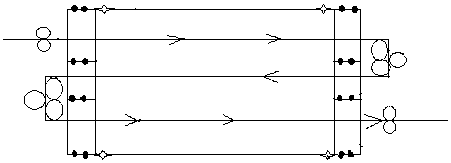

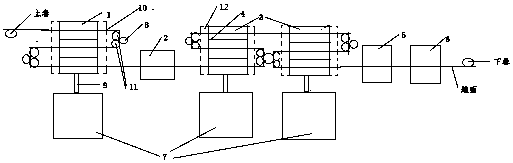

An electroplating process

An electroplating process and copper plating technology, which is applied in the field of continuous electroplating of steel strips, can solve the problems of low comprehensive production efficiency, large one-time investment, waste of financial and material resources, etc., and achieve the effects of protecting safety, saving floor space, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] This embodiment is used to illustrate an electroplating process provided by the present invention.

[0012] (1) Pretreatment tank

[0013] (1) Hot water washing tank: fully immerse the 300mm wide steel strip in hot water at 70-80°C, and wash it for 20-30s. The size of the tank body: length 1800mm, width 1200mm, height 500mm.

[0014] (2) Ultrasonic degreasing tank, ultrasonic degreasing cleaning agent, the concentration is 5%, the temperature is 40 ~ 50 ℃, the ultrasonic frequency is 25 kHz, the size of the tank body: length 1800mm, width 1200mm, height 500mm;

[0015] (3) Electrolytic degreasing tank: immerse the steel strip treated in step (2) into the electrolytic degreasing solution, the temperature of the alkali solution is 60-80°C, and the current density is 8-10A / dm 2 , first degreasing the cathode for 1min, then degreasing the anode for 15s (after degreasing, use low chloride ion water or pure water with a concentration below 600ppm for cleaning).

[0016] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com