Method for improving by-product phosphogypsum quality during phosphoric acid production process

A technology of production process and by-product phosphorus, which is applied in the field of phosphoric acid, can solve the problems of no improvement in the quality of phosphogypsum, no new technology, and difficulty in expanding the scope of use, and achieve the effect of reducing phosphorus content and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] First, the phosphorus concentrate is measured by the feeding belt, and the phosphoric acid is measured by the flow meter and enters the reaction tank together. The liquid-solid ratio of phosphoric acid and phosphorus concentrate is controlled to be 8:1, and the reaction time is 4 hours at a temperature of 35°C. The reaction slurry enters the plate frame Type filter press, remove the filter residue, and the filtrate enters the second reaction tank.

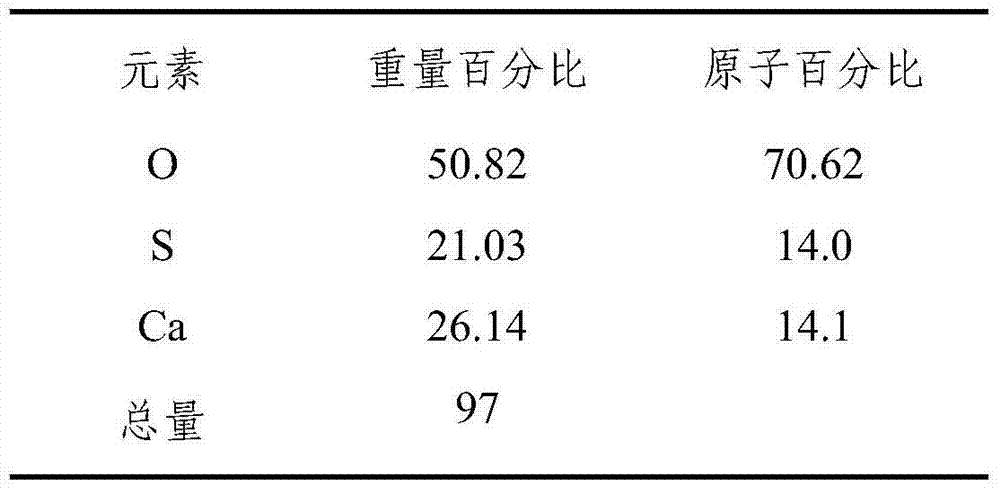

[0013] The content of dihydrate gypsum in the phosphogypsum produced by the method of the present invention can reach 97%, which is much higher than 90% of the traditional technology, the phosphorus content is significantly reduced, and the quality is greatly improved, providing better raw materials for downstream phosphogypsum-made building materials. Lay the foundation for making full use of phosphogypsum. Applicable to wet-process phosphoric acid production enterprises planning to process and utilize phosphogypsum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com