosed by the invention comprises the following steps of: firstly, mixing a sludge phosphorus raw material with hot water at 60-90 DEG C, so as to melt and settle simple-substance phosphorus in the sludge phosphorus raw material under the heat insulation of the hot water; secondly, only drawing the melted and settled substances in the mixture aforementioned in a terminal membrane microfiltration device, so as to filter the melted and settled substances by a membrane component at a filter temperature of 50-85 DEG C and under a filter pressure of 0.1-0.3 MPa; and finally, conveying the product passing through the membrane component aforementioned to a phosphorus-receiving tank, and settling at the bottom of the phosphorus-receiving tank to obtain simple-substance phosphorus. A production process adopting the method aforementioned for yellow phosphorus comprises the steps of pouring the raw materials of phosphorite, coke, silica and the like in an electric furnace to react, and then performing spray-cooling on a furnace gas and obtaining crude phosphorus, wherein after that, the crude phosphorus is directly used as a raw material, and the operation is performed according to the method aforementioned for recovering simple-substance phosphorus from sludge phosphorus.

Owner:CHENGDU INTERMENT TECH

Method for comprehensively utilizing red mud and high-phosphorus iron ore

The invention relates to a method for comprehensively utilizing red mud and high-phosphorus iron ore, and specifically relates to a red mud and high-phosphorus iron ore solid dephosphorization and iron extraction technology. The method comprises the following preparation steps of: a, evenly mixing powdered high-phosphorus iron ore, powdered red mud and pulverized coal according to the proportion of 100: (1-100): (1-100), b, heating the mixed material obtained in the step a in a temperature range of 100-900 DEG C and preserving the temperature for 10-300min, c, after the material obtained in the step b is cooled, soaking the material by water for 10-120min and then filtering the liquid, and d, carrying out magnetic separation on the solid filtered in the step c, wherein the magnetic part is hematite or magnet or iron ore concentrate and the phosphorus content is less than 0.3wt%. According to the method, the red mud can be effectively utilized to reduce the pollution to the environment, and at the same time, the phosphorus content of the high-phosphorus iron ore can be decreased for recycling. The method is simple in process, low in production cost and beneficial to industrial popularization.

Owner:UNIV OF SCI & TECH BEIJING

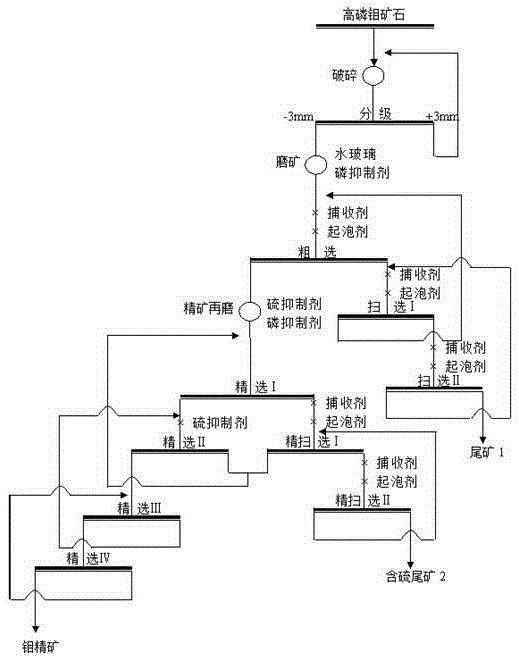

Physical concentration and phosphorus reduction method for skarn-type high-phosphorus molybdenum ore

The invention discloses a physical concentration and phosphorus reduction method for a skarn-type high-phosphorus molybdenum ore. The physical concentration and phosphorus reduction method comprises the following steps of (1) crushing, namely crushing raw ores by using a crusher, sieving, and returning a +3mm-grade raw ore to crush until the particle size of the raw ore is up to the -3mm grade; (2) grinding the ores, namely adding the crushed -3mm-grade raw ore into raw ore grinding equipment to carry out closed-circuit ore grinding operation, meanwhile, adding 500-1000g / t of water glass and 250-800g / t of a phosphate mineral inhibitor into a grinding machine, and grinding the raw ore until the particle size is up to the -0.075mm grade and the phosphorus content is up to 55-75%; (3) carrying out roughing operation; (4) carrying out scavenging operation; (5) regrinding a roughed molybdenum concentrate, namely adding 100-280g / t of a sulfur inhibitor and 150-300g / t of a phosphate mineral inhibitor to regrind the roughed molybdenum concentrate in roughed molybdenum concentrate regrinding equipment until the particle size is up to the -0.045mm grade and the phosphorus content is up to 70-95%; and (6) carrying out fine flotation operation. By using the physical concentration and phosphorus reduction method, the phosphorus content of a molybdenum concentrate product can be reduced to be lower than the standard, and a high-quality molybdenum concentrate product can be obtained.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

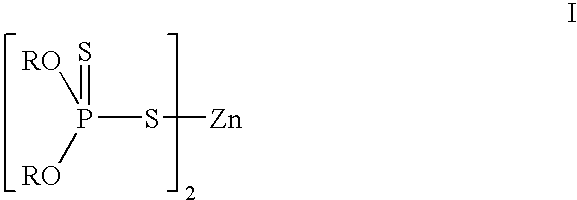

Low phosphorus lubricating oil composition having lead corrosion control

The present invention provides a low phosphorus lubricating oil composition containing a mixture of zinc dithiophosphates in a certain ratio surprisingly yields improved lead corrosion. The synergistic combination of mixed zinc dithiophosphates containing a zinc primary dialkyl dithiophosphate, zinc secondary dialkyl dithiophosphate and zinc diaryl dithiophosphate in a respective ratio, based on the phosphorus content, of the zinc primary dialkyl dithiphosphate to zinc secondary dialkyl dithiophosphate from about 2:1 to about 1:2 and the ratio of the mixture of zinc primary dialkyl dithiophosphate and zinc secondary dialkyl dithiophosphate to zinc diaryl dithiophosphate from about 6:1 to about 1:1. When used in a lubricating oil composition having a total phosphorus content less than about 0.06 wt %, based on the total weight of the lubricating oil composition to lubricate internal combustion engines. The mixture of zinc dithiophosphates greatly reduces lead corrosion.

Owner:CHEVRON ORONITE CO LLC

Method for recovering simple-substance phosphorus from sludge phosphorus via cross-flow membrane microfiltration and application for same

ActiveCN103213959AHigh recovery rateShort production processPhosphorus compoundsSludgeMicrofiltration

The invention discloses a method for recovering simple-substance phosphorus from sludge phosphorus via cross-flow membrane microfiltration, which is remarkably increased in the recovery rate of simple-substance phosphorus compared with the existing method. The invention further discloses a production process for yellow phosphorus, which omits a two-stage refining groove and an all sludge phosphorus pool compared with the existing process, so that lots of investment, manpower, water and energy consumption can be saved. The method for recovering simple-substance phosphorus from sludge phosphorus disclosed by the invention comprises the following steps of: firstly, mixing a sludge phosphorus raw material with hot water at 60-90 DEG C, so as to melt and settle simple-substance phosphorus in the sludge phosphorus raw material under the heat insulation of the hot water; secondly, only drawing the melted and settled substances in the mixture aforementioned in a cross-flow membrane microfiltration device, so as to filter the melted and settled substances by a membrane component at a filter temperature of 50-85 DEG C and under a filter pressure of 0.1-0.3 MPa; and finally, conveying the product passing through the membrane component aforementioned to a phosphorus-receiving tank, and settling at the bottom of the phosphorus-receiving tank to obtain simple-substance phosphorus, wherein the speed of the mixture flowing along the surface of the membrane component during filtering is controlled to be 0.01-0.5 m / s.

Owner:CHENGDU INTERMENT TECH

Preparation method of scale and corrosion inhibitor

InactiveCN108911189AImprove hydrophilic abilityChange state of chargeScale removal and water softeningIon exchangeElectronegativity

The invention discloses a preparation method of a scale and corrosion inhibitor, which belongs to the technical field of preparation of water treatment chemicals. Nano cellulose prepared by utilizingneedle wood leaves is used as an adsorption carrier of corrosion inhibitor. The parent corrosion inhibitor prepared by the invention is Mannich base, by virtue of quaternization, the parent corrosioninhibitor adopts nitrogen atoms with larger electronegativity as a center polar group, the polar group is extremely high in hydrophilic performance, the concentration of the metal ions which are easyin forming scales such as calcium and magnesium can be reduced, the surface of a chelated adsorption material is coated with oxidized nano cellulose to form a nano filter membrane, the metal ions canbe efficiently adsorbed, the corrosion of saline-alkaline water for a salt discharging concealed pipe can be reduced, and when the added graphene oxide is oxidized, the graphene lamina is swelled, sothat a gap between two layers can be enlarged, the ion exchange is likely to occur for the metal ions in the saline-alkaline water, and the scale and corrosion inhibitor provided by the invention is high in capability for adsorbing and controlling the metal ions in the saline-alkaline water, and wide in application prospect.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

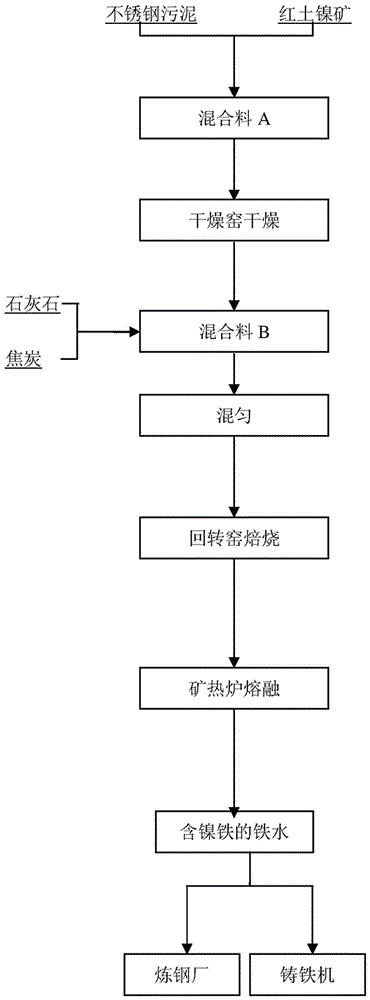

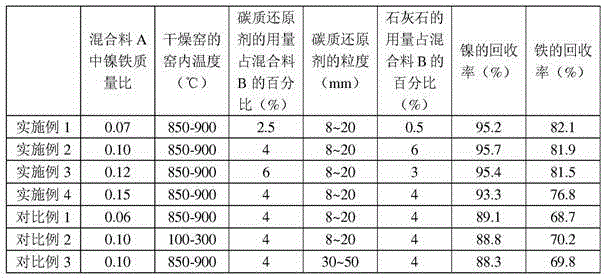

Method for efficiently recovering ferronickel alloy from stainless steel sludge

The invention provides a method for efficiently recovering a ferronickel alloy from stainless steel sludge. Firstly, the stainless steel sludge and a nickel laterite ore are mixed according to a nickel-iron mass ratio of 0.07-0.15, and then, are dried by a drying kiln; the temperature in the drying kiln is 850-900 DEG C; and the drying time is 15-20 min; a carbon reducing agent with a particle size of 8-20 mm and limestone are added for roasting by a rotary kiln; the stop time in the rotary kiln is 90-180 min; the temperature of a high-temperature section in the rotary kiln is 600-1100 DEG C; finally, the mixture is reduced and smelted by a submerged arc furnace to obtain molten iron containing the ferronickel alloy; and the smelting temperature in the submerged arc furnace is 1550-1600 DEG C. The method enables the recovery rates of nickel and iron in the stainless steel sludge to respectively reach above 93% and 81%, and meanwhile, prevents the environmental pollution problem in wet smelting.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Treatment method for high-concentration phosphorus-containing wastewater

InactiveCN110526448AFully removedFully removeWater contaminantsTreatment involving filtrationHigh concentrationPhosphoric acid

The invention discloses a treatment method for high-concentration phosphorus-containing wastewater. The treatment method comprises the steps: adding alkali liquor into the high-concentration phosphorus-containing wastewater, adjusting pH to 7.2 to 8 to enable ortho-phosphate to present in forms of monohydrogen phosphate and dihydrogen phosphate, then, adding a precipitant to enable phosphate and the precipitant to form an insoluble compound, and carrying out filtering; adding filter liquor into a supercritical water oxidation reaction device, thoroughly blending organics, oxygen gas and waterduring reaction under a supercritical state so as to form a uniform phase, rapidly oxidating organic phosphorus into inorganic phosphate, and releasing the inorganic phosphate into a liquid phase; andadding ferric polysulfate and an anionic polyacrylamide solution into supercritical treated wastewater, and carrying out condensation and flocculation processes, so as to settle and remove phosphate.According to the method, phosphorus is removed by employing a supercritical oxidation and chemical precipitation cooperated method, phosphorus removal is rapid and thorough and is relatively wide inrange, high-concentration organic phosphorus and inorganic phosphorus can be treated, and the content of total phosphorus in final wastewater is lower than 1mg / L.

Owner:石家庄新奥环保科技有限公司

Method for degumming rice bran oil with oxalic acid

InactiveCN102453606AImprove degumming effectLow in phosphorusFatty-oils/fats refiningChemical industryPhosphoric acid

The invention which relates to a method for processing rice bran oil and concretely relates to a method for degumming rice bran oil with oxalic acid belongs to the technical field of the chemical industry. According to the method, crude extracted rice bran oil is degummed by oxalic acid and undergoes processes of decoloring, dewaxing and physical depickling to obtain refined rice bran oil. Compared with routine high temperature hydration methods and phosphoric acid hydration methods, the method of the invention is better in the degumming effect which is mainly reflected in the following aspects: the content of phosphor in the degummed oil is low and the color of the degummed oil is light. Oxalic acid which has a good degumming effect also has an auxiliary decoloring effect. The color of the crude rice bran oil degummed through the high temperature hydration is darker than before; and the color of the crude rice bran oil degummed through the phosphoric acid hydration is basically unchanged.

Owner:李洪运

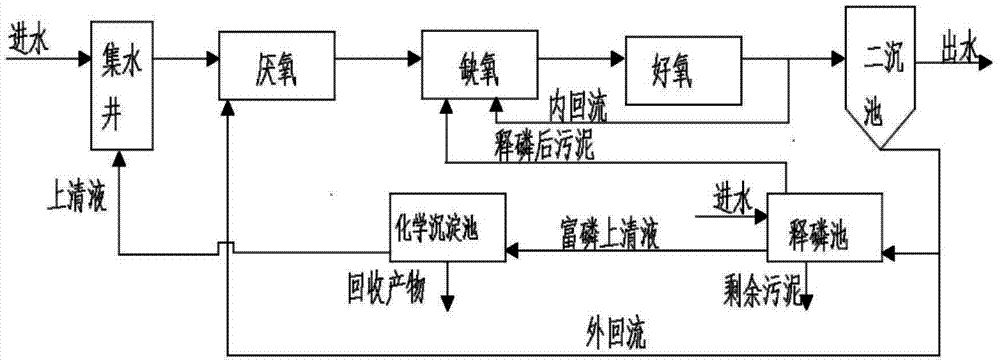

Coupled sewage biological nitrogen and phosphorus removal and phosphate recovery method

ActiveCN104743734ALow costImprove recycling efficiencyMultistage water/sewage treatmentPhosphorus compoundsRecovery methodPhosphate

The invention relates to a coupled sewage biological nitrogen and phosphorus removal and phosphate recovery method. According to the method based on a biological nitrogen and phosphorus removal mainstream process of a sewage plant, phosphorus releasing ponds which operate in a side stream sequencing batch manner and are coupled with the main stream process is arranged, the amount of sludge introduced into a secondary sedimentation tank of each of the phosphorus releasing ponds is based on the volume ratio of water inflow: sludge inflow of the phosphorus releasing pond=(0.5-2.0): 1, and the total sludge amount entering into the phosphorus releasing pond everyday is below 10% of the daily average flow rate of the sewage plant; each of the phosphorus releasing ponds operates 2-4 periods everyday, and residual sludge is discharged from the phosphorus releasing ponds. The phosphorus releasing ponds can be flexibly adjusted according to a result of pilot run of the phosphorus releasing ponds and phosphate recovery, the phosphate is recovered to the optimum extent, and the biological treatment effect of the sewage is improved. According to the method provided by the invention, not only do the sewage treatment indexes meet the national discharge standard, but also phosphorus in the sewage can be recovered. The method is a sewage treatment and resource recovery method in sustainable development and is suitable for a newly constructed municipal sewage treatment plant or a constructed sewage plant with a nitrogen and phosphorus removal function.

Owner:TONGJI UNIV

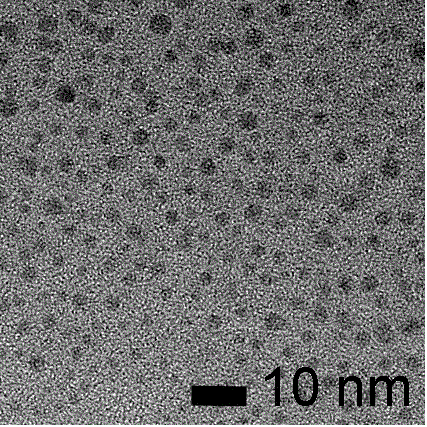

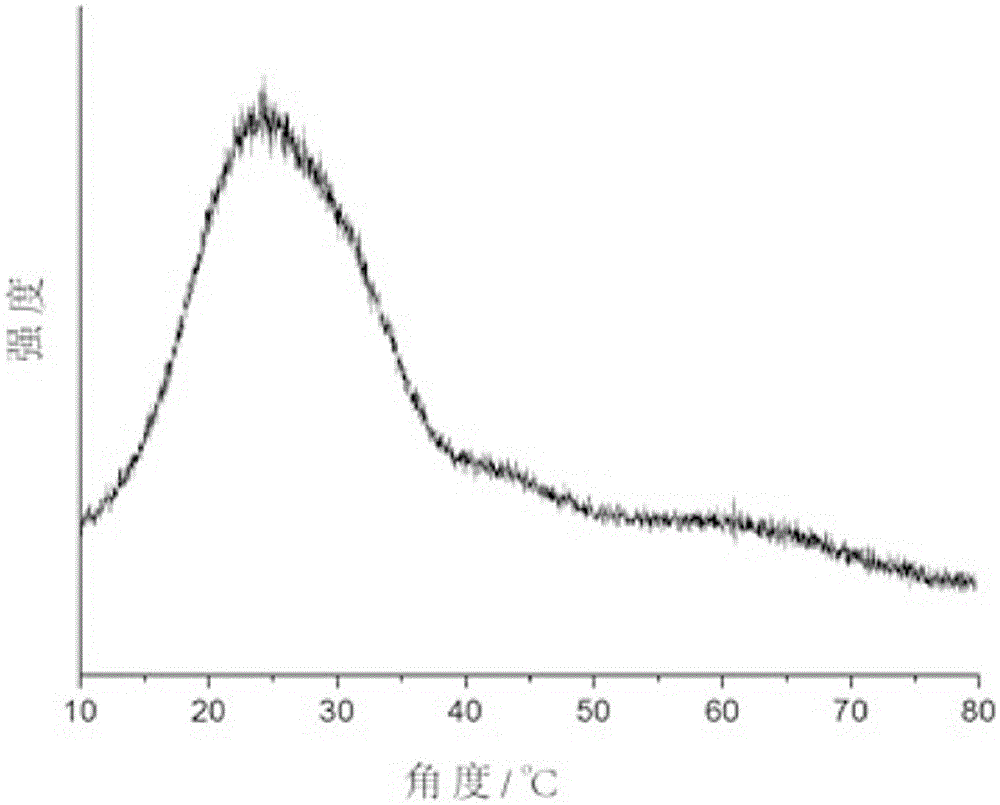

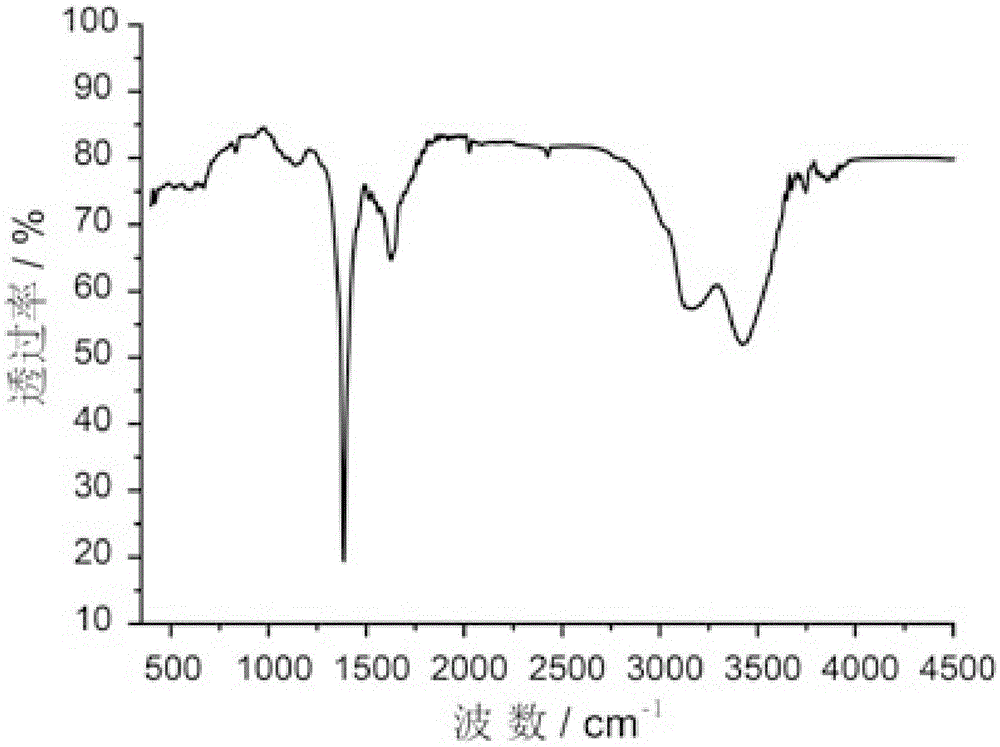

Method for extracting fluorescent carbon quantum dots from semi coke

InactiveCN105621391AStrong fluorescenceFixed carbon heightMaterial nanotechnologyLuminescent compositionsDistillationCentrifugation

The invention provides a method for extracting fluorescent carbon quantum dots from semi coke. The method comprises the following steps: firstly, adding semi coke powder into a 4M to 6M nitric acid solution, and carrying out stirred refluxing at the temperature of 80 DEG C to 120 DEG C; carrying out natural cooling, then, carrying out centrifugation for 30 minutes to 60 minutes at the rate of 10,000r / min to 15,000r / min, collecting supernatant, removing precipitates, and drying the obtained supernatant by distillation in a reduced-pressure distillation manner, so as to obtain black solids; dispersing the black solids in deionized water, carrying out neutralizing by ammonia water, then, carrying out centrifugation for 30 minutes to 60 minutes at the rate of 10,000r / min, and collecting supernatant; dialyzing the supernatant by dialysis bags, collecting solutions in the dialysis bags, and carrying out vacuum drying for 24 hours to 48 hours at the temperature of 60 DEG C to 80 DEG C, thereby obtaining the carbon quantum dots. According to the method, the semi coke which is low in cost and easy in raw material obtaining is adopted as a carbon source, and the carbon quantum dots can be obtained through simple chemical oxidation, evaporation, neutralization, centrifugation and dialysis treatment processes. The carbon quantum dots have the particle size of 3nm to 5nm and are uniform in dispersion, and surfaces of the carbon quantum dots have a large number of carboxyl groups and hydroxyl groups, so that a relatively good fluorescent property is shown.

Owner:XINJIANG UNIVERSITY

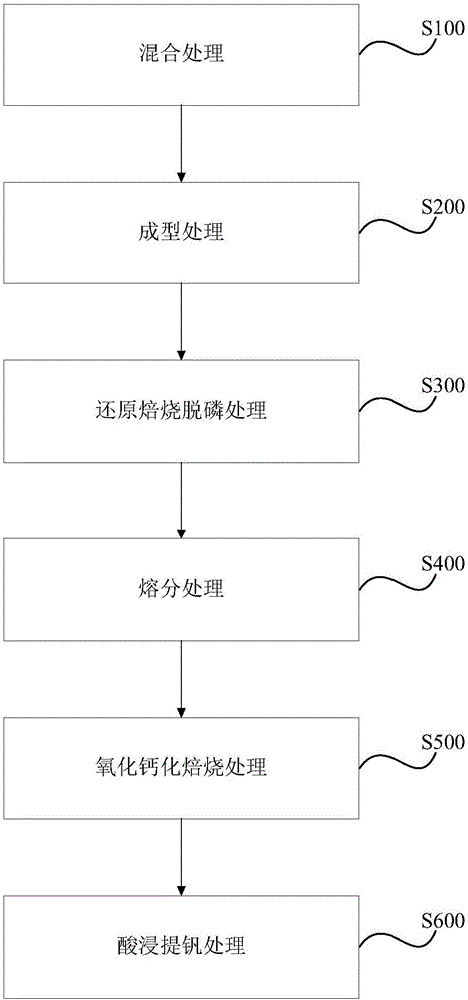

Method and system for processing high-calcium and high-phosphorus vanadium slag

PendingCN106756120AEfficient removalLow in phosphorusProcess efficiency improvementSlagMixed materials

The invention discloses a method and system for processing high-calcium and high-phosphorus vanadium slag. The method for processing the high-calcium and high-phosphorus vanadium slag comprises the following steps: mixing the high-calcium and high-phosphorus vanadium slag, silica, reducing coal and a binder, so as to obtain a mixed material; carrying out formation on the mixed material, so as to obtain mixed pellets; carrying out reducing roasting dephosphorization on the mixed pellets, so as to obtain dephosphorized metallized pellets and phosphorus-containing flue gas; carrying out melt separation on the dephosphorized and metallized pellets, so as to obtain molten iron and low-phosphorus vanadium slag; carrying out oxidation roasting with calcium on the low-phosphorus vanadium slag, so as to obtain acid-soluble calcium vanadate clinker; and carrying out acid leaching and vanadium extraction on the acid-soluble calcium vanadate clinker, so as to obtain a vanadium pentoxide product. By utilizing the method for processing the high-calcium and high-phosphorus vanadium slag, phosphorus in the high-calcium and high-phosphorus vanadium slag can be effectively removed, so that the recycling rates of iron and vanadium are remarkably increased, and the qualities of the iron and the vanadium are remarkably improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Electronic connector assembly electric plating process

The invention discloses an electronic connector assembly electric plating process, which sequentially comprises the steps of electric plating pretreatment, electric plating process and an electric plating post treatment process, wherein the electric plating pretreatment comprises the process steps of deoiling, water washing, activation and water washing. The electric plating process comprises theprocess steps of nickel plating and pure tin atomization; the electric plating post treatment comprises a drying process. A steel belt has the S-shaped trend; the occupied area is greatly reduced; about 1 / 2 of the production line cost is reduced; the phosphorus content in sulfate copper plating is very low, so that the plating layer combination is tighter; a manufactured electronic device cannot easily generate desoldering; the resources can be effectively saved; the safety of personnel is protected.

Owner:JIANGSU AOGUANG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com