Patents

Literature

32results about How to "Not easy to desolder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

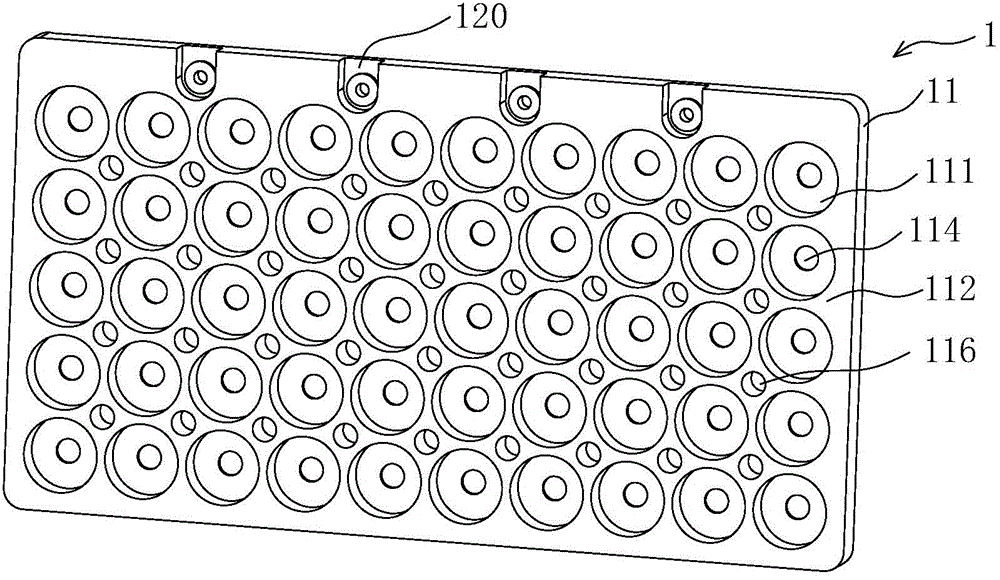

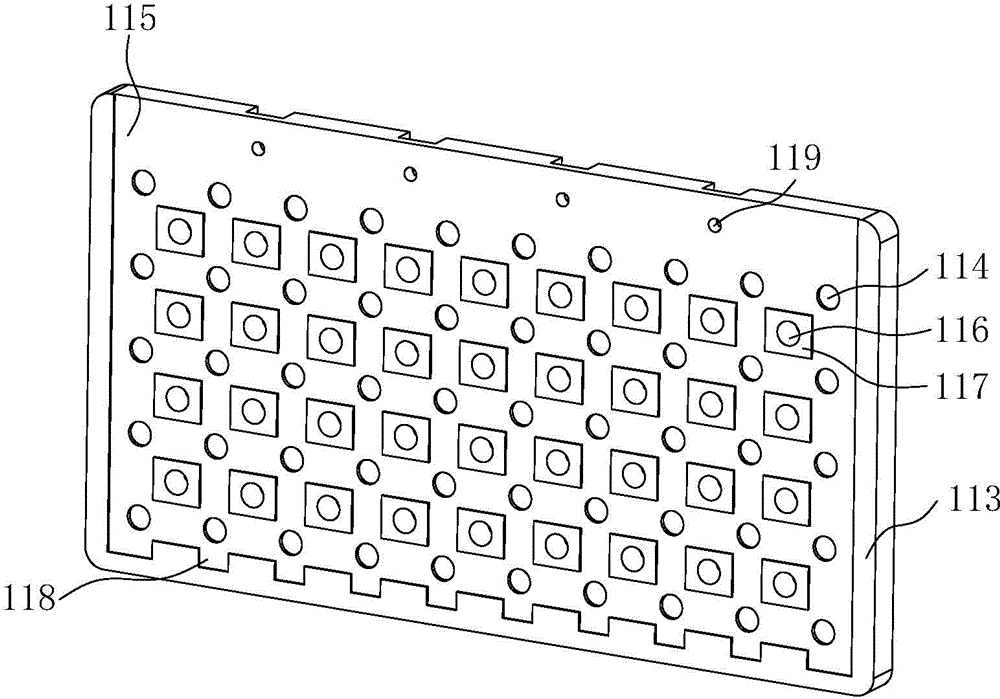

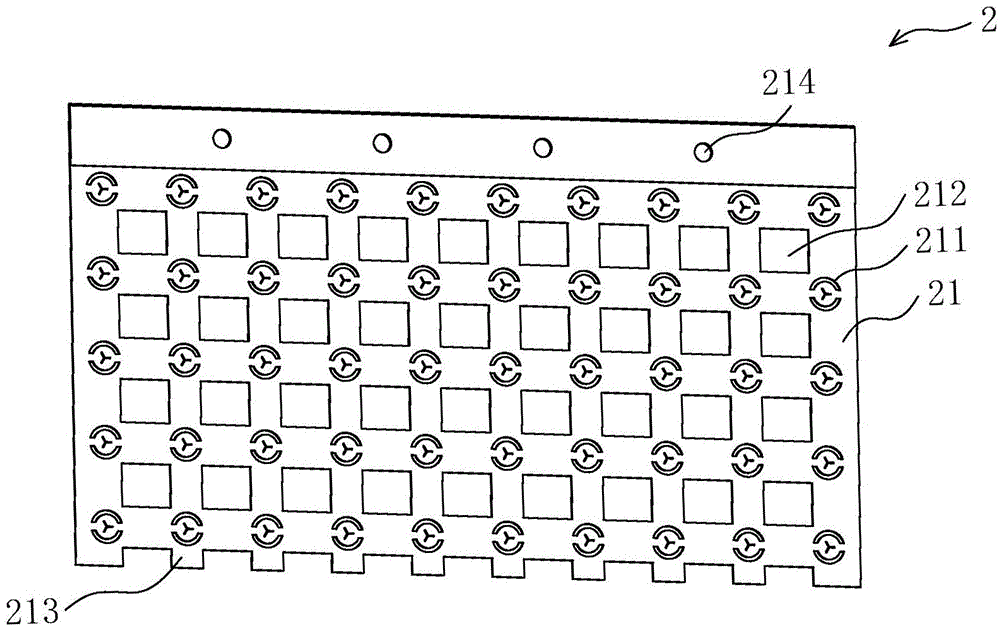

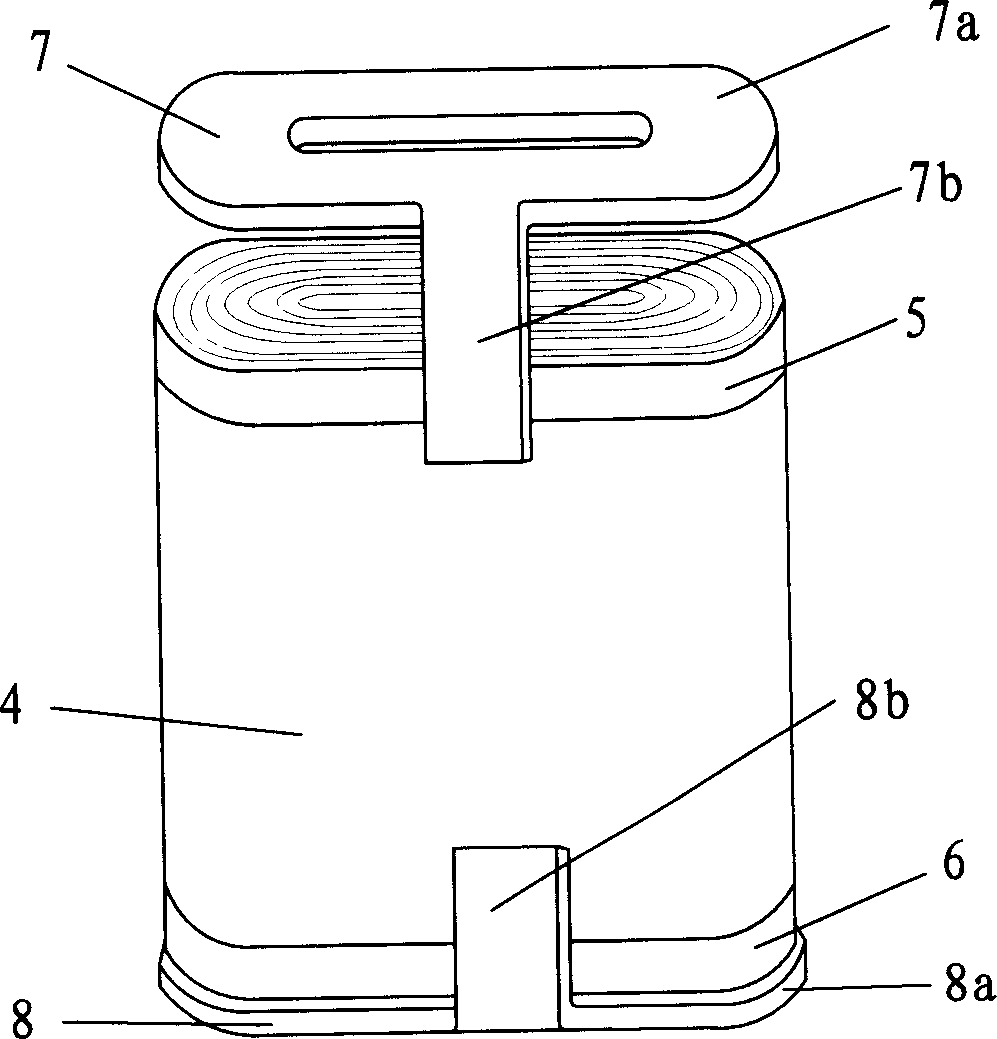

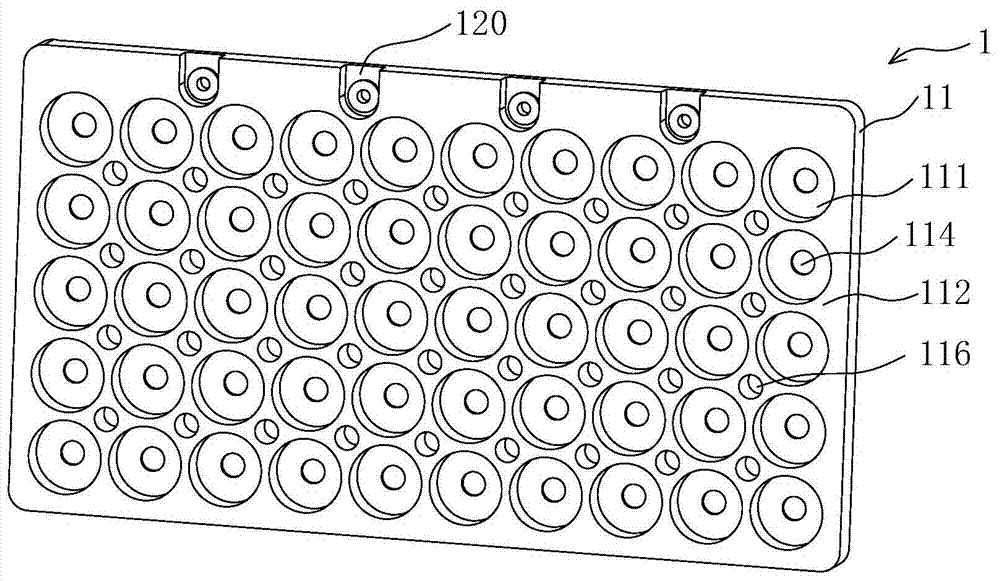

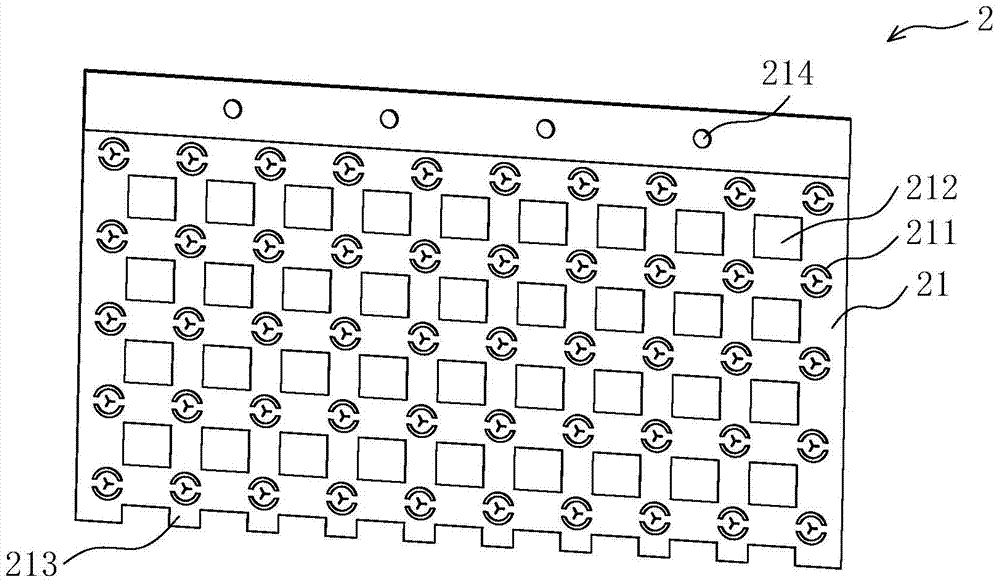

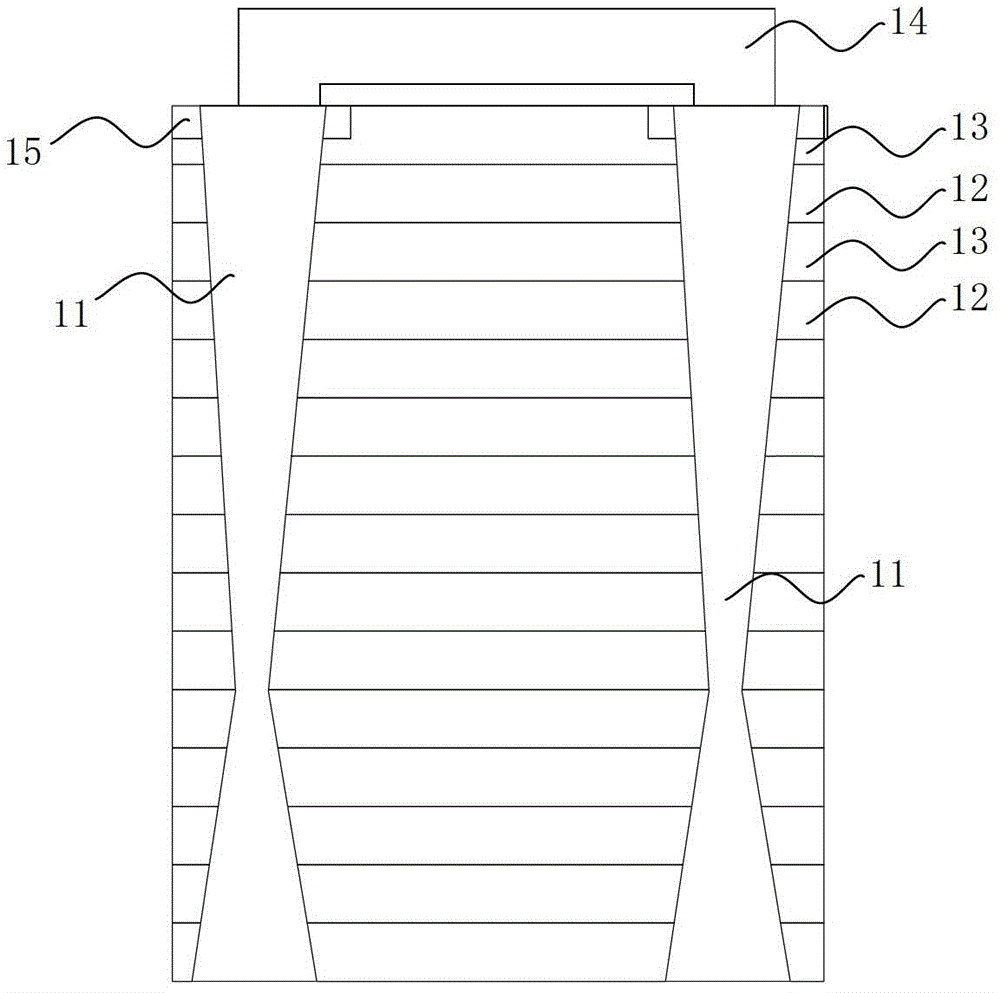

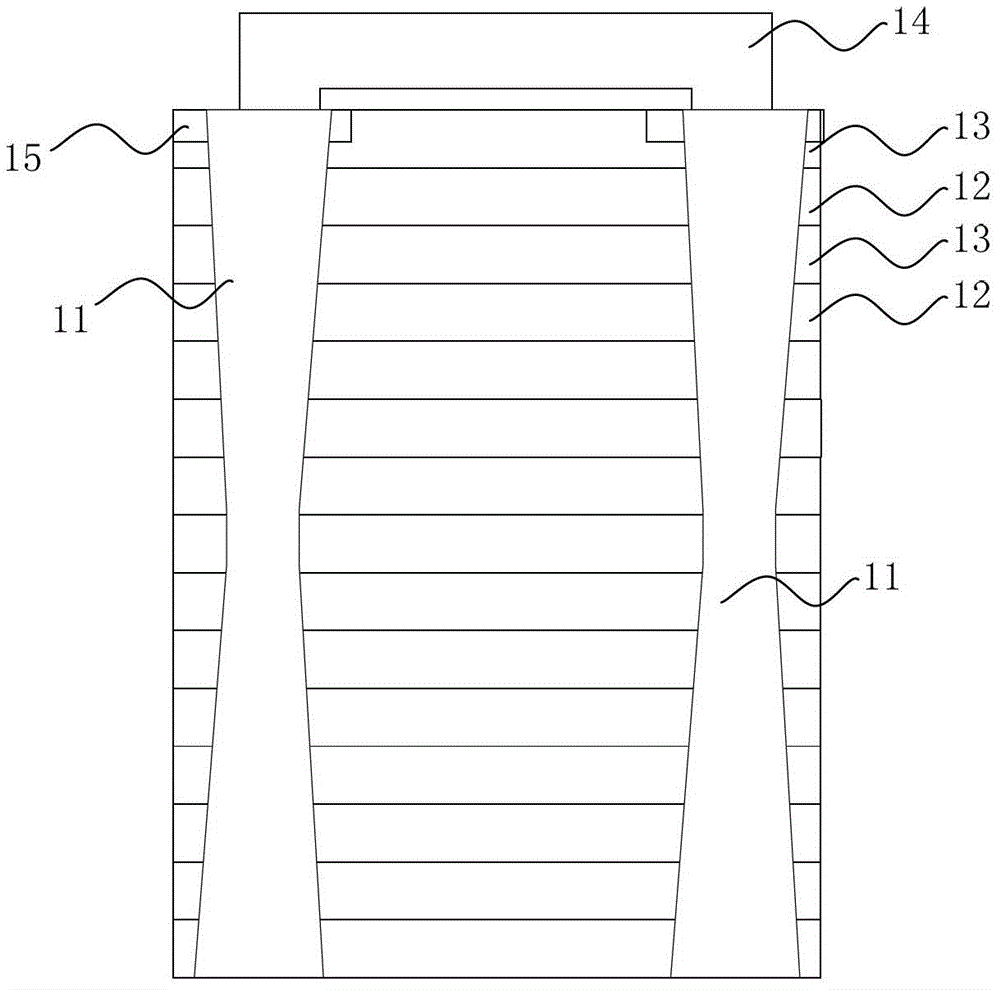

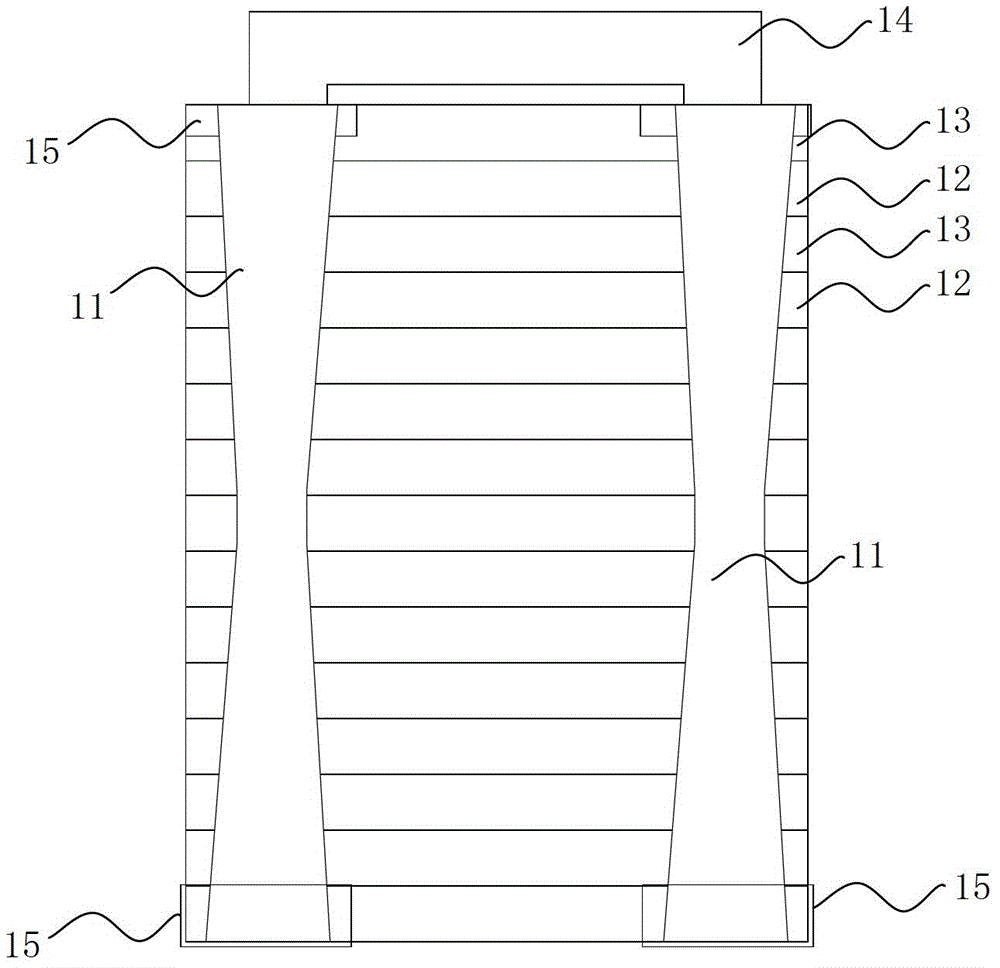

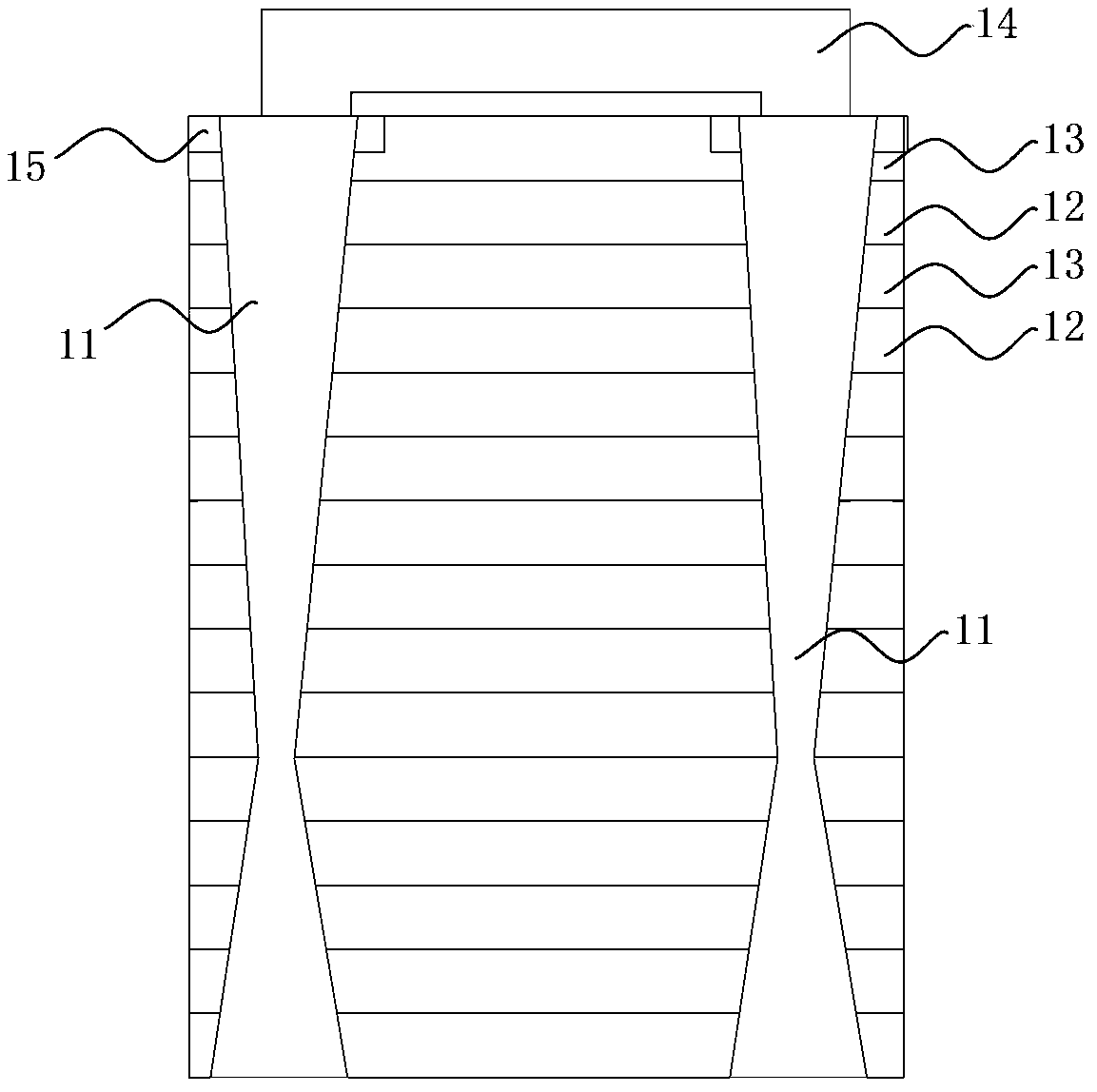

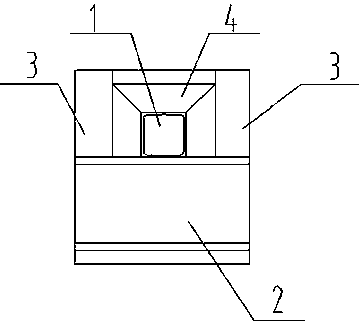

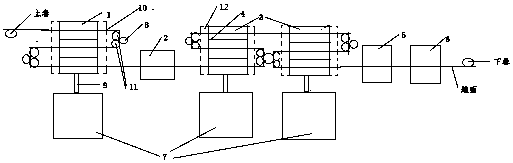

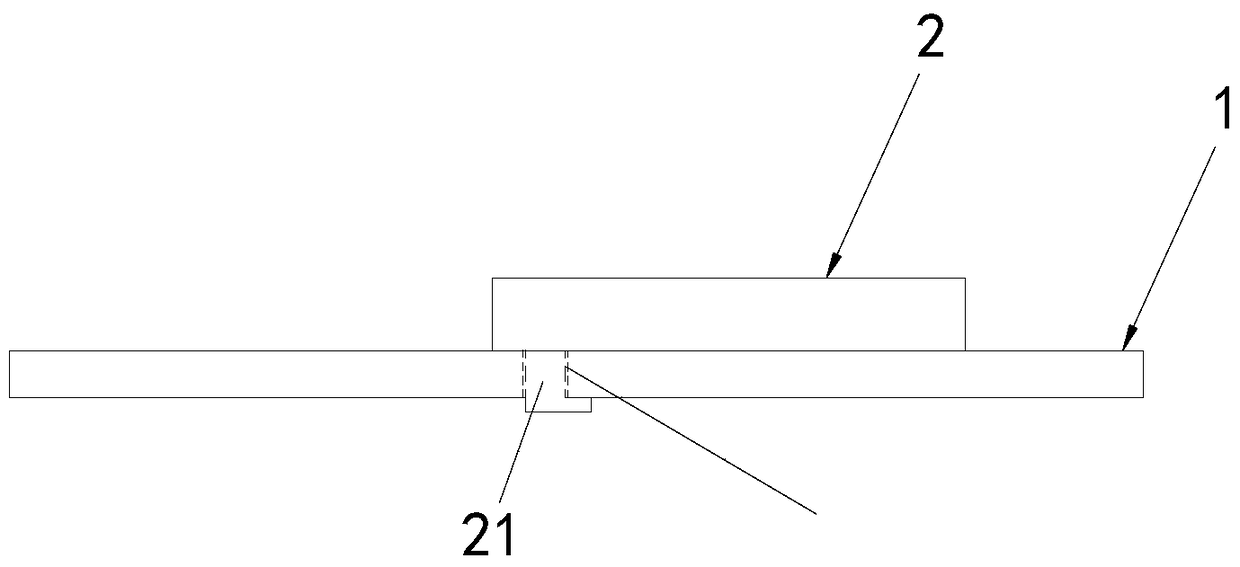

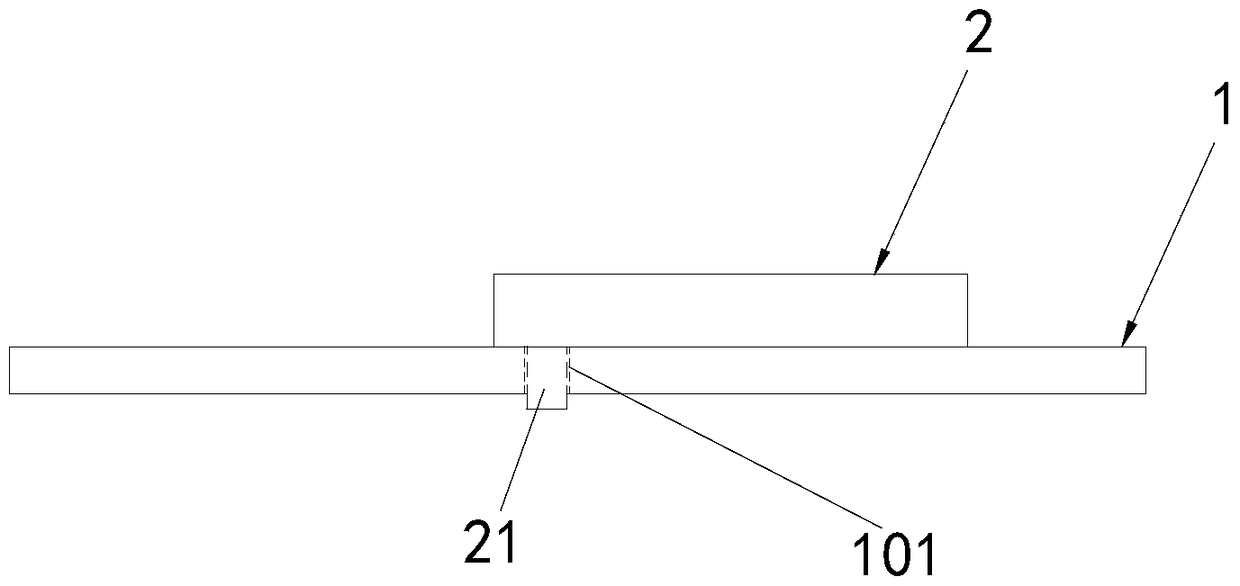

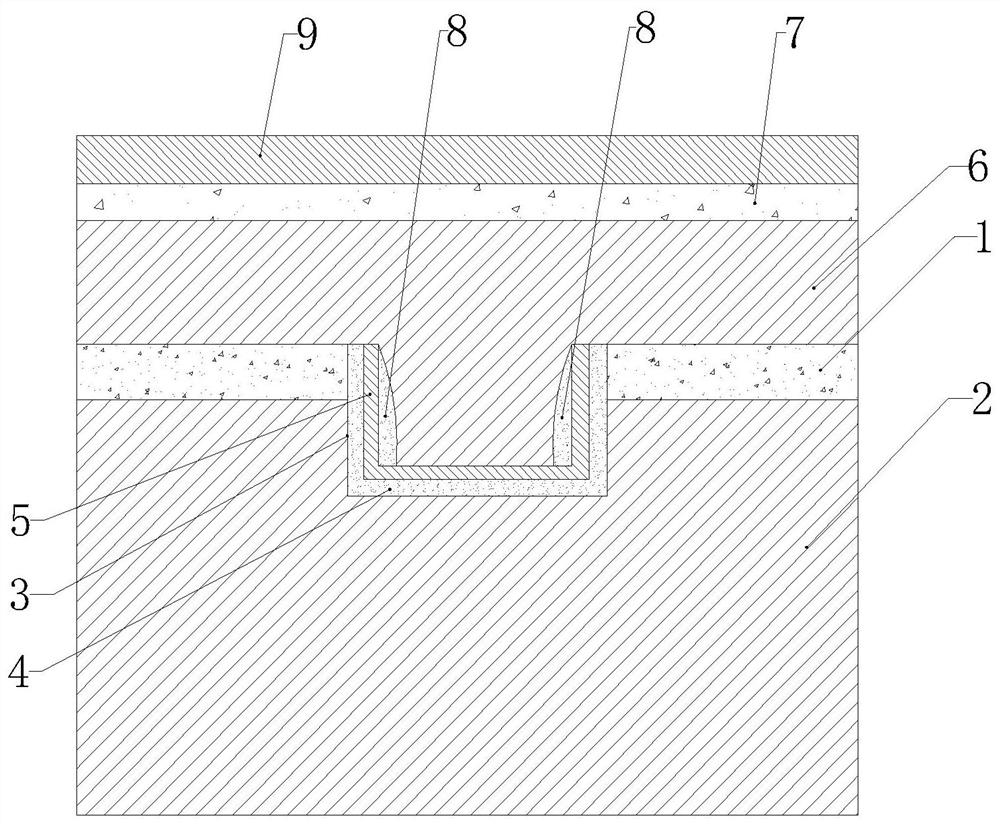

Battery grouping structure and battery pack comprising same

ActiveCN104576994AStable supportAchieving Conformance RequirementsCurrent conducting connectionsBatteriesElectrical batteryEngineering

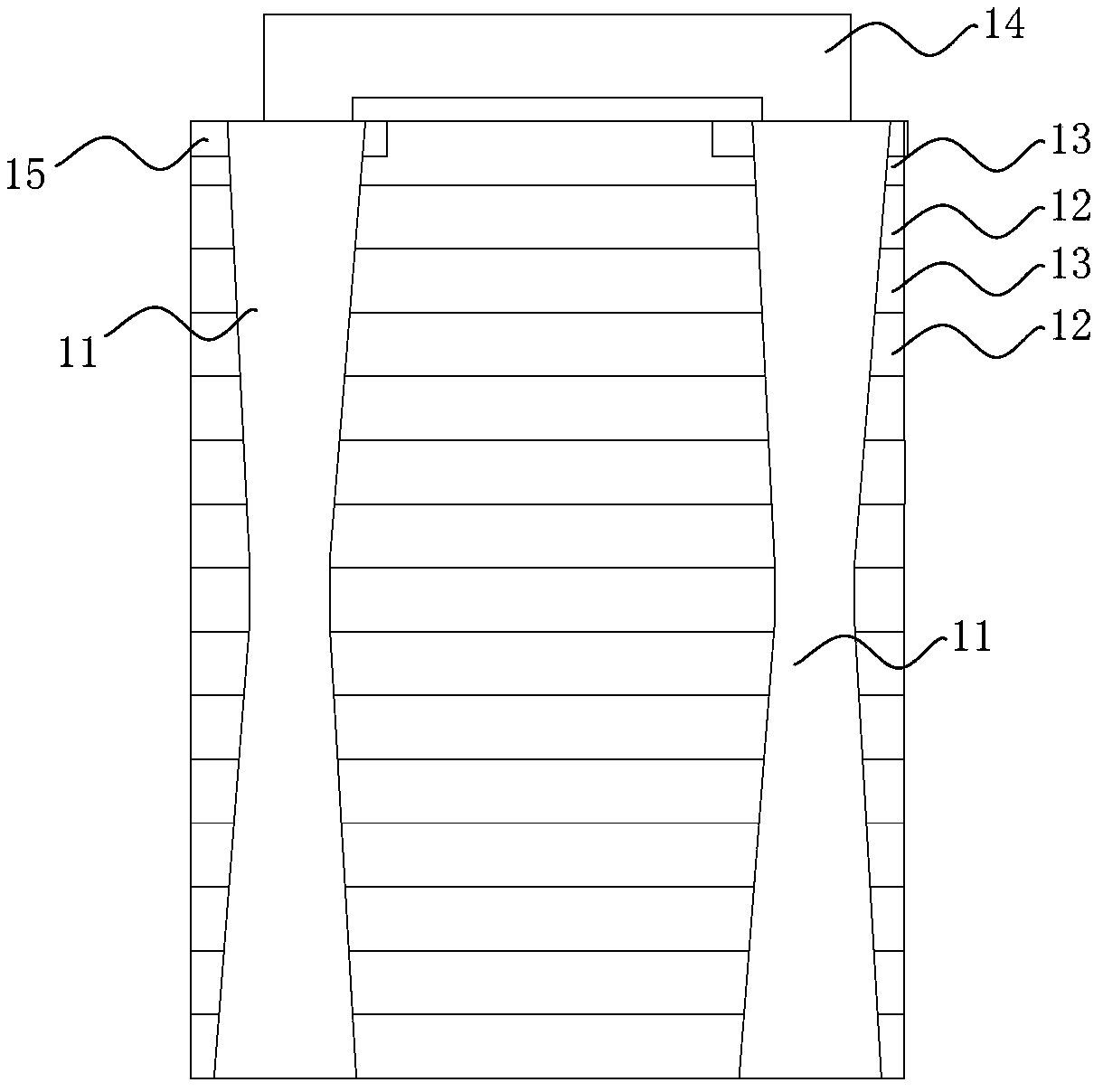

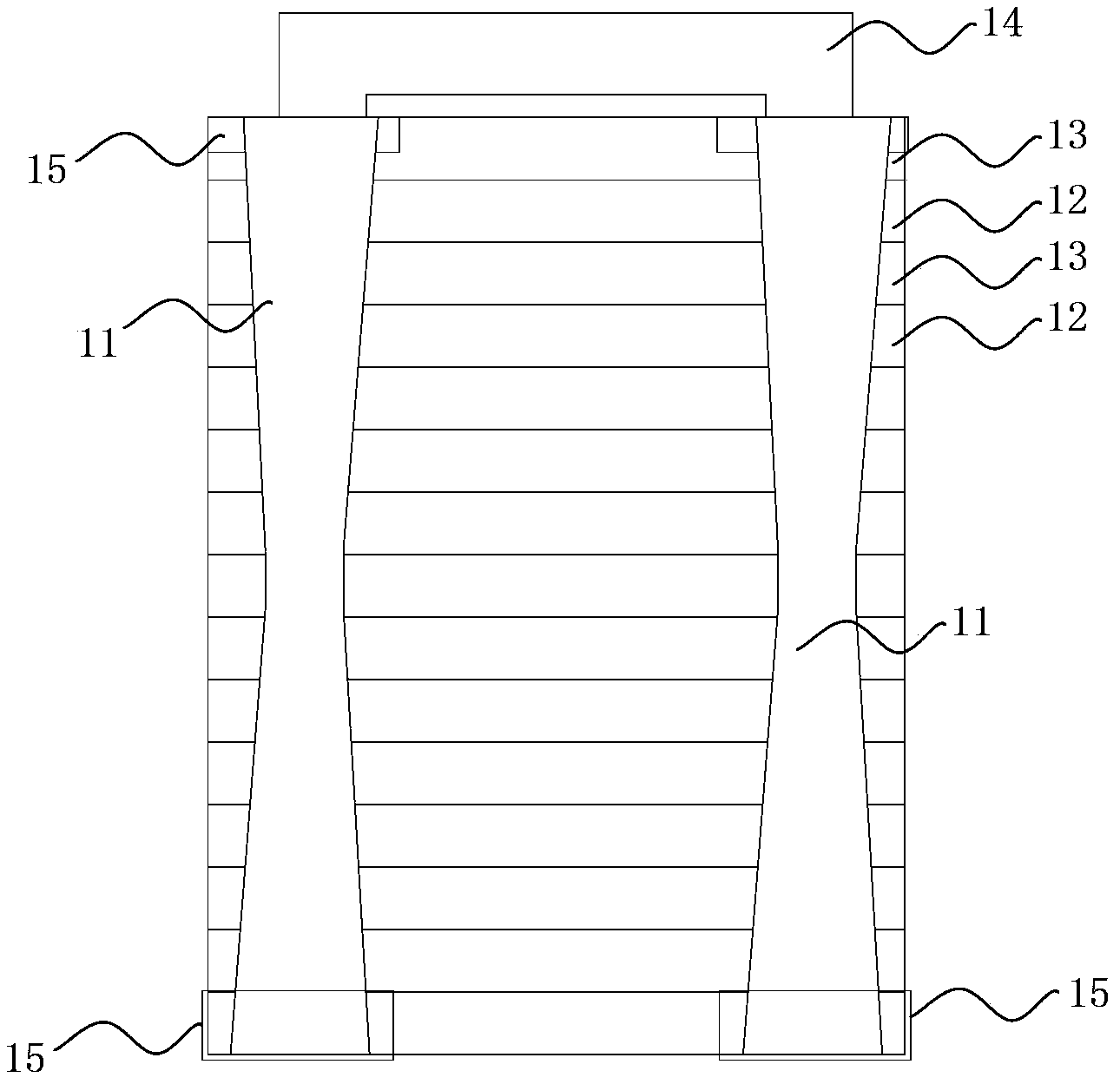

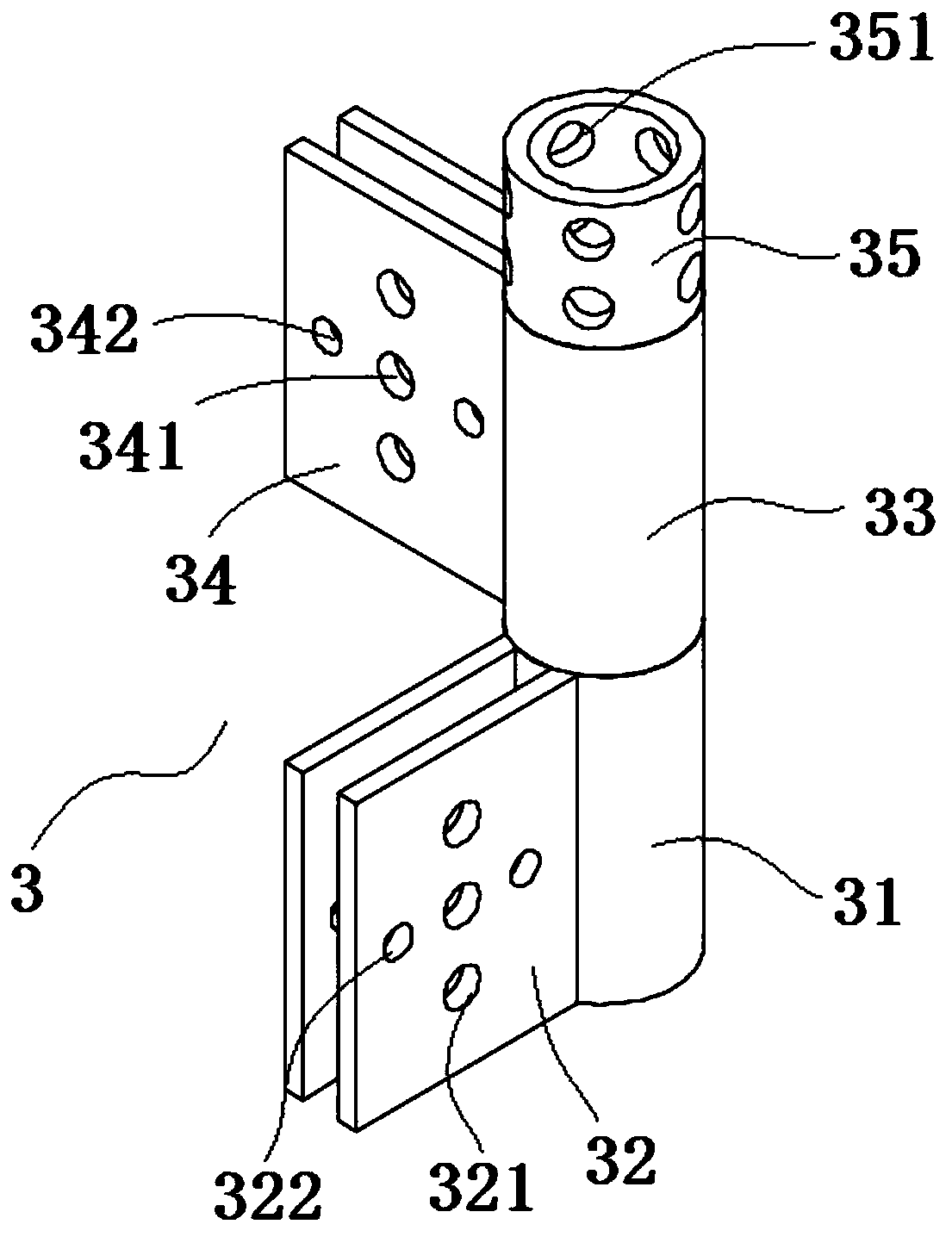

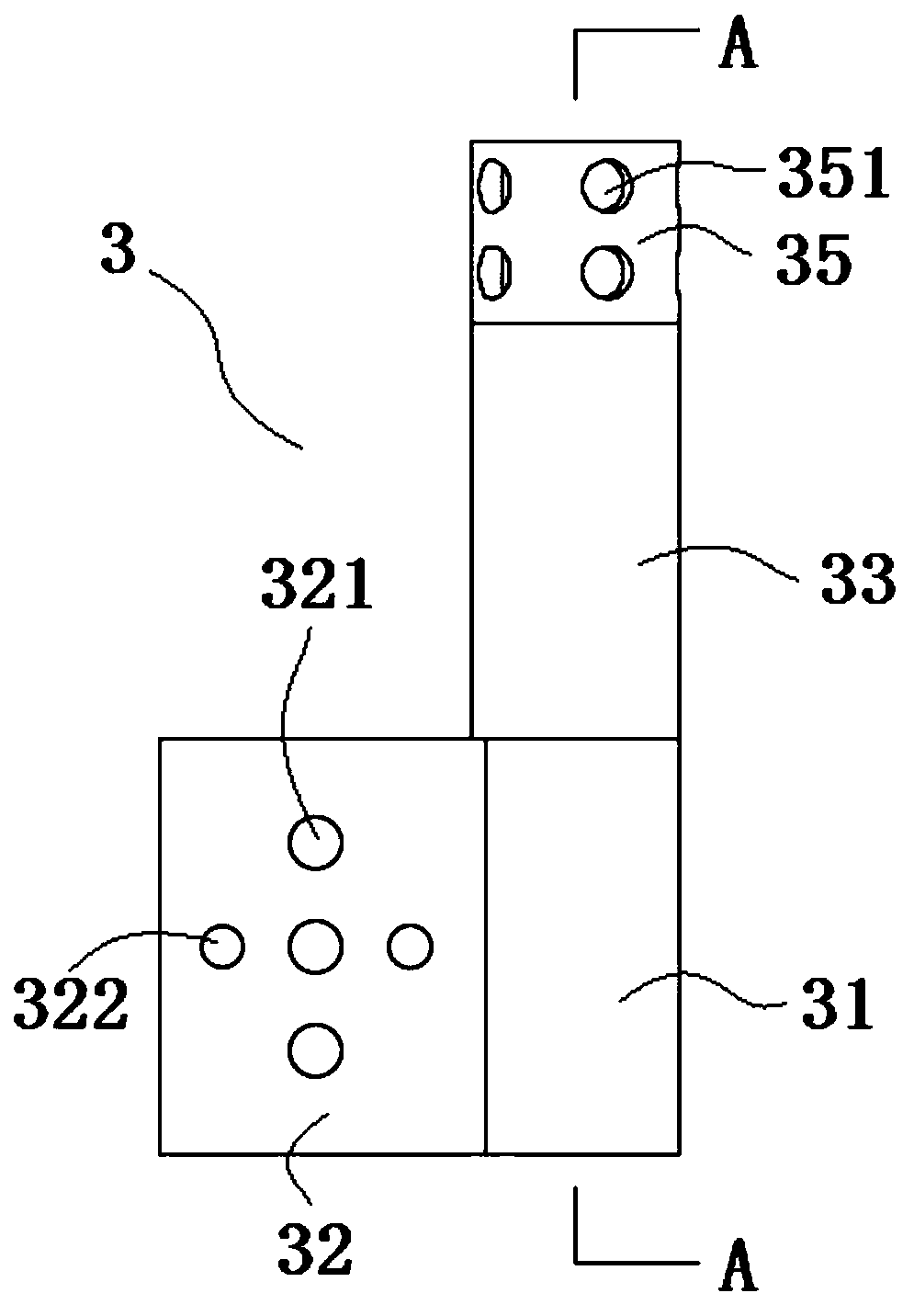

The invention discloses a battery grouping structure which comprises two fixing plates and a connecting plate, wherein the fixing plates can be arranged at two ends of a battery; the connecting plate can be arranged on one side surface, which deviates from the battery, of the fixing plates; at least one part of the connecting plate is conductive; fixing holes used for limiting the ends of the battery therein are formed in the fixing plates; through holes used for exposing the ends of the battery on one side surface, which deviates from the battery, of the fixing plates are formed in the bottoms of the fixing holes, so that the ends of the battery can penetrate through the through holes and are welded with the connecting plate; and a limiting groove used for limiting the welding position is formed in a position, which corresponds to the through hole, of the connecting plate. According to the battery grouping structure, the battery is clamped between two fixing plates, and a good effect of supporting the battery is achieved; and moreover, the through holes are formed in the bottoms of the fixing holes, so that the ends of the battery are exposed, the battery is fixed with the connecting plate in a welding mode, series-parallel connection among multiple batteries is realized by virtue of the connecting plate, and the grouping structure is fewer in parts, easy to operate and suitable for batch production.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

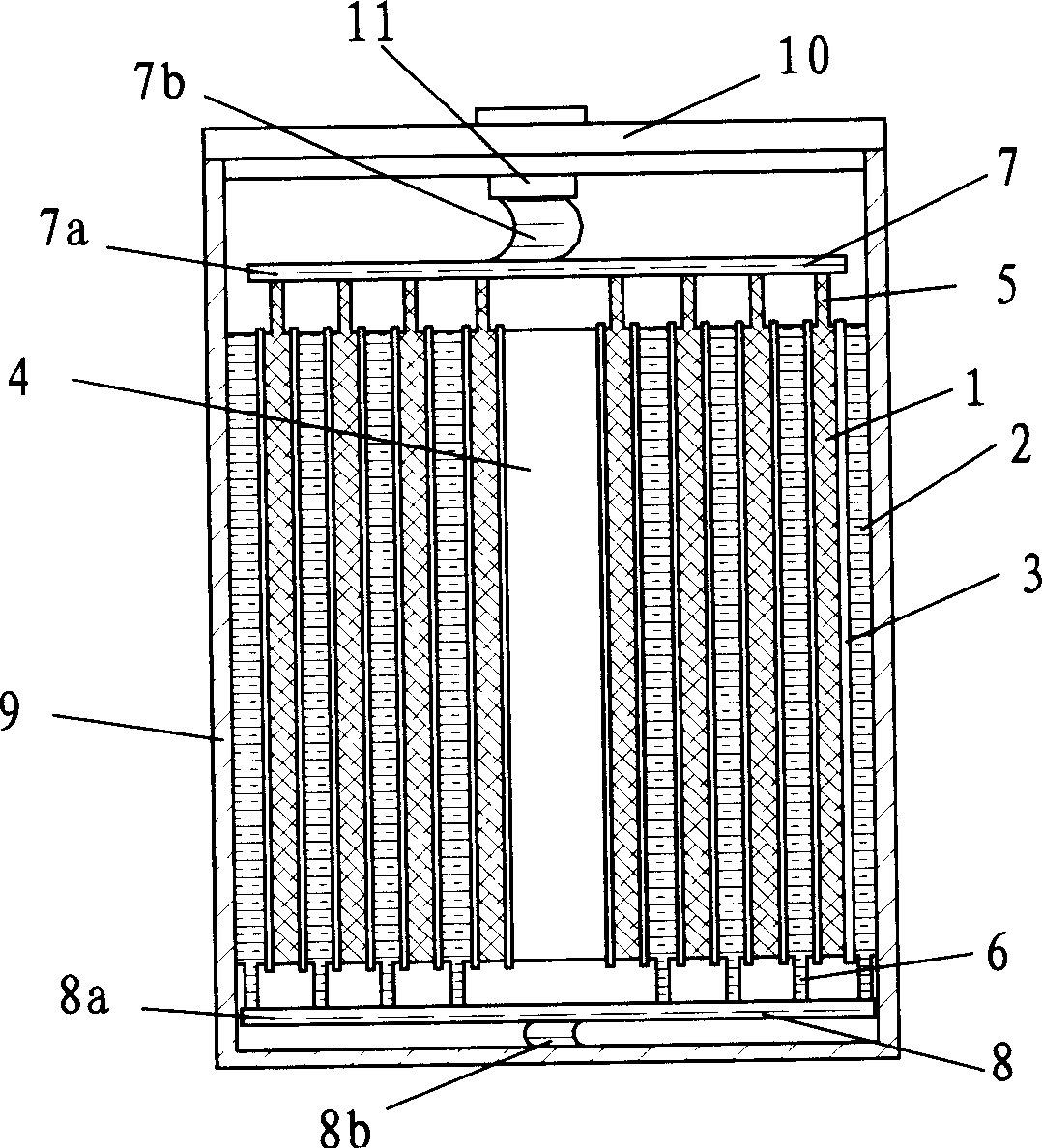

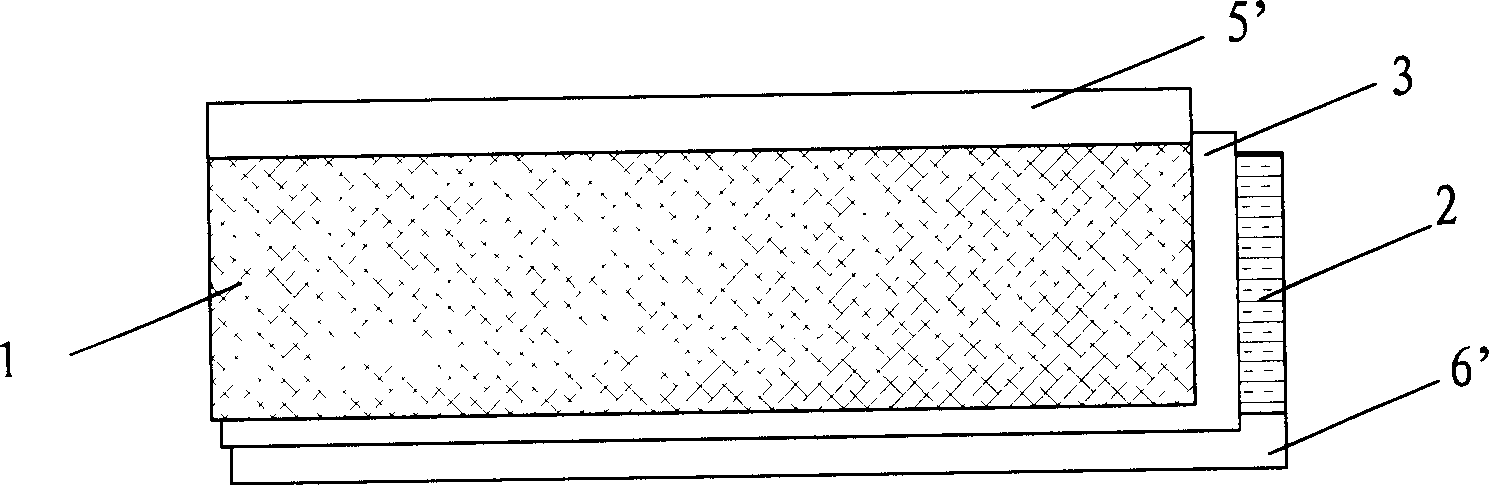

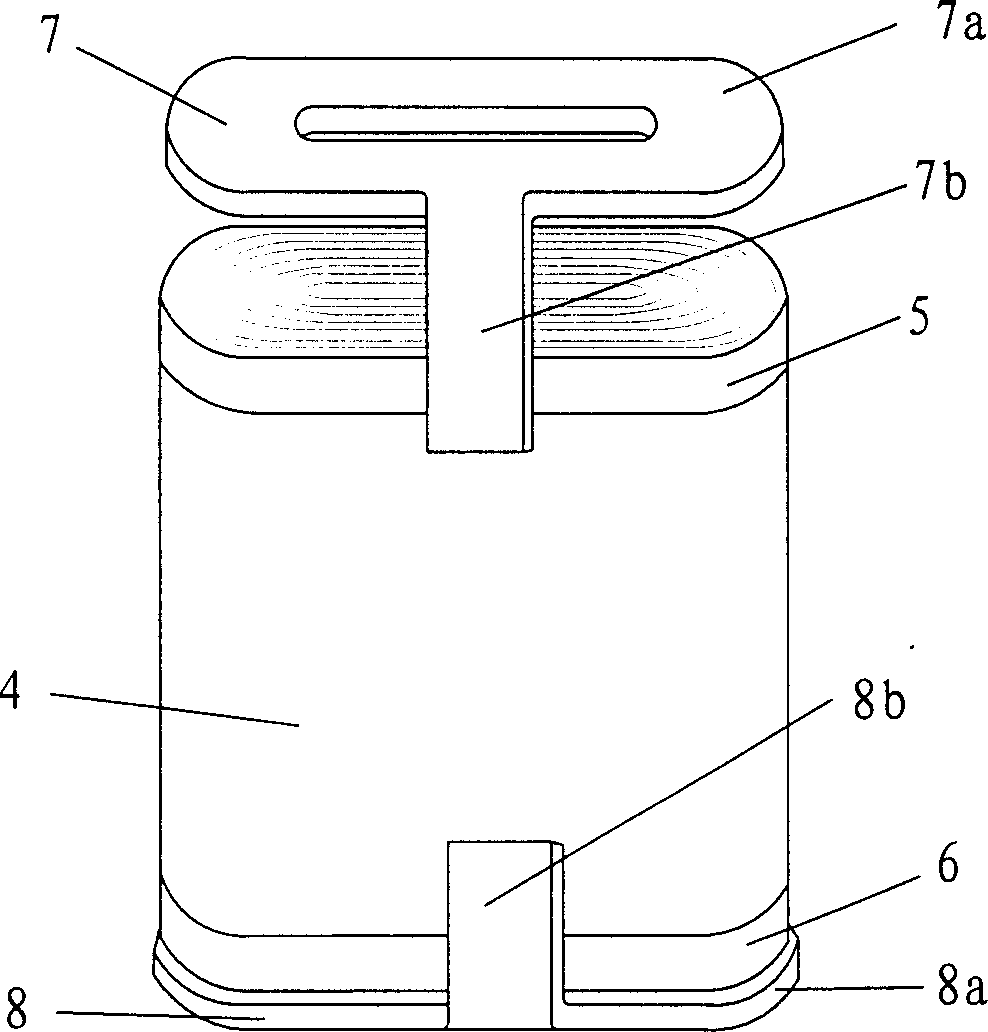

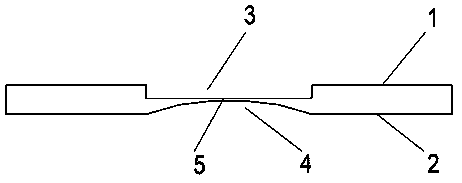

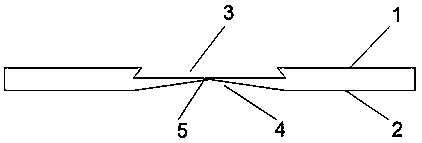

Lithium ion secondary cell

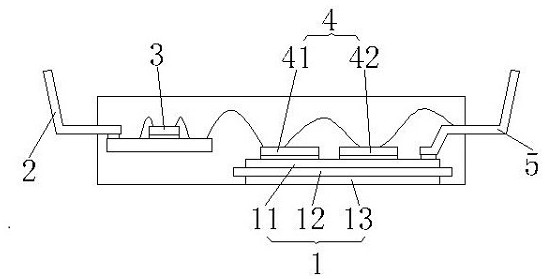

InactiveCN1532961AImprove connection strengthNot easy to desolderActive material electrodesLi-accumulatorsLithiumInternal resistance

A Li ionic secondary battery includes an electrode component composed a positive, a negative and membranes, a collecting component and electrolyte contained in a battery case, among which, the collecting component includes a connecting board and a lead-out plate, the face of the board is soldered together with the end face of an end collector of the electrode component in the way of sweating of immersing melted solders, one end of the lead-out plate is conducted with the connecting board, the other is linked with the battery pole, the collecting part has high connection strength, so sealing-off or short circuit would not happen.

Owner:BYD CO LTD

Method for welding ultra-pure copper target material and back plate

PendingCN112122763AImprove welding strengthIntegrity guaranteedNon-electric welding apparatusVery large scale integrated circuitsWeld strength

The invention discloses a method for welding an ultra-pure copper target material and a back plate. The welding method comprises the steps that coating of a welding surface of the back plate with a thread is performed; then the back plate and the ultra-pure copper target material are assembled; the assembled ultra-pure copper target material and back plate are put into a sheath; the sheath is sealed and vacuumized; the vacuumized sheath is subjected to hot isostatic pressing treatment; and welding of the ultra-pure copper target material and the back plate is completed. According to the method, as the structure of the welding surface of the back plate is improved, threaded protrusions can be embedded into the target material, and then a combination effect of the target material and the back plate is enhanced, then diffusivity of a coating film is utilized, and the target material and the welding surface of the back plate are fully covered, so that the welding combination degree betweenthe target material and the back plate is improved, and the welding strength is high; the coating film is placed on the back plate, so that completeness of the coating film is ensured during welding,and damage caused to the coating film by the threaded protrusions is avoided. According to the welding method, a hot isostatic pressing process is adopted to control the size of crystal grains of thetarget material, so that the target material meets application requirements of a super-large-scale integrated circuit.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

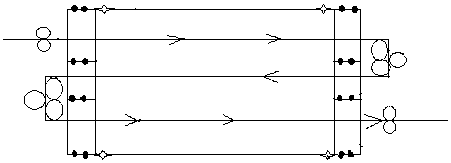

Electronic connector assembly electric plating process

The invention discloses an electronic connector assembly electric plating process, which sequentially comprises the steps of electric plating pretreatment, electric plating process and an electric plating post treatment process, wherein the electric plating pretreatment comprises the process steps of deoiling, water washing, activation and water washing. The electric plating process comprises theprocess steps of nickel plating and pure tin atomization; the electric plating post treatment comprises a drying process. A steel belt has the S-shaped trend; the occupied area is greatly reduced; about 1 / 2 of the production line cost is reduced; the phosphorus content in sulfate copper plating is very low, so that the plating layer combination is tighter; a manufactured electronic device cannot easily generate desoldering; the resources can be effectively saved; the safety of personnel is protected.

Owner:JIANGSU AOGUANG ELECTRONICS

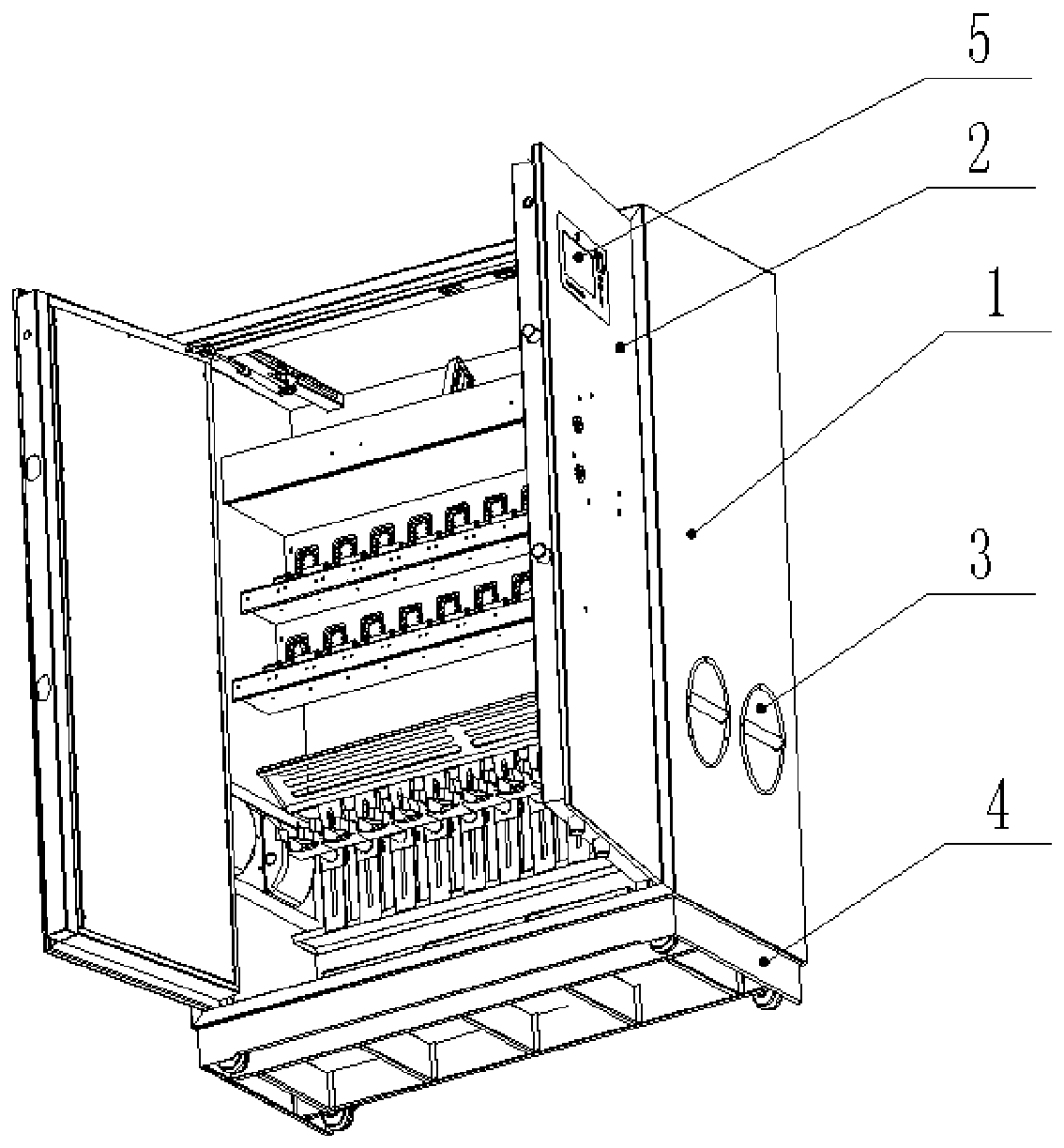

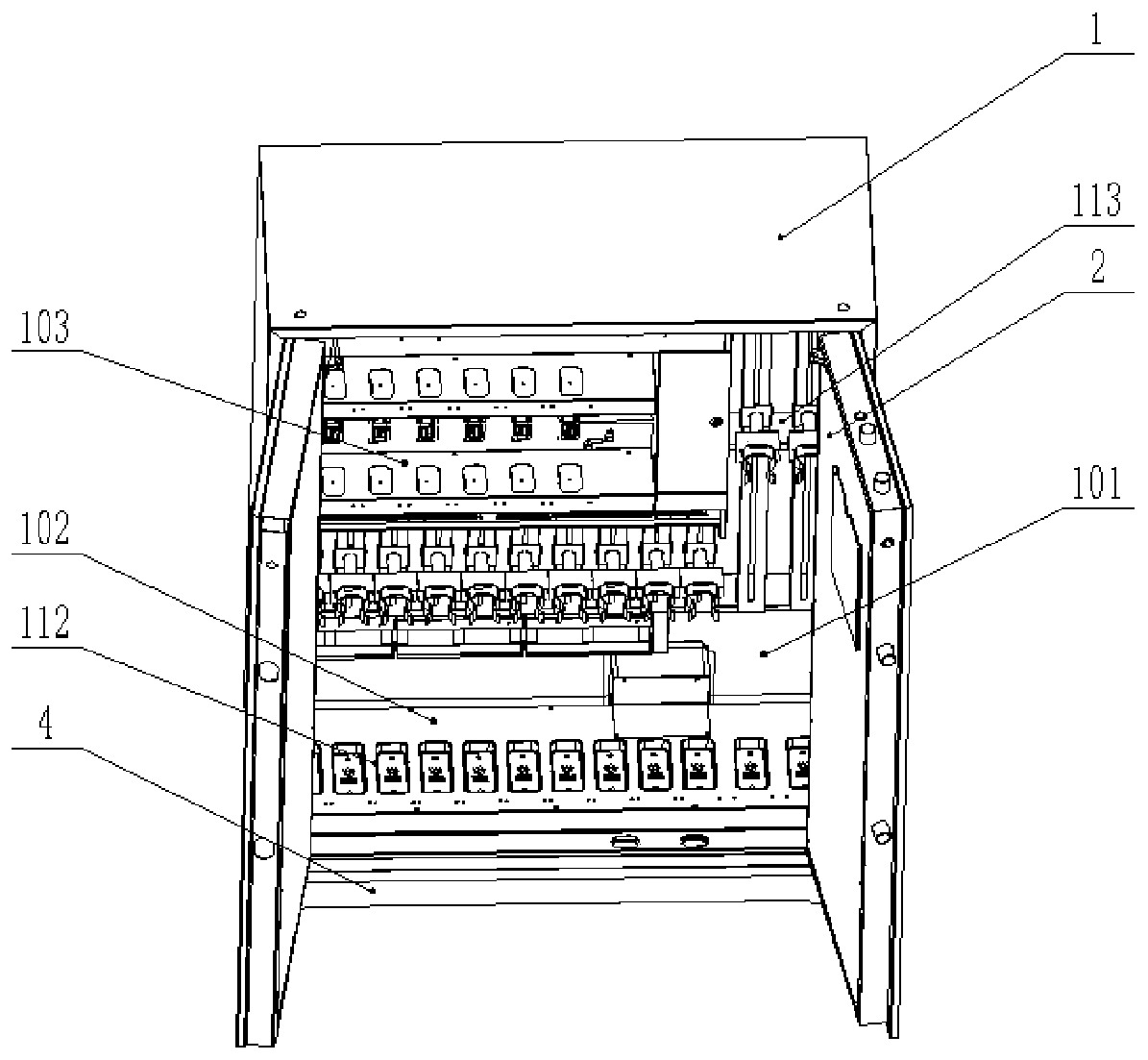

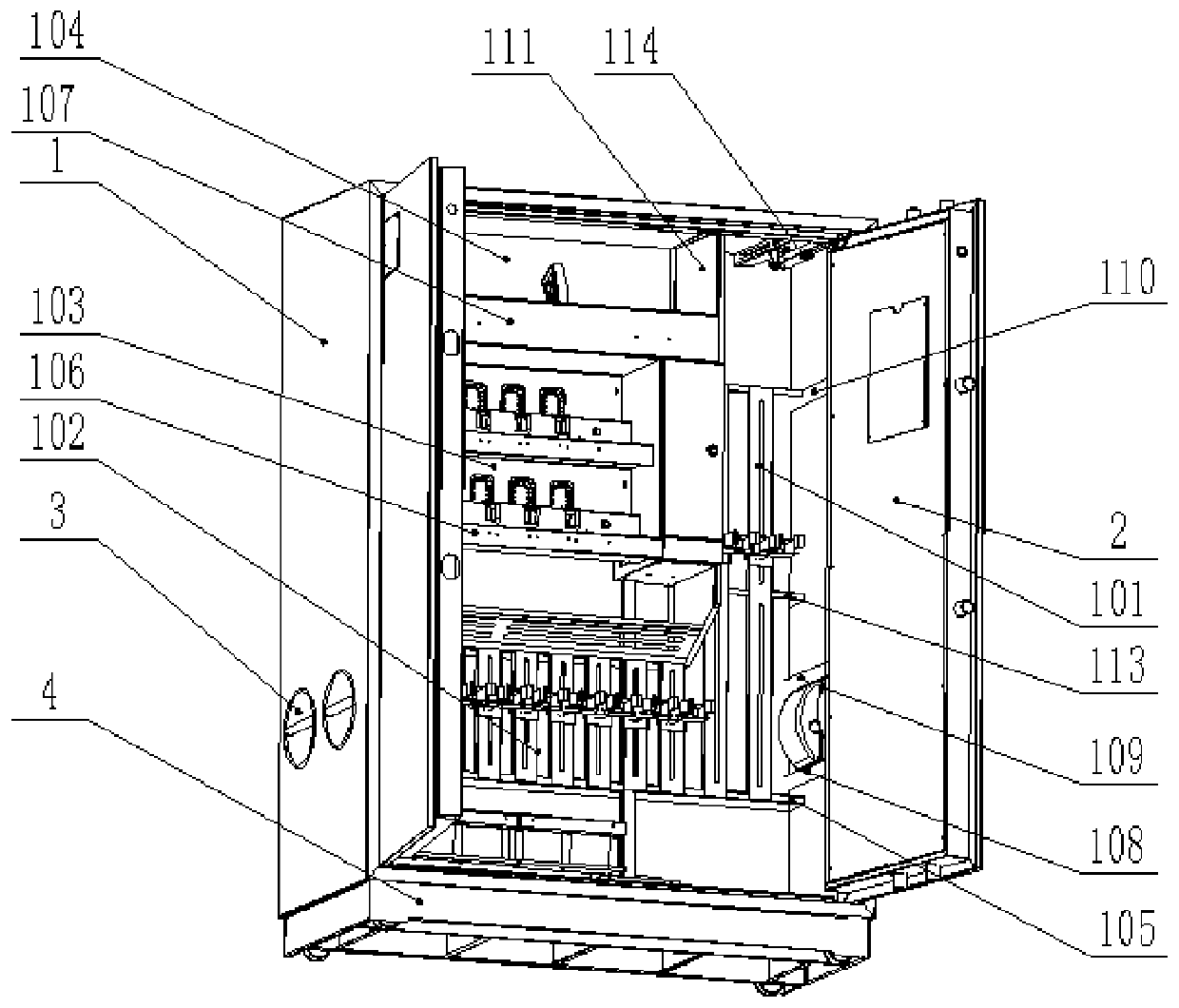

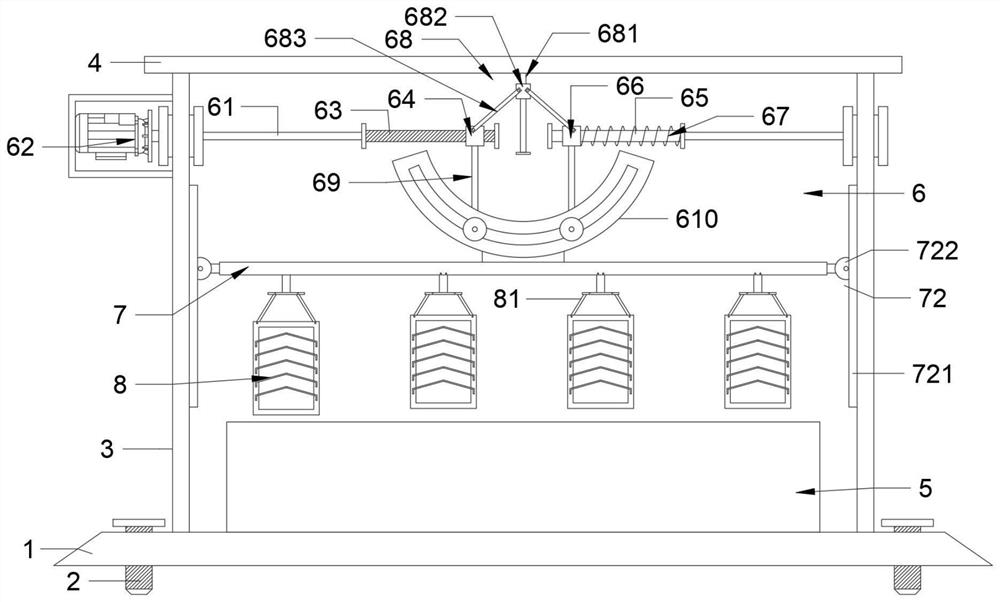

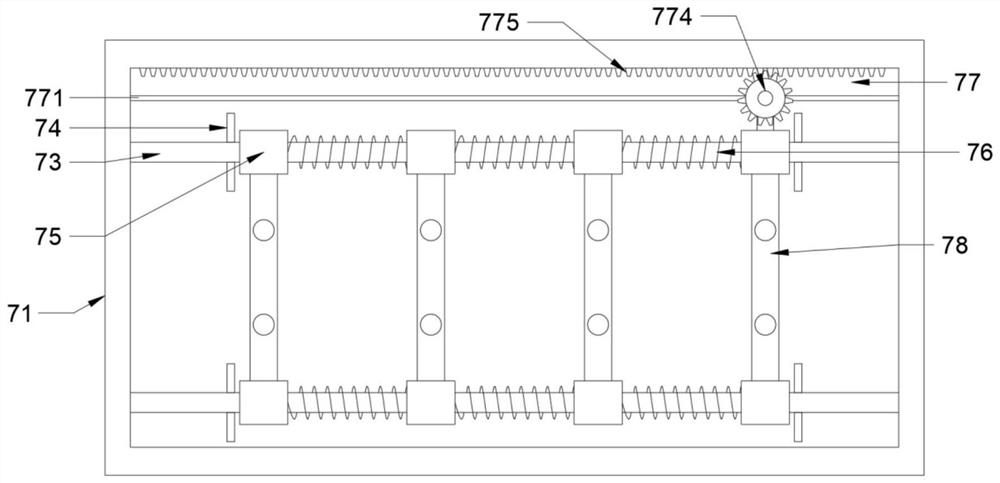

Multifunctional intelligent comprehensive anti-deformation bullet cabinet

PendingCN110051148AEasy to useEnsure decentralizationNon-mechanical controlsCabinetsChinese charactersElectromagnetic lock

The invention discloses a multifunctional intelligent comprehensive anti-deformation bullet cabinet. The bullet cabinet comprises a cabinet body, a base and a main control unit; the base is fixedly installed at the bottom of the cabinet body, and universal wheels are symmetrically installed on the base; the cabinet body and the base are of a structure layout shaped like a Chinese character 'jin',and all partition plates support and limit one another and have a high stabilization function on the cabinet body. Two unlocking modes such as an electromagnetic lock and a manual lock are adopted fora cabinet door, a manual lock mode with dual-direction authentication and dual-authentication is adopted for the electromagnetic lock, the decentralized management and authentication are guaranteed,and operation data is recorded in real time. Compared with products, with the same type, on the market, the cabinet has the qualitative technical progress. According to the cabinet, based on the humanengineering, a rotatable lifting hand is arranged, and the bullet cabinet accords with quick maneuvering processing.

Owner:湖南鑫垒科技有限公司

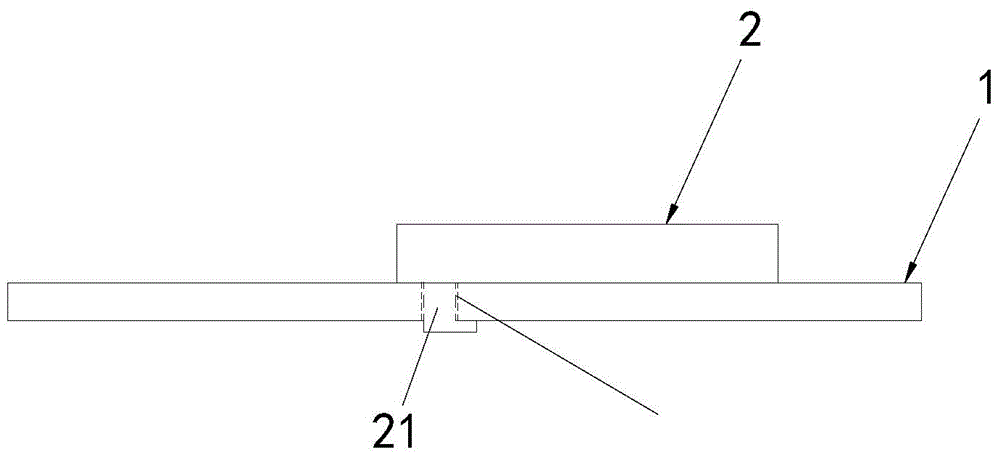

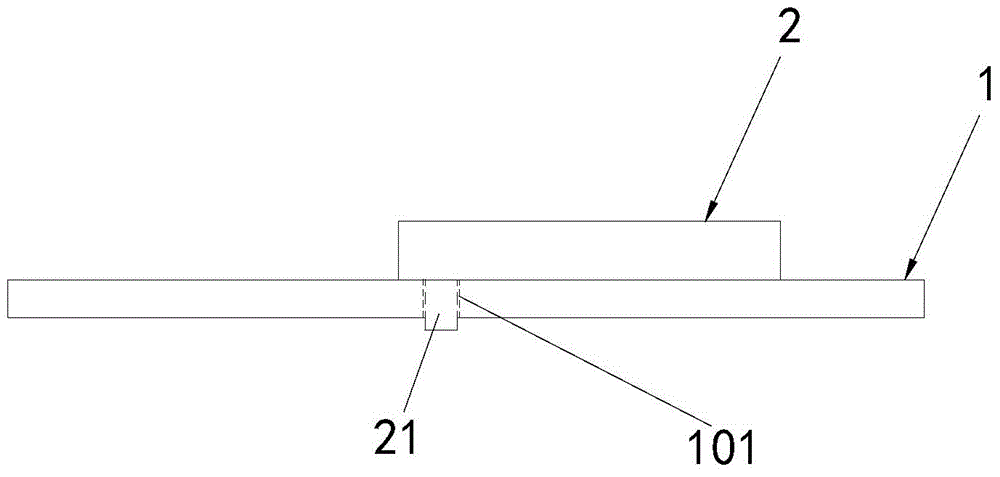

Encapsulation method of card seat and mobile terminal

InactiveCN105025129ANot easy to desolderImprove bindingPrinted circuit assemblingTelephone set constructionsComputer terminalEngineering

The invention is applied to the technical field of card seat encapsulation, and discloses an encapsulation method of a card seat and a mobile terminal. The encapsulation method comprises the steps as follows: preparing a card seat with plug pins and a circuit board with plating through holes, inserting the plug pins of the card seat in the plating through holes, and welding the plug pins of the card seat to the plating through holes. The mobile terminal comprises a mobile terminal main body and the circuit board arranged in the mobile terminal main body. The card seat is connected on the circuit board; the circuit board is provided with the plating through holes; the card seat is provided with the plug pins which are inserted in the plating through holes and are welded to the plating through holes. According to the encapsulation method of the card seat and the mobile terminal provided by the invention, the plug pins of the card seat could be inserted and weld in the plating through holes so that the card seat is not easy to be unsoldered even when the force for inserting and pulling the card is large or the card needs to be forcibly pulled under the condition that the card is inversely inserted to avoid the scrapping of a master board with excellent reliability.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

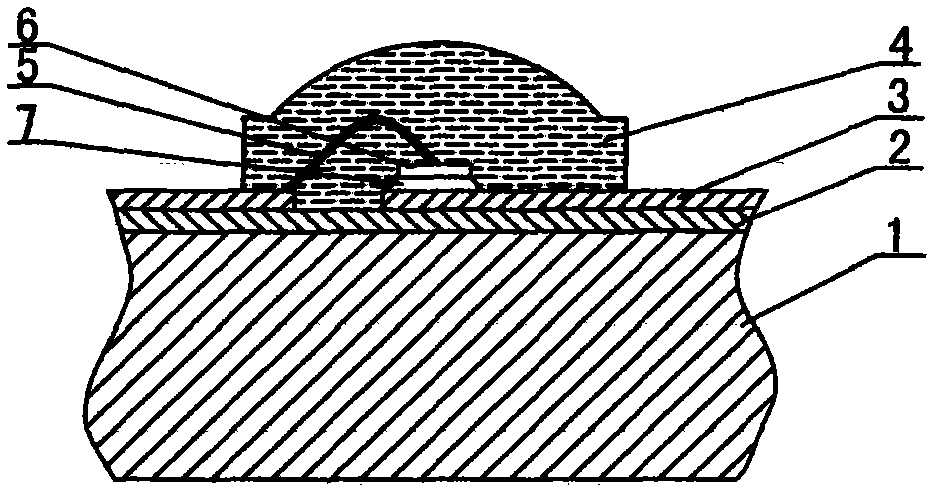

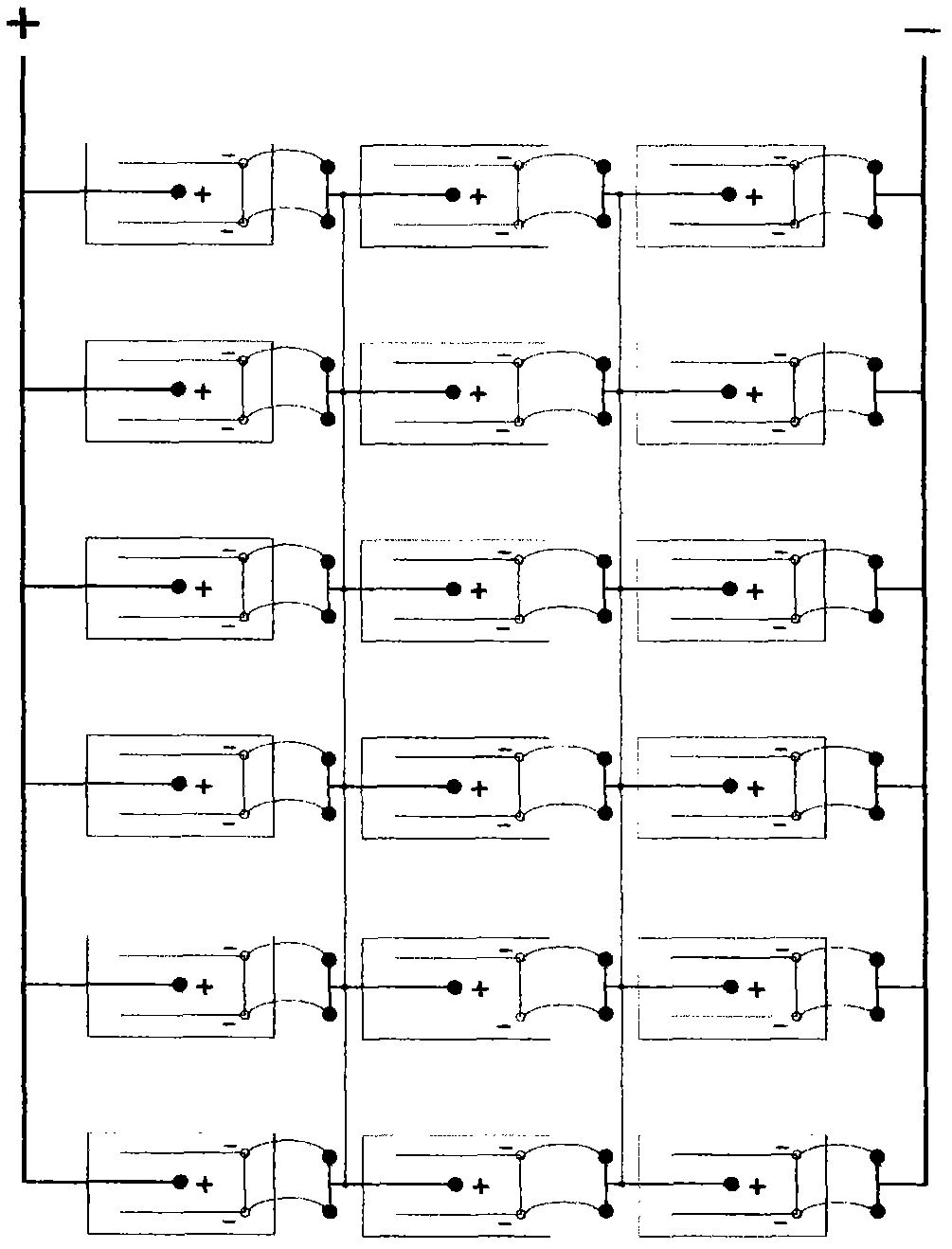

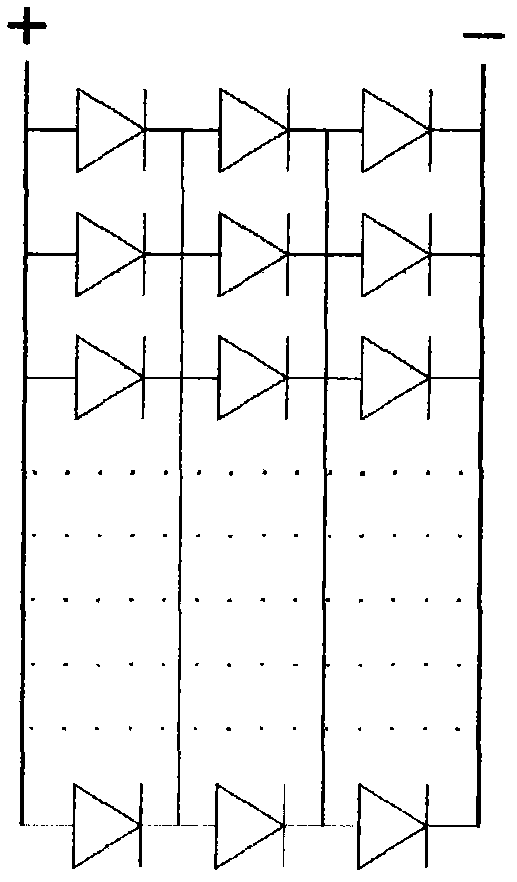

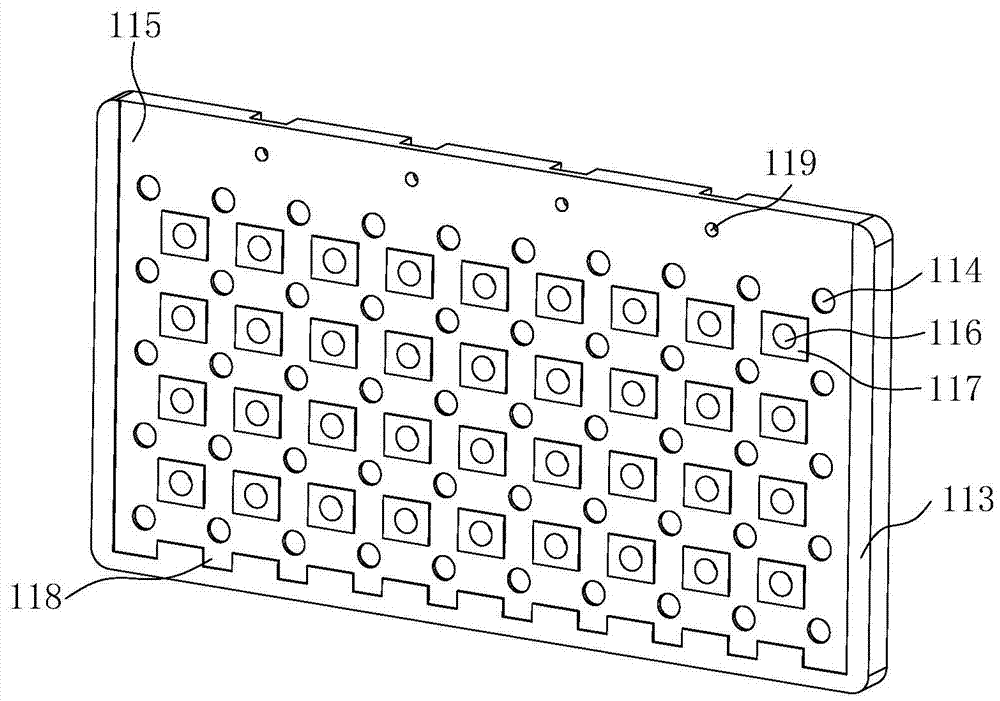

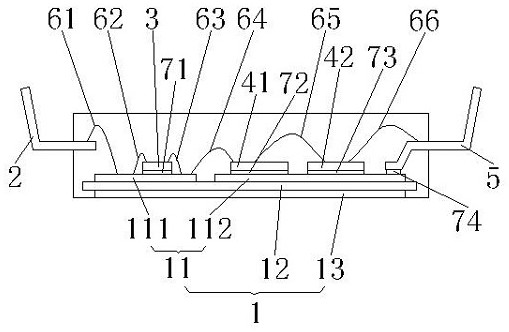

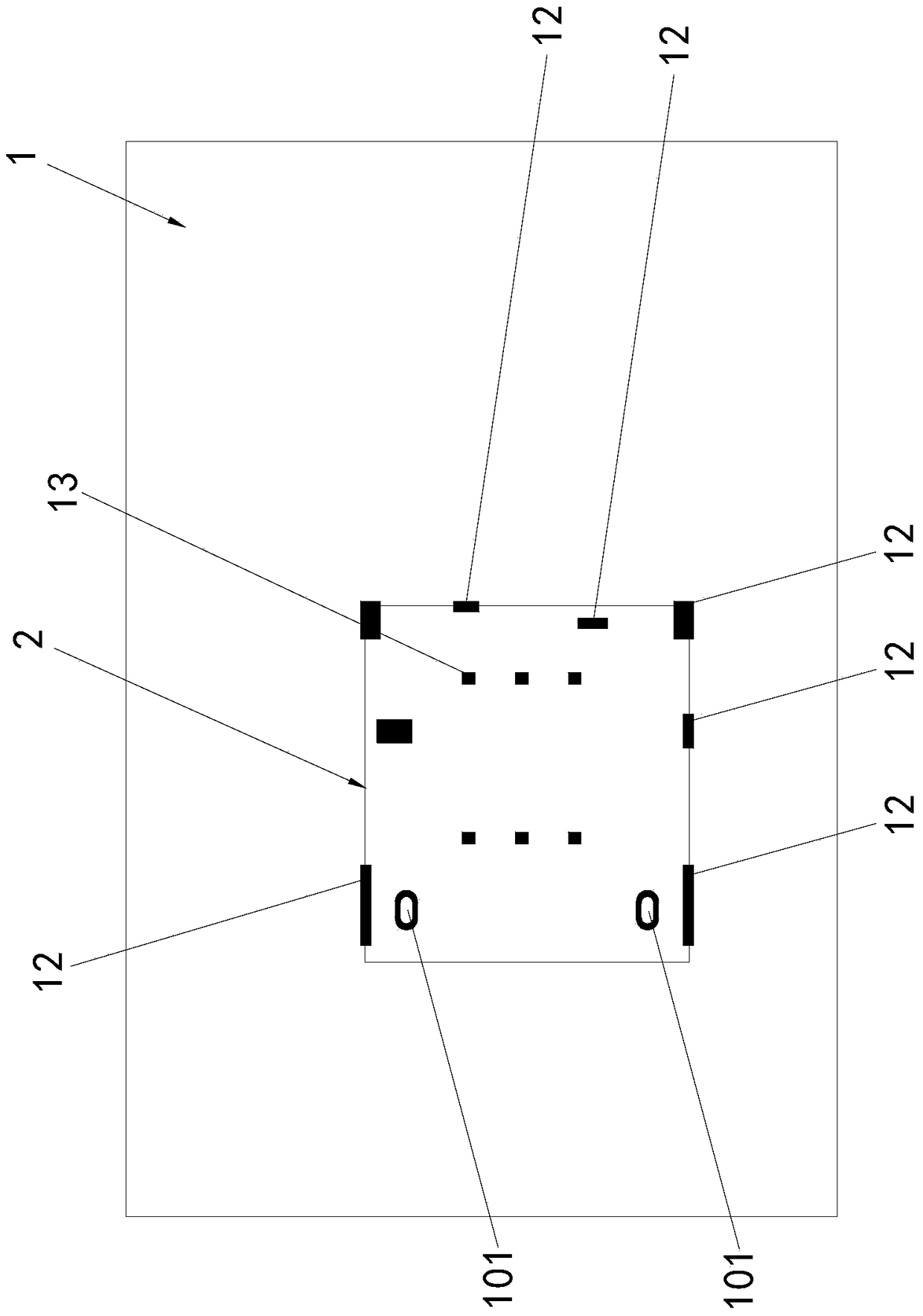

Multiple-chip array type chip-on-board (COB) inversely-installed eutectic packaging structure and method

InactiveCN103378079AShorten the cooling pathReduce thermal resistanceSolid-state devicesSemiconductor devicesEutectic bondingOn board

The invention relates to a multiple-chip array type chip-on-board (COB) inversely-installed eutectic packaging structure and method. The multiple-chip array type COB inversely-installed eutectic packaging structure comprises a ceramic heat-radiating substrate, a fluorescent powder and silica gel mixed packaging layer and light-emitting diode (LED) chips, wherein an insulating layer is arranged on the upper surface of the ceramic heat-radiating substrate, a circuit conductor layer is arranged above the insulating layer, and multiple LED chip connecting units are installed on the upper side of the ceramic heat-radiating substrate. Each LED chip connecting unit consists of a bonding layer, an LED chip and a gold wire shared by thermo-sonic keys, wherein the positive pole ends of the chips are in eutectic bonding with the bonding layers and connected with the circuit conductor layer, and the negative pole ends of the LED chips are connected with one end of the circuit conductor layer on the front side of the substrate through the gold wires. The multiple-chip array type COB inversely-installed eutectic packaging structure and method has the advantages of being excellent in heat-radiating effect and capable of avoiding the problems including chip defects or reduced luminous efficiency and the like caused by the different expansion degree of the chip and the substrate with heat, facilitating wire arrangement, reducing bonding temperature, improving the reliability performance and solving the problems of false welding and unsoldering of wires.

Owner:GUANGDONG JINYUAN LIGHTING TECH

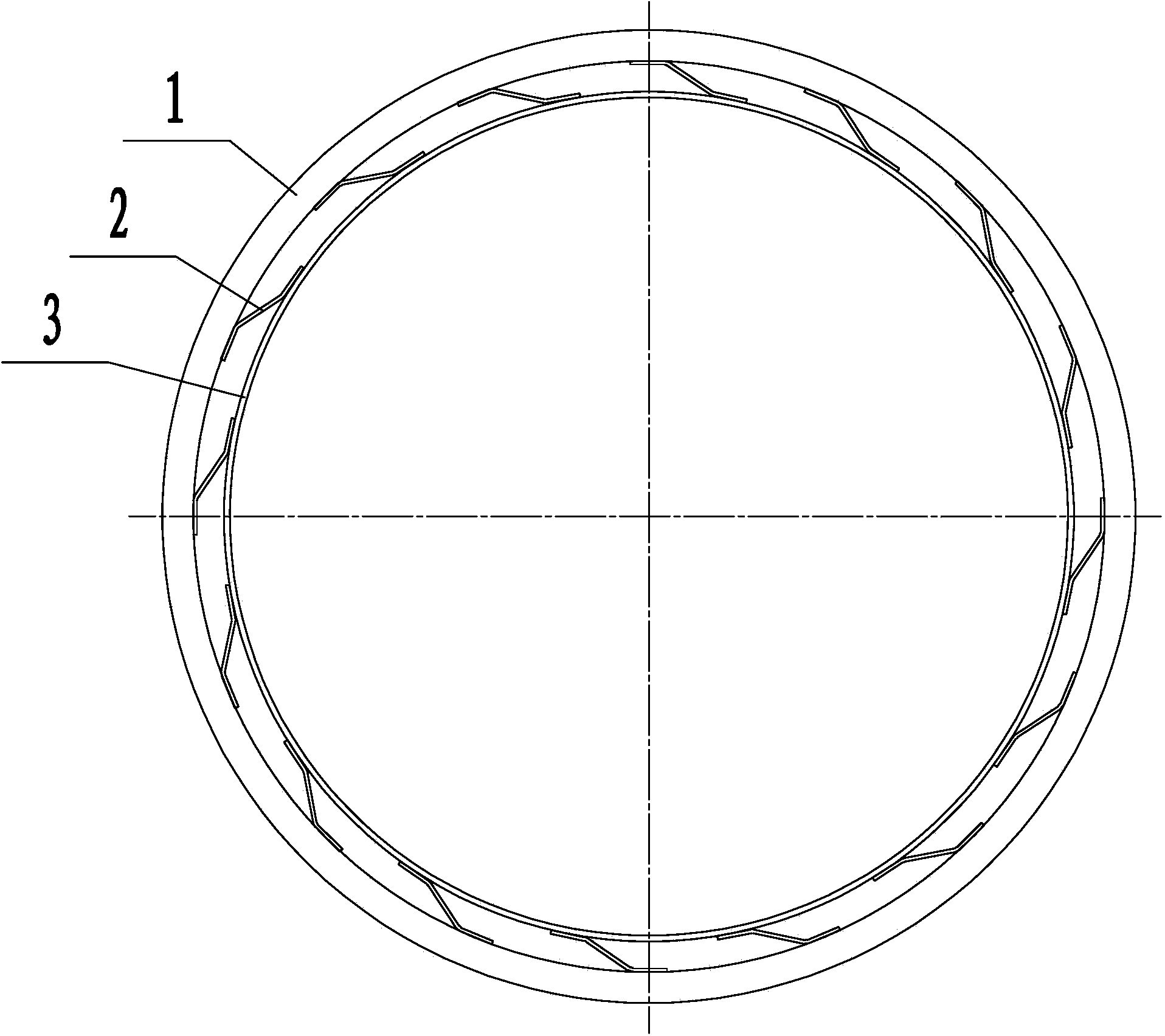

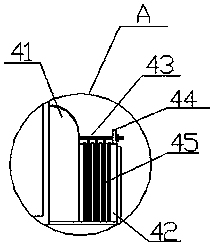

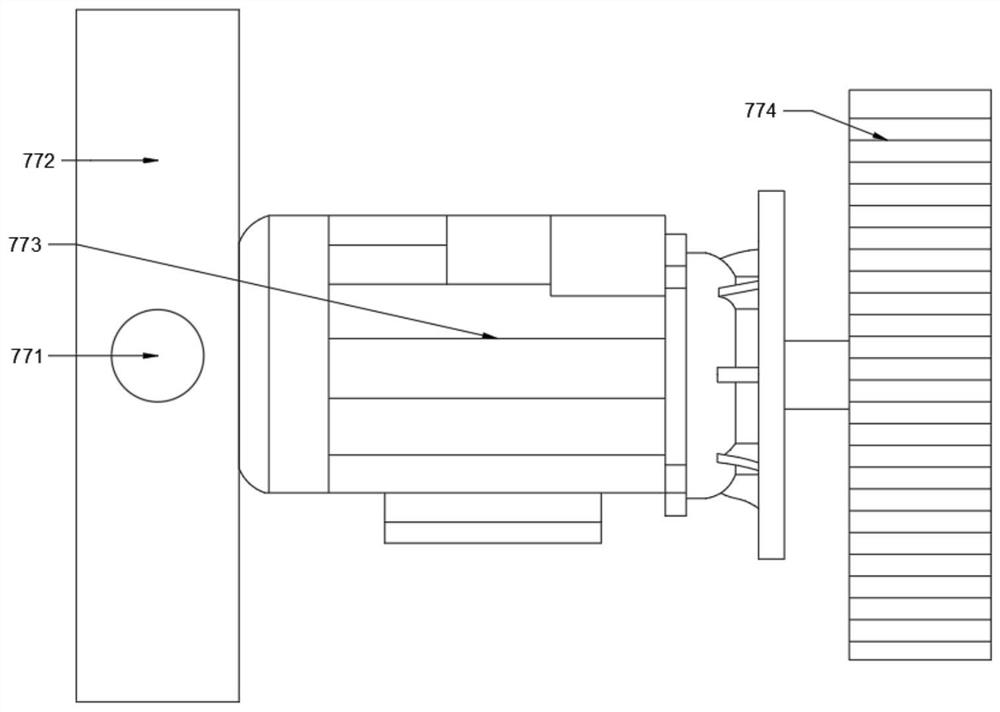

Elastic supporting structure of drying cylinder

InactiveCN104109994ANot easy to desolderSimple structureRoads maintainenceWhole bodyThermal expansion

The invention relates to an elastic supporting structure of a drying cylinder. The elastic supporting structure comprises a rolling ring, elastic plates and the drying cylinder, wherein the bottom surfaces of the elastic plates are soldered onto the drying cylinder, and the top surfaces of the elastic plates are soldered onto the rolling ring; the elastic plates, the drying cylinder and the rolling ring are combined to form a whole body; an external driver drives the rolling ring so as to drive the drying cylinder to rotate. The structure is simple and reasonable, and the probability of unsoldering of the elastic plate and the rolling ring is low. Meanwhile, as the elastic plates are flexible, when the drying cylinder is expanded with heat and contracted with cold, force can be directly applied to the elastic plates, the circular degree of the rolling ring is unlikely to be abnormal, asphalt stirrer equipment is not easily damaged, and the normal operation of the equipment can be ensured.

Owner:WUXI HUAZHONG TECH

Non adhesive aluminum honeycomb board

PendingCN107160747AImprove reliabilityNot easy to desolderMetal layered productsAdhesiveMechanical properties of carbon nanotubes

The invention belongs to the technical field of honeycomb boards, and in particular relates to a non adhesive aluminum honeycomb board including an aluminum honeycomb core, a panel and a bottom plate, the honeycomb core is arranged between the panel and the bottom plate, a solder layer is compounded on the inner side surface, opposite to the honeycomb core, of the bottom plate, the surface of the solder layer is provided with a soldering aid, the upper end face and the lower end face of the honeycomb core are in correspondingly brazed connection with the panel and the inner side surface of the bottom plate, and the non adhesive aluminum honeycomb board improves the welding effect, has the advantages of stable structure, good mechanical properties and no pollution, and can better meet the requirements of environmental protection.

Owner:江苏晟兴和金属板业有限公司

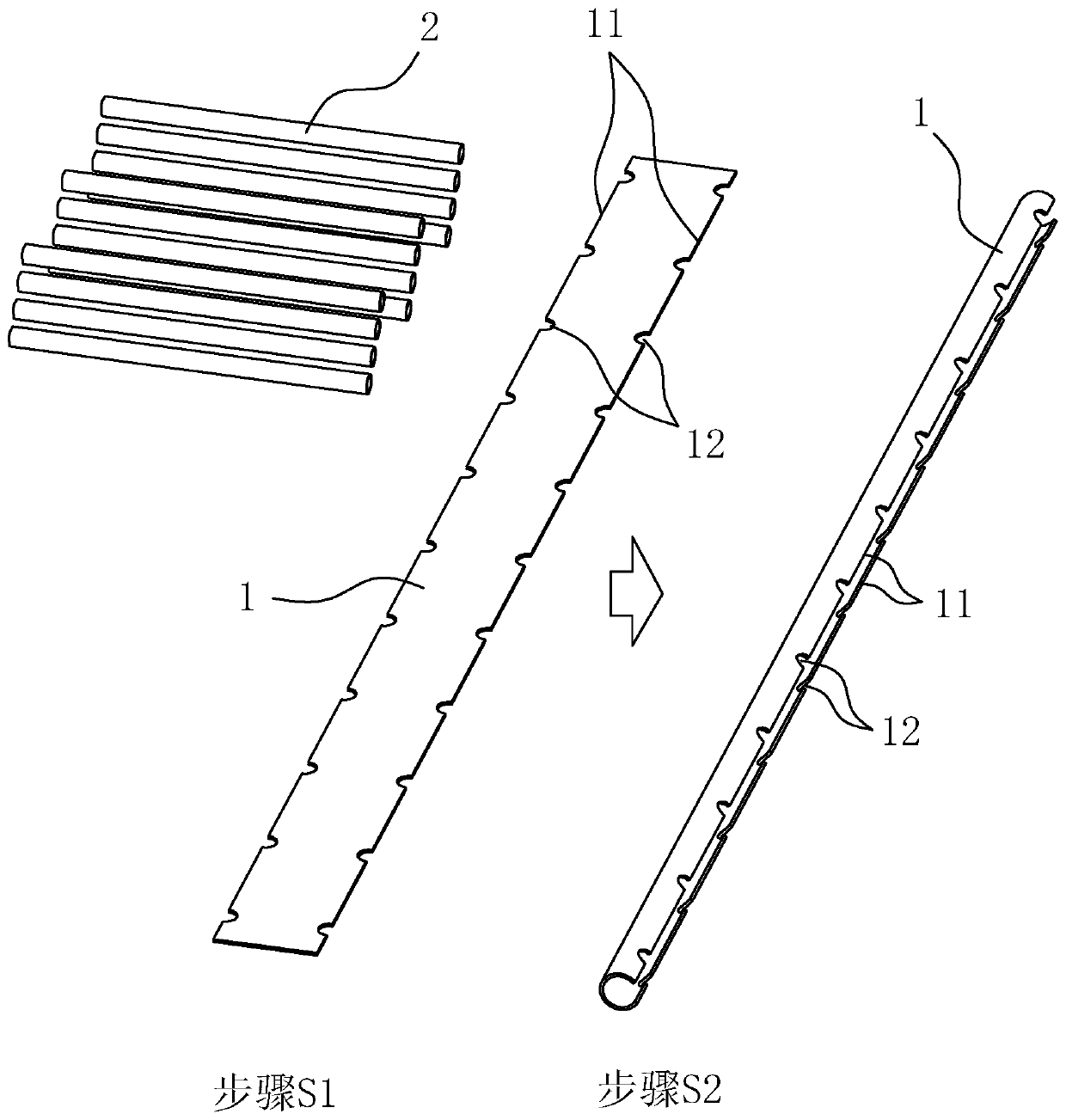

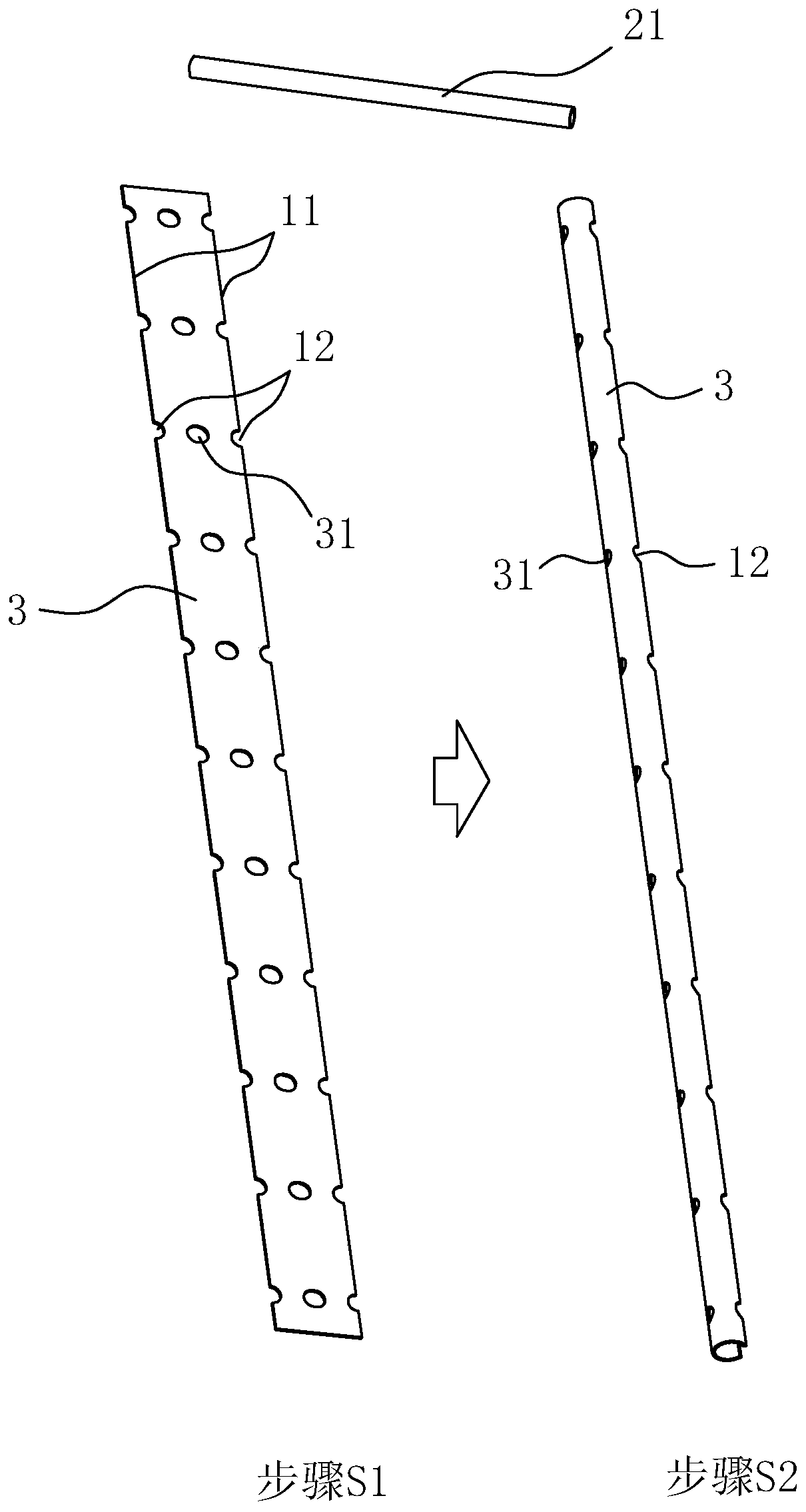

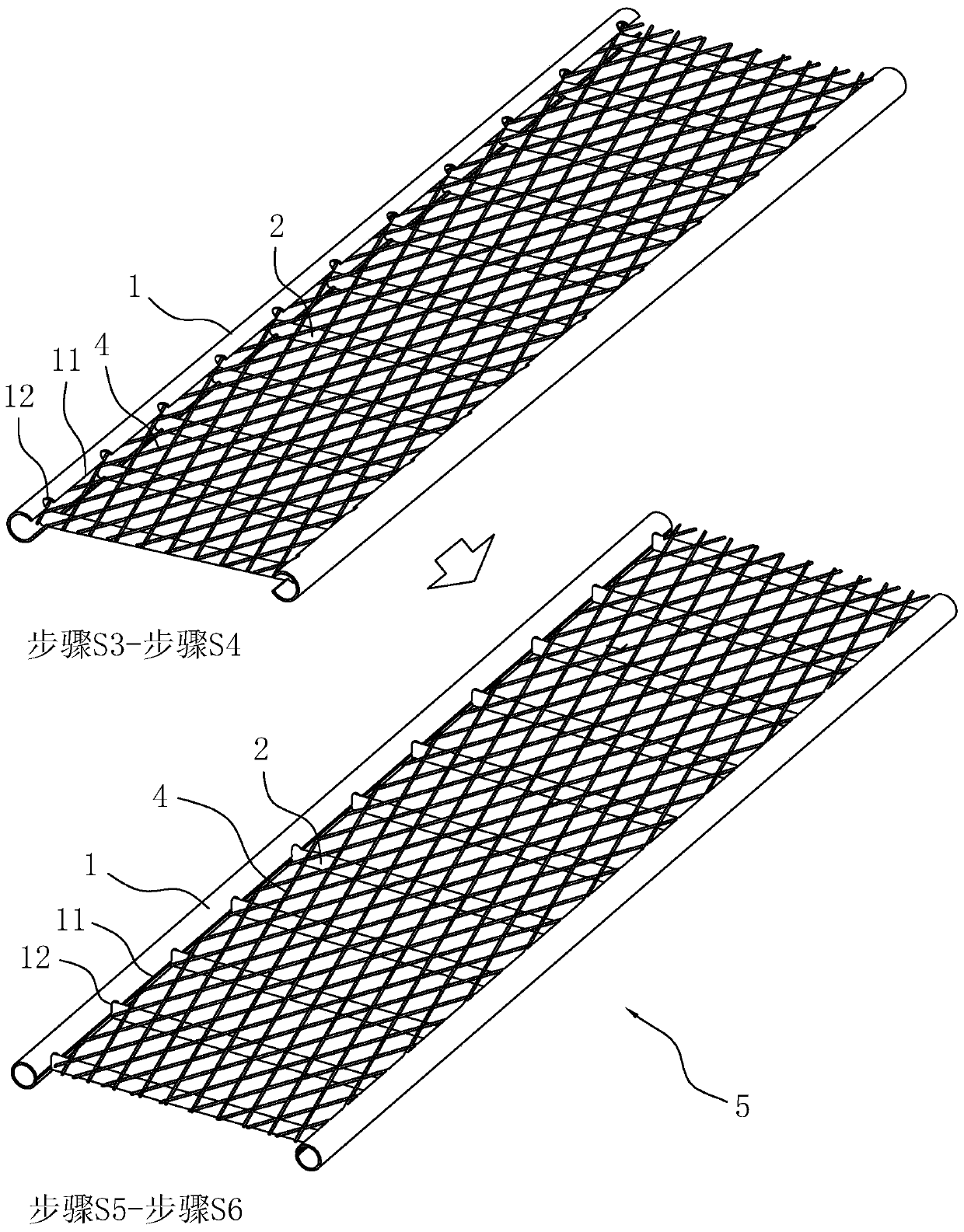

Scaffold production process

ActiveCN111215524AImprove the fixing strengthNot easy to desolderBuilding scaffoldsUltimate tensile strengthIndustrial engineering

The invention discloses a scaffold production process, and relates to the technical field of scaffolds. According to the technical scheme, the scaffold production process comprises the following stepsthat S1, a steel plate is taken, and blank parts are obtained by performing cutting or stamping on the steel plate, wherein two opposite sides, in the width direction, of each blank part are closed sides, and notches are formed in the closed sides; S2, the blank parts are curled through a plate rolling machine, so that the closed sides are close to each other, and the blank parts are curled intoa C shape; S3, two curled blank parts are taken, so that C-shaped openings of the two blank parts are opposite to each other, and cross rods are erected between the two blank parts; S4, a net plate isplaced on the cross rods, and the net plate extends into the C-shaped openings of the two blank parts; and S5, the blank parts are pressed through a press machine, so that the closed sides press thenet plate, and the notches are buckled to limit the cross rods. According to the scaffold production process, the fixing strength of the net plate is high, and the net plate is not prone to sealing off or damage when being stressed; and the production process has few requirements on the types of raw materials, and the utilization rate of the raw materials is improved.

Owner:上海森大机械制造有限公司

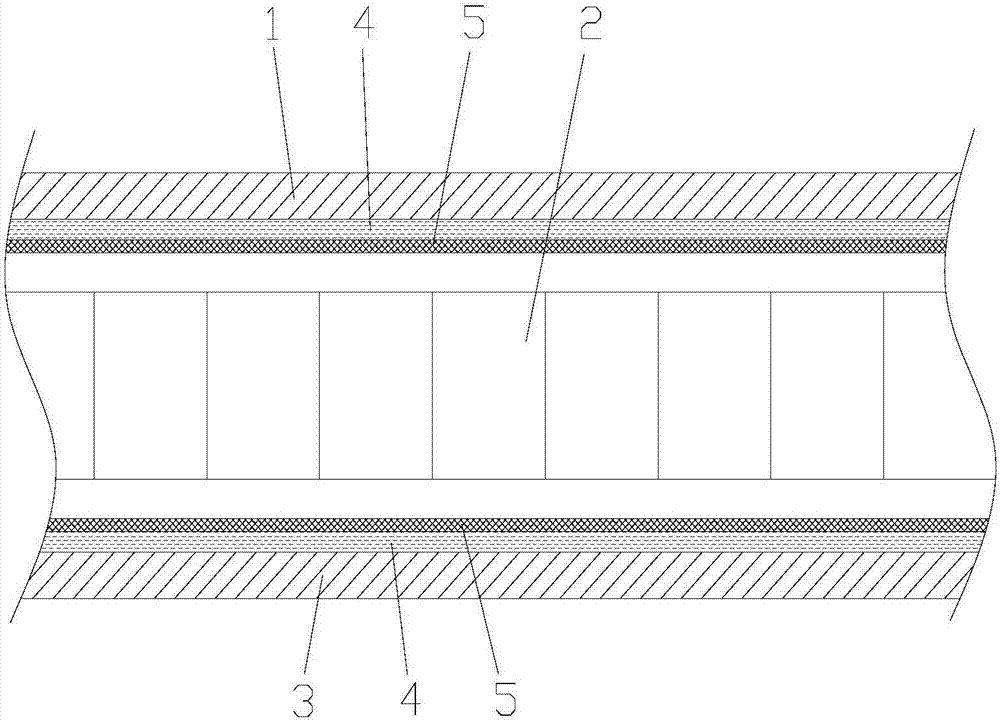

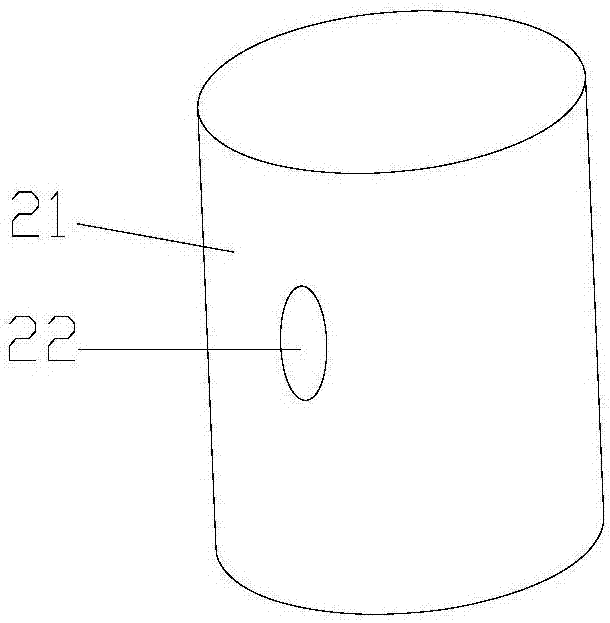

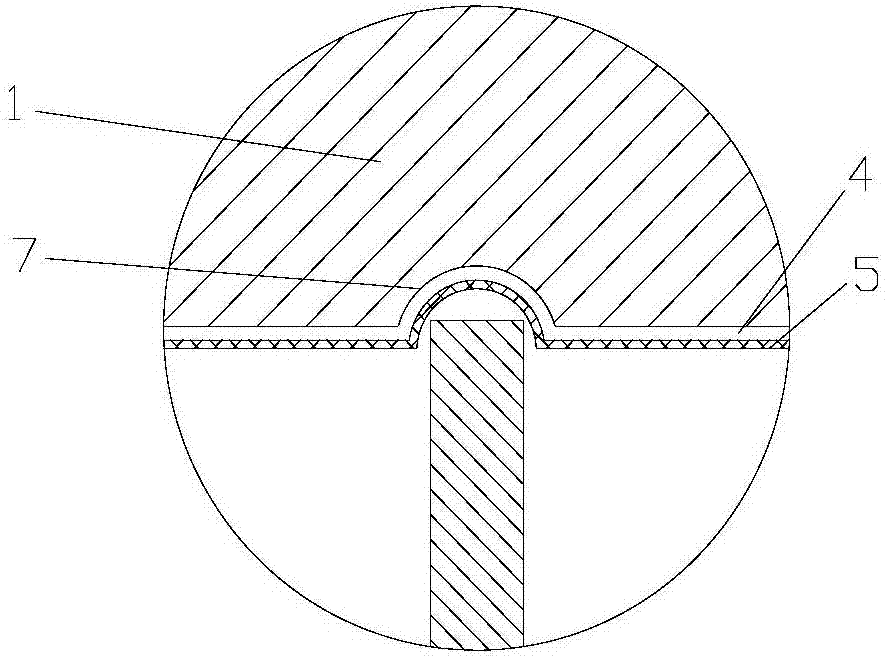

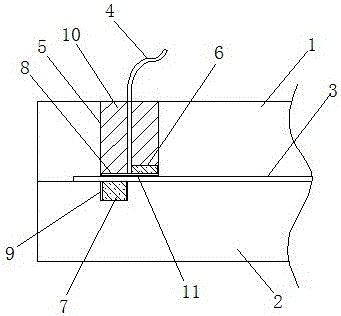

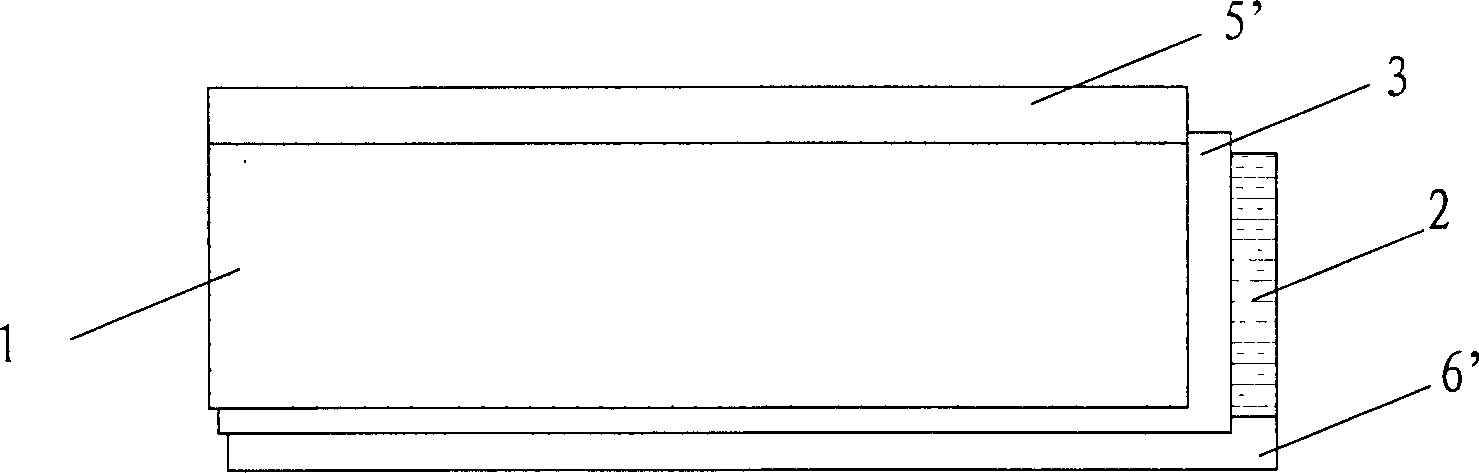

Convenient-to-remove electrode connection structure for electric heating floor

The invention discloses an easily detachable electric heating floor electrode connection structure, which comprises a base plate, a panel and a conductive heating layer arranged between the base plate and the panel, and the electrodes of the conductive heating layer are connected to a power supply through wires with conductive sheets welded at the ends , the bottom plate and the panel on both sides of the electrode are respectively provided with a hole and a B magnet, the hole is connected to an insulating plug, the wire passes through the insulating plug, the insulating plug is cylindrical, and it fits the conductive sheet The bottom end is also embedded with an A magnet, and the A magnet and the B magnet are respectively arranged on one side of the axis of the insulating plug. The invention staggers the A magnet and the B magnet by rotating the insulating plug to reduce the attraction force, the removal is very convenient, and the wire is not easy to desolder, which is convenient for reuse.

Owner:鄢贵龙

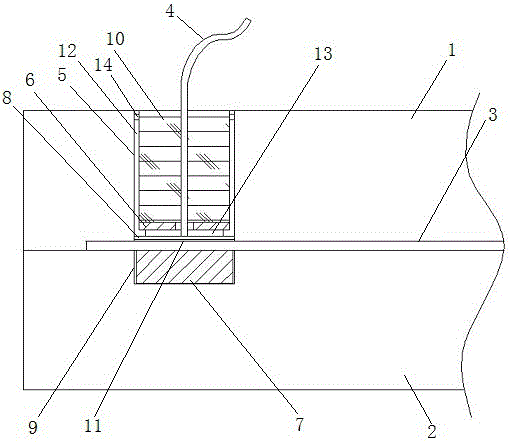

Convenient-to-remove electrode connection structure for electric heating floor

InactiveCN107438296AEasy to take and putNot easy to desolderHeating fuelOhmic-resistance electrodesEngineeringMagnet

The invention discloses an electrode connection structure of an electric heating floor which is easy to disassemble, which comprises a bottom plate, a panel and a conductive heating layer arranged between the bottom plate and the panel, and the electrodes of the conductive heating layer are connected to a power supply through wires with conductive sheets welded at the ends , the bottom plate and the panel on both sides of the electrode are respectively provided with holes and B magnets, and the wires in the holes are covered with A magnets and insulating plugs, and also include a cylindrical magnet seat connected to the hole, the magnet seat The closed end is provided with a wire perforation, the outer wall of the closed end is attached to the conductive sheet, the inner wall is attached to the A magnet, and the insulating plug is connected to the inner cavity of the magnet seat. When the invention is removed, the insulating plug is firstly taken out, and then the active force is applied to the movable A magnet through the magnet seat, so that the lead wires will not be desoldered and are convenient for reuse.

Owner:鄢贵龙

Electroplating technology

The invention discloses an electroplating technology. The electroplating technology sequentially comprises the steps of pretreatment before electroplating, the electroplating process and electroplating post-treatment, wherein pretreatment comprises the steps of oil removal, water washing, activation and water washing; the electroplating process comprises the steps of palladium and nickel plating,nickel plating, gold plating and pure matte tin; electroplating post-treatment comprises a drying process. A steel strip is in an shape, so that the occupied area is greatly saved, and the cost of a production line is reduced by about one half; the content of phosphorus in sulfate copper plating is extremely small, so that the bonding of a coating is tighter; an manufactured electronic device is not easy to deweld; resources can be effectively saved; the safety of personnel is protected.

Owner:JIANGSU AOGUANG ELECTRONICS

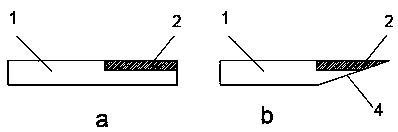

Method for machining tool billet

The invention discloses a method for machining a tool billet. The method comprises the following steps that (1) a substrate is produced, an inlay groove is formed in the upper surface of the substrate, and a high speed steel bar is arranged in the inlay groove, the depth of the inlay groove is equal to the thickness of the high speed steel bar, and a cutting planer groove is formed in the lower surface of the substrate and formed under the inlay groove; (2) the high speed steel bar is nested into the inlay groove in the main body of the substrate to be fixed; (3) the main body of the substrateinlaid with the high speed steel bar is welded, so that the high speed steel bar is firmly connected with the main body of the substrate; and (4) cutting is conducted, the welded substrate main bodyand the high speed steel bar are cut into two parts in the length direction of the cutting planer groove. The method can further save the raw material cost of a machining tool and improve the utilization rate of the material, meanwhile, can further reduce the cutting or planing workload of the follow-up work, further reduce the production cost, improve the production efficiency, and have outstanding economic and social benefits.

Owner:DONGE LIYUAN MACHINERY KNIFE

Lithium ion secondary cell

InactiveCN1248332CImprove connection strengthNot easy to desolderActive material electrodesLi-accumulatorsElectrolytic agentElectrical battery

A Li ionic secondary battery includes an electrode component composed a positive, a negative and membranes, a collecting component and electrolyte contained in a battery case, among which, the collecting component includes a connecting board and a lead-out plate, the face of the board is soldered together with the end face of an end collector of the electrode component in the way of sweating of immersing melted solders, one end of the lead-out plate is conducted with the connecting board, the other is linked with the battery pole, the collecting part has high connection strength, so sealing-off or short circuit would not happen.

Owner:BYD CO LTD

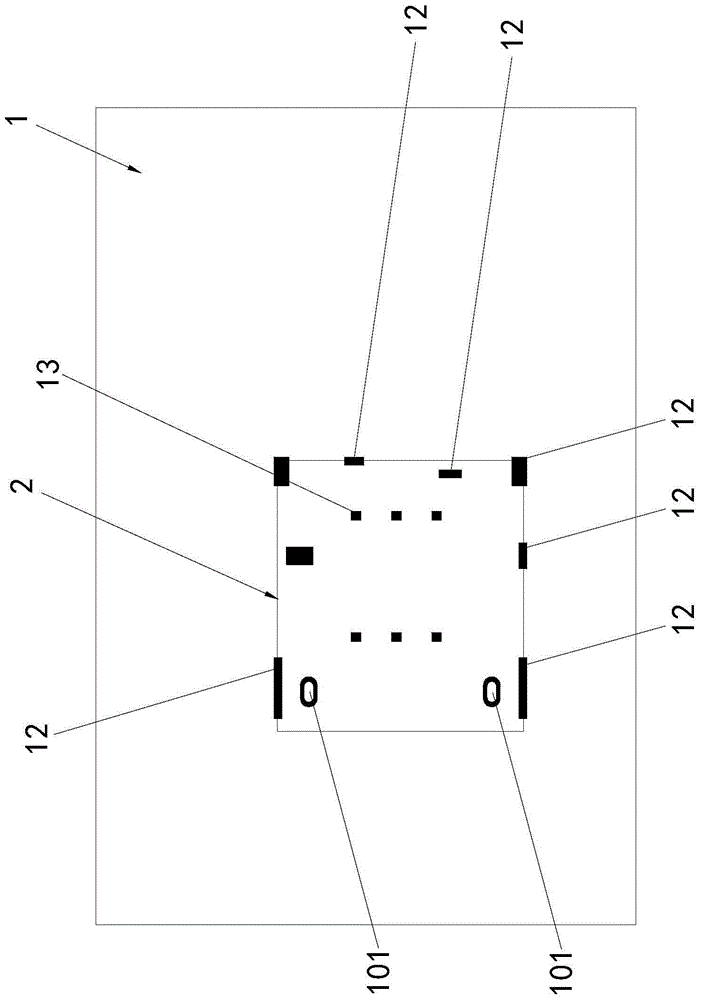

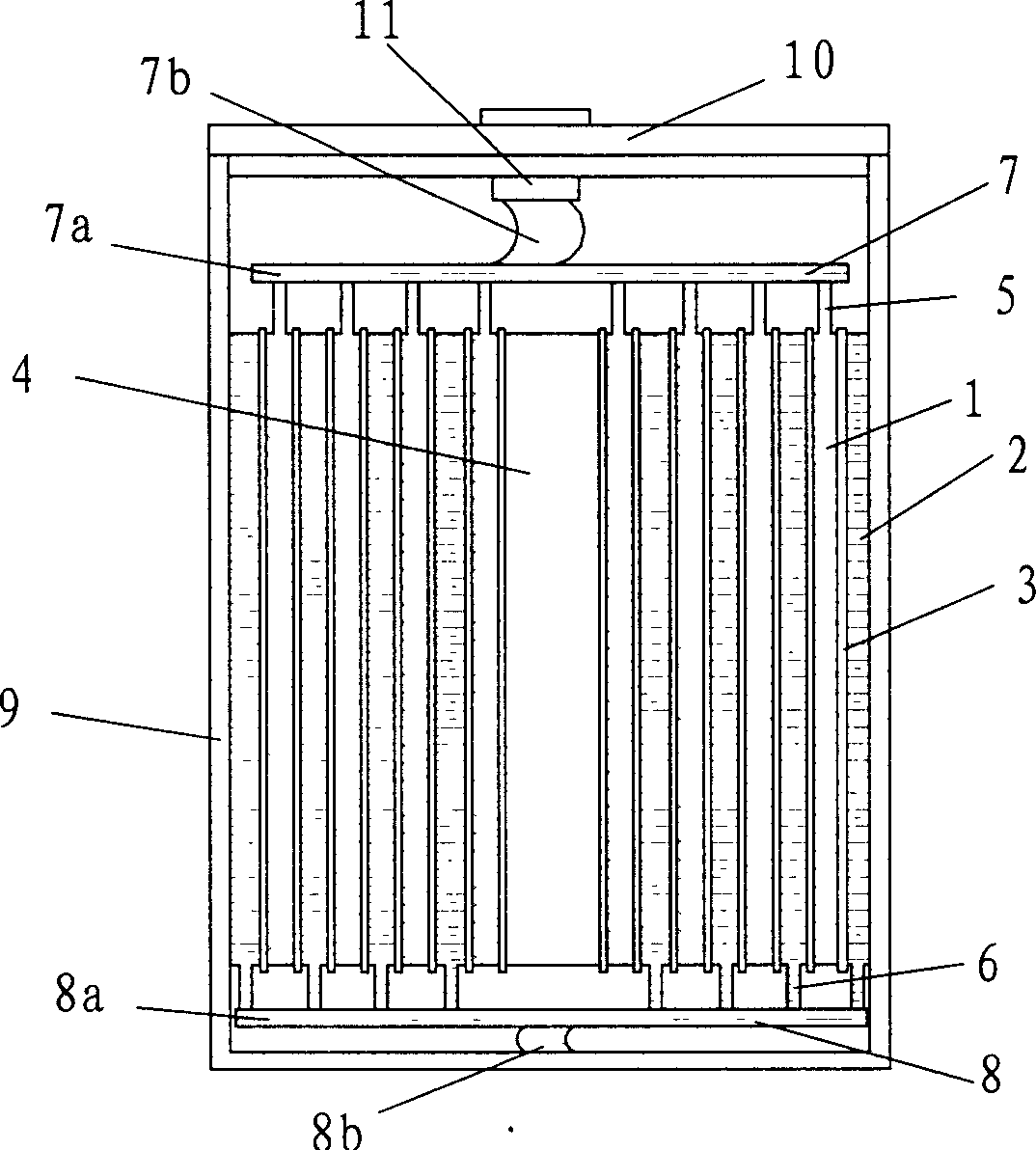

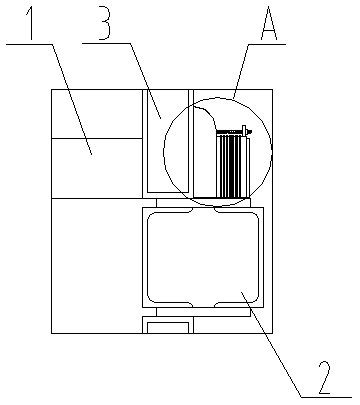

Battery pack structure and battery pack containing it

ActiveCN104576994BStable supportAchieving Conformance RequirementsCurrent conducting connectionsBatteriesEngineeringStructural engineering

The invention discloses a battery group structure, comprising: two fixing plates that can be arranged at both ends of the battery, and an at least partially conductive connecting plate that can be arranged on a side of the fixing plate that is away from the battery; wherein, the fixing A fixing hole is opened on the plate to limit the battery end inside, and a through hole is opened at the bottom of the fixing hole to expose the battery end to the side of the fixing plate facing away from the battery, so that all The end of the battery can be welded to the connection plate through the through hole, and the connection plate is provided with a limit slot corresponding to the through hole to limit the welding position. The battery group structure provides good support for the battery by using two fixing plates to clamp the battery in the middle; by opening a through hole at the bottom of the fixing hole, the end of the battery is exposed and fixed to the connecting plate by welding , the series and parallel connection between multiple batteries is realized through the connection board, the group structure has few parts, is easy to operate, and is suitable for mass production.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Base plate for cutter machining

PendingCN109590091AEasy to fixEasy to weldGrain treatmentsMetal working apparatusSocial benefitsEconomic benefits

The invention discloses a base plate for cutter machining. The base plate comprises a base plate main body, an embedding groove is formed in the upper surface of the base plate main body, the embedding groove is used for fixing a high-speed steel bar, a cutting and edge-planing groove is formed in the lower surface of the base plate main body, and the cutting and edge-planing groove is formed under the embedding groove. According to the base plate, in the welding process, the welding quality can be improved, cutting and edge-planing are convenient after welding, so that the cutting and edge-planing efficiency is improved, and consumption on labor, equipment and electric energy in the production process is reduced; and meanwhile, generation of waste materials in the cutting and edge-planingprocess is greatly reduced, the utilization rate of steel materials is effectively improved, and the base plate has very good economic benefit and social benefit.

Owner:DONGE LIYUAN MACHINERY KNIFE

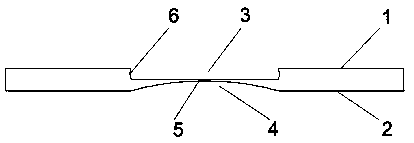

printed circuit board

ActiveCN103369827BImprove product qualityThe connection is stable and reliableElectrical connection printed elementsElectronic structureButt joint

The invention discloses a printed circuit board which comprises a plurality of layers of circuit board bodies. The printed circuit board comprises at least one via hole used for being connected with the portions, at the end portion of the printed circuit board, of the layers of circuit board bodies. The via hole is in a two-cone shape, wherein the two cones are in butt joint. According to the printed circuit board, the electronic structure materials are firm and stable in connection and not prone to unsoldering, a product with the printed circuit board is better in quality, and the production testing cost of the product and the after-sale cost are low.

Owner:HUAQIN TECH CO LTD

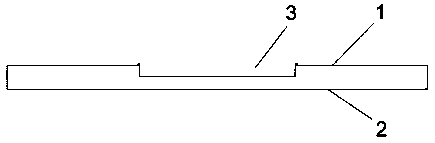

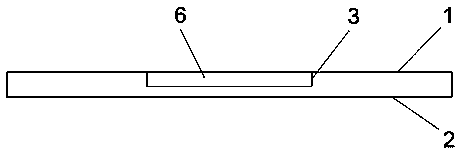

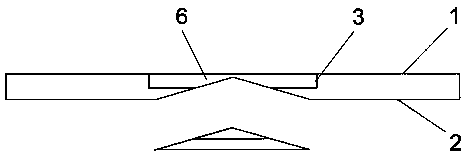

Printed circuit board

ActiveCN103369827AImprove product qualityThe connection is stable and reliableElectrical connection printed elementsElectronic structureButt joint

The invention discloses a printed circuit board which comprises a plurality of layers of circuit board bodies. The printed circuit board comprises at least one via hole used for being connected with the portions, at the end portion of the printed circuit board, of the layers of circuit board bodies. The via hole is in a two-cone shape, wherein the two cones are in butt joint. According to the printed circuit board, the electronic structure materials are firm and stable in connection and not prone to unsoldering, a product with the printed circuit board is better in quality, and the production testing cost of the product and the after-sale cost are low.

Owner:HUAQIN TECH CO LTD

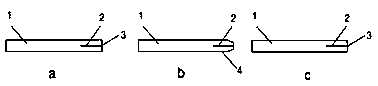

Hard alloy bar difficultly loosing weld

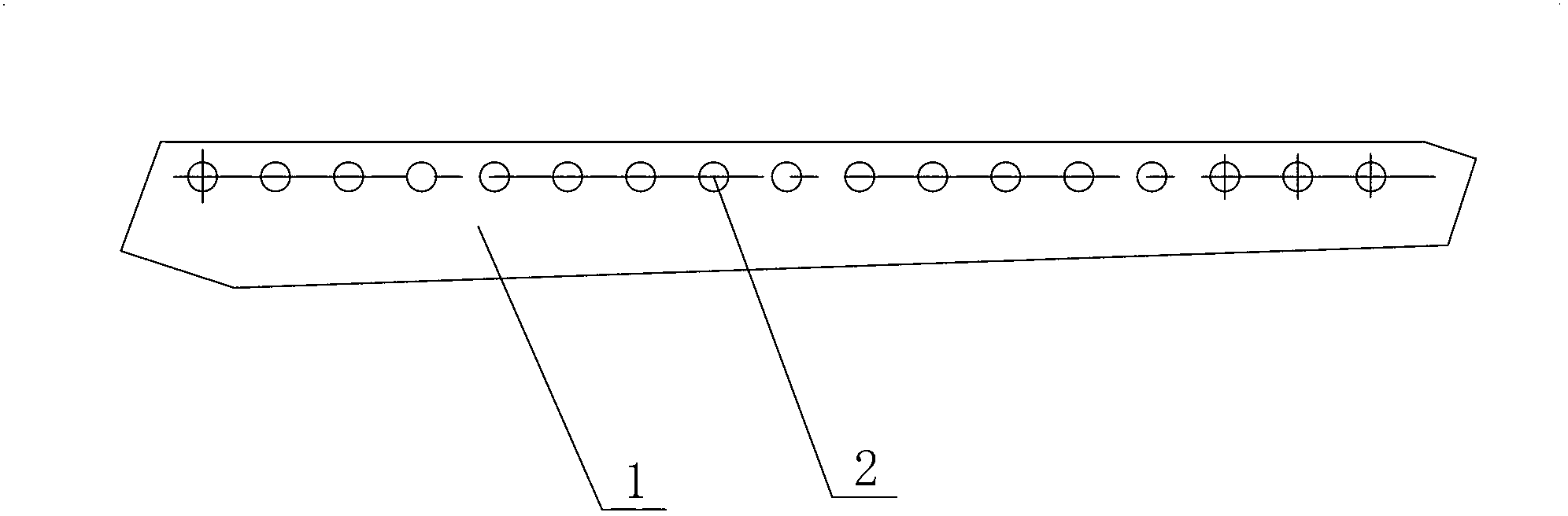

InactiveCN103075632AHigh bonding strengthImprove welding performanceElongated constructional elementsSlagBonding strength

The invention discloses a hard alloy bar difficultly loosing weld. The hard alloy bar is mainly used for steel slag reaming. The hard alloy bar comprises an elongated alloy bar body, wherein a plurality of through holes are formed on the alloy bar body; and the through holes are uniformly distributed on the alloy bar body in one row. Through the through holes, when products are welded, the welding fluid can effectively fix the alloy bar body and a base body through the through holes, so that the bonding strength is improved, the welding performance of the product is improved, and the welding is difficult to loose.

Owner:中地装(无锡)钻探工具有限公司

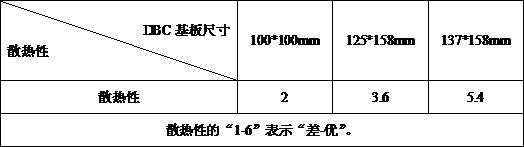

Low-cost high-heat-dissipation intelligent function module

PendingCN112908973AWeld firmlyGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The invention discloses a low-cost high-heat-dissipation intelligent function module which comprises a DBC substrate, the DBC substrate is sequentially connected with a copper wiring layer, a ceramic layer and a copper heat dissipation layer from top to bottom, and the copper wiring layer comprises a first copper wiring layer arranged above one end of the ceramic layer and a second copper wiring layer arranged above the other end of the ceramic layer; the function module further comprises a first side pin, and one end of the first side pin is electrically connected with a first bonding wire arranged on the first copper wiring layer; the function module further comprises an IC chip, the IC chip is welded on the first copper wiring layer, a first welding flux layer is arranged between the IC chip and the first copper wiring layer, and the IC chip is welded on the first copper wiring layer. The problems of insufficient welding, high cost and relatively poor heat dissipation performance of pins of the intelligent function module are solved, the purposes that the pins of the intelligent function module are not easy to deweld and stable in welding are realized, the heat dissipation performance is good, the quality of the intelligent function module is effectively guaranteed, and meanwhile the manufacturing cost is effectively reduced.

Owner:志豪微电子(惠州)有限公司

A Sealing Structure Applied to Economizer Ventilation Beam

ActiveCN106051155BSimple structureReduce welding difficultyEngine sealsFeed-water heatersSteel frameEconomizer

The invention discloses a sealing structure applied to a ventilating beam of an economizer. The sealing structure comprises the ventilating beam of the economizer, a steel frame beam, protective plates of the economizer and a sealing device, wherein the protective plates of the economizer are fixedly arranged on the steel frame beam, the expanding end of the ventilating beam of the economizer penetrates through the protective plates of the economizer and is arranged on the steel frame beam, and the sealing device sleeves the expanding end of the ventilating beam of the economizer and is welded with the protective plates of the economizer and the steel frame beam, respectively. The sealing structure disclosed by the invention has the beneficial effects that the sealing structure is simple in structure, low in welding difficulty, hard to seal off, good in sealing effect and stable and safe in equipment operation.

Owner:河北热华锅炉有限公司

An electroplating process

The invention relates to an electroplating technology which mainly comprises a front treatment process, an electrocoppering process and an aftertreatment groove. The front treatment process mainly comprises the steps of ultrasonic oil removal, electrolytic degreasing, washing, activating and washing; a front treatment groove is divided into three parts including an ultrasonic oil removal groove, an electrolytic degreasing groove and an activating groove, and the three parts independently exist in closed space; and the electrocoppering process mainly comprises copper pre-plating, copper plating, recovering and washing; and an aftertreatment process mainly comprises the steps of drying and oil immersion. The electroplating technology is mainly characterized in that a steel strip is in an S-shaped walking direction in the overall process, and the cost of the steel strip is about one third of the cost of a production line. A closed treatment groove can conduct emergency treatment, meanwhile, the phosphorus content in sulfate copper electroplating is extremely small, plating layer bonding is more compact, a manufactured Bundy pipe is not prone to desoldering, resources can be effectively saved, and safety of persons is protected; and a cyanide copper plating solution is used for conducting copper preplating firstly, and therefore adhesiveness of the plating layer on the steel strip is good, and meanwhile, the electroplating technology meets the current environment-friendly production principle.

Owner:SHANDONG JIANZHU UNIV

Card holder packaging method and mobile terminal

InactiveCN105025129BNot easy to desolderImprove bindingPrinted circuit assemblingTelephone set constructionsComputer terminalMotherboard

The invention is applicable to the technical field of card socket packaging, and discloses a card socket packaging method and a mobile terminal. The encapsulation method comprises the steps of preparing a socket with pins and a circuit board with metallized holes, inserting the pins of the socket into the metallized holes, and welding the pins of the socket to the metallization Hole slot. The mobile terminal includes a mobile terminal body and a circuit board arranged in the mobile terminal body, the circuit board is connected with a card holder, the circuit board is provided with a metallized hole groove, and the card holder has a The slot is metallized and welded to the pin of the metallized slot. The card socket packaging method and mobile terminal provided by the present invention can insert the pins of the card socket into the metallized hole, and weld the pins of the card socket to the metallized hole, even if the card is inserted and pulled out. When the force is too strong or the card is reversed, it is not easy to cause the card holder to be desoldered, avoiding scrapping of the motherboard, and good reliability.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

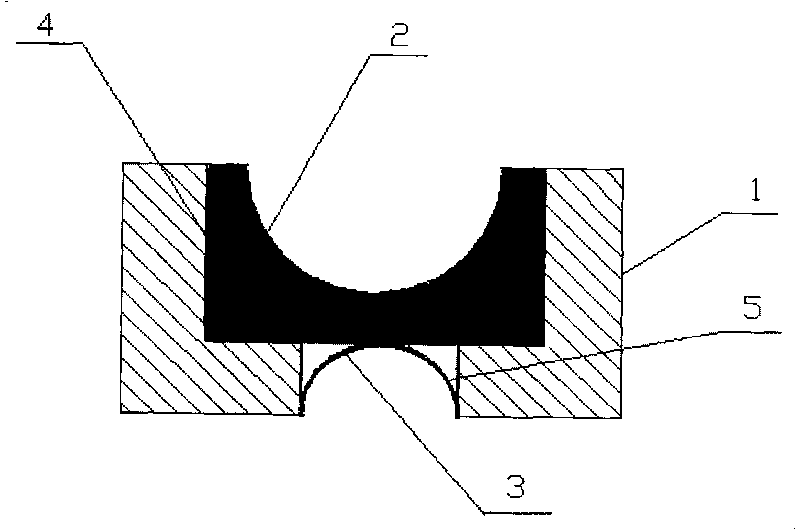

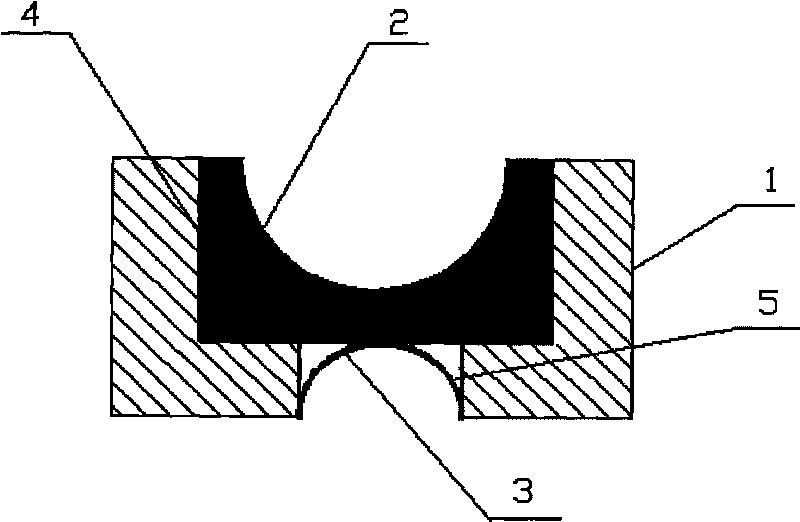

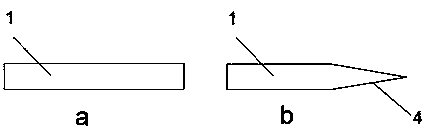

Spherical bowl seat with steel frame net structure

The invention discloses a spherical bowl seat with a steel frame net structure. A steel plate (1) is machined into needed bulk, a large ball seat outer wall (4) and a small ball seat outer wall (5) are reinforced and welded on the bulk foundation of the steel plate (1), and a large ball bowl seat (2) and a small ball bowl seat (3) are machined according to the actual requirement respectively. According to the requirements of the structure, bowl balls and bowl seats, when the spanned steel frame net structures are interconnected, only the large bowl ball and the large ball bowl seat (2), the small bowl ball and the small ball bowl seat (3) are mutually welded. The spherical bowl seat with the steel frame net structure has the advantages that the spherical bowl seat is easy to weld, is not easy to weld off and rust, and has a stable structure and long service life.

Owner:王思长

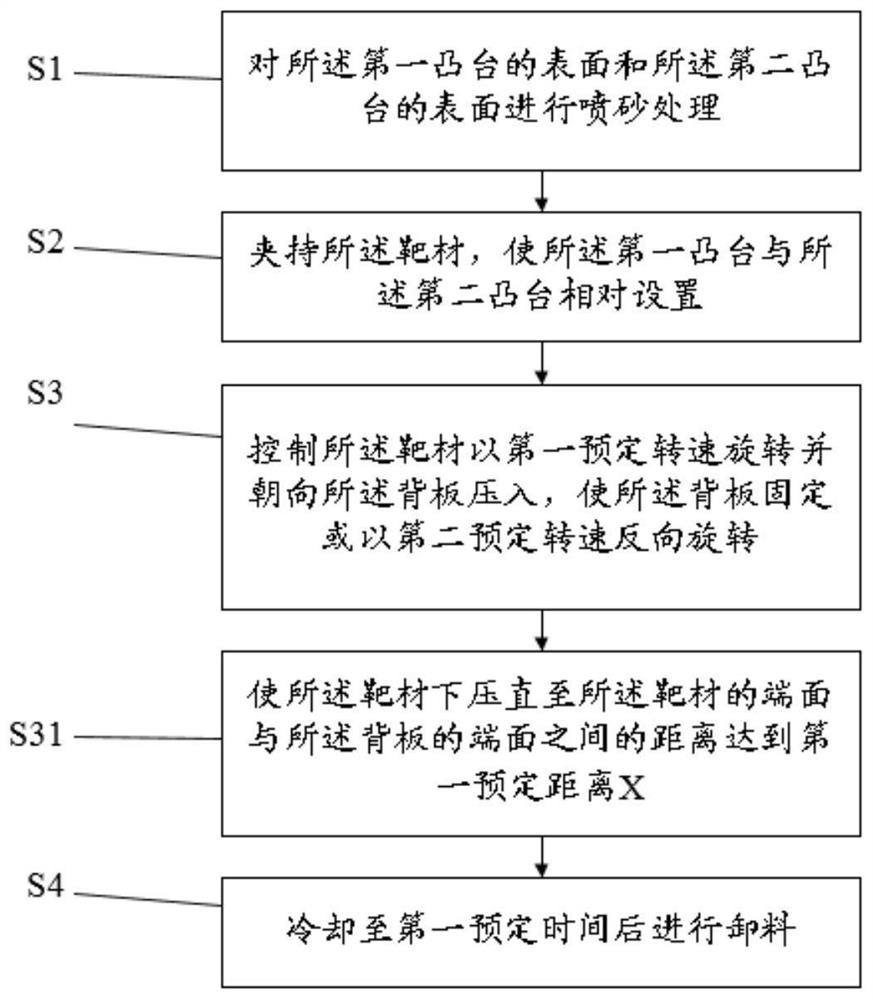

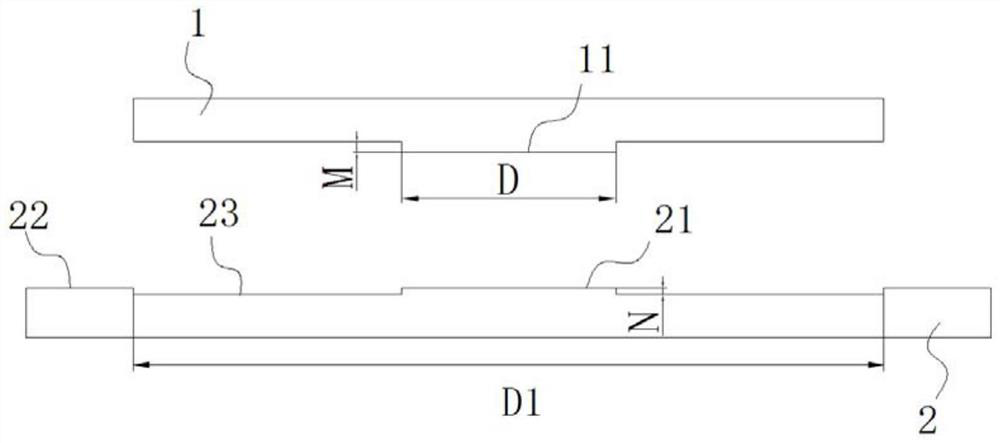

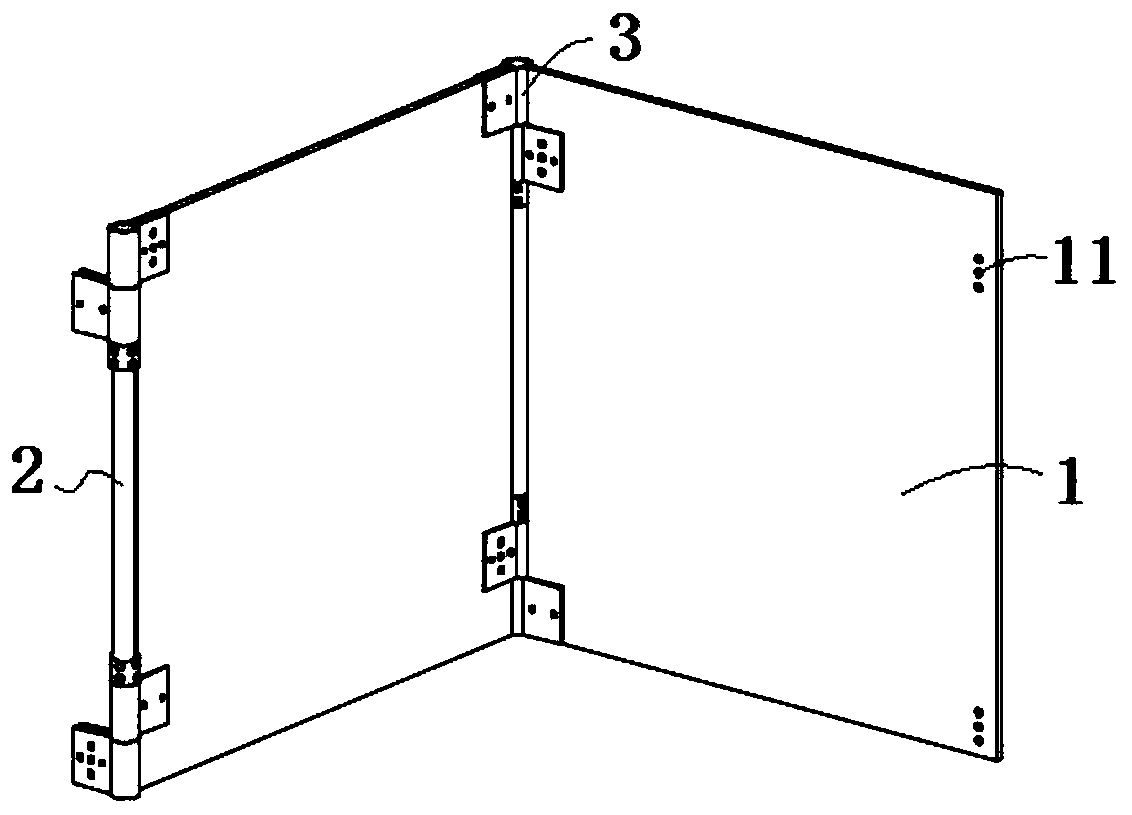

Friction welding method for target material assembly

ActiveCN114273771AHigh strengthShort timeNuclear energy generationNon-electric welding apparatusIndiumWeld seam

The invention relates to the technical field of welding, and discloses a friction welding method of a target material assembly, according to the friction welding method, heat generated by friction between a target material rotating at a high speed and a back plate is used for locally melting a first boss and a second boss, and a compact solid-phase welding seam is formed under extrusion of a welding tool. According to the friction welding method, the welding bonding layer is formed through melting, the bonding strength is higher than that of brazing indium, the high-temperature resistance is better, and desoldering is not prone to occurring; compared with electron beam welding, the welding area of the first boss and the second boss is larger, namely, the metallurgical bonding area is larger, and the overall strength is higher; compared with diffusion welding, the friction welding method is shorter in consumed time, inert gas or other working conditions do not need to be adopted for protection, and the cost is low; and secondly, the friction welding method is small in friction force, low in equipment requirement, low in energy consumption and short in welding time consumption, and small-area contact friction is not prone to causing overall deformation of the target material or the back plate.

Owner:先导薄膜材料(安徽)有限公司

Guardrail for nursery stock maintenance

InactiveCN109006081AHigh strengthNot easy to desolderPlant protective coveringsMechanical engineeringEngineering

The invention discloses a guardrail for nursery stock maintenance, and relates to the technical field of nursery stock maintenance and planting. The guardrail comprises supporting columns and baffle plates. One baffle plate is fixed between every two adjacent supporting columns through four connecting pieces and a plurality of screws. Each connecting piece comprises a cylinder body matched with the supporting columns. The opening end of the cylinder body is fixedly provided with a first pipe body, and the outer side of the first pipe body is rotationally matched with a second cylinder body. Athird pipe body is fixed at one end of the first pipe body. Two first clamping plates are arranged on the outer peripheral side of the cylinder body in parallel. A plurality of first fixing holes anda plurality of first fastening holes are formed in the first clamping plates. Two second clamping plates are arranged on the outer peripheral side of the second cylinder body in parallel. A pluralityof second fixing holes and a plurality of second fastening holes are formed in the second clamping plates. The first fixing holes, the first fastening holes, the second fixing holes and the second fastening holes are all threaded holes. According to the invention, the nursery stock protection guardrail is formed by assembling the supporting columns, the baffle plates and the connecting pieces. Therefore, the problems that an existing nursery stock protection guardrail is heavy in structure and the desoldering phenomenon of the existing nursery stock protection guardrail often occurs during thefixation process can be solved.

Owner:合肥草木蕃景生态科技有限公司

Hanging fixture for gasket galvanization

ActiveCN113755775ANot easy to desolderSolution to short lifeHot-dipping/immersion processesProcess efficiency improvementEngineeringScrew thread

The invention relates to the technical field of galvanization, in particular to a hanging fixture for gasket galvanization. The hanging fixture comprises a bottom plate, a galvanizing bath and a sedimentation mechanism; fixing screws penetrate through four surfaces of the bottom plate in a threaded manner, the bottom plate can fix an equipment body through the fixing screws, side plates are fixedly arranged at the two sides of the bottom plate, a top plate is fixedly arranged at the side, away from the bottom plate, of each side plate, and the bottom plate, the side plates and the top plate form an equipment body supporting framework; the galvanizing bath is fixedly mounted on the bottom plate; and the two ends of the sedimentation mechanism are rotationally installed on the side plates, the power input end of the sedimentation mechanism is arranged outside the side plates, the power output end of the sedimentation mechanism is fixedly provided with a moving mechanism, a clamp is fixedly arranged on the moving mechanism, the sedimentation mechanism can drive the clamp through the moving mechanism to enter the galvanizing bath for galvanizing, and the moving mechanism is used for moving the clamp for gasket feeding and discharging. According to the hanging fixture for gasket galvanization, the feeding and discharging processes can be greatly simplified, the gasket clamp is not prone to desoldering, the service life is long, operation is easy, and the practicability is high.

Owner:ANHUI HONGYUAN IRON TOWER

Machining process of high-wear-resistance alloy cutter

The invention discloses a machining process of a high-wear-resistance alloy cutter. The machining process comprises the following steps that (1), the requirements of different cutters, including the thickness of a cutter body and the thickness of a blade peak of the cutter body during normal work are determined so as to prepare the cutter body and an alloy strip with corresponding thicknesses; (2), the cutter body is machined, specifically, a strip-shaped groove is formed in the side, facing the blade peak, of one side of a blade part of the cutter body in the length direction of the cutter body, and two cutter body base layers capable of clamping an alloy layer are formed on the blade part of the cutter body; (3), the alloy strip in the strip-shaped groove is brazed to form the alloy layer, so that the blade part forms a layered structure which is formed by tightly and firmly connecting the alloy strip clamped by the two cutter body base layers; and (4), shaping and trimming the cutter body base layers are carried out to enable the side edges of the alloy strip to protrude out of the two cutter body base layers to form blade peaks and enable the cutter body base layers on the twosides of the alloy strip to form smooth blade parts. By utilizing the process to machine the alloy cutter, the steps are simpler and easy to implement, the machined alloy cutter is sharp in blade, good in abrasion resistance, long in service life and high in production efficiency in the using process, and the mechanical energy consumption is effectively reduced.

Owner:DONGE LIYUAN MACHINERY KNIFE

Semiconductor device for preventing surface metal layer from desoldering and manufacturing method thereof

InactiveCN112542435ANot easy to desolderImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialTitanium nitride

The invention relates to a semiconductor device for preventing a surface metal layer from desoldering, which comprises a semiconductor device with an insulating dielectric layer on the surface, wherein a contact hole is arranged on the surface of the semiconductor device, a contact layer made of a metal titanium material is arranged on the inner side surface of the contact hole, a barrier layer made of a titanium nitride material is arranged on the surface of the contact layer, a side wall protection layer made of a metal tungsten material is further arranged on the inner side surface of the contact hole, a metal interconnection layer is further arranged in the contact hole and on the surface of the semiconductor device, and a first passivation layer and a second passivation layer are arranged above the metal interconnection layer. According to the semiconductor device for preventing the surface metal layer from desoldering, the surface metal layer is not easy to fall off and peel offafter bonding, and the reliability is high. In addition, the invention also relates to a manufacturing method of the semiconductor device.

Owner:上海擎茂微电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com