Patents

Literature

35results about How to "Easy to take and put" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

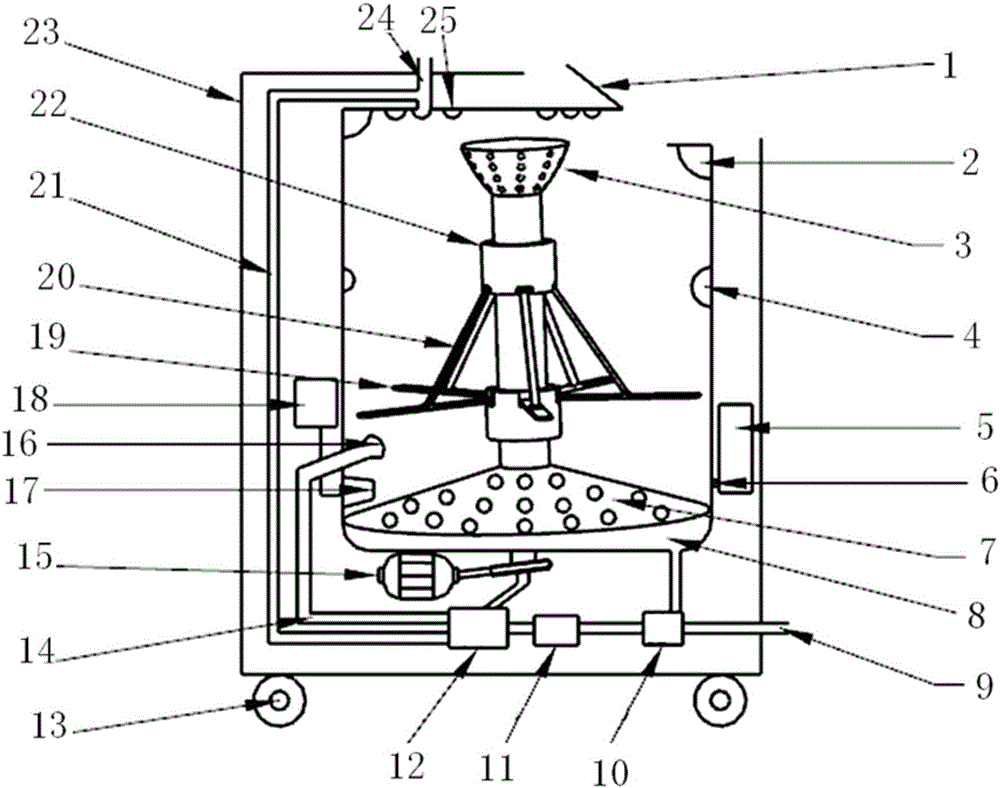

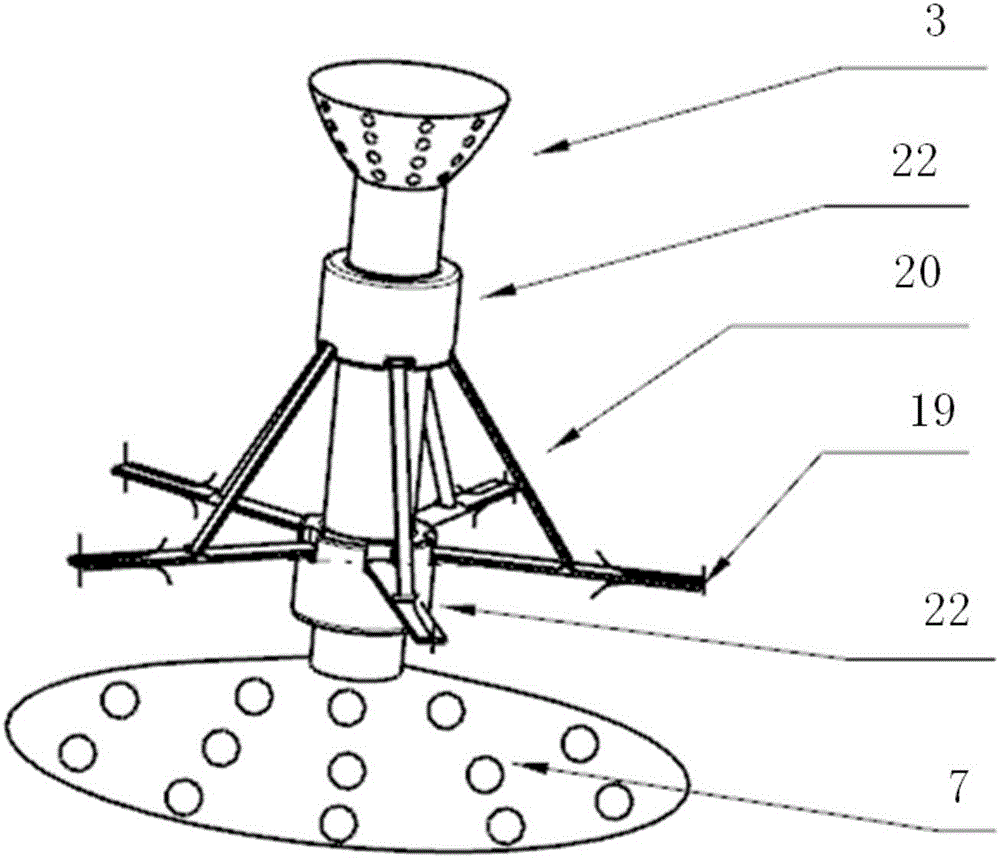

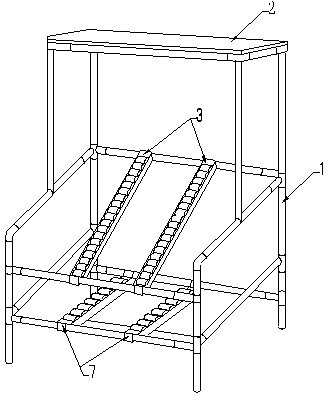

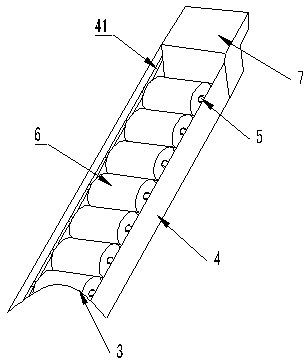

Ultrasonic washing and water flow flushing compound type double-layered shoe washing machine and shoe washing method thereof

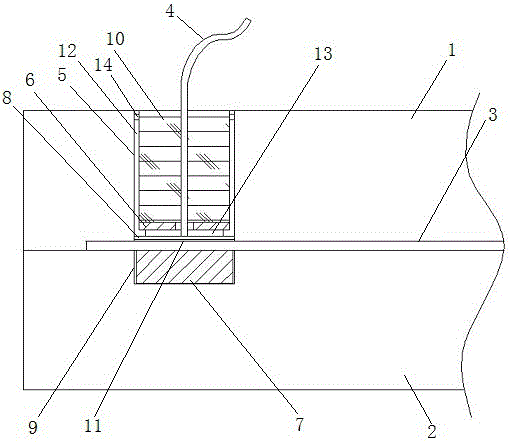

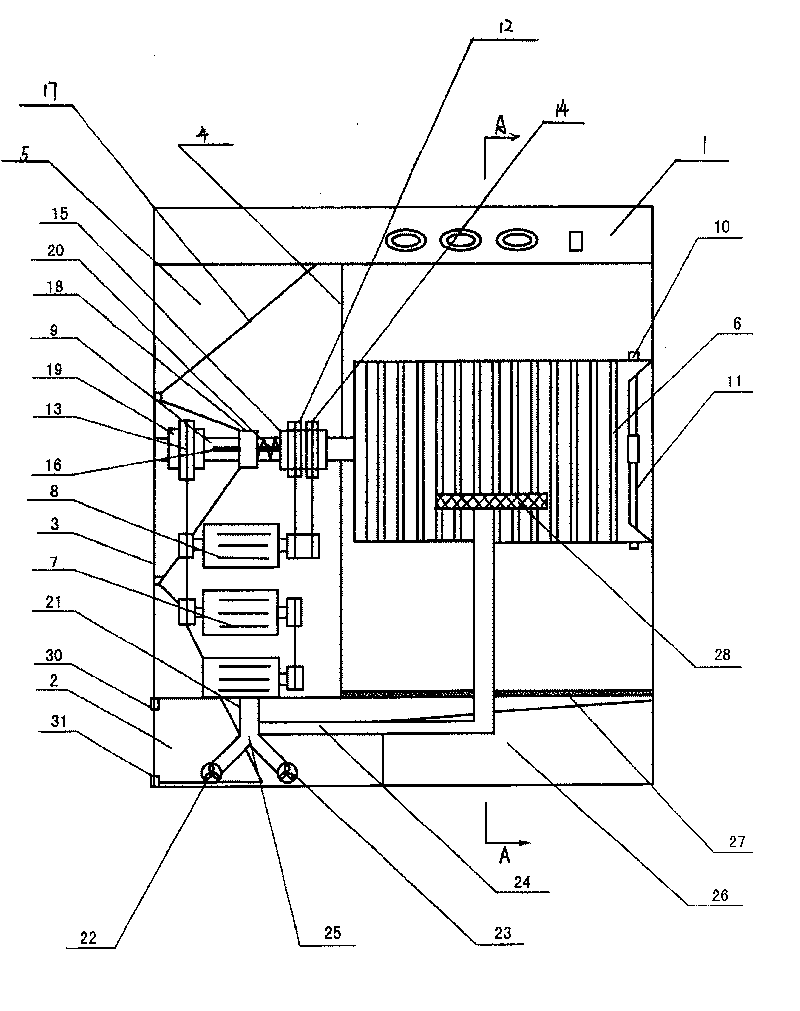

The invention discloses an ultrasonic washing and water flow flushing compound type double-layered shoe washing machine and a shoe washing method thereof. Shoes can be washed by adopting ultrasonic washing based on an ultrasonic generator and an energy converter and water flow flushing based on a swinging head spraying and washing device, a central high-pressure water flow nozzle and a high-pressure water flow spraying device; the ultrasonic washing and the water flow flushing are combined to have better washing effect; a bracket for storing shoe clips is a retractable bracket and the water flow flushing and the ultrasonic washing are organically combined; and meanwhile, the shoes are convenient to take and put. The ultrasonic washing and water flow flushing compound type double-layered shoe washing machine is simple in structure, low in manufacturing cost and convenient to use; the quantity of washing the shoes in one step is improved and the shoes can be washed cleanly and sanitarily and are not damaged; and water saving and environmental friendliness are realized and the machine is suitable for washing various types of shoes.

Owner:SHAANXI UNIV OF SCI & TECH

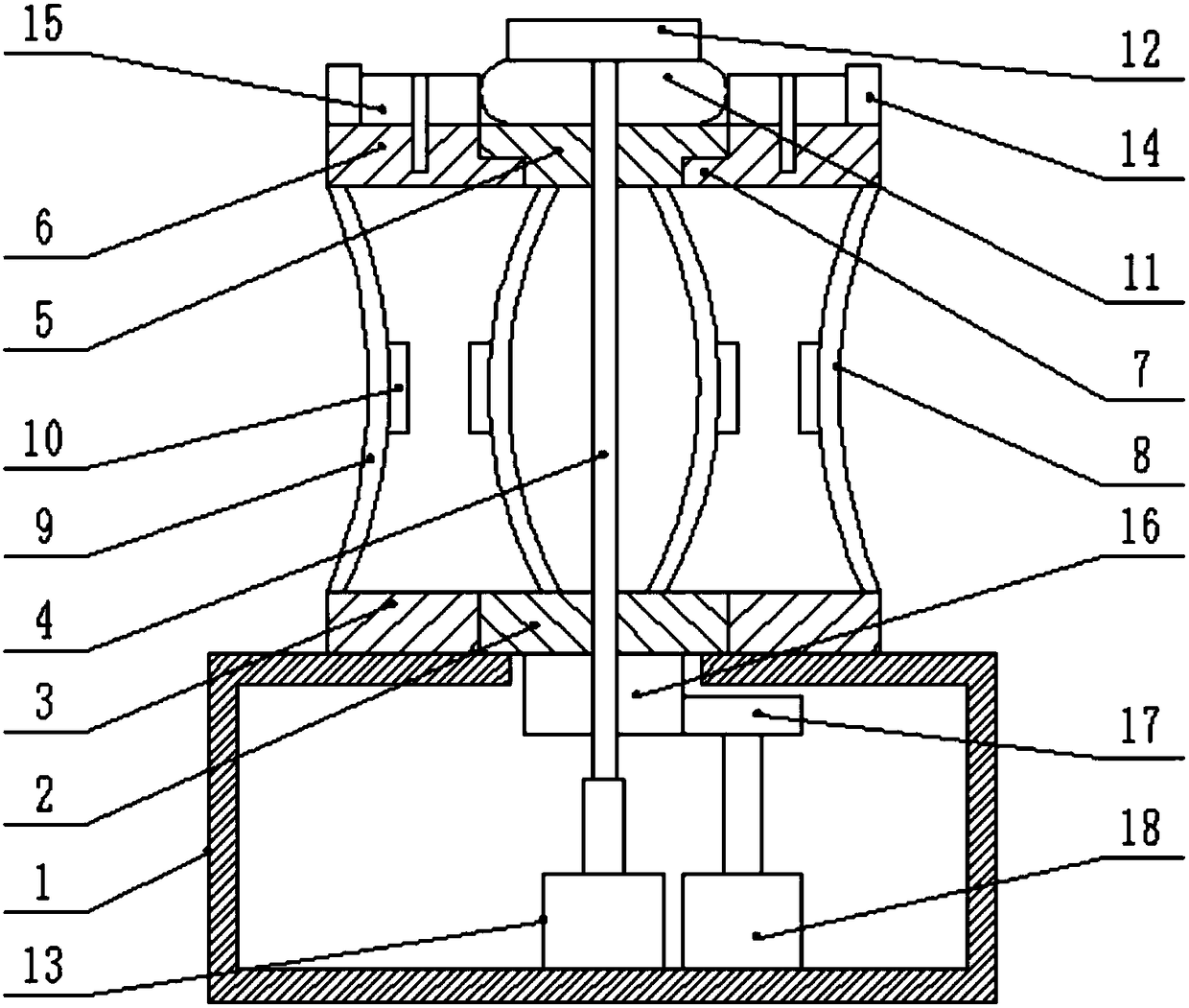

Grinding device for parts and components

InactiveCN108188876APrevent looseningEasy to take and putGrinding carriagesGrinding drivesDrive wheelEngineering

The invention relates to the technical field of part and component processing, and discloses a grinding device for parts and components. The grinding device comprises a rack, wherein a first rotary table and a first circular ring which are concentric are rotatably connected to the rack, a telescopic rod is connected to the first rotary table in a sliding mode, a second rotary table is connected tothe telescopic rod in the sliding mode, a concentric second circular ring is rotatably connected to the outer side of the second rotary table, and the second circular ring is composed of two semicircular rings; a convex strip is arranged between the first rotary table and the second rotary table, a concave strip is arranged between the first circular ring and the second circular ring, and grinding blocks are respectively arranged on the convex strip and the concave strip; a driving air bag and a limiting block are arranged on the telescopic rod, a coaxial friction ring is arranged on the second circular ring, a driving wheel is arranged on the second circular ring, one side of the driving wheel is abutted with the driving air bag, and the other side of the driving wheel is abutted with the friction ring; and a coaxial gear ring is arranged on the first rotary table, and a gear is engaged with the gear ring. According to the grinding device, the inner and outer walls of a part can be ground at the same time, and the convex strip and the concave strip are arranged so as to clamp the part, so that the part can be prevented from loosening during grinding.

Owner:宁波高新区新柯保汽车科技有限公司

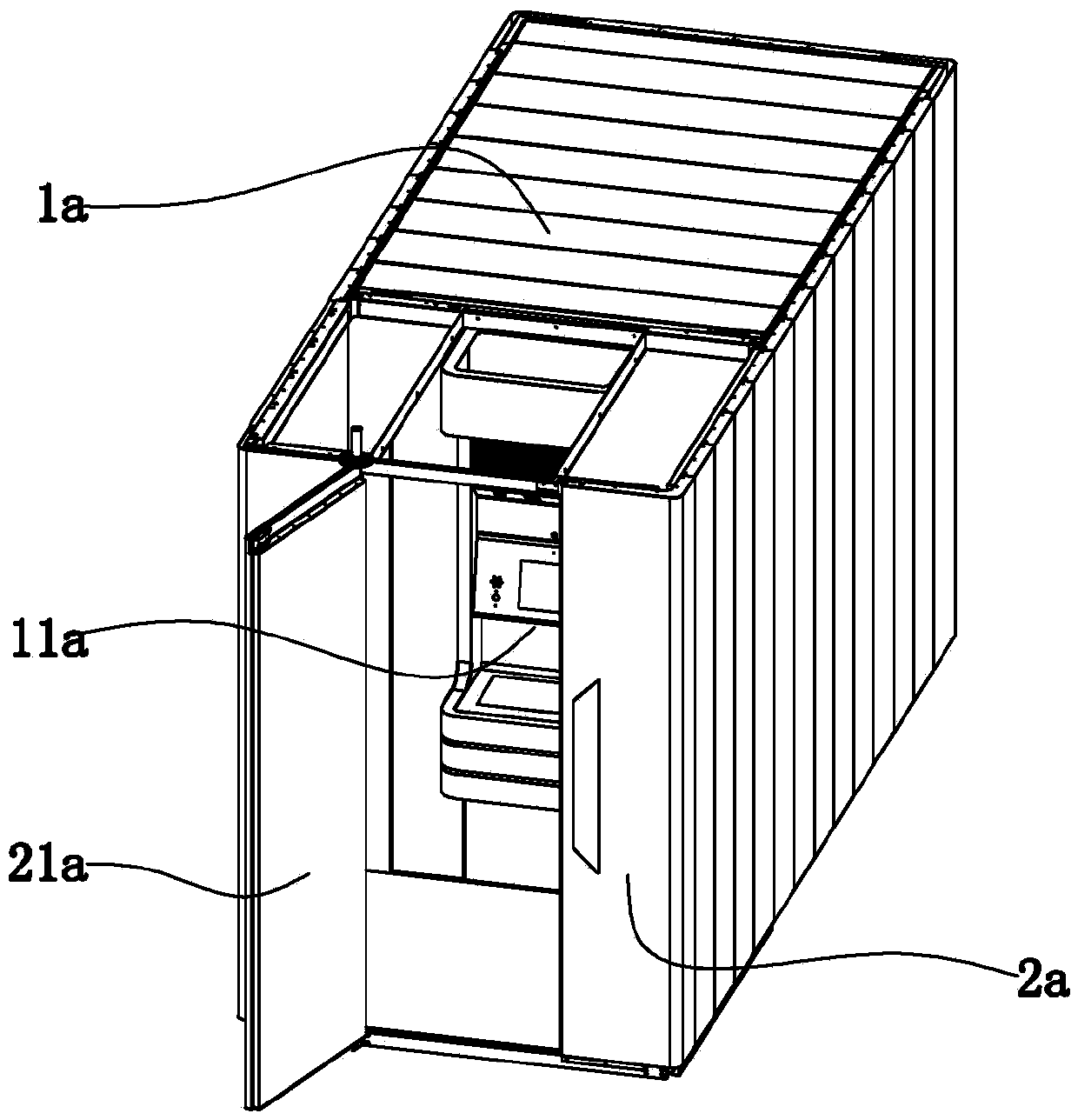

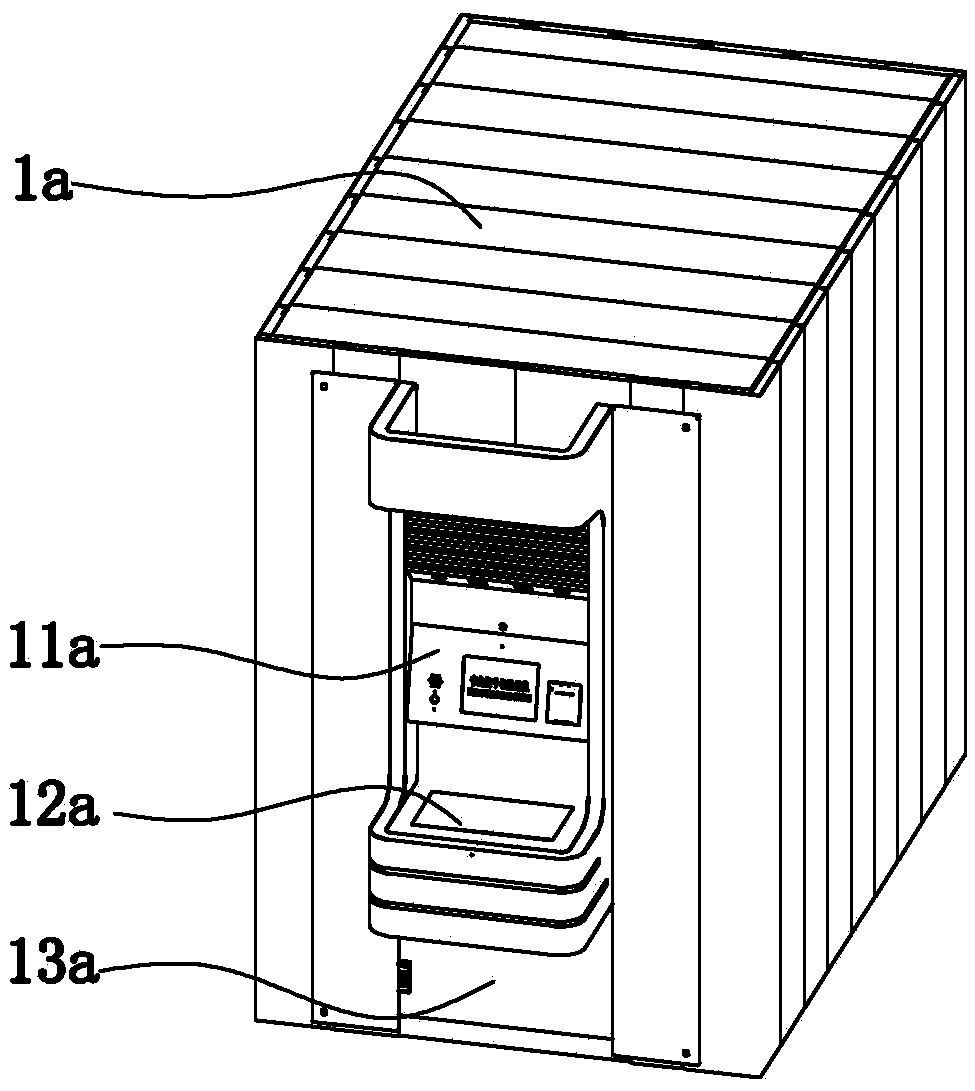

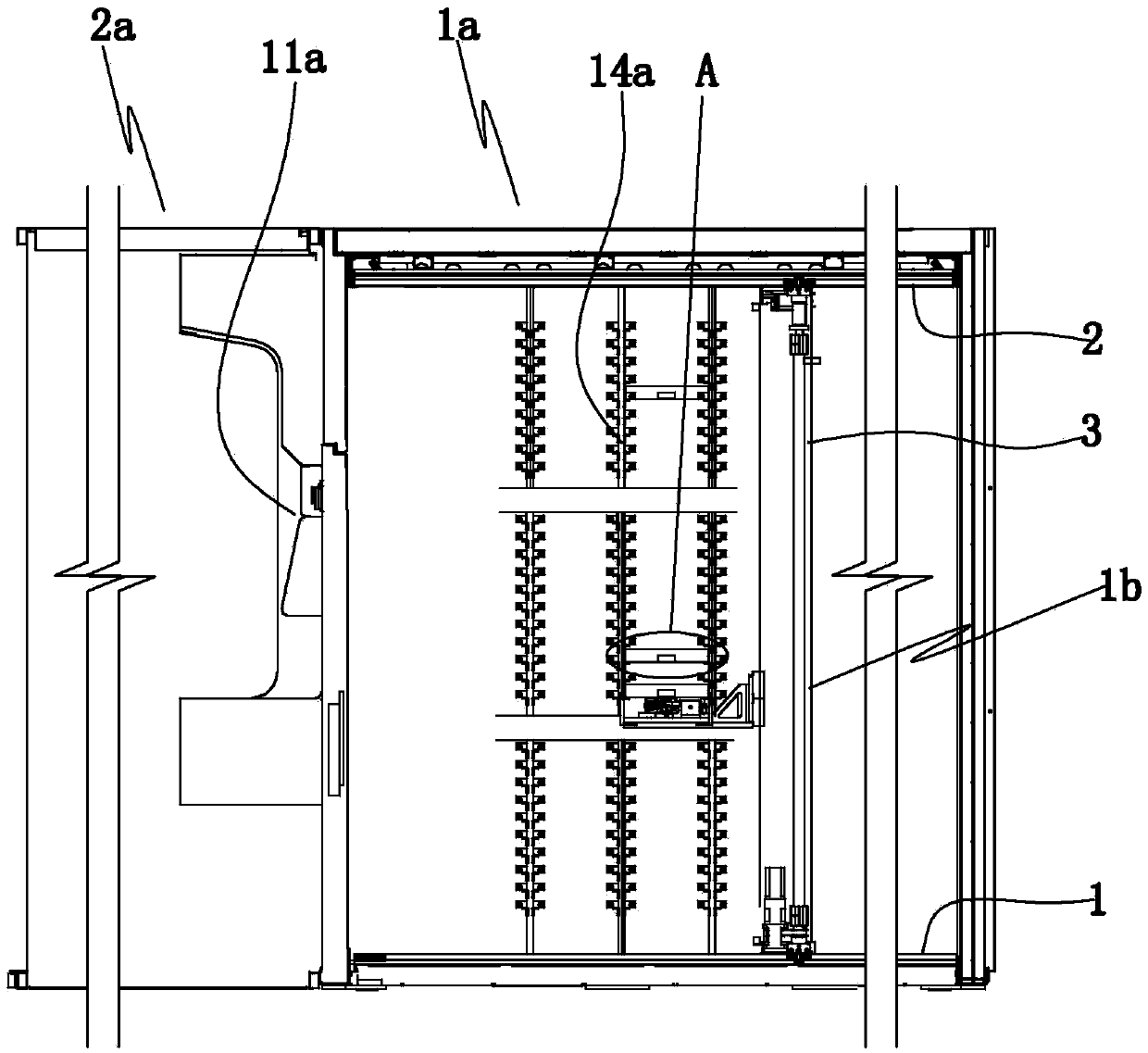

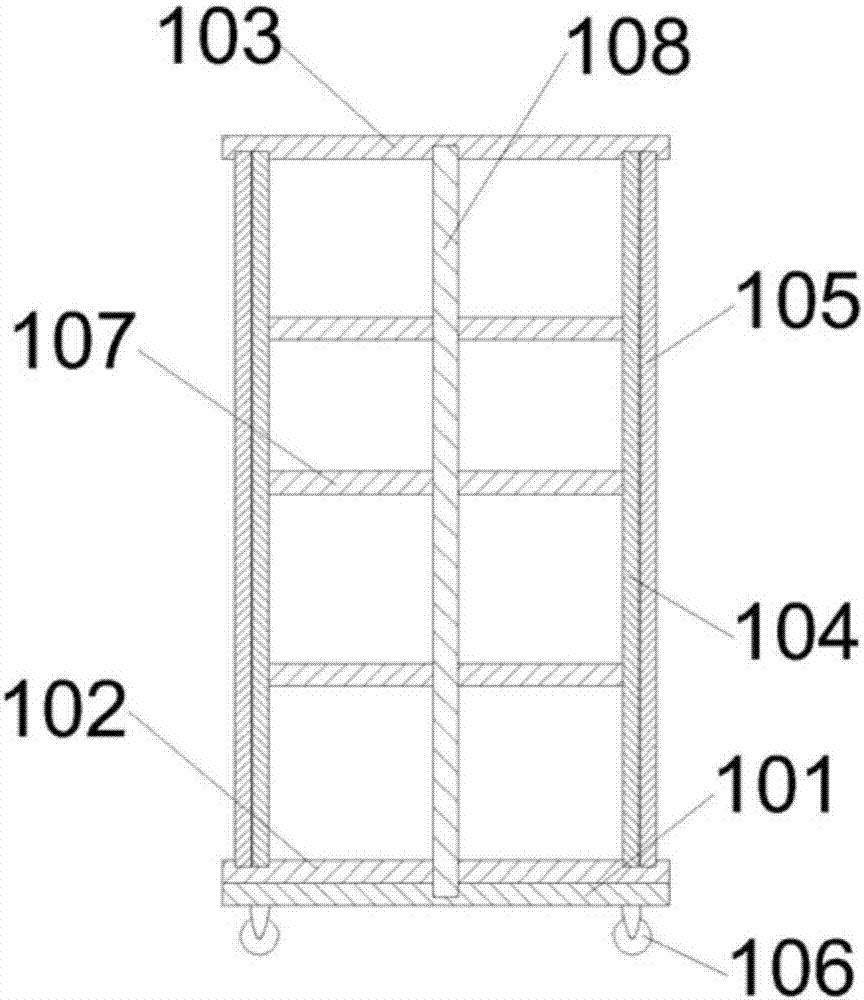

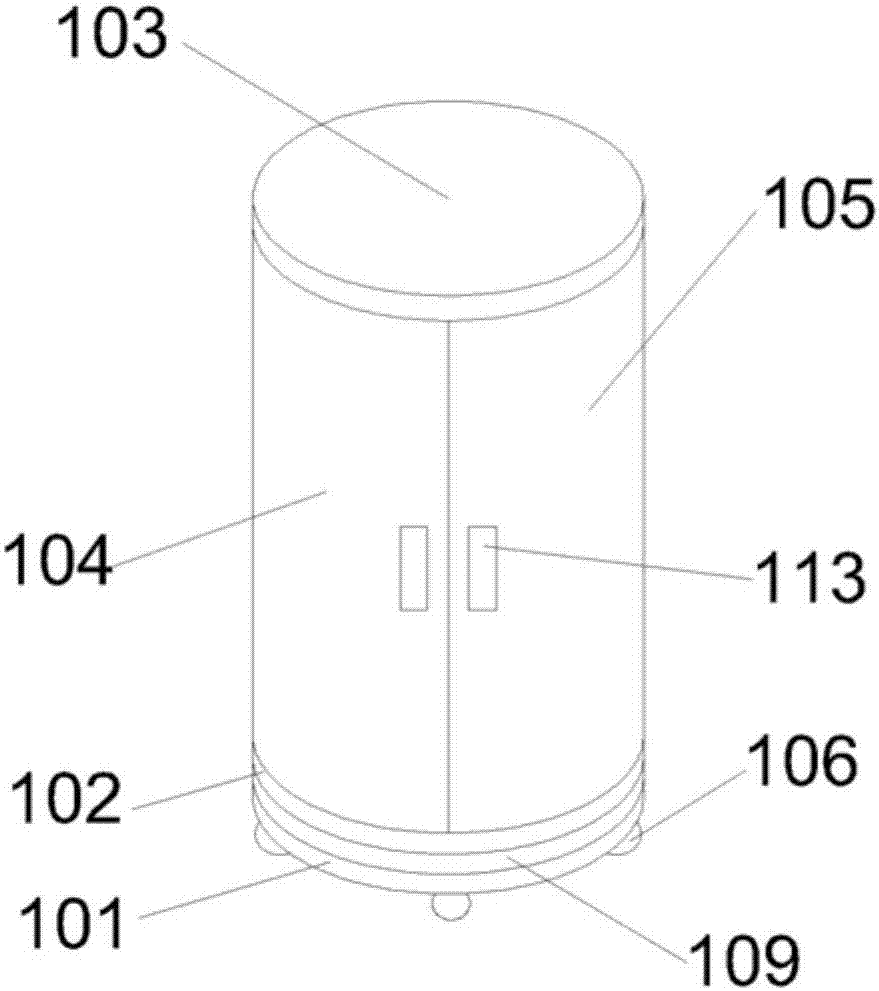

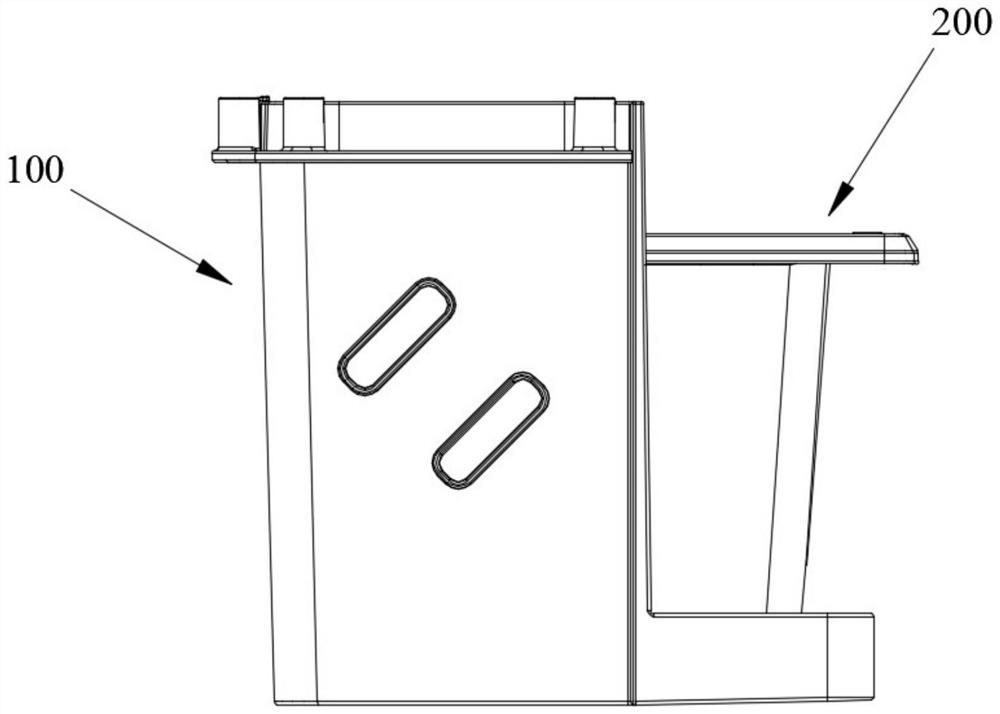

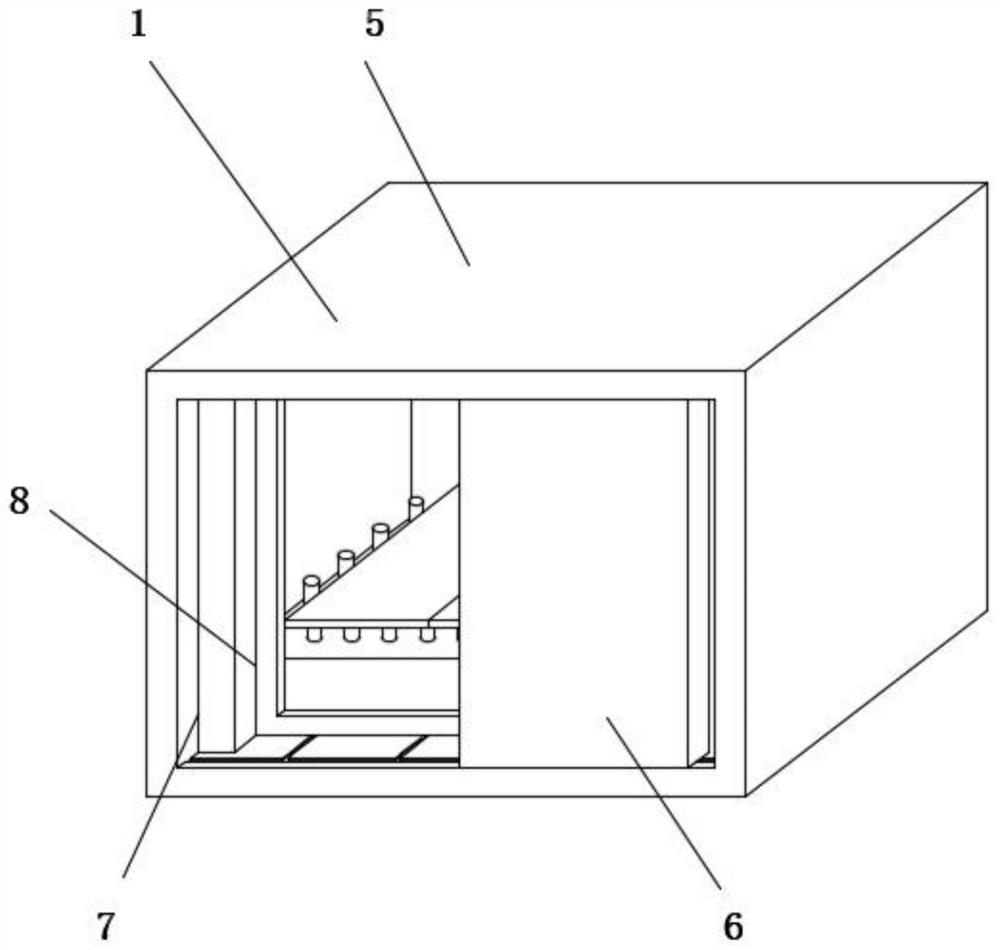

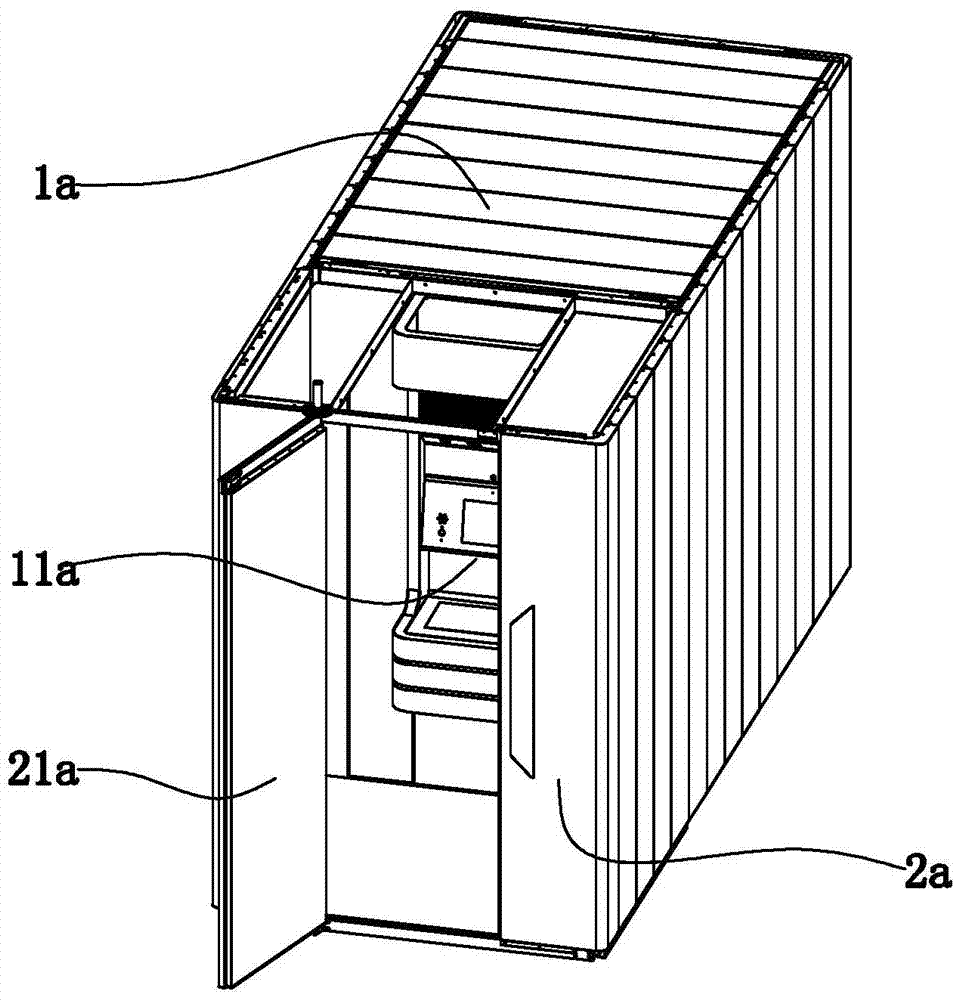

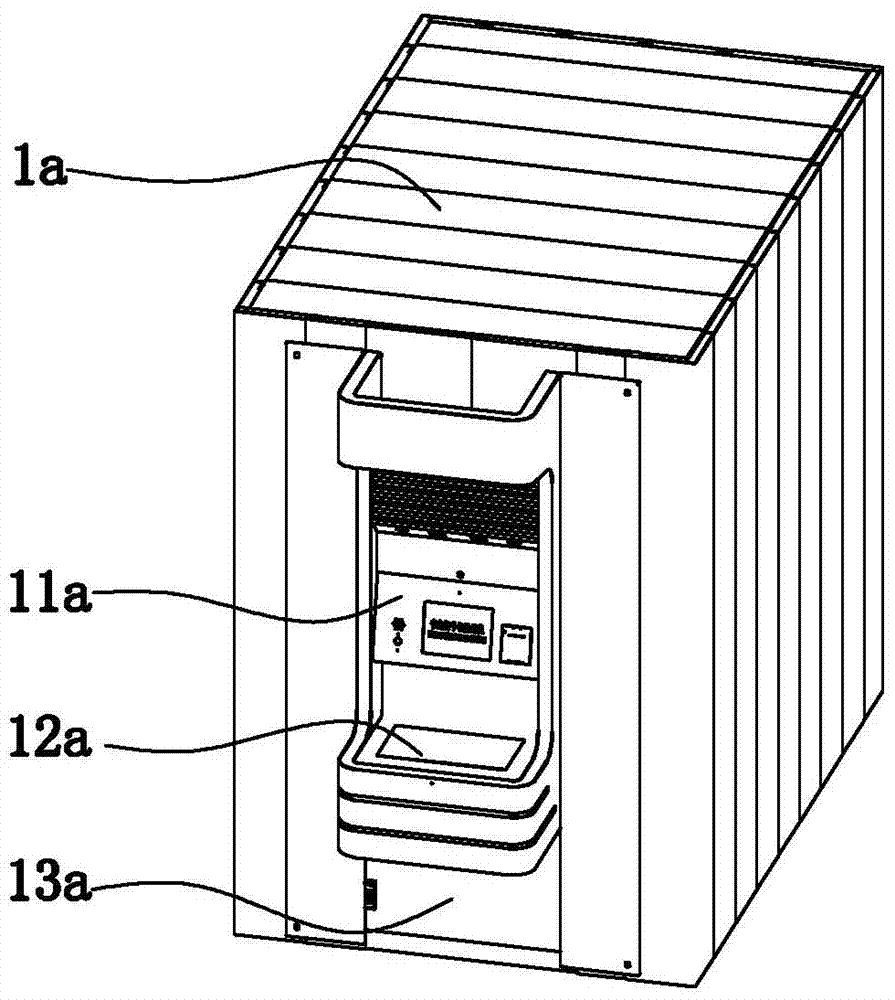

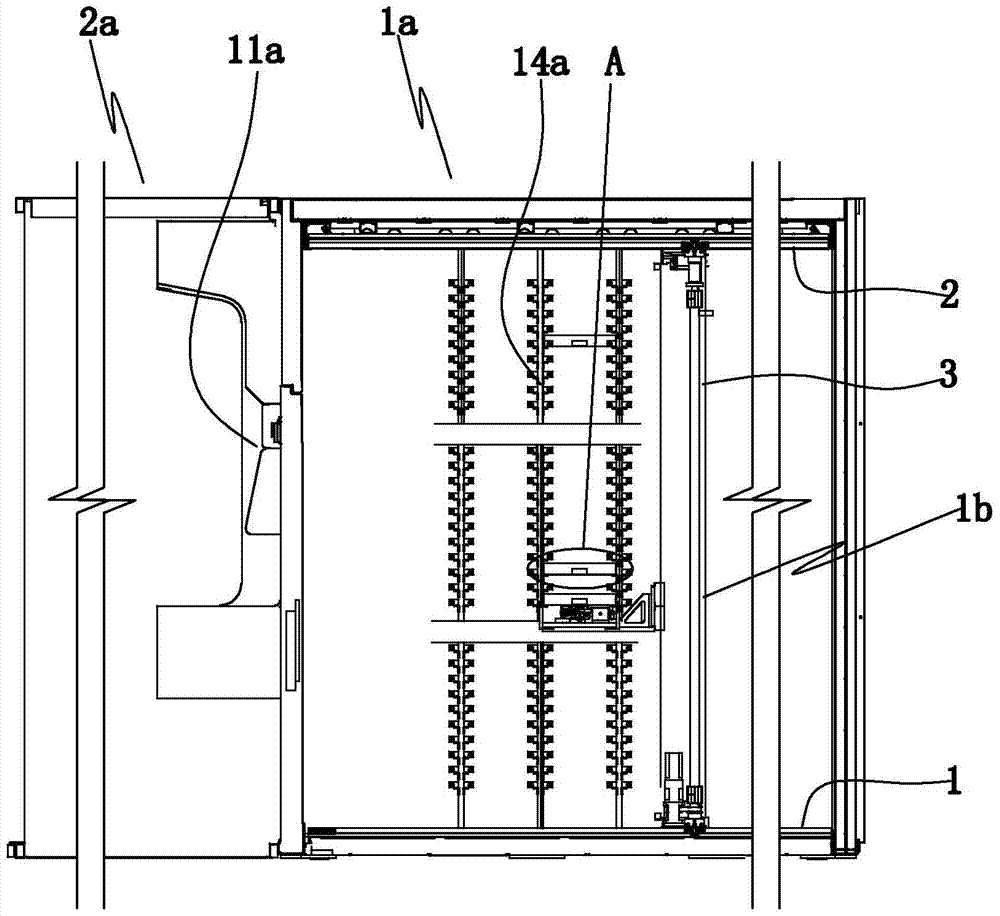

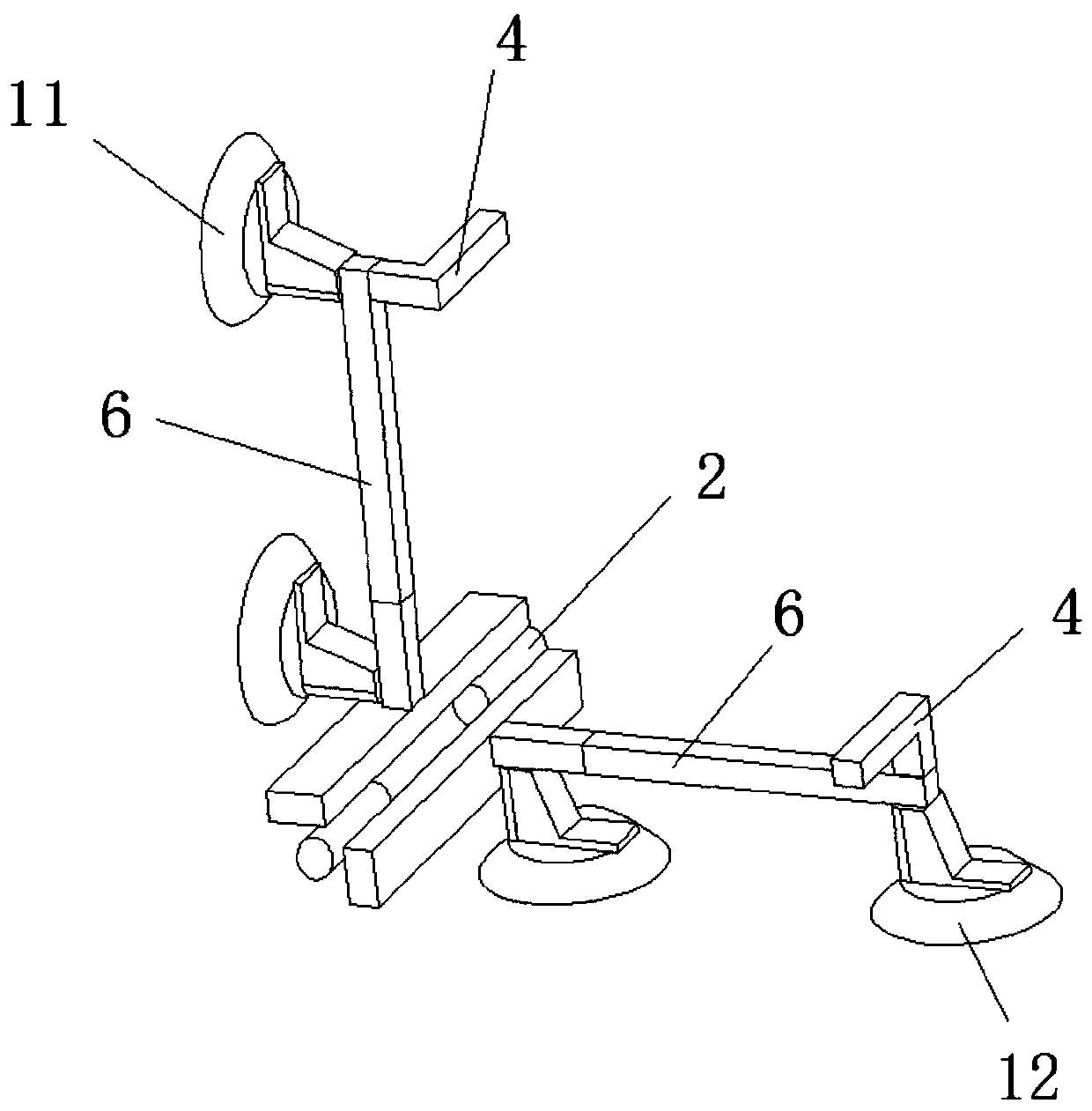

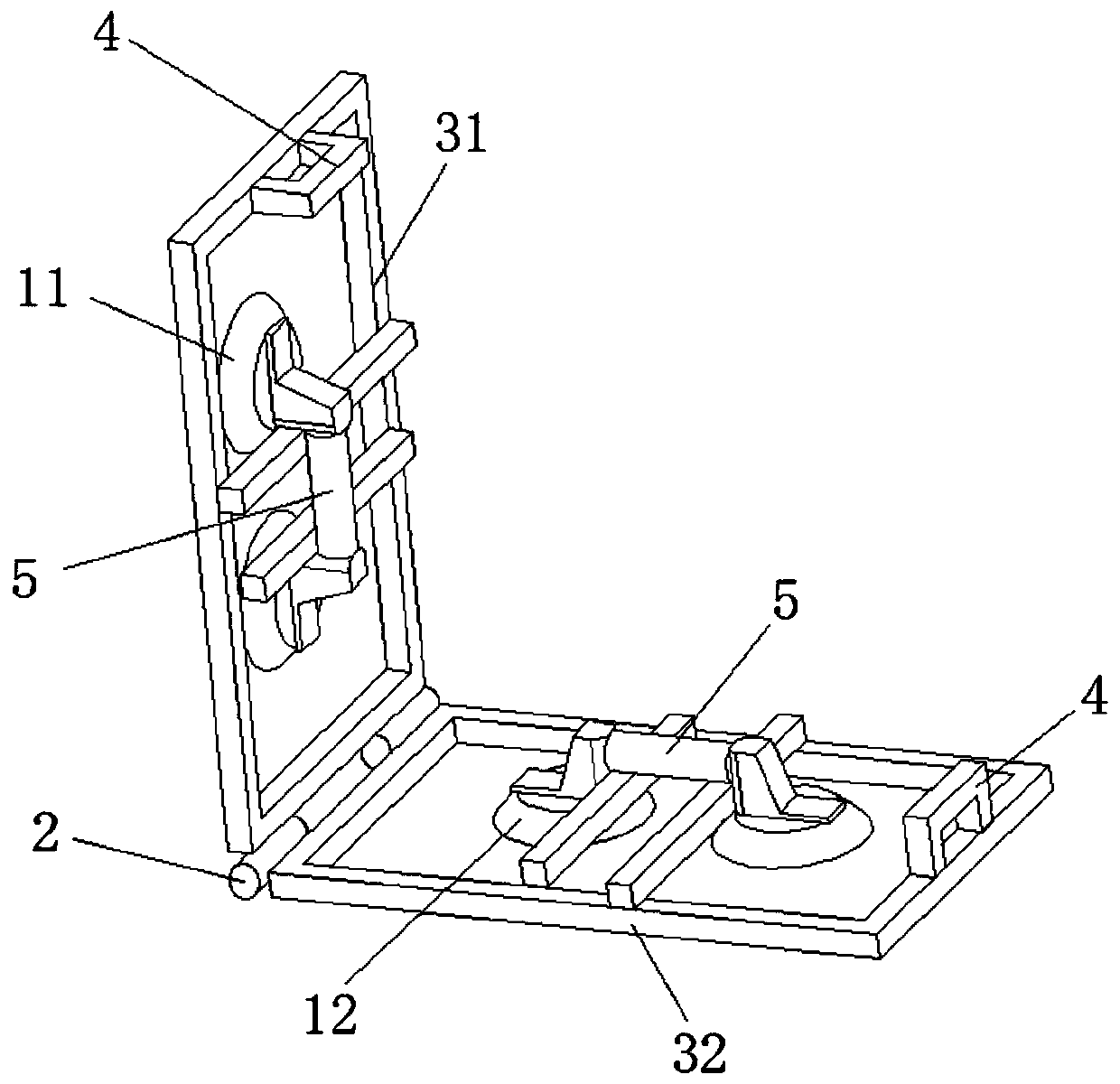

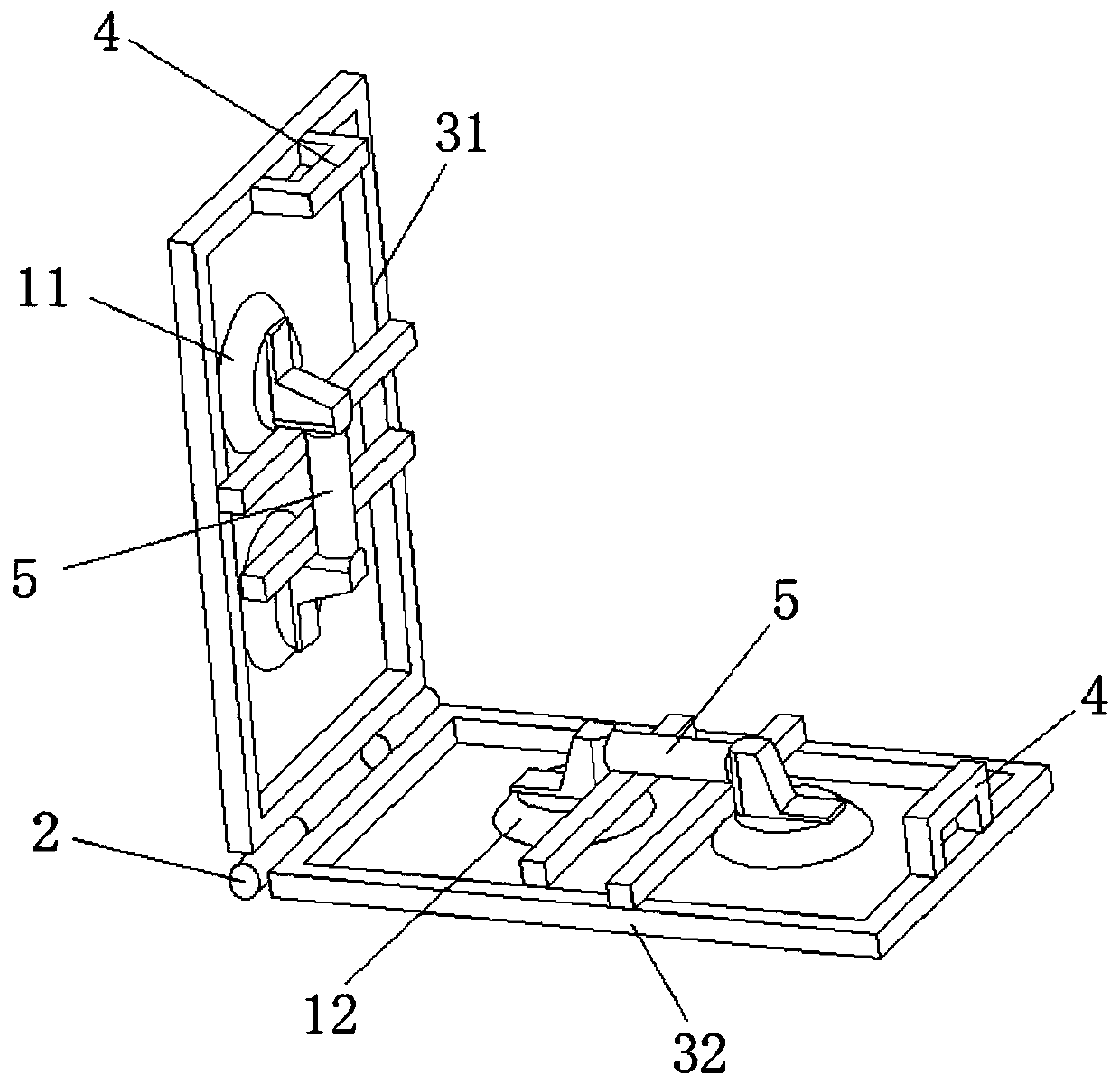

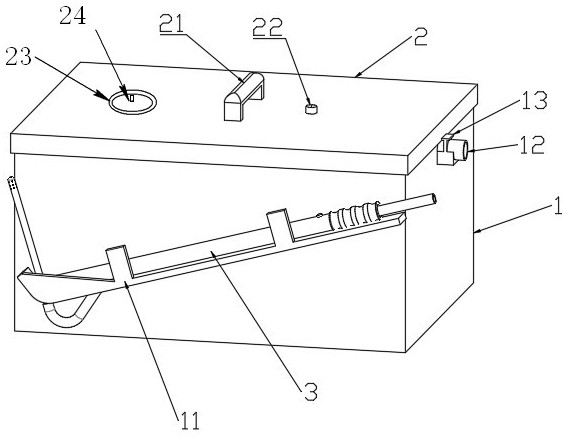

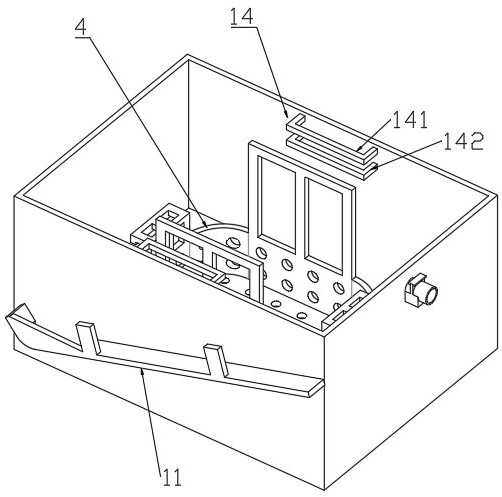

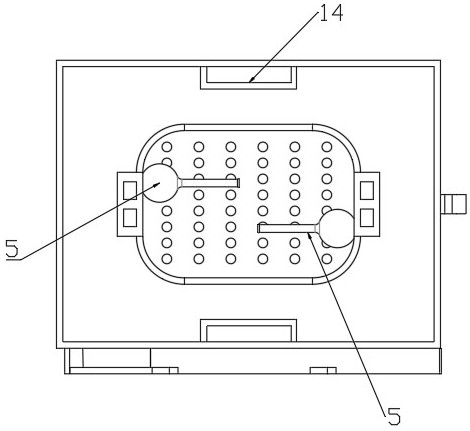

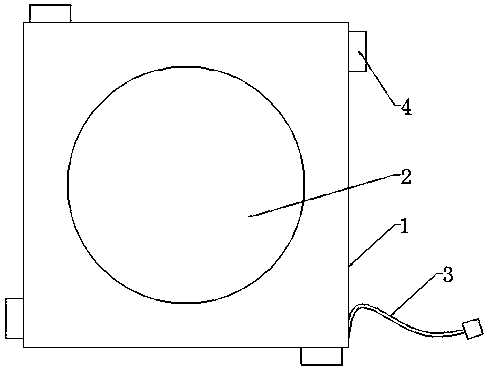

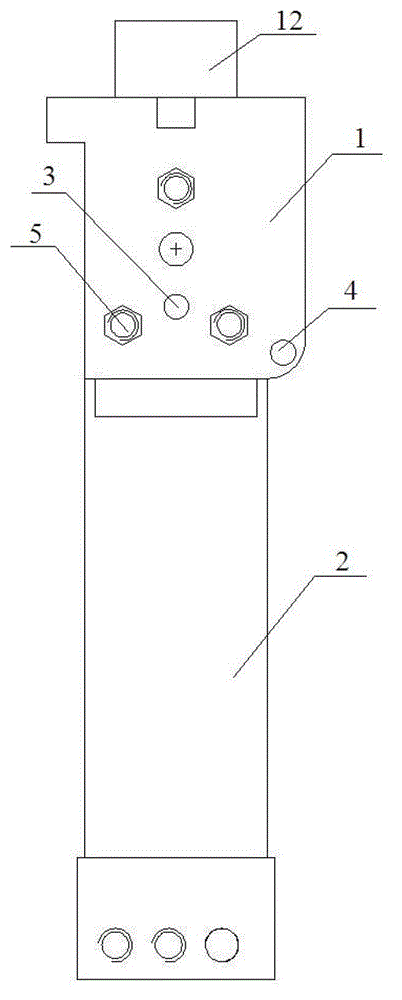

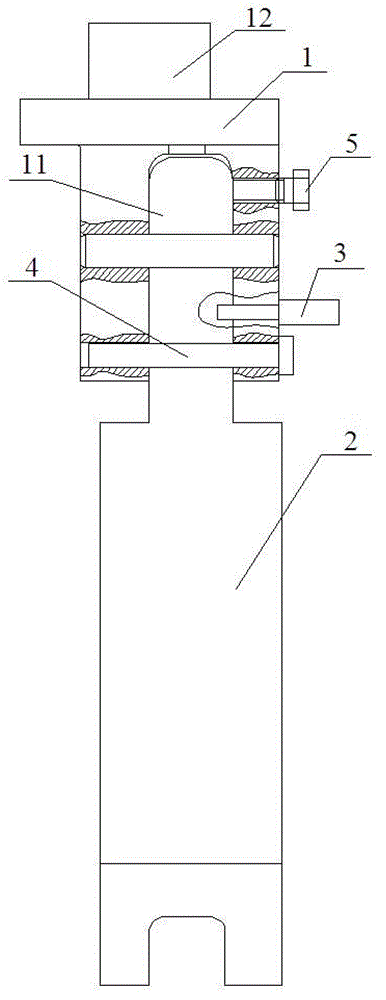

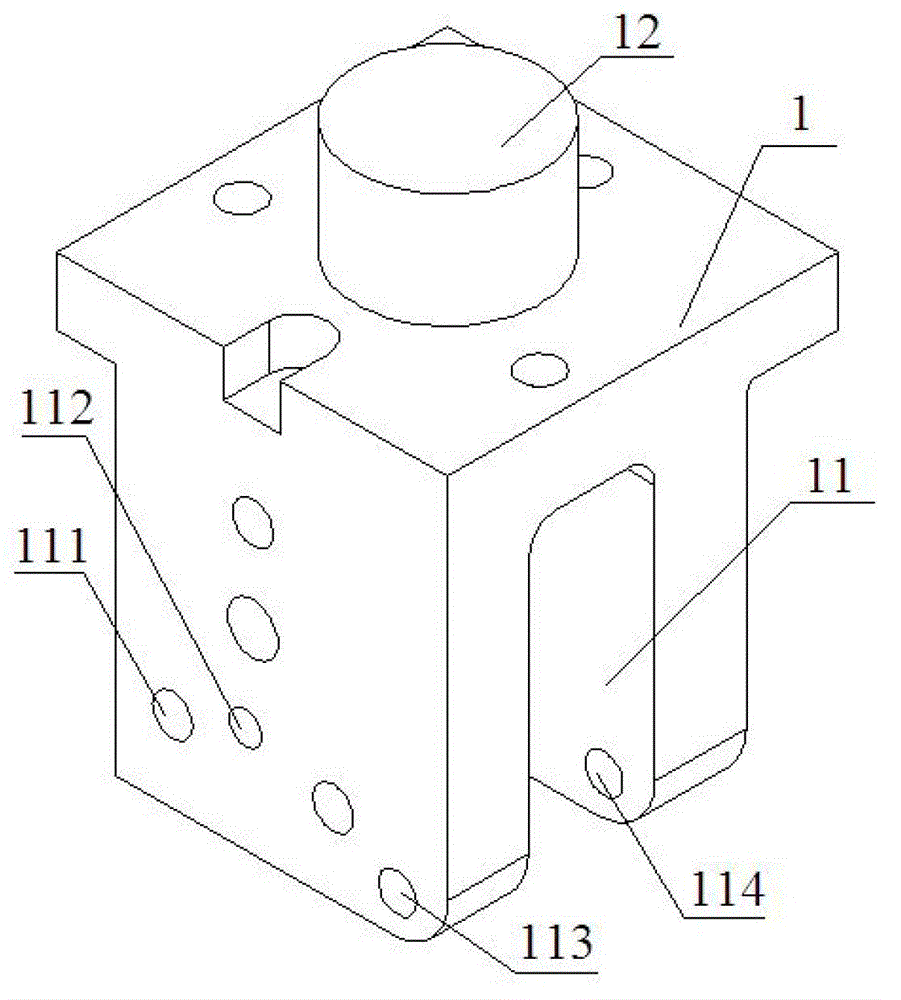

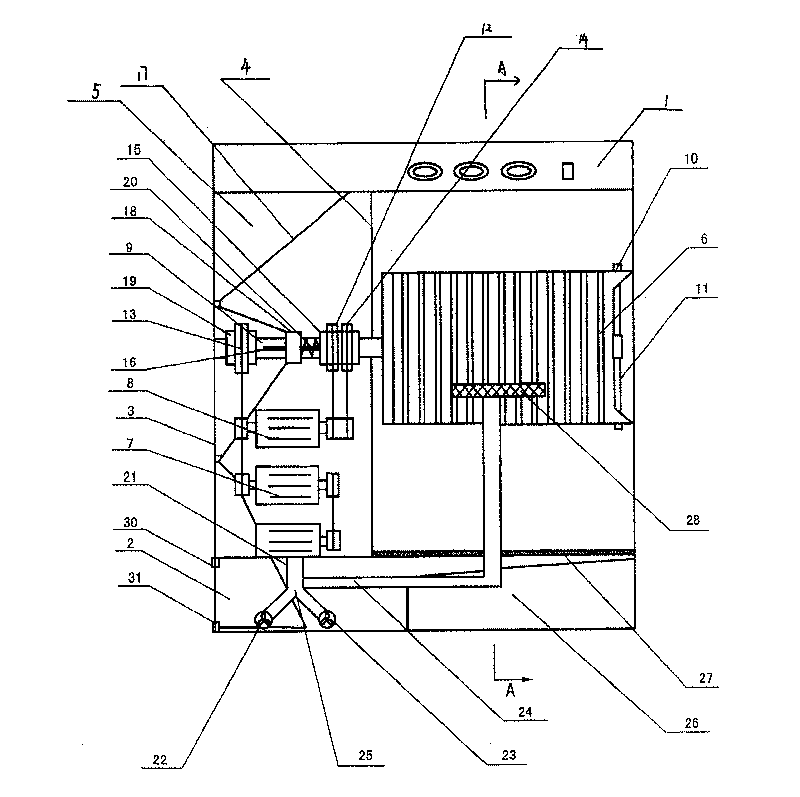

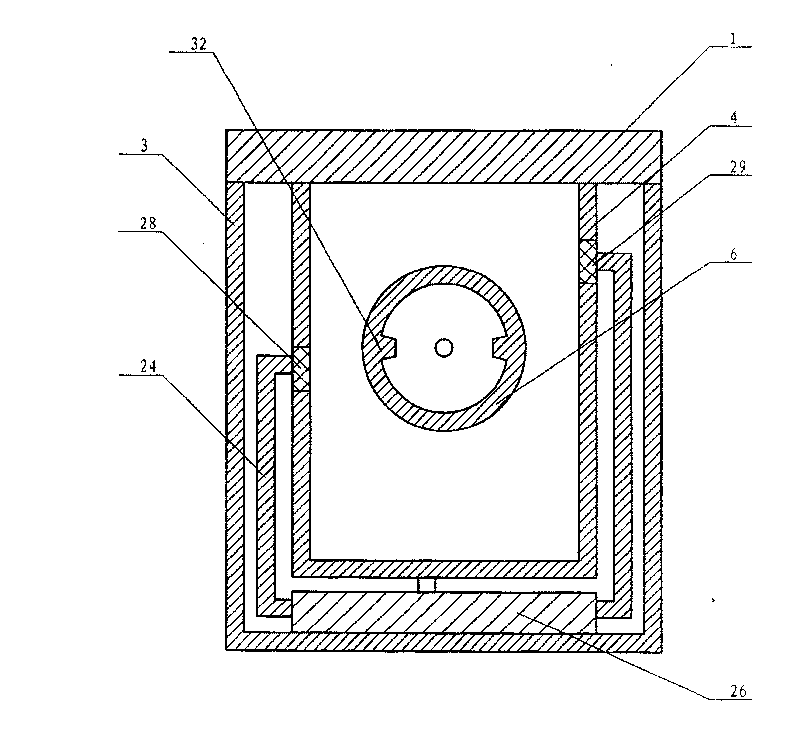

Mini-size safe deposit box

ActiveCN105370142AEasy to take and putImprove mobile stabilitySafesEngineeringMechanical engineering

The invention discloses a mini-size safe deposit box, and aims at providing the mini-size safe deposit box good in structural stability, smooth in running, good in stability of storage box taking / placing and moving and convenient to actually mount and manufacture. The mini-size safe deposit box comprises a box body, a vault door arranged on the side face of the box body, a storage box containing frame arranged in the box body and a rail type fetching device arranged in the box body. The mini-size safe deposit box is characterized in that the rail type fetching device comprises an upper rail, a lower rail, a lifting mechanism trolley and a first horizontal movement execution mechanism, wherein the upper rail and the lower rail are arranged in the box body in parallel, the lifting mechanism trolley is arranged between the upper rail and the lower rail and can slide along the upper rail and the lower rail, and the first horizontal movement execution mechanism is used for driving the lifting mechanism trolley to slide along the upper rail and the lower rail; the lifting mechanism trolley is provided with a vertical guide rail, a lifting containing table capable of descending and ascending along the vertical guide rail and a lifting execution mechanism used for driving the lifting containing table; and a box fetching mechanism is arranged on the lifting containing table.

Owner:NINGBO CHAOPING INTELLIGENT TECH

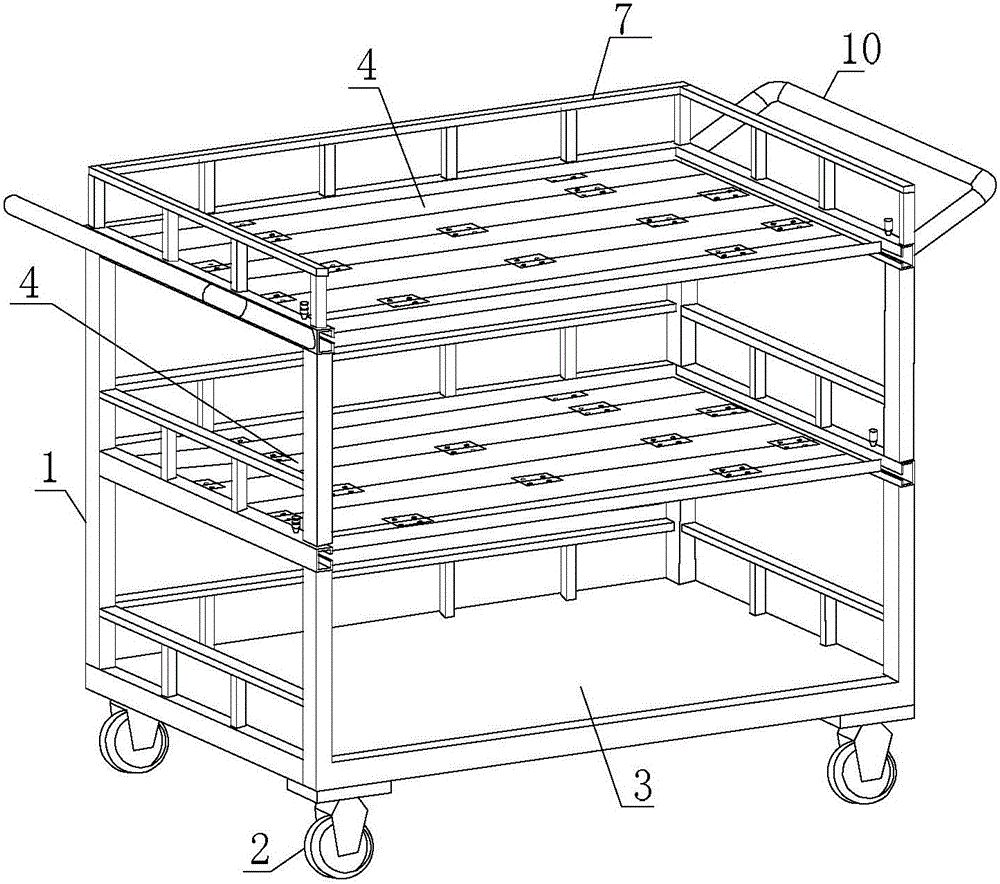

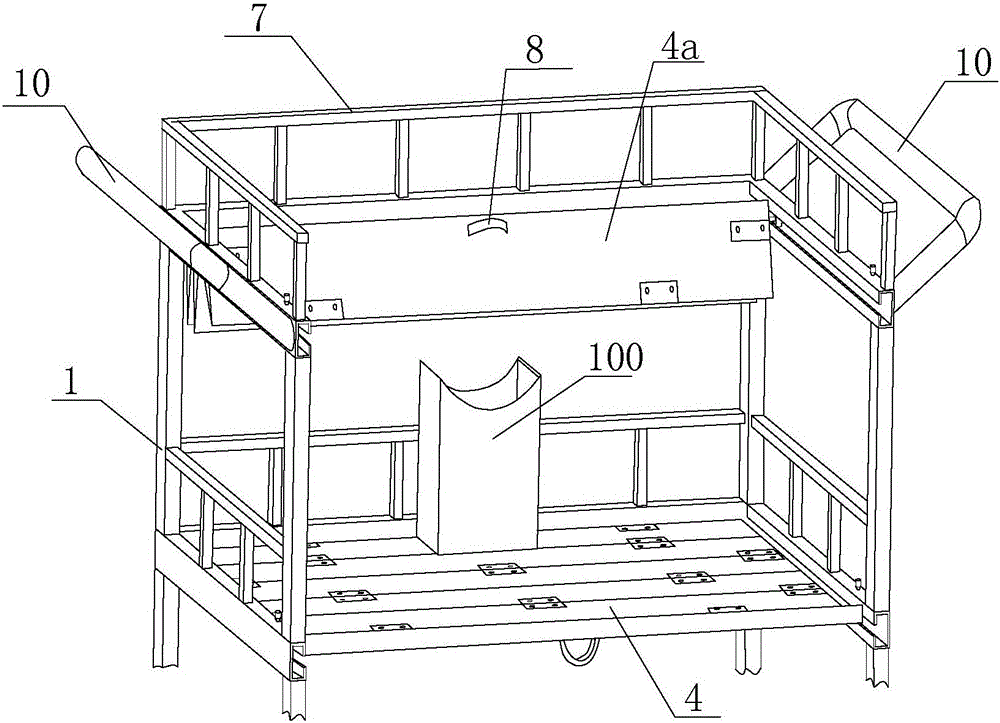

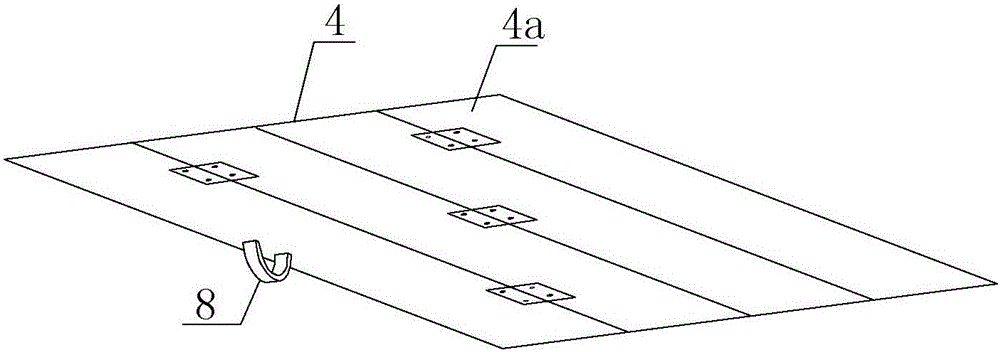

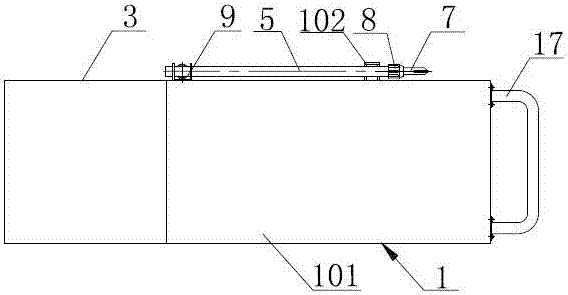

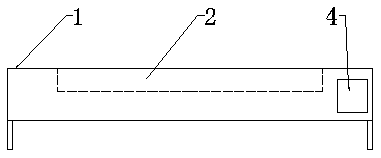

Silicon-wafer transport trolley

The invention discloses a silicon-wafer transport trolley, and belongs to the technical field of solar-cell production. The silicon-wafer transport trolley comprises a trolley frame and a plurality of layers of partition plates which are arranged on the trolley frame and used for allowing silicon wafers to be placed, wherein rolling wheels are arranged at the bottom of the trolley frame. The silicon-wafer transport trolley is characterized in that the partition plates comprise a bottom plate positioned at the bottom, and a plurality of upper partition plates positioned above the bottom plate; each upper partition plate comprises a plurality of folding plates which can be overlapped and unfolded mutually; the height of the bottom end of each of the folded folding plates is higher than that of the upper end of a silicon-wafer box; two ends of each upper partition plate are connected with the trolley frame in a sliding manner; the inner side of each upper partition plate is hinged to the trolley frame. Through the adoption of the silicon-wafer transport trolley disclosed by the invention, the silicon-wafer box is convenient to fetch and place, and the phenomenon that because silicon wafers are collided during moving, the silicon wafers are damaged is avoided; besides, the transportation volume of a unit transport machine is increased, and the transport efficiency is improved.

Owner:TRINA SOLAR CO LTD

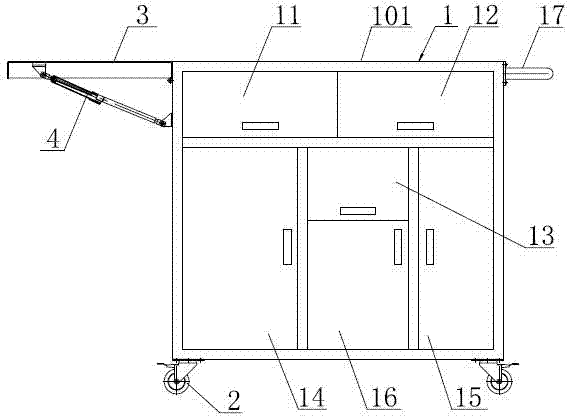

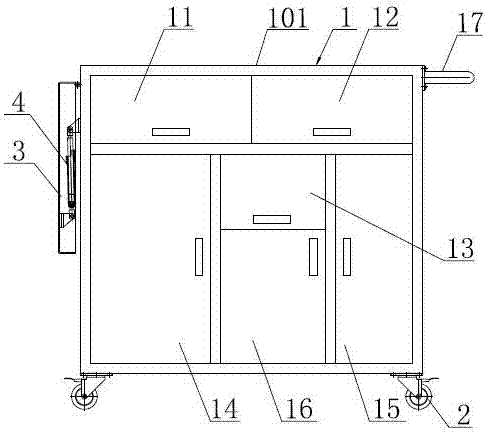

Multifunctional vaccination emergency ambulance

ActiveCN107080658AEasy to take and putSimple structureSurgical furnitureInfusion devicesVaccinationGas spring

The invention discloses a multifunctional vaccination emergency ambulance. The multifunctional vaccination emergency ambulance includes a car body; the bottom of the car body is provided with a roller; the top of the car body is an operation table board; the interior of the car body is an accepting space; the accepting space is separated into a plurality of drawers and a plurality of accepting cabinets; all the drawers and accepting cabinets are opened at the same side; one end of the car body is provided with an emergency operation table plate; one end of the emergency operation table plate is hinged to the car body; a self-locking type gas spring is connected to the emergency operation table plate; a piston rod of the self-locking type gas spring is hinged to the plate bottom of the emergency operation table plate; the emergency operation table plate can turn up to a position where the top surface of the emergency operation table plate is flush with the operation table board at the top of the car body, and locks the position, then the emergency operation table plate can turn down to a position where the emergency operation table plate is stored at one end of the car body. The multifunctional vaccination emergency ambulance has the advantages of being simple and practical, flexible and convenient, sufficient and orderly in accepting space, and providing great convenience for first aid.

Owner:中华人民共和国张家港海关

Multifunctional shoe rack

PendingCN106901513AEasy accessEasy to classify and placeWardrobesStructural engineeringMechanical engineering

Owner:彭威

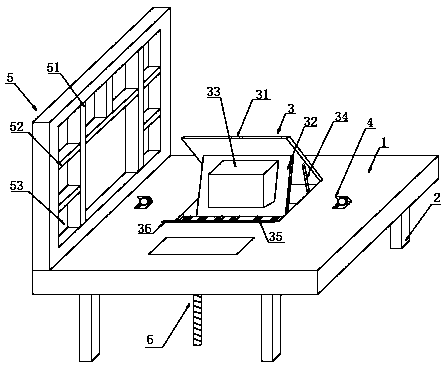

Computer Internet of things teaching and practical training device

InactiveCN110367694AAdjustable angleConvenient teaching workStands/trestlesTablesDeskInternet of Things

The invention discloses a computer Internet of things teaching and practical training device, relates to the field of Internet of things teaching, and mainly aims at solving the problem that an existing computer Internet of things teaching and practical training device is low in functionality. The computer Internet of things teaching and practical training device includes a practical training desk, a teaching mechanism, a lamp and a storage device are arranged on the practical training desk, the teaching mechanism includes a protection cavity, a first cover plate is arranged on the protectioncavity, a fixed plate is further connected on the first cover plate in a rotating manner, a projector is fixed on the fixed plate, a lifting device is arranged on the practical training desk, the lifting device includes a lifting base arranged on the practical training desk, a fixing rod is fixed on the bottom of the lifting base, support rods are arranged on the two sides of the fixing rod and buffering balls are arranged on the tops of the support rods, thus the functionality of the practical training device is improved and the effect of teaching is improved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Bamboo pen container

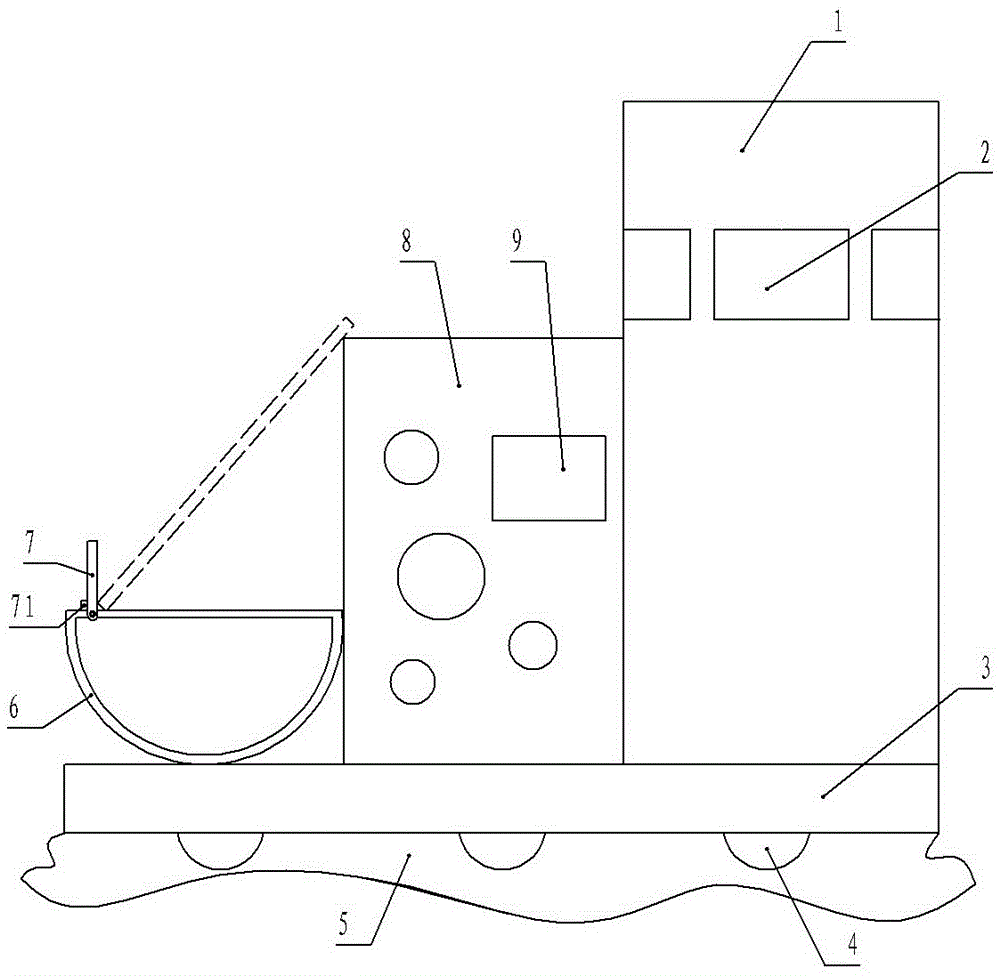

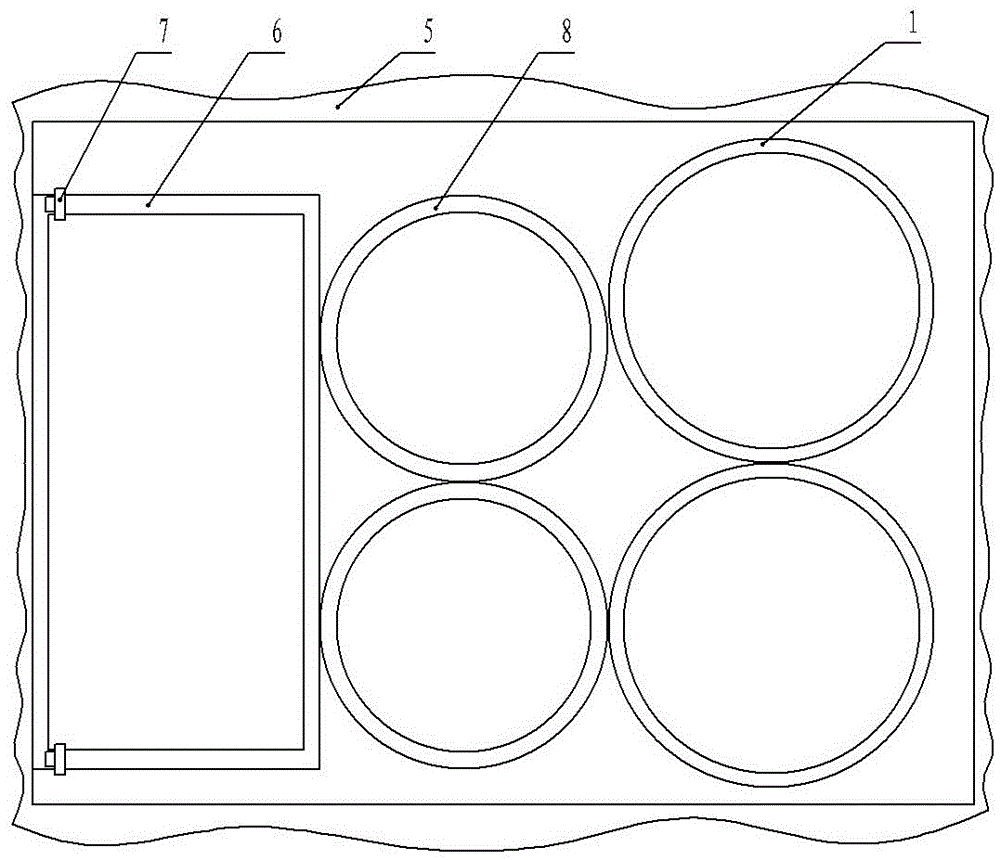

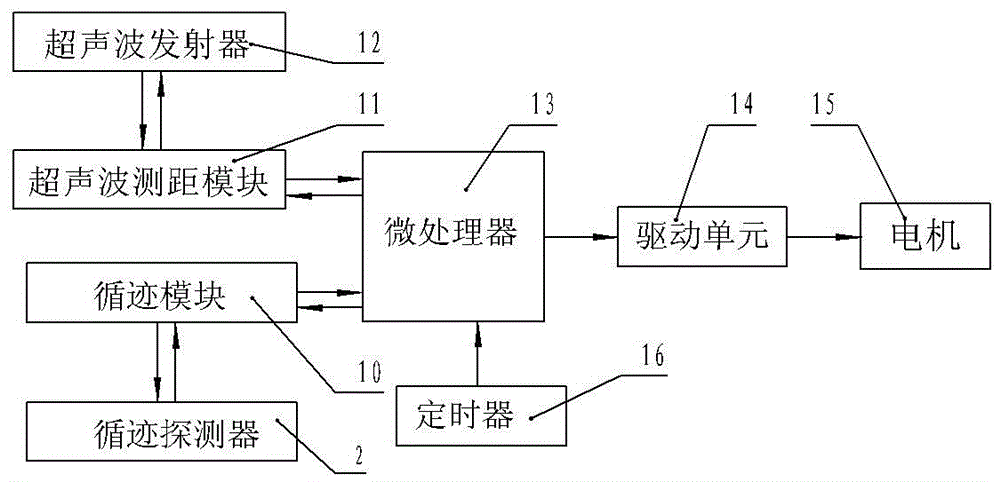

InactiveCN106183570AEasy to take and putEasy to watchAutomatic obstacle detectionTravelling automatic controlElectricityEngineering

The invention discloses a bamboo pen container, and belongs to the technical field of bamboo processing. The pen container comprises container bodies, wherein a plurality of the container bodies with different heights are provided, and are all vertically arranged at the upper end of a support shell, a half container body with an upward opening and transverse to each container body is arranged at one side of the container body, and location columns stretching outwards are hinged at the two opposite sides of each half container body; and a tracking detector and a clock are arranged on one of the container bodies, a duster cloth is movably connected to the outer edge of the support shell, a motor controlled through a controller is arranged in the support shell, universal wheels driven through the motor are arranged at the bottom end of the support shell, and the tracking detector and the clock are electrically connected with the motor through the controller. The bamboo pen container disclosed by the invention is capable of solving the problem of a single function of an existing bamboo pen container.

Owner:三江县善茶轩工艺品有限公司

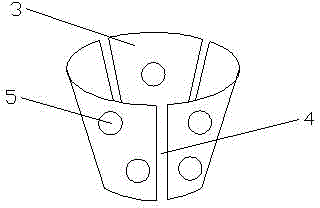

Wafer cooling tray

InactiveCN104576466AEasy to transportEasy to put and takeSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention discloses a wafer cooling tray which comprises a tray main body and a plurality of wafer cooling tables arranged on the tray main body, wherein the wafer cooling tables are arranged on the tray main body in a projecting way; each wafer cooling table is formed by annularly splicing three arc-shaped sheets and is an inverted circular truncated cone body; the bottoms of the arc-shaped sheets are fixed on the tray main body, gaps are formed among the arc-shaped sheets, and breathable holes are formed in the outer side surfaces of the arc-shaped sheets. By the mode, the wafer cooling tray can cool and carry the wafer, is convenient for transportation, is convenient to clamp, place and take and greatly improves the cooling efficiency.

Owner:WUXI KENUODA ELECTRONICS

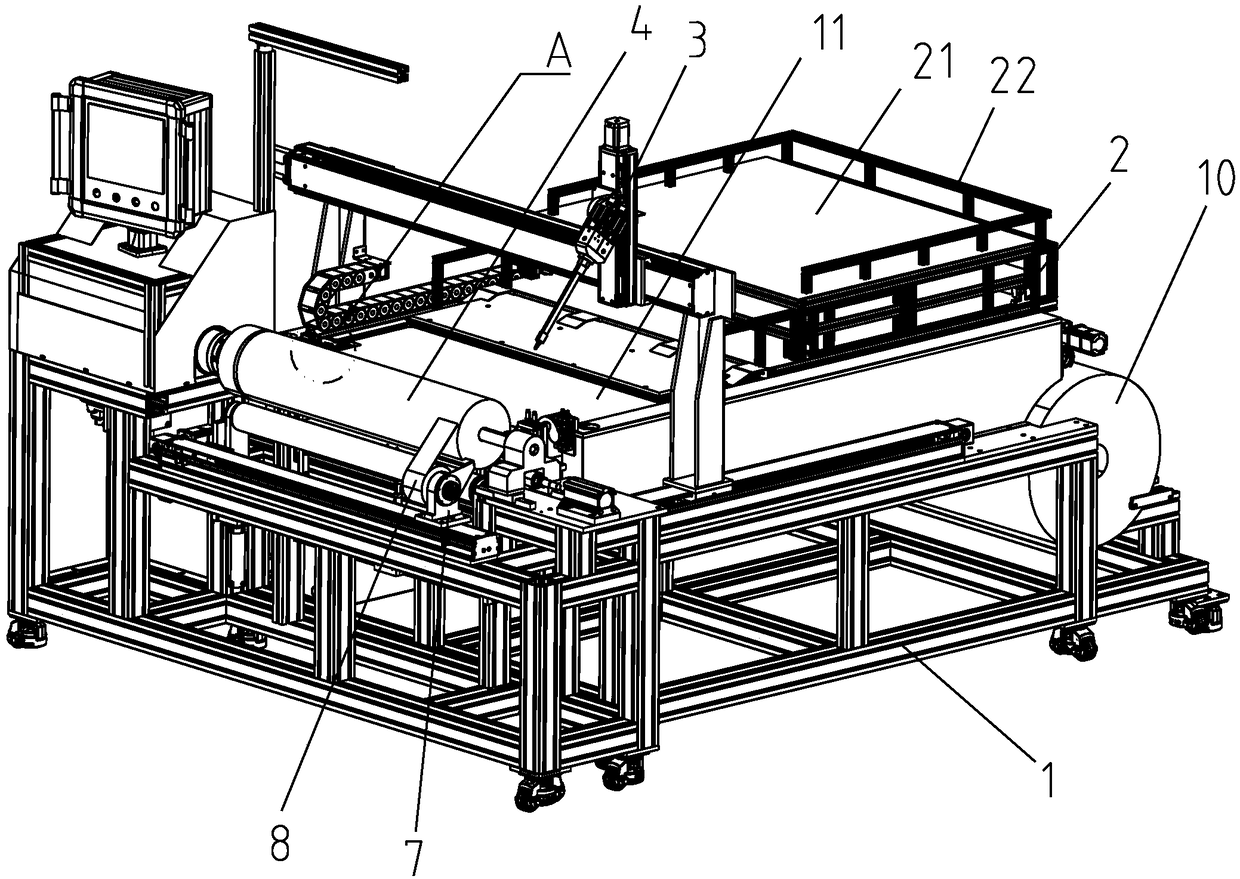

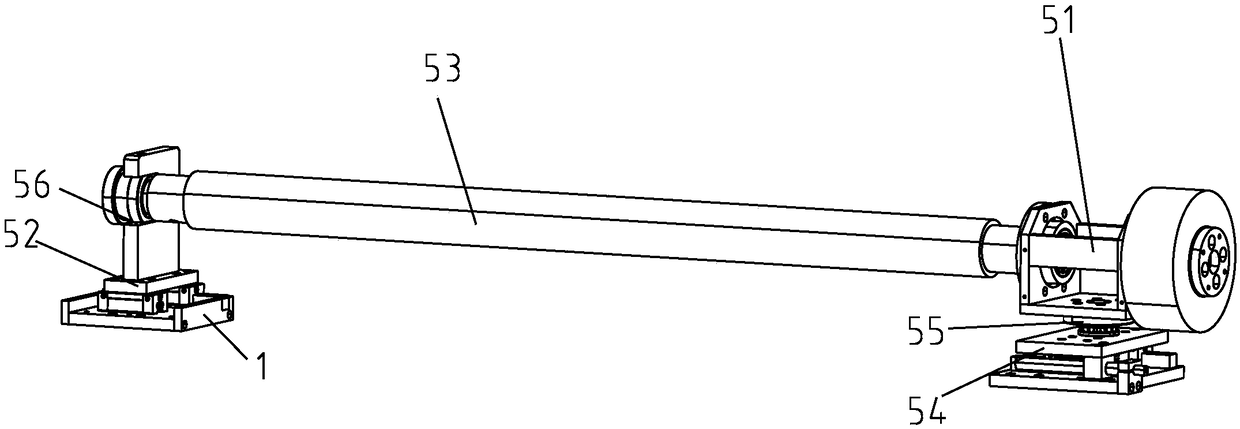

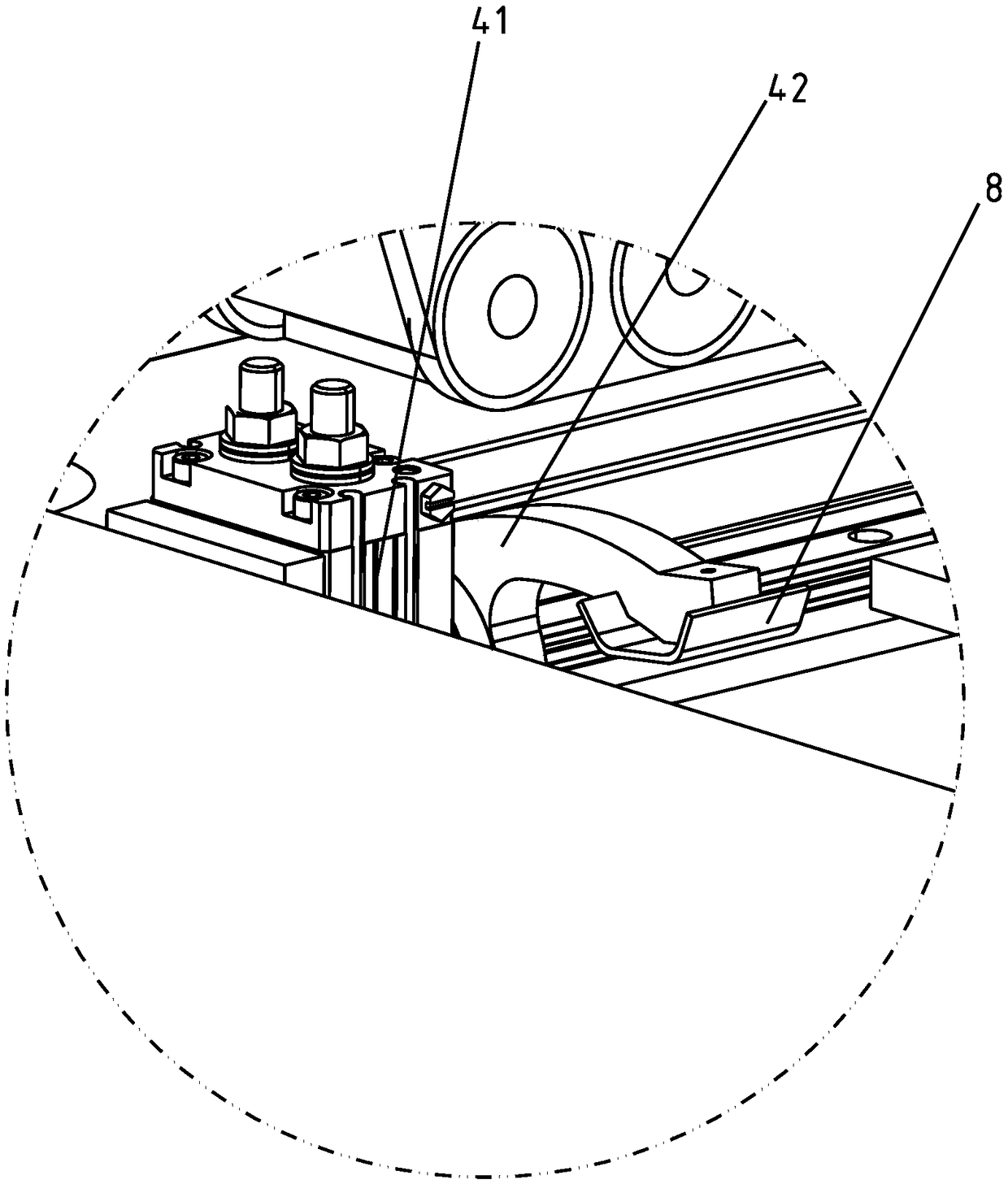

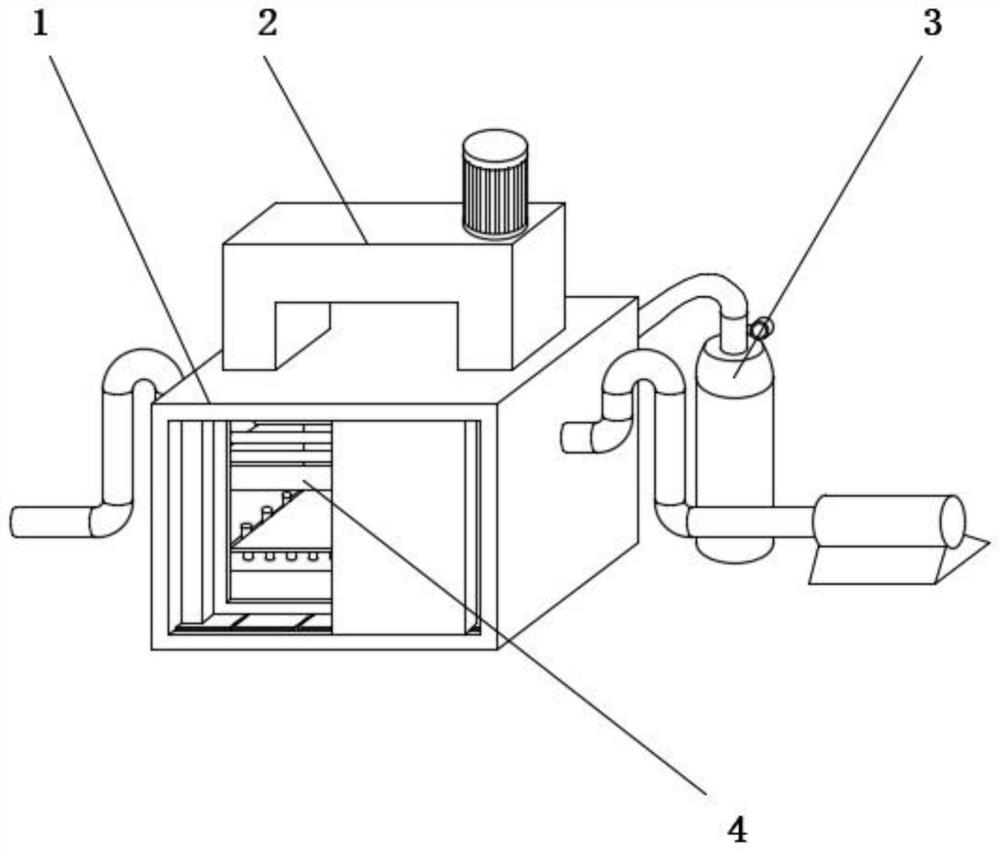

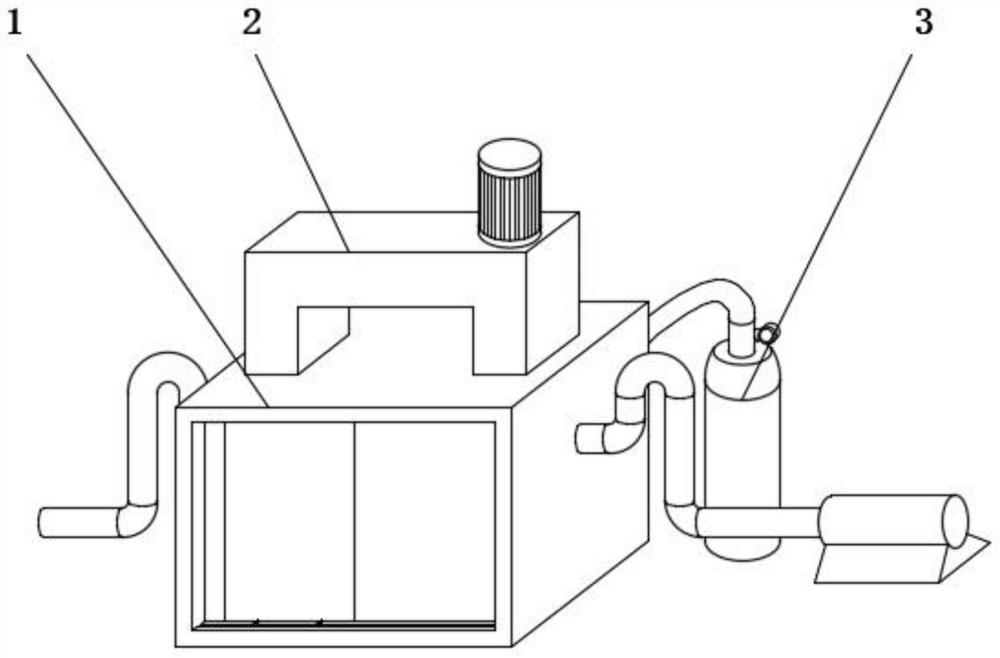

Industrial film winding machine and working method thereof

The invention discloses an industrial film winding machine and a working method thereof. The industrial film winding machine comprises a rack, an unwinding mechanism for supporting fresh water net rolls and unwinding the fresh water net rolls, a filter screen support for containing a filter screen, a glue applying mechanism used for conducting glue applying operation on the filter screen, a movingdrive device and a winding mechanism for winding a fresh water net on a fresh water net table and the filter screen to form a filter element; the rack is provided with the fresh water net table for supporting the fresh water net; the fresh water net unwound by the unwinding mechanism is flatly laid on the fresh water net table; the filter screen support is arranged on the rack in a sliding fit manner; and the moving drive device is arranged between the rack and the filter screen support so that the moving drive device can drive the filter screen support to move forwards to facilitating takingof the filter screen and placing of the filter screen on the fresh water net table and the moving drive device can drive the filter screen support to move backwards for resetting to facilitate glue applying operation on the filter element on the fresh water net table through the glue applying mechanism. By means of the industrial film winding machine and the working method, the filter element canbe well prepared, operation of a worker is facilitated, and the yield and quality of the filter element are ensured.

Owner:江苏讯海自动化科技有限公司

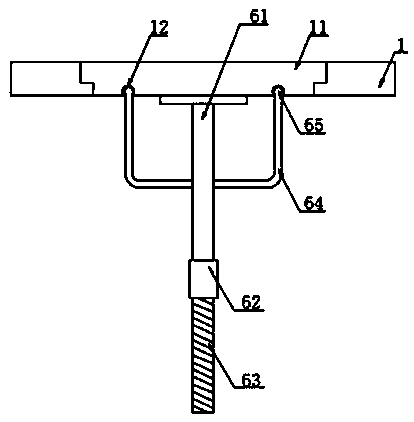

Convenient-to-remove electrode connection structure for electric heating floor

InactiveCN107438296AEasy to take and putNot easy to desolderHeating fuelOhmic-resistance electrodesEngineeringMagnet

The invention discloses an electrode connection structure of an electric heating floor which is easy to disassemble, which comprises a bottom plate, a panel and a conductive heating layer arranged between the bottom plate and the panel, and the electrodes of the conductive heating layer are connected to a power supply through wires with conductive sheets welded at the ends , the bottom plate and the panel on both sides of the electrode are respectively provided with holes and B magnets, and the wires in the holes are covered with A magnets and insulating plugs, and also include a cylindrical magnet seat connected to the hole, the magnet seat The closed end is provided with a wire perforation, the outer wall of the closed end is attached to the conductive sheet, the inner wall is attached to the A magnet, and the insulating plug is connected to the inner cavity of the magnet seat. When the invention is removed, the insulating plug is firstly taken out, and then the active force is applied to the movable A magnet through the magnet seat, so that the lead wires will not be desoldered and are convenient for reuse.

Owner:鄢贵龙

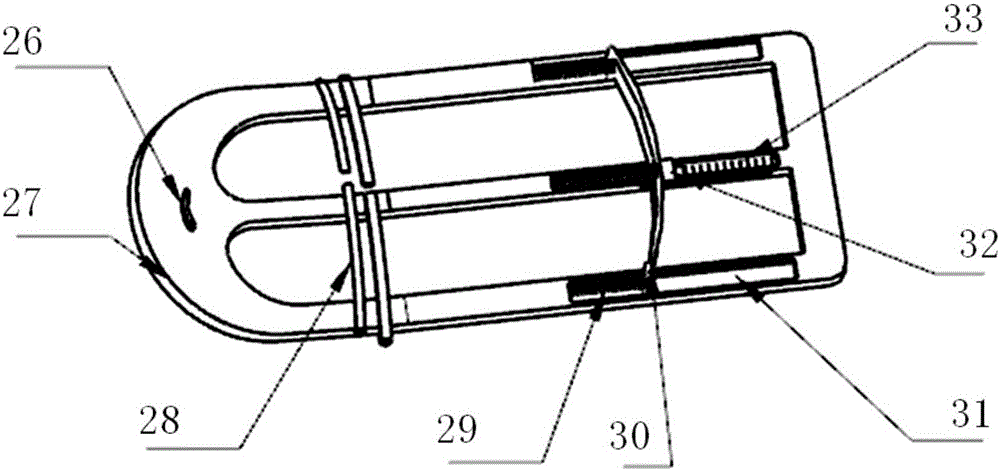

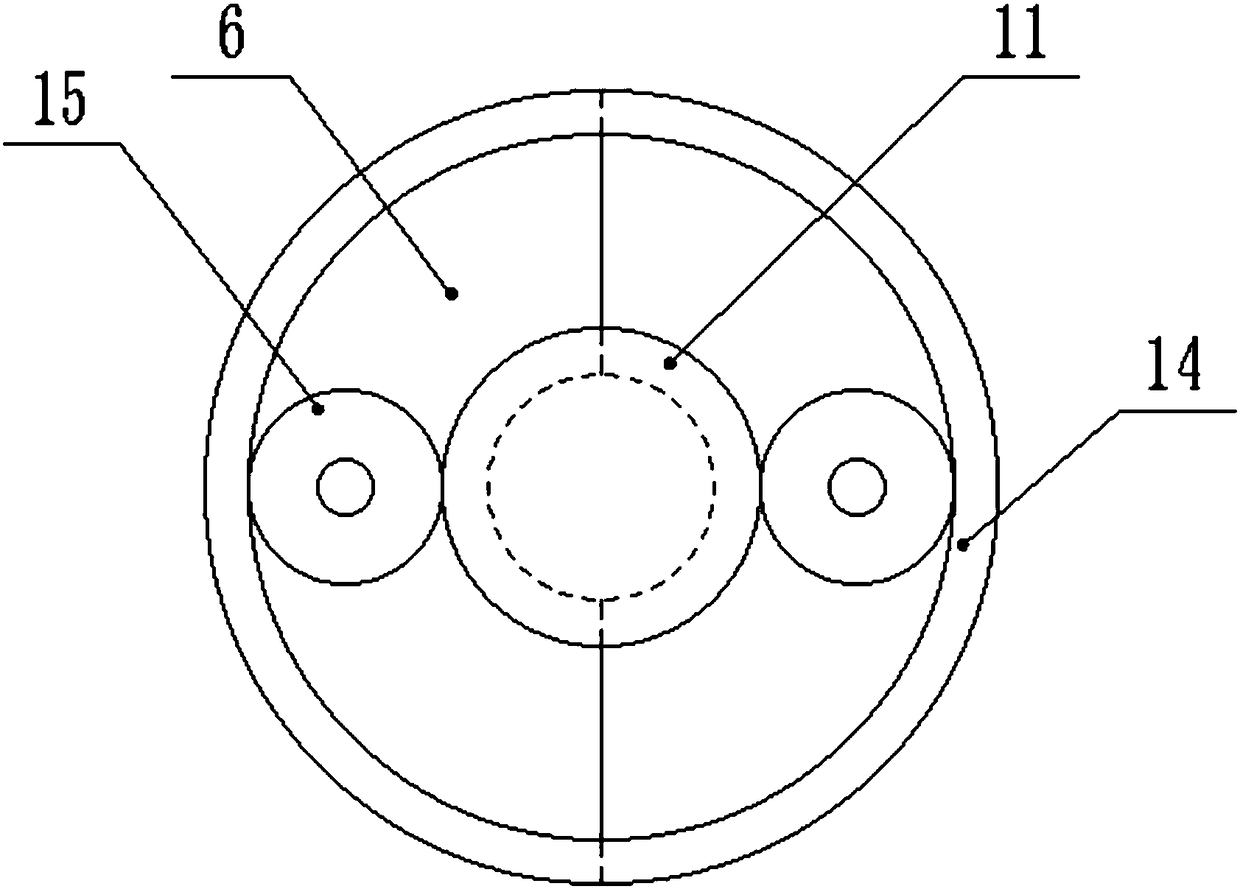

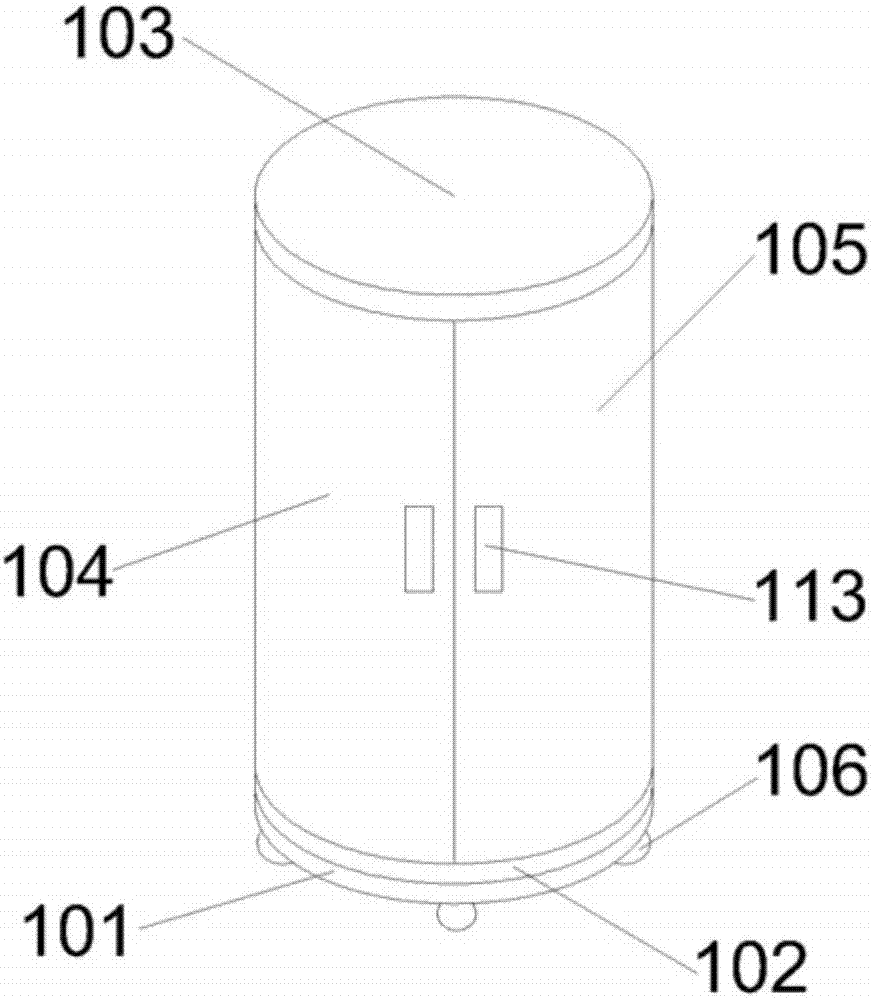

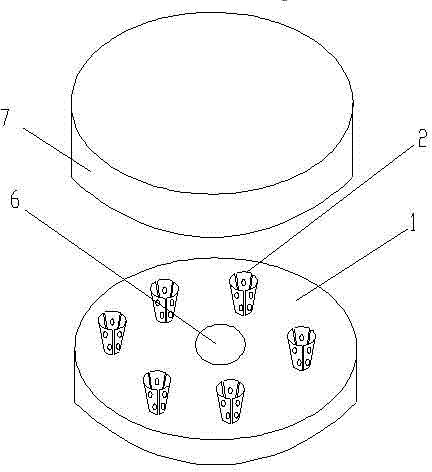

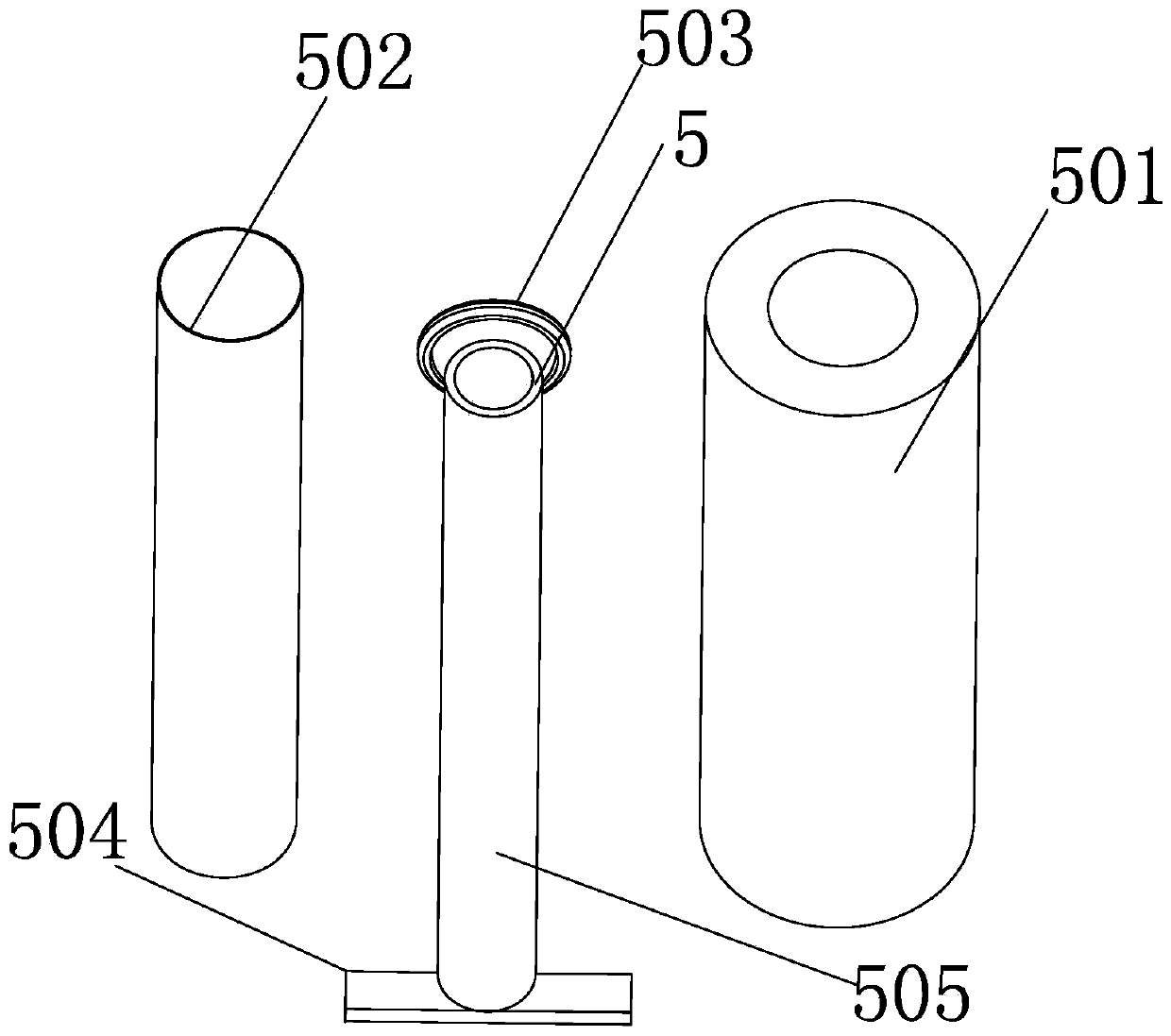

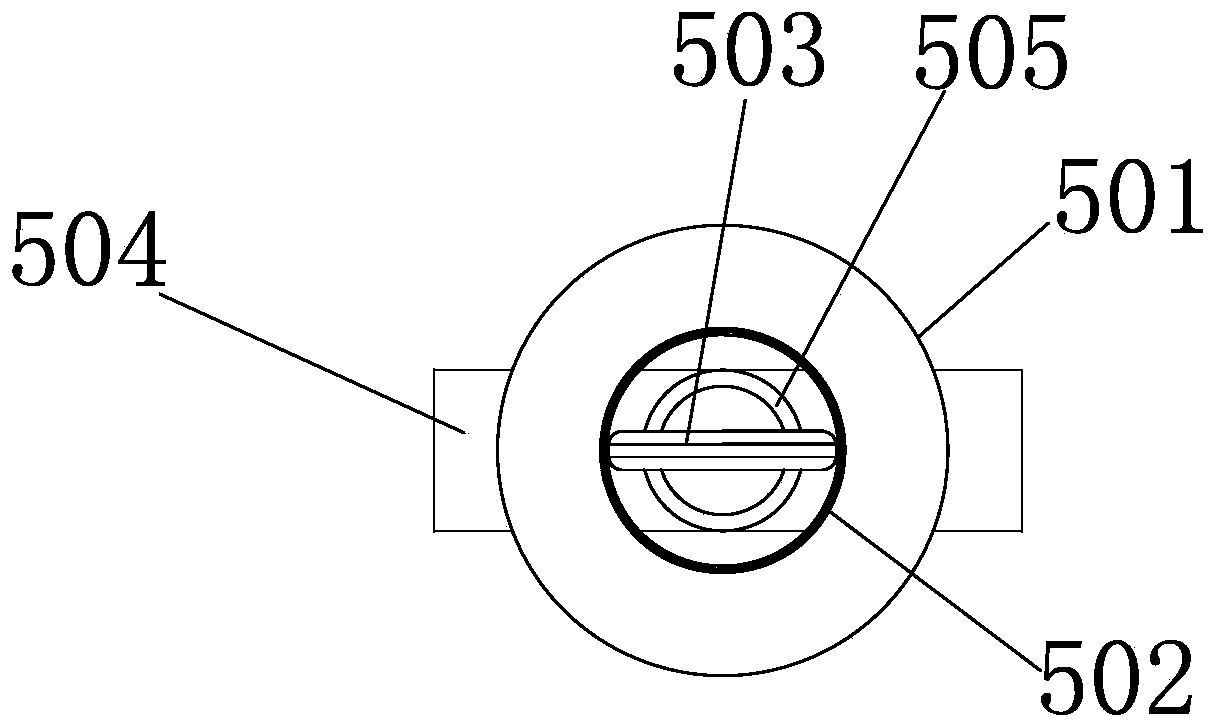

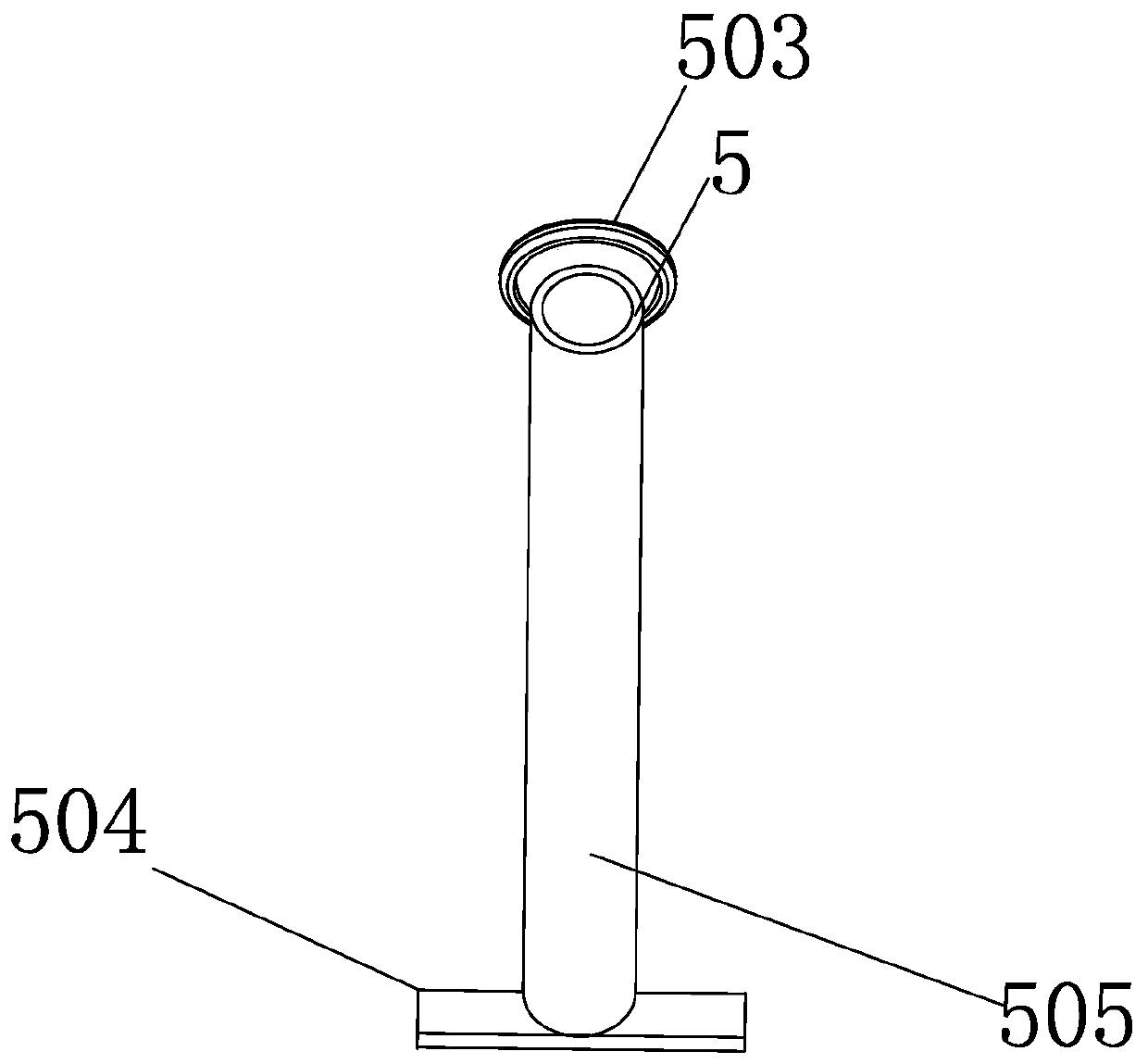

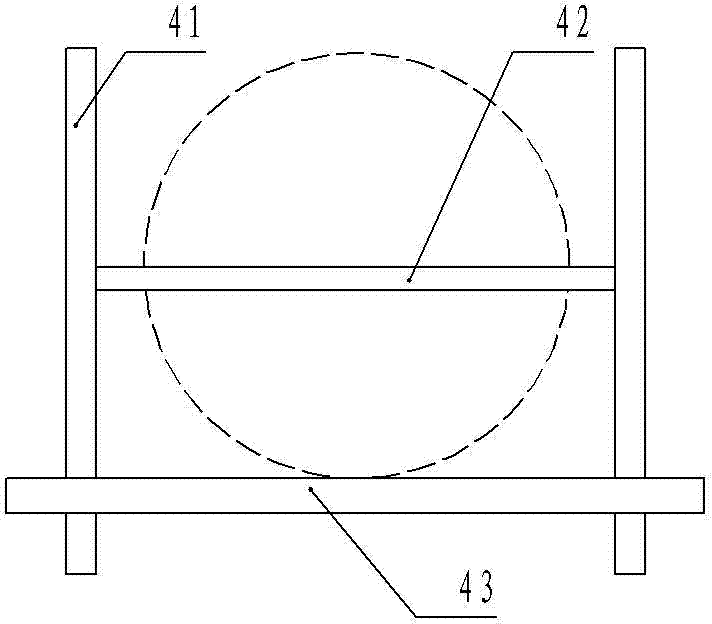

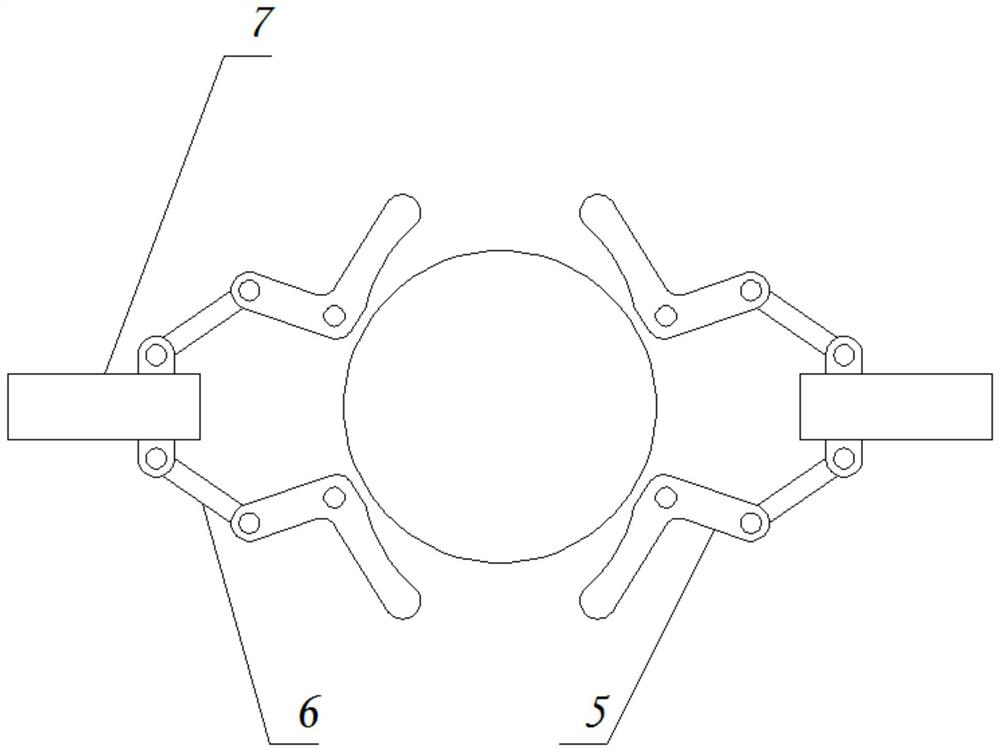

Acoustic emission inspection device for storage tank base plate corrosion

InactiveCN105241956APrecise positioningEasy to take and putAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesAcoustic emissionDisplay device

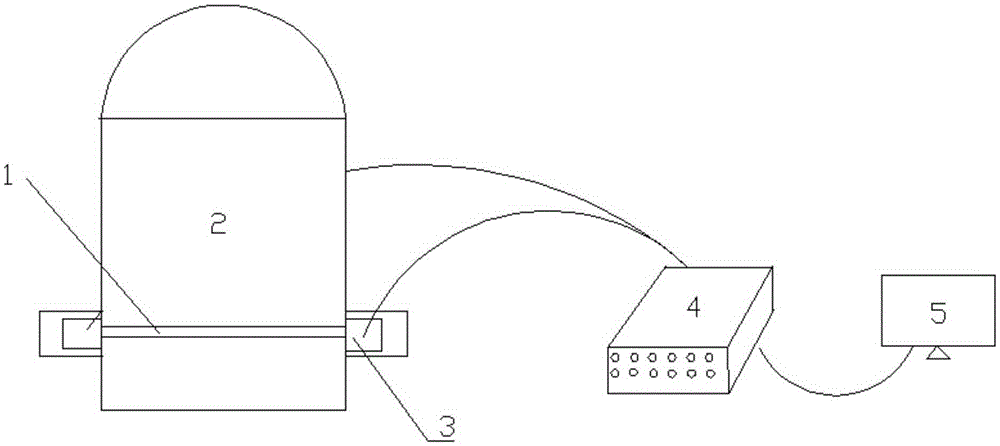

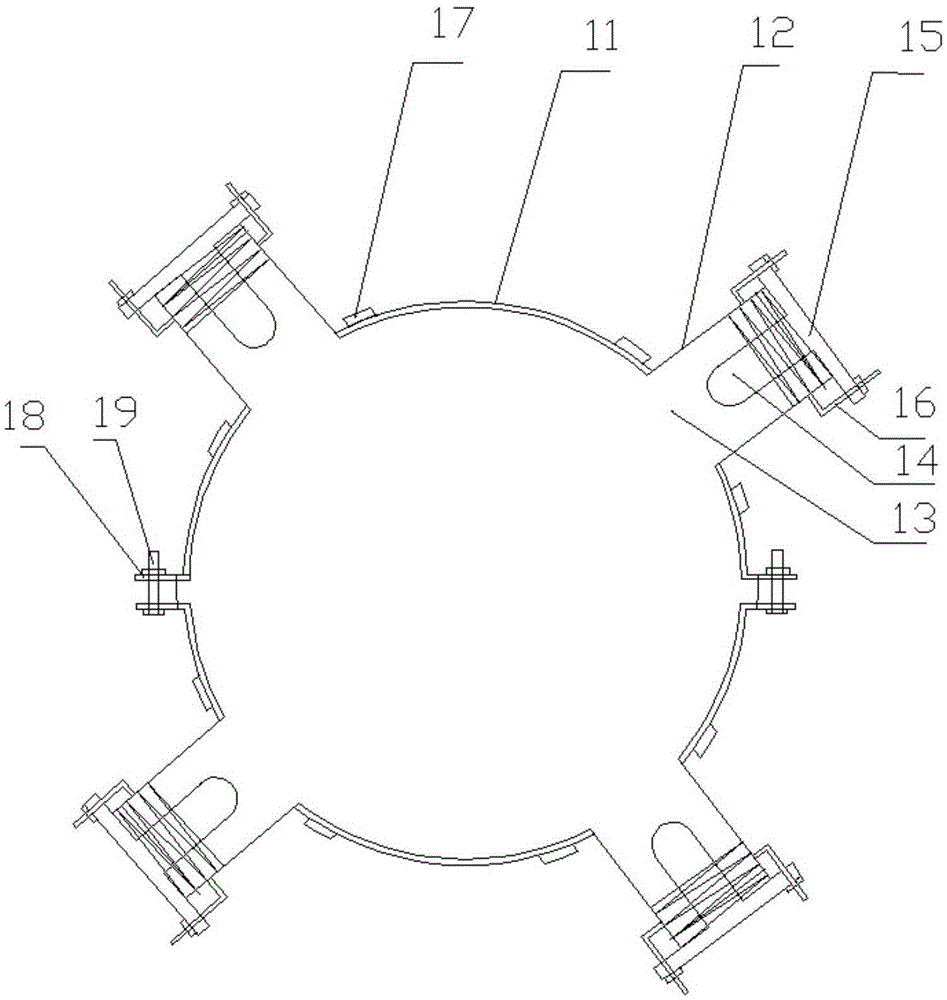

The invention discloses a detection device for storage tank base plate corrosion. The device includes acoustic emission inspection sensors adsorbed near the bottom of the storage tank through a magnet base, an acoustic emission detector connected to the acoustic emission inspection sensor through a data line, and a display connected to the acoustic emission detector. The magnet base comprises a hoop sleeving near the bottom of the storage tank; the hoop comprises two semicircular hoop rings detachably connected in a splicing way; 2-6 acoustic emission sensor cavities are uniformly arranged along the circumferential direction of the hoop; the sensor cavity is a cylinder with openings on both ends; the positions installed with the sensor cavities on the hoop are provided with through holes communicated with the sensor cavities; the front side wall of the sensor cavity is provide with an inverted U-shaped wire slot; and the top of the sensor cavity is detachably provided with a spring gland. The device facilitates the positioning and the installation of a plurality of acoustic emission inspection sensors along the circumference direction of the outer wall of the storage tank, not only improves the work efficiency, but also makes the effect of the measuring signal more accurate.

Owner:南京通用化工设备技术研究院有限公司

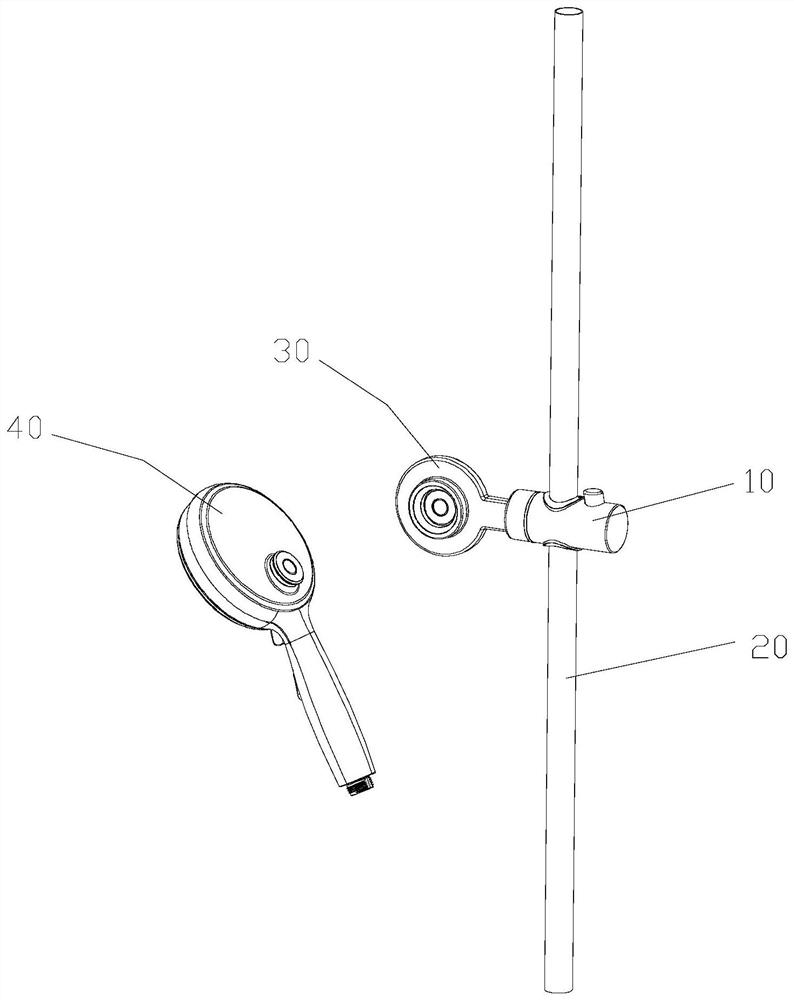

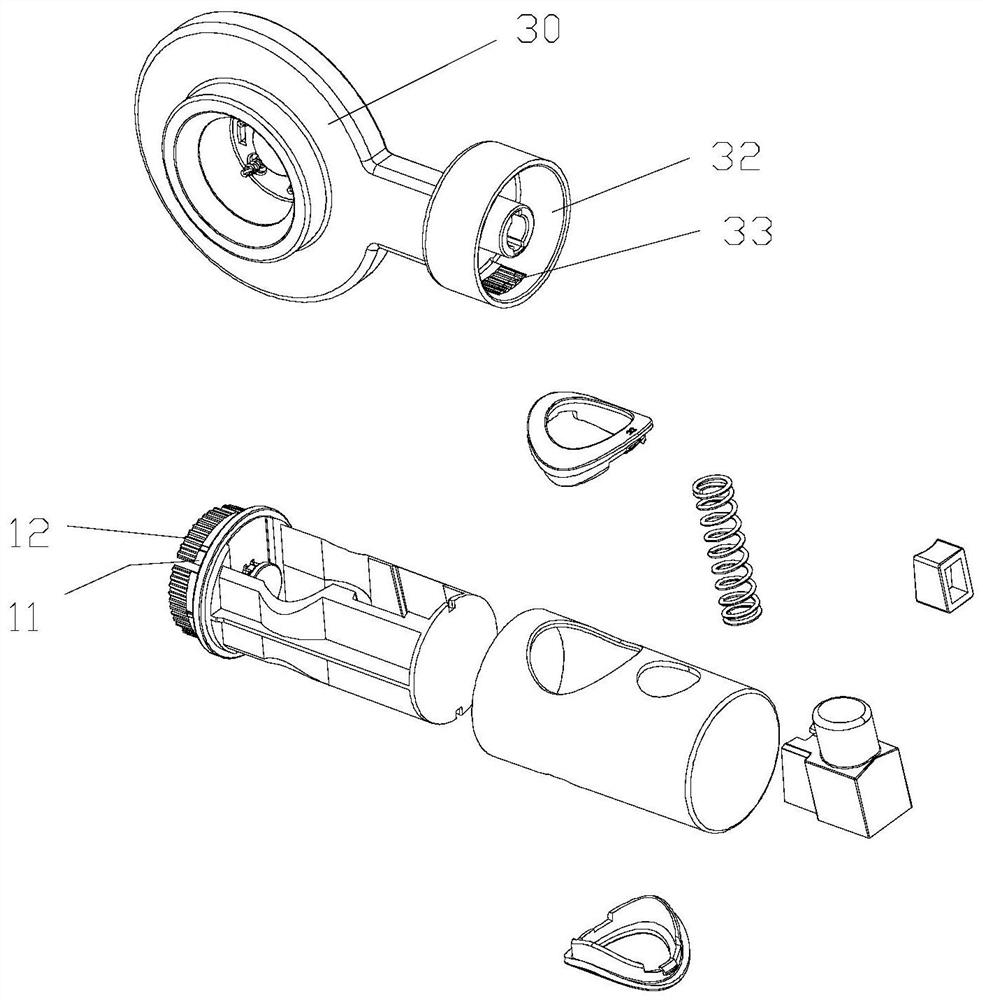

Magnetic attraction sliding seat

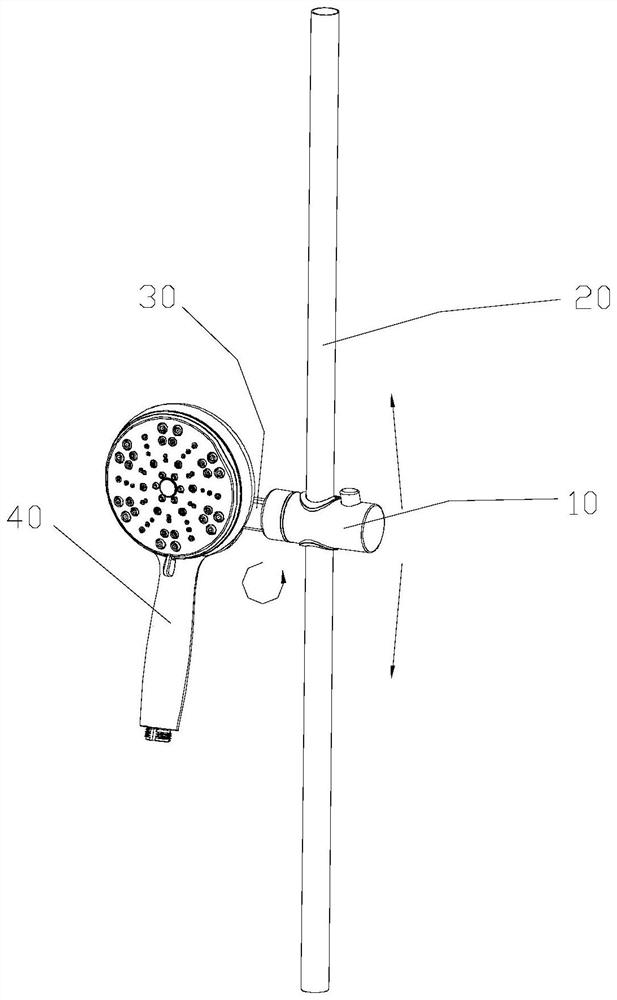

PendingCN113714014AEasy to operateEasy to take and putSpraying apparatusStructural engineeringControl theory

Owner:XIAMEN EASO CO LTD

Material transferring trolley for vehicle lamp

InactiveCN104260072AEasy turnoverAvoid bumps and scratchesWork tools storageRoller-waysEngineeringMaterial transfer

Owner:JIANGSU SHENTONG AUTO PARTS

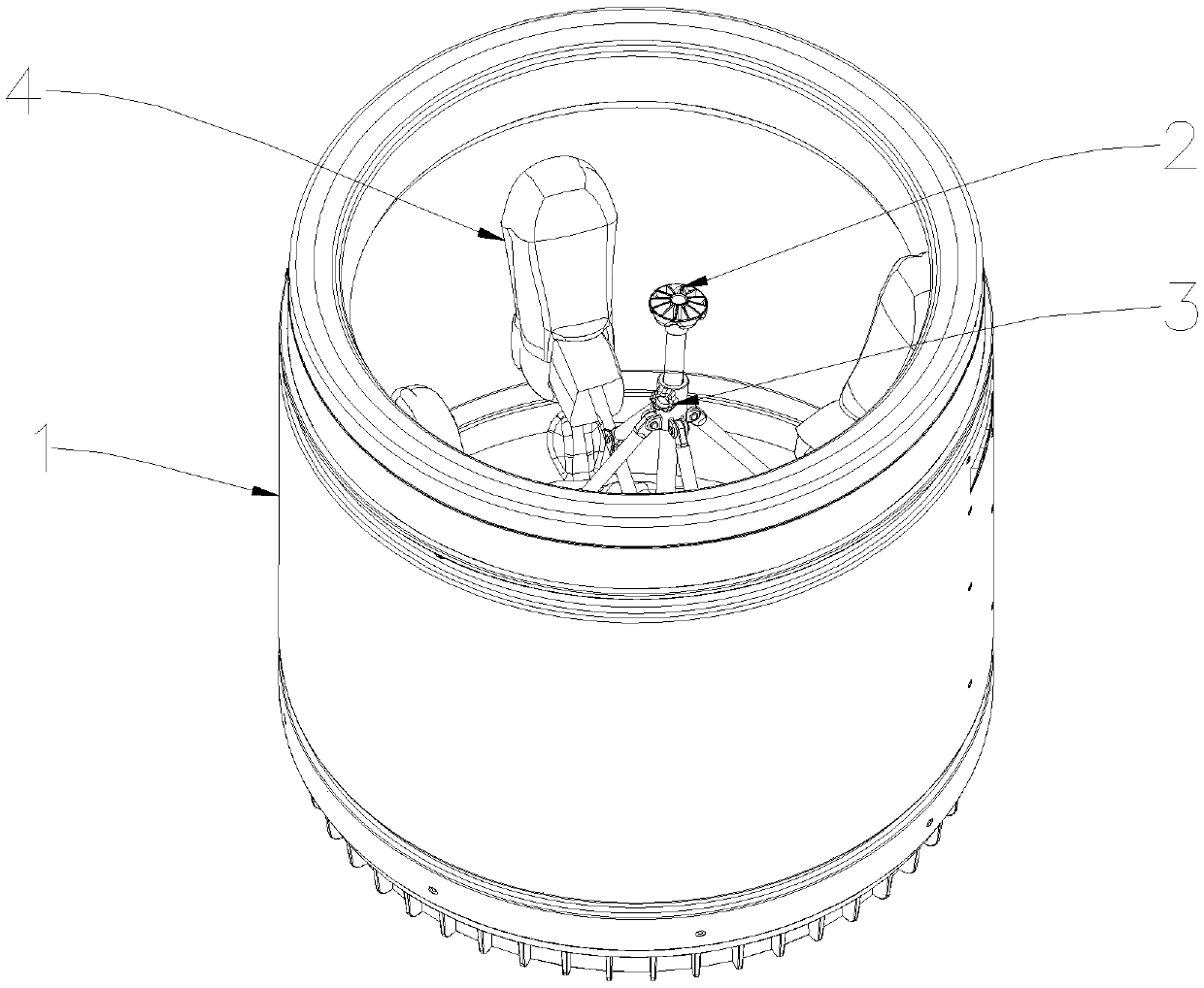

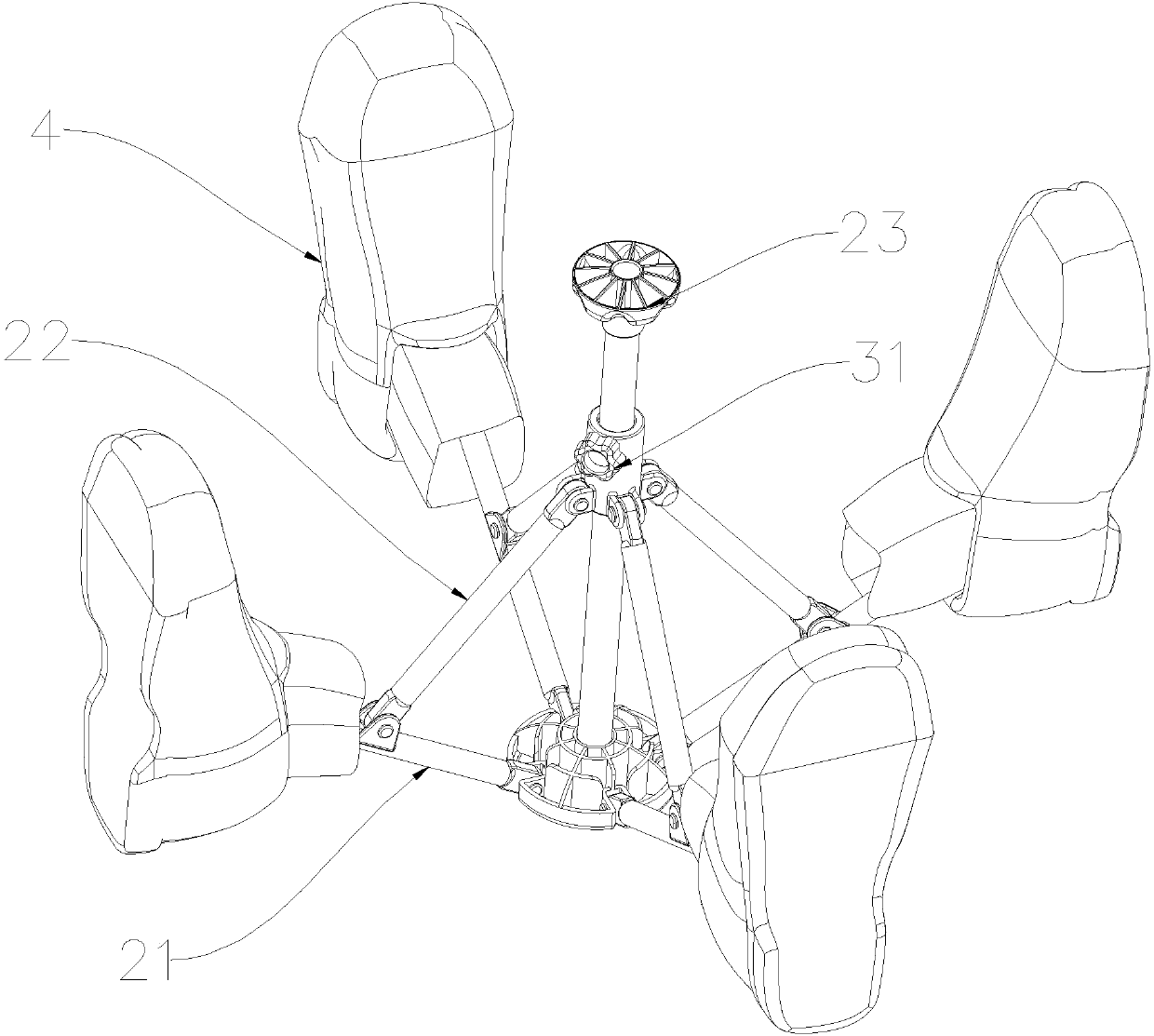

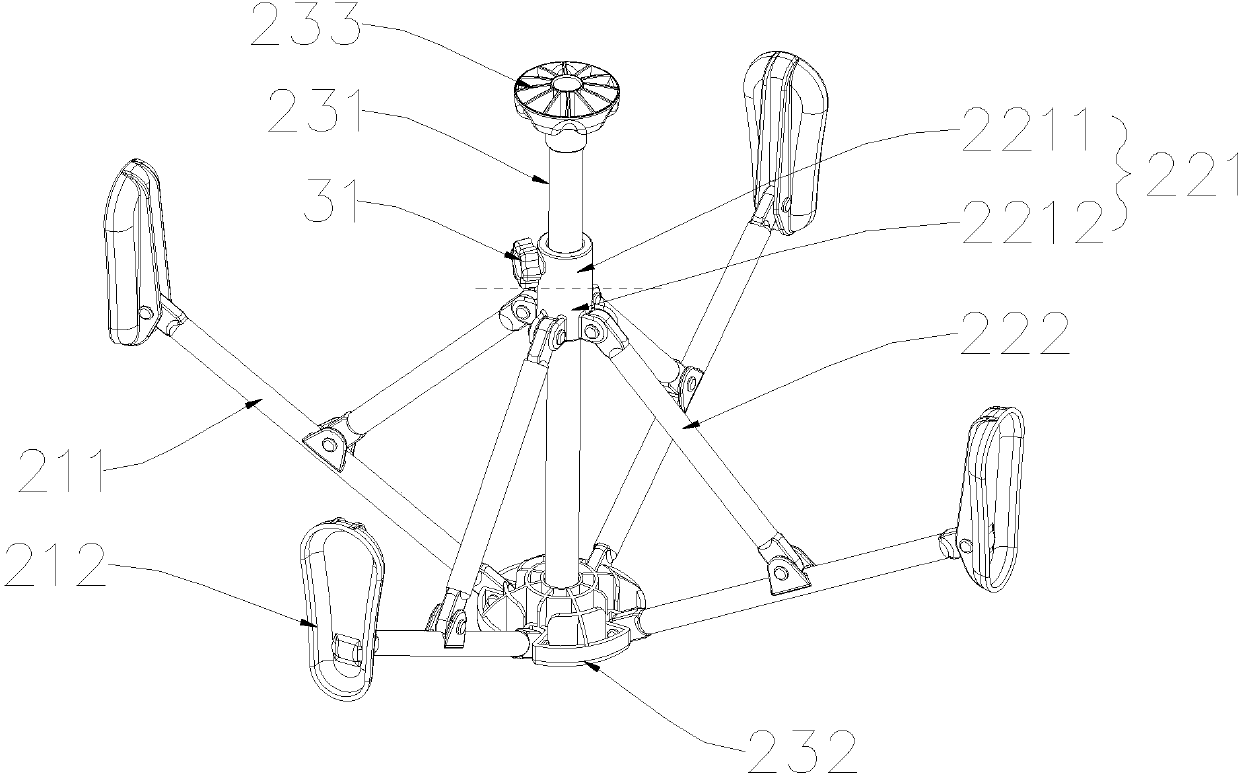

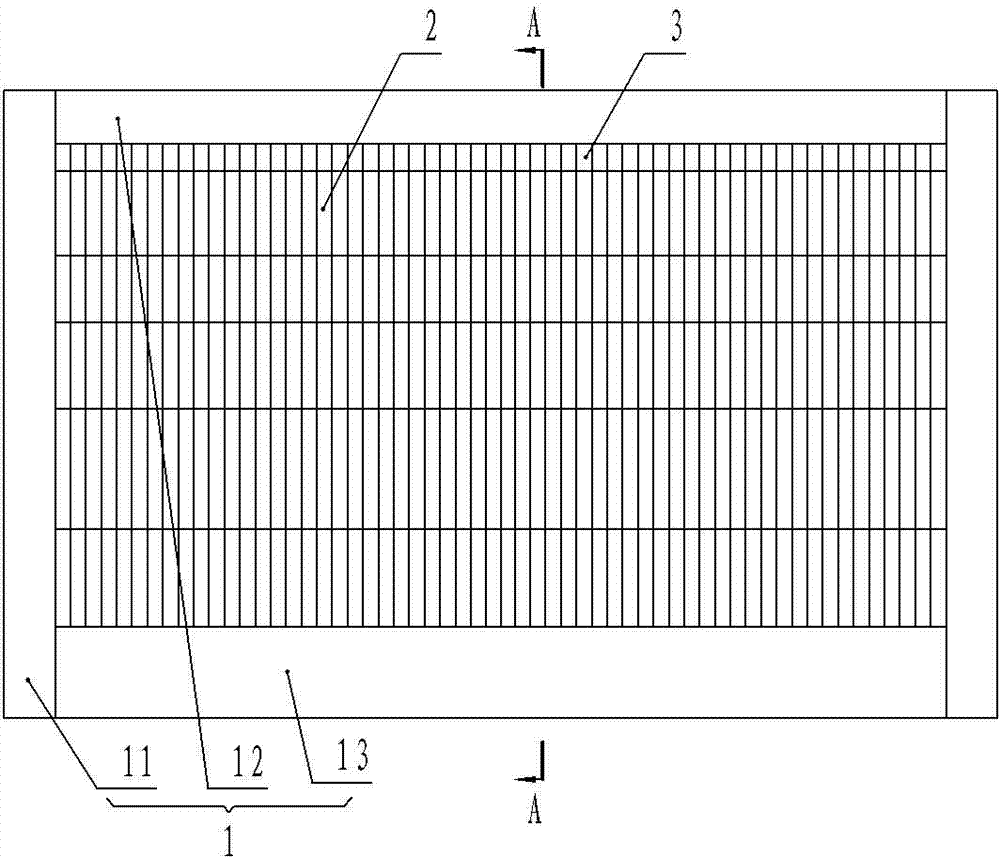

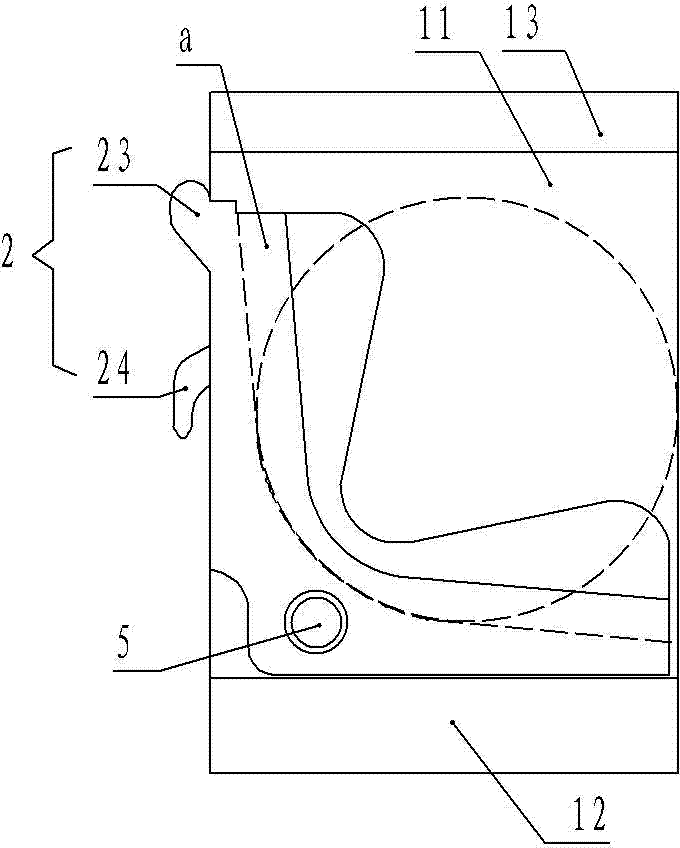

Washing device and supporting device for same

PendingCN110042622AAvoid violent shakingAvoid shakingOther washing machinesTextiles and paperEngineeringSpins

The invention relates to the technical field of washing devices, and particularly provides a washing device and a supporting device for the same. The problem that when an existing machine performs spin-drying and cleaning of a shoe, the shoe to be cleaned is hard to fix effectively is solved. In order to solve the problem, the washing device comprises a washing tub, the supporting device is used for supporting the shoe to be cleaned, the supporting device and the cleaning tub are matched to fix the shoe to be cleaned in a clamped mode so that spin-drying operation can be performed on the shoeto be cleaned. The washing device comprises the supporting device. The shoe to be cleaned is fixed to the inner wall of the washing tub in the clamped mode through the supporting device, the phenomenon that the shoe to be cleaned runs inside the cleaning tub in disorder is avoided, the phenomenon that asymmetric centrifugal force is generated for the washing tub is avoided, the phenomenon that thewashing tub generates acute vibration is avoided, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

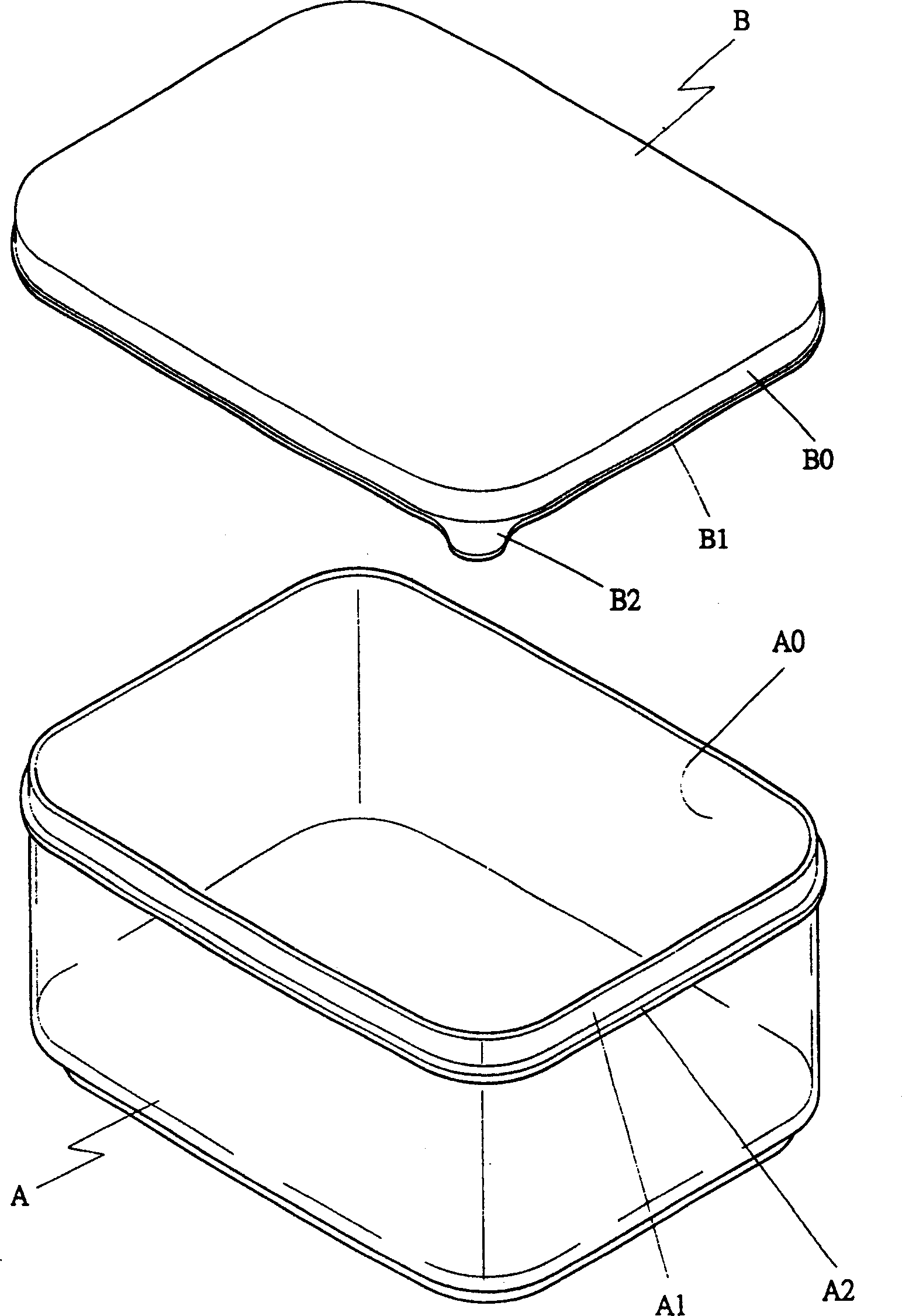

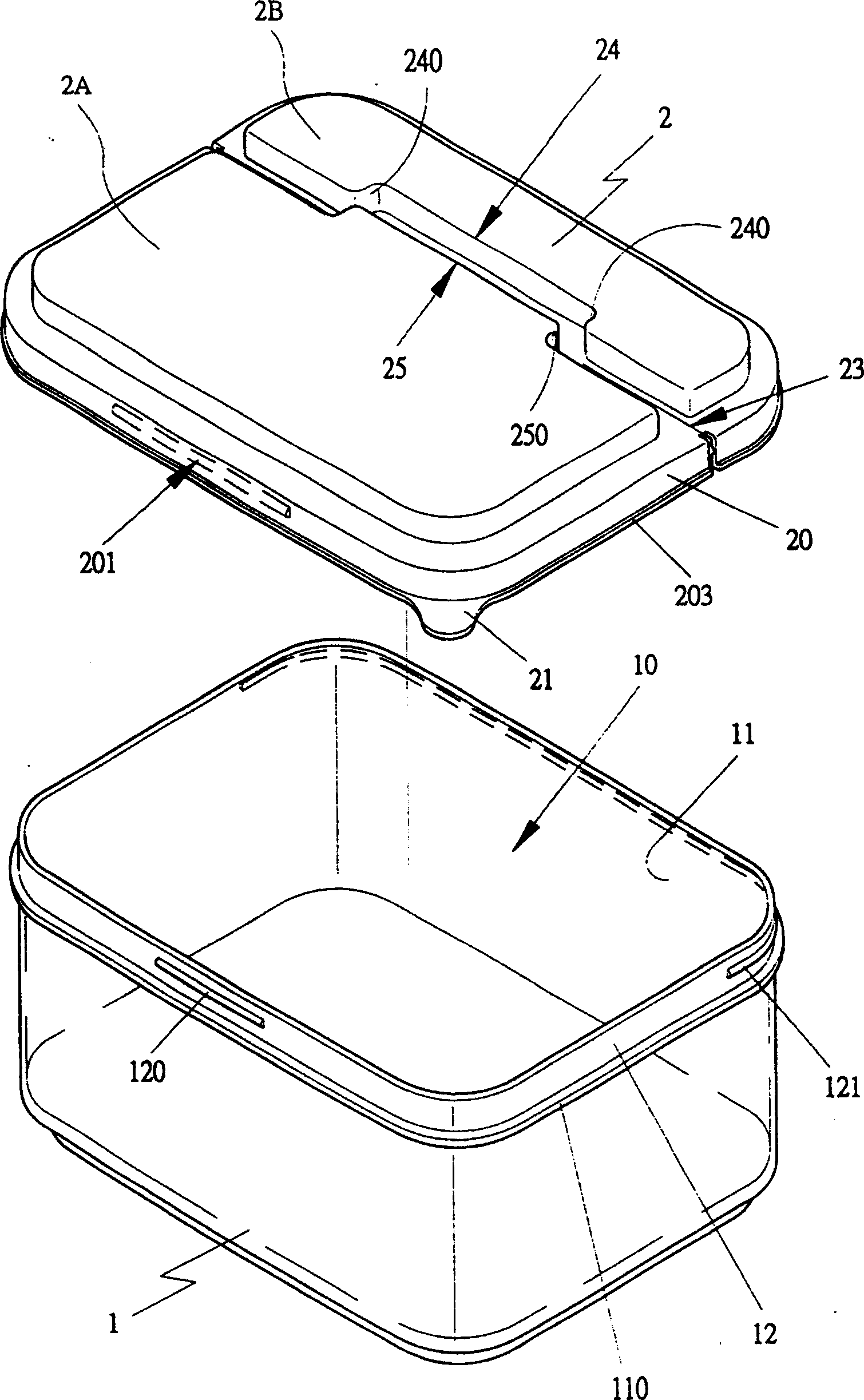

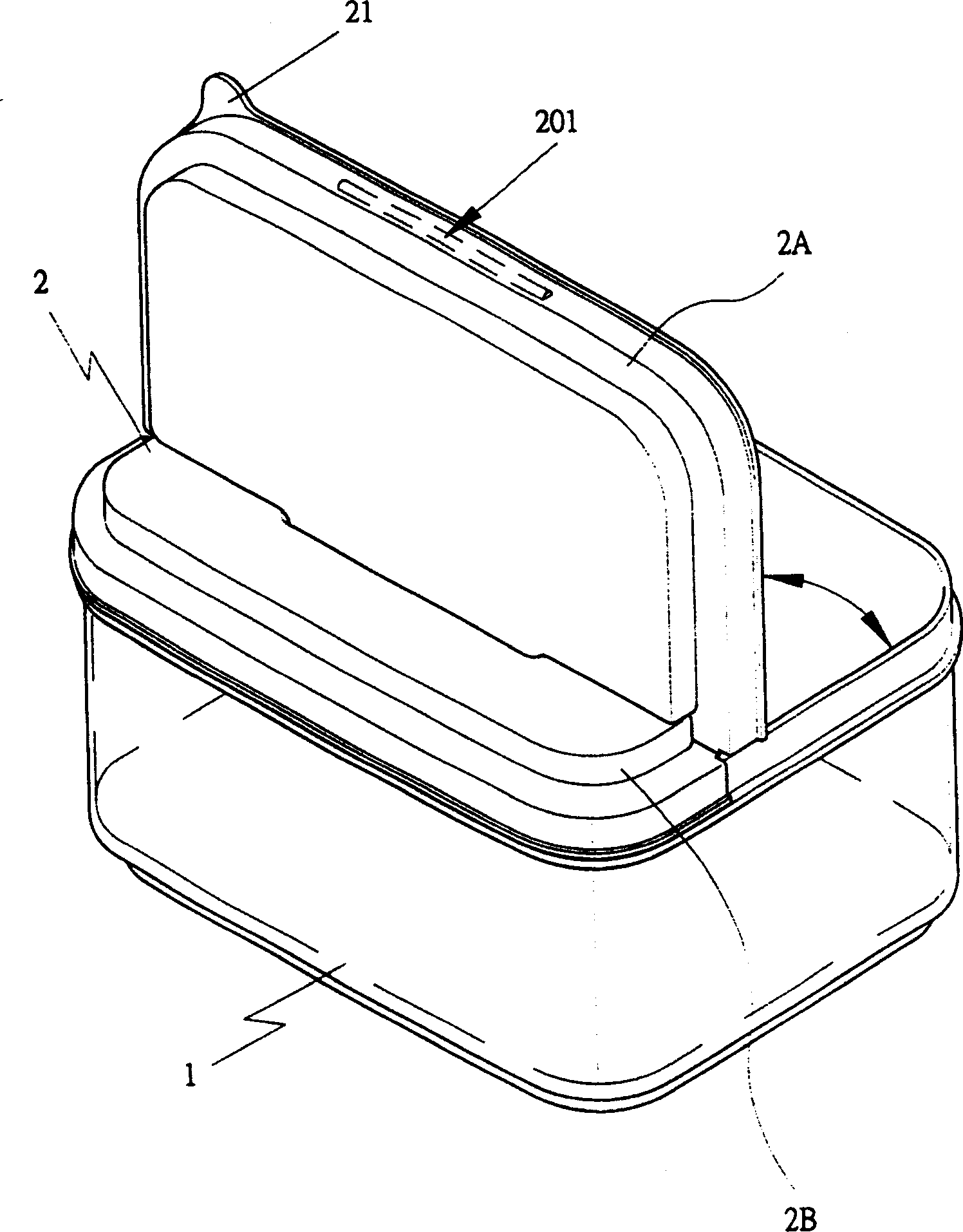

Box capable of being opened partially

The box capable of being opened partially for firm combination and convenient setting and taking article includes box body and box cover. The box body has closed wall with combining enclosure and combining flanges, and the box cover has corresponding combining enclosure and combining slots. The box cover has several folding lines to separate the box cover into several parts from the front to the back, and the separated parts have slots corresponding to the flanges.

Owner:陈焕章

Ice storage box installation structure and refrigerator

ActiveCN109373660BSimple installation structureSimple structureDomestic cooling apparatusLighting and heating apparatusIce storageIcebox

The invention discloses an ice storage box installation structure and a refrigerator, comprising: a support frame, the support frame includes a base and an ice storage box inlet and outlet; an ice storage box, the ice storage box is used to be arranged on the base; The first magnetic piece set on the support frame and the second magnetic piece set at the corresponding position of the ice storage box, so that the second magnetic piece can be attracted by the first magnetic piece to move the ice storage box Adsorbed and fixed to the base, the ice storage box installation structure can save the traditional track ribs and reverse shaft structures, so that the ice storage box installation structure of the present invention is simple in structure, strong in reliability, and easy to take and place in the ice storage box. Convenience is good.

Owner:HEFEI HUALING CO LTD +2

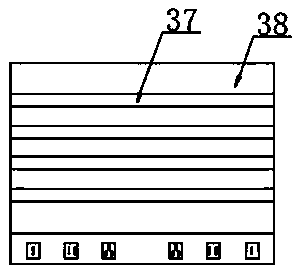

Intelligent cloth storage system and cloth storing and taking method

InactiveCN111099229AEasy to take and putSuitable for useStorage devicesMechanical engineeringWireless signal

The invention relates to an intelligent cloth storage system and a cloth storing and taking method. The storage system comprises a hanging assembly, circulation vehicles, cloth and a master control machine. The hanging assembly comprises a hanging plate and multiple supporting heads mounted at intervals evenly, each circulation vehicle is provided with a wireless communication module, a microprocessor, and a lifting hook used for lifting the cloth, the lifting hooks can move in the three directions of X, Y and Z according to a received signal, the circulation vehicles used in cooperation withhook assemblies are mounted in the first direction and the second direction which are perpendicular, each hook assembly comprises a supporting ring and hooks connected with the supporting ring, each supporting ring is provided with an upper ring and a lower ring which are perpendicular, the hooks are connected to the lower end of the lower rings, the cloth is provided with a cloth roll and a lifting ring hung on the hooks, the master control machine sends out an instruction through a wireless signal, the circulation vehicles in the first direction and the second direction move along reserved tracks, and through the hook assemblies, the cloth is hung on the position between two supporting heads on the designated position on the hanging plate. Mechanical automatic transfer is achieved, and work efficiency is improved.

Owner:海宁小二慧储智能科技有限公司

Plastic digital video disk rack

InactiveCN104778962ANot easy to fall ashEasy to take and putApparatus modification to store record carriersDigital videoEngineering

The invention discloses a plastic digital video disk rack and belongs to the technical filed of stationery commodities. The plastic digital video disk rack comprises a box body with an opening in the front end, wherein the box body is formed by a bottom plate arranged between two side plates, top plates and a back plate in an enclosing manner; a plurality of digital video disk plug-in racks which are the same as each side plate in direction and are arranged from left to right in sequence are hinged between the two side plates through a hinged shaft; an identifier is arranged on the top plate corresponding to each digital video disk plug-in rack. The plastic digital video disk rack disclosed by the invention can solve the problems that an existing plastic digital video disk rack is hard to find as the identifier is absent, ash is easy to fall off, and the damage of a digital video disk player and a disk are easily caused.

Owner:LIUZHOU CITY QIANYANG MACHINERY & ELECTRIC

Efficient coating spraying curing oven

PendingCN114273176AImprove heating efficiencyHeating evenlyDispersed particle separationPretreated surfacesFan bladeMaterials science

The invention provides an efficient coating spraying curing oven which comprises a curing device, the curing device comprises a curing oven body, a sealing door, a moving groove, a mounting groove, a curing groove, a bearing plate, a base, a stand column and a heating lamp, the moving groove is formed in the front end face of the curing oven body, and the mounting groove is formed in the rear side of the moving groove; the sealing door is slidably connected into the moving groove, the curing groove is formed in the curing oven body, the base is fixedly connected to the bottom of the curing groove, the stand column is fixedly connected to the upper end face of the base, the bearing plate is placed on the upper end face of the stand column, and the two sets of heating lamps are installed on the inner walls of the two sides of the curing groove correspondingly. The upper end face of the curing device is fixedly connected with a peculiar smell adsorption device, the peculiar smell adsorption device comprises a communicating pipe, an induced draft fan, fan blades and an adsorption mechanism, the induced draft fan is fixedly connected to one side of the upper end face of the communicating pipe, coating curing is more uniform, meanwhile, the cooling capacity of the device is improved, and the curing efficiency is higher.

Owner:东莞市慧江平成机械有限公司

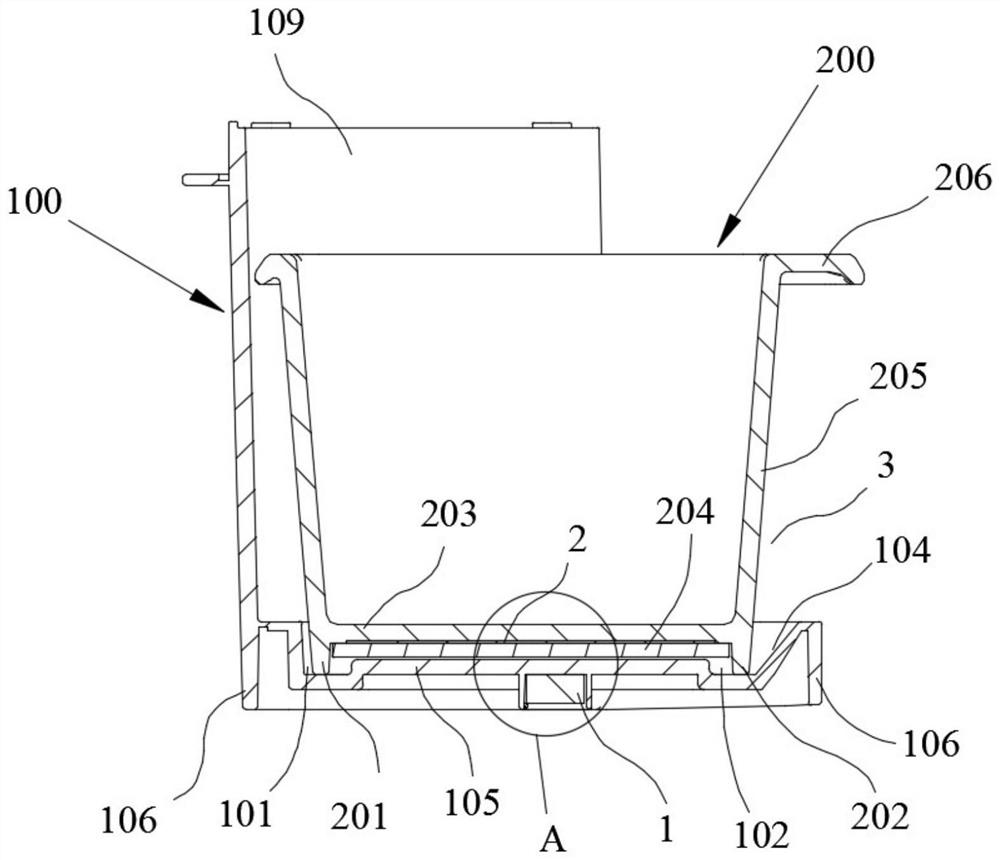

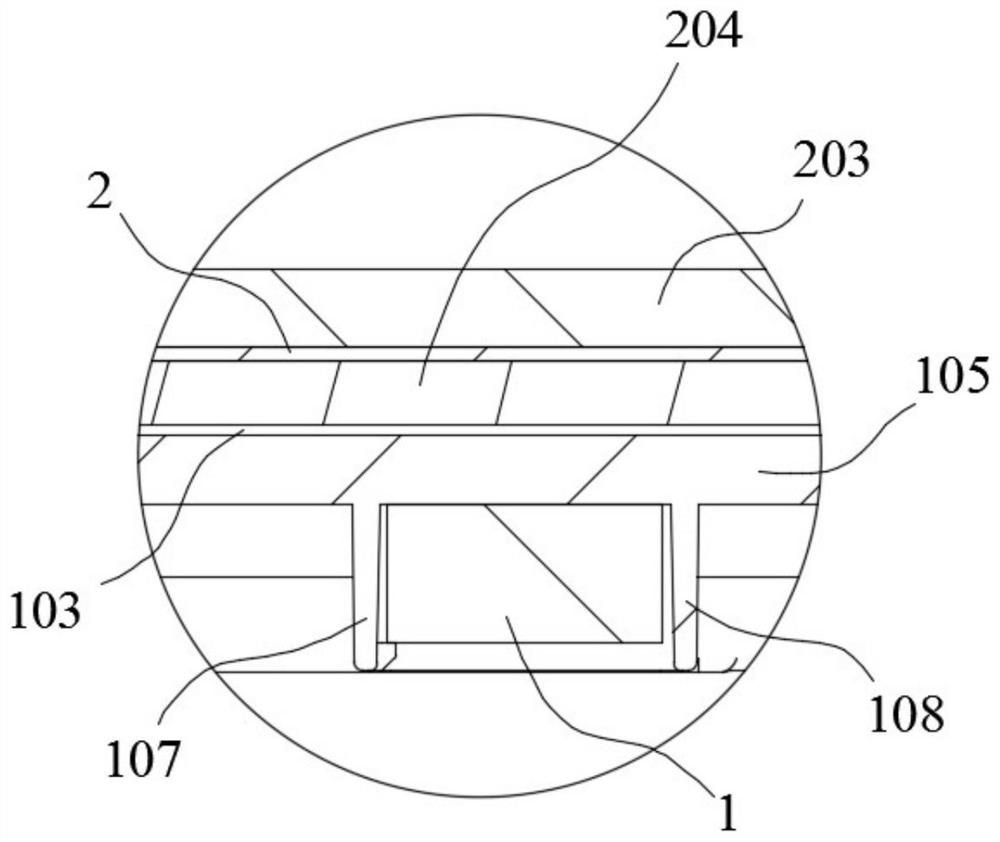

mini safe

The invention discloses a mini safe deposit box, aiming to provide a mini safe deposit box with good structural stability, stable operation, good storage box picking / putting and moving stability, and is convenient for actual installation and production. It includes a box body, a vault door arranged on the side of the box body, a storage box placement rack arranged in the box body, and a track-type pick-up device arranged in the box body, and the feature is that the track-type pick-up device includes a set The upper and lower rails parallel to each other in the box, the lifting mechanism body that is arranged between the upper and lower rails and can slide along the upper and lower rails, is used to drive the lifting mechanism body to slide along the upper and lower rails The first translation actuator; the body of the elevating mechanism is provided with a vertical guide rail, the elevating storage table that can be lifted along the vertical guide rail and the elevating actuator for driving the elevating storage table; the elevating storage table is provided with a box mechanism.

Owner:NINGBO CHAOPING INTELLIGENT TECH

Floor tile laying and pasting device

InactiveCN109838076AReduce work intensityImprove work efficiencyBuilding constructionsEngineeringClosed state

The invention belongs to the technical field of floor tile laying and pasting equipment, and particularly relates to a floor tile laying and pasting device. The floor tile laying and pasting device comprises a first suction disc group, a second suction disc group and a hinging assembly, wherein the first suction disc group and the second suction disc group are hinged through the hinging assembly;when the hinging assembly is in an unfolded state, the facing directions of the adsorption surfaces of the first suction disc group and the second suction disc group are identical; and when the hinging assembly is in a closed state, the facing directions of the adsorption surfaces of the first suction disc group and the second suction disc group are opposite. In the use process, a worker can use the first suction disc group and the second suction disc group for respectively adsorbing a floor tile; then, the first suction disc group or the second suction disc group is turned for realizing the floor tile turning; the floor tile turning process by the worker is simpler and more convenient, so that the work intensity of the worker is reduced; the floor tile laying and pasting work efficiency is effectively improved; and the floor tile turning is realized by turning the first suction disc group or the second suction disc group, so that the occurrence of the condition that the hand of the worker is injured by the floor tile can be avoided.

Owner:颜耀权

Acid cylinder device for laboratory

ActiveCN114225985AEasy to useReduce concentrationBio-packagingLaboratory glasswaresGlass vesselEngineering

The invention discloses an acid cylinder device for a laboratory, which comprises a cylinder body, acid liquor for cleaning glassware is contained in the cylinder body, a cover is arranged on the cylinder body, a bracket is obliquely and fixedly arranged on the outer wall of the cylinder body, a hooking tool for taking and placing the glassware is movably placed on the bracket, and the hooking tool comprises a long rod; a handle is arranged at the tail of the long rod, a straight hook is fixedly connected to the head of the long rod, the included angle between the straight hook and the long rod ranges from 60 degrees to 120 degrees, and the length of the long rod is larger than or equal to the height of the cylinder body. According to the acid cylinder device, the operation of taking and placing glassware by experimenters is greatly facilitated, and the harm of acid liquor to human bodies is remarkably reduced.

Owner:刘志光

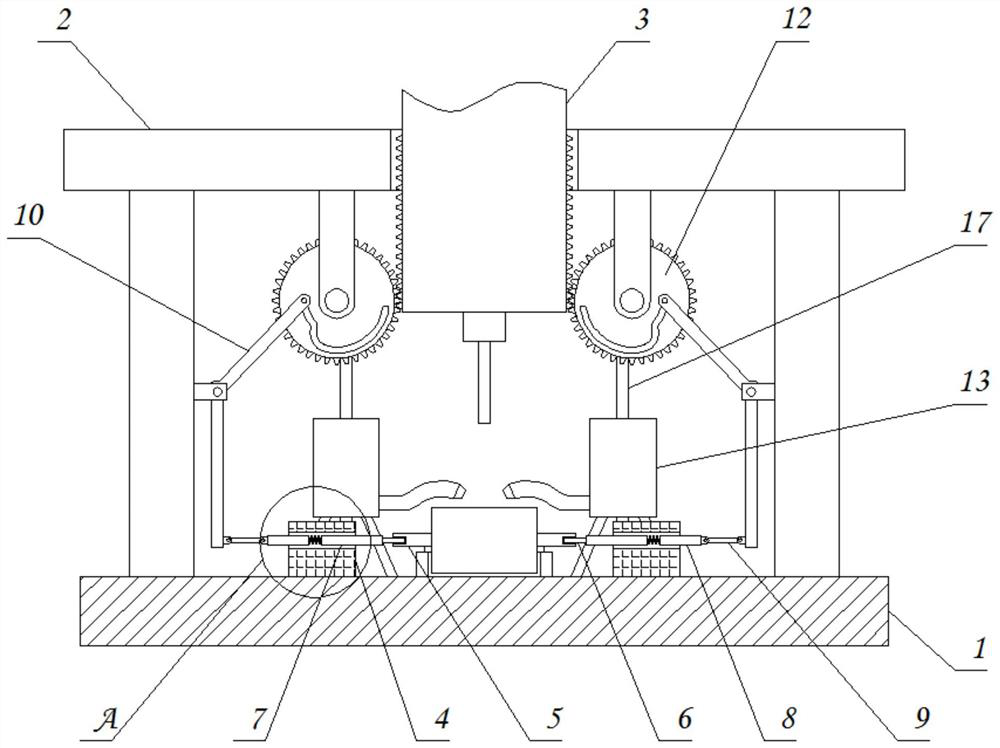

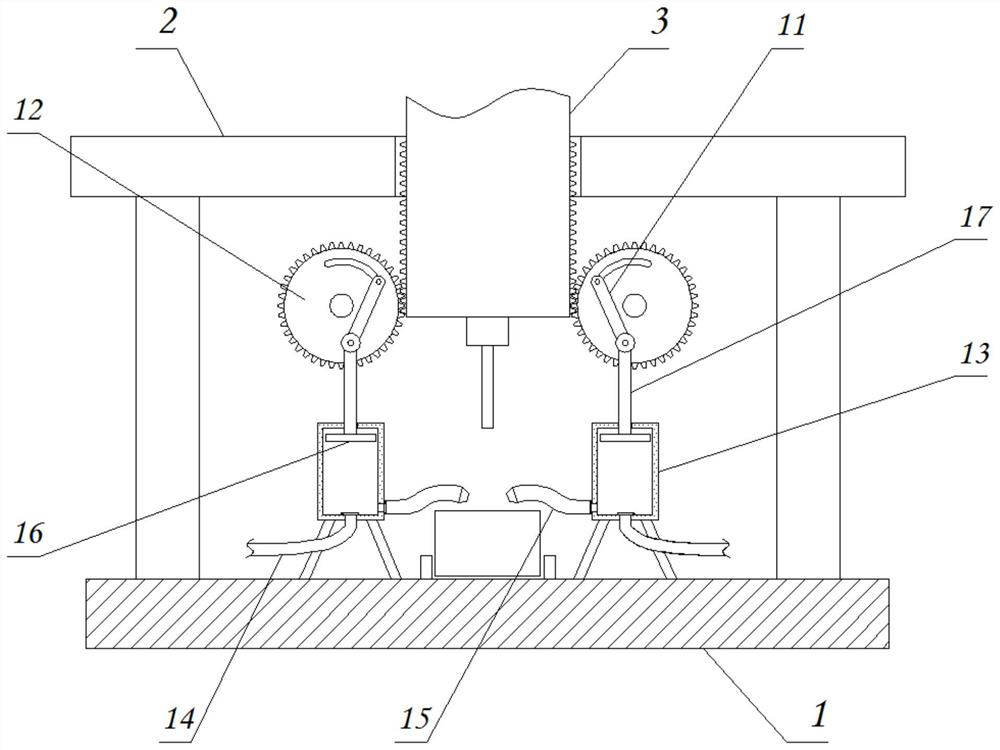

Tapping device easy to fix, take and place and used for hardware part machining

InactiveCN112427751AEasy to fixEasy to take and putThread cutting feeding devicesThread cutting machinesGear driveGear wheel

The invention relates to the technical field of hardware machinery, and discloses a tapping device easy to fix, take and place and used for hardware part machining. The tapping device comprises a workbench, a top plate and a base, wherein two gears are fixedly connected to the bottom of the top plate, and two fixed blocks are fixedly connected to the top of the workbench; first movable rods and second movable rods are inserted into the two fixed blocks, two first connecting rods are rotatably connected to the opposite sides of the two first movable rods, clamping rods are rotatably connected to the opposite sides of the four first connecting rods, and second connecting rods are rotatably connected to the sides, with the back to each other, of the two second movable rods; and rotating rodsare rotatably connected to the sides, with the back to each other, of the two second connecting rods. The gears are driven by the base to rotate, the gears drive the rotating rods to rotate, then theclamping rods are driven by connecting rod mechanisms to be tightly attached to a part to fix the part, and therefore, the easy fixing effect is achieved, the operation difficulty of workers is reduced, and tapping efficiency is improved.

Owner:施明建

Safe type electrical furnace for heating

InactiveCN109724141ASave electricityEasy to useLighting and heating apparatusElectric heating systemFire - disastersControl switch

The invention discloses a safe type electrical furnace for heating. The safe type electrical furnace for heating comprises a furnace seat, a heat emitter, a power plug and multiple pedal switches. Theheat emitter is fixed to the center of the top face of the furnace seat. The multiple pedal switches are uniformly distributed on all side faces of the furnace seat. After being in parallel connection through a circuit, the multiple pedal switches form a multi-control switch. The multi-control switch, the heat emitter and the power plug form a series connection loop. According to the electrical furnace for heating, automatic switching-off is achieved through the pedal switches; electric energy is saved, and the electrical furnace is convenient to use; and when a user forgets to switch off theelectrical furnace for heating, fire disaster cannot be caused.

Owner:陶然

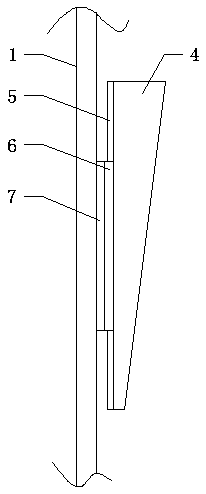

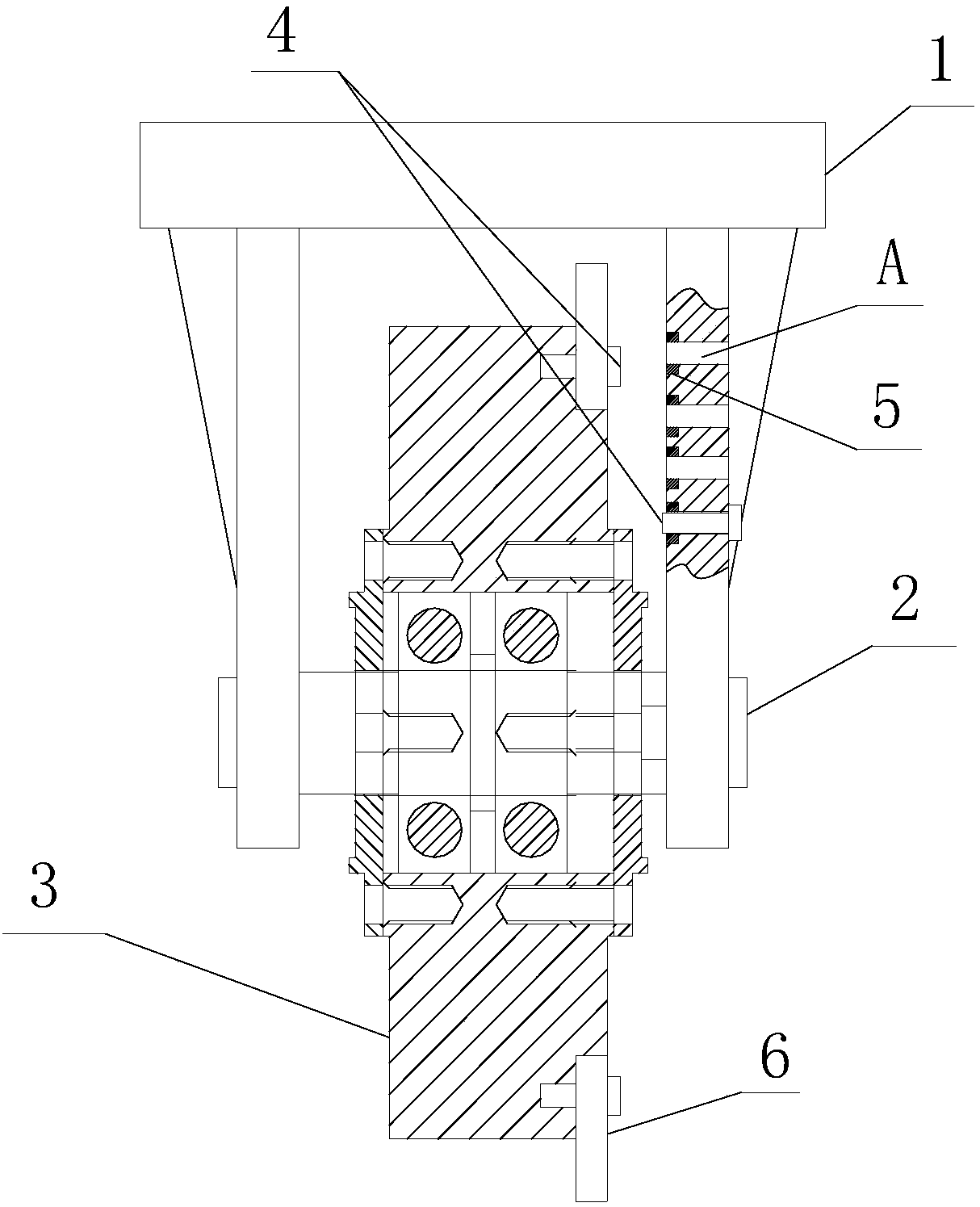

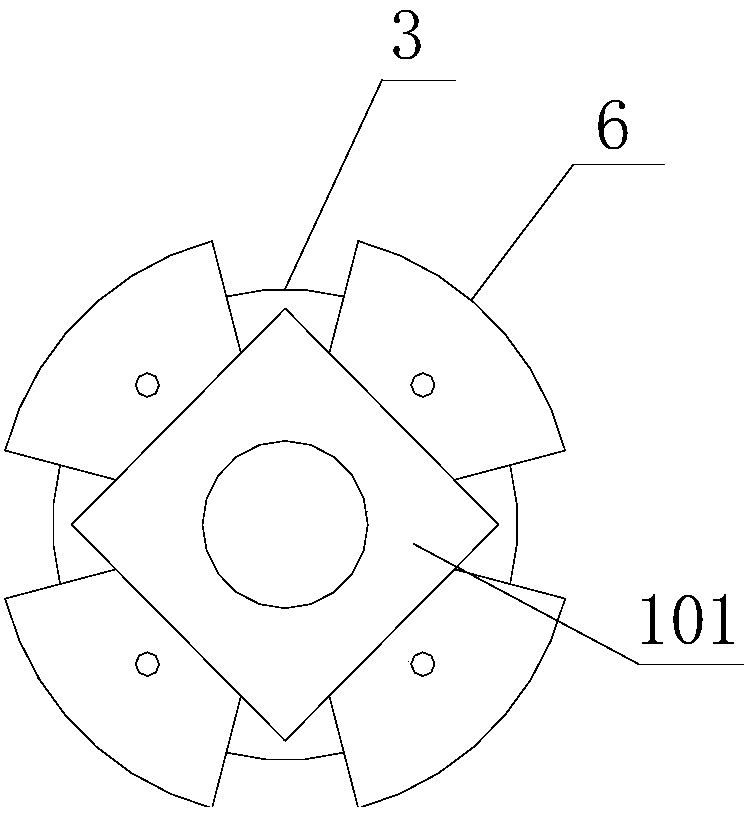

Machining method and special hinged tool post for ultra-long and deep vertical turning

ActiveCN103264168BEasy to take and putSimple structureMetal-working apparatusStructural engineeringMachining

Disclosed are a machining method of ultra-depth vertical turning, and a hinged tool rest special for the same. The method includes: setting a machining program, pulling a tool bar until the axis of the tool bar is perpendicular to the axis of a spindle, moving the spindle, pulling off stop pins after moving the spindle, inserting a positioning insert bar after the axis of the tool bar is superposed with that of the spindle, tightening positioning bolts, and machining a workpiece; after machining, loosening the positioning bolts, pulling off the positioning insert bar to allow the axis of the tool bar to be perpendicular to that of the spindle, re-inserting the stop pins, and taking out the workpiece. The special hinged tool rest comprises a spindle connecting block, a tool bar, a positioning insert bar, stop pins and positioning bolts. The upper end of the spindle connecting block is fixed to a lathe spindle. The lower end of the spindle connecting block is provided with an elongated tool bar mounting groove. The tool bar comprises a tool shank and a tool mounting rack for mounting a tool. The upper end of the tool shank is hinged to a connecting shaft inside the tool bar mounting groove. The machining method and the special hinged tool rest have the advantages that the structure is simple, safety factor is high, repeated positioning has small errors, mounting is quick, and the workpiece is convenient to take and place.

Owner:慈溪汇丽机电股份有限公司

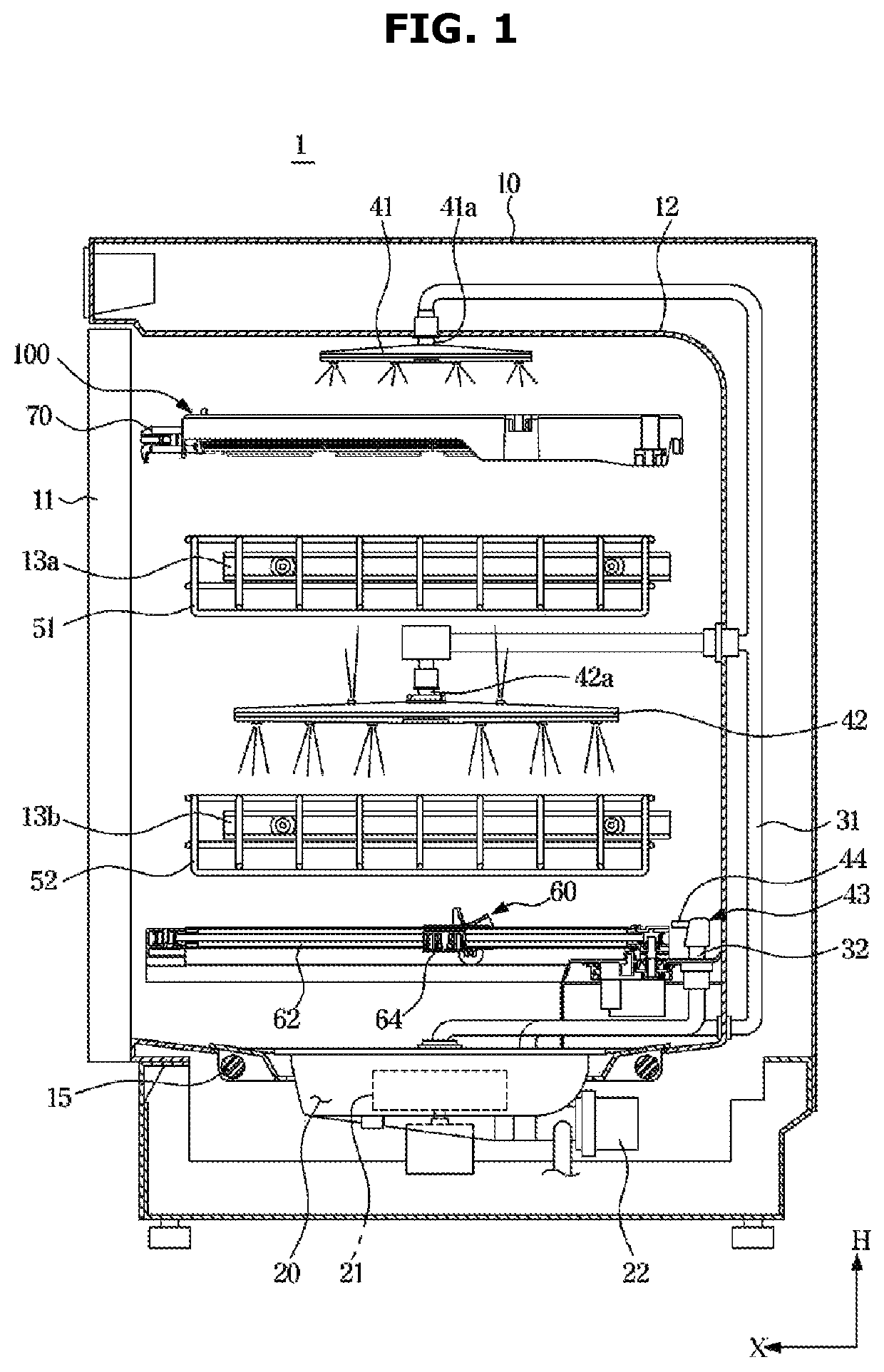

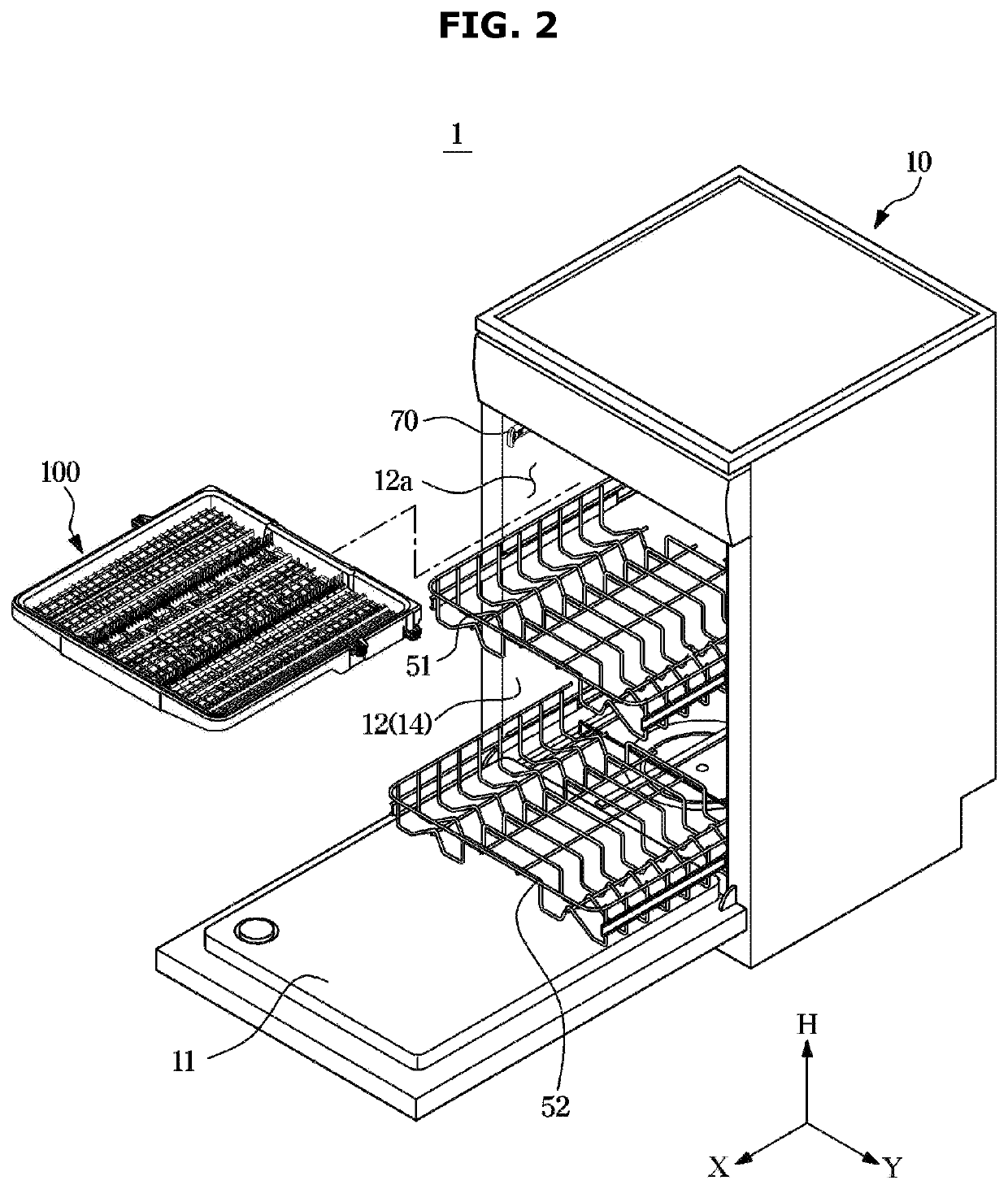

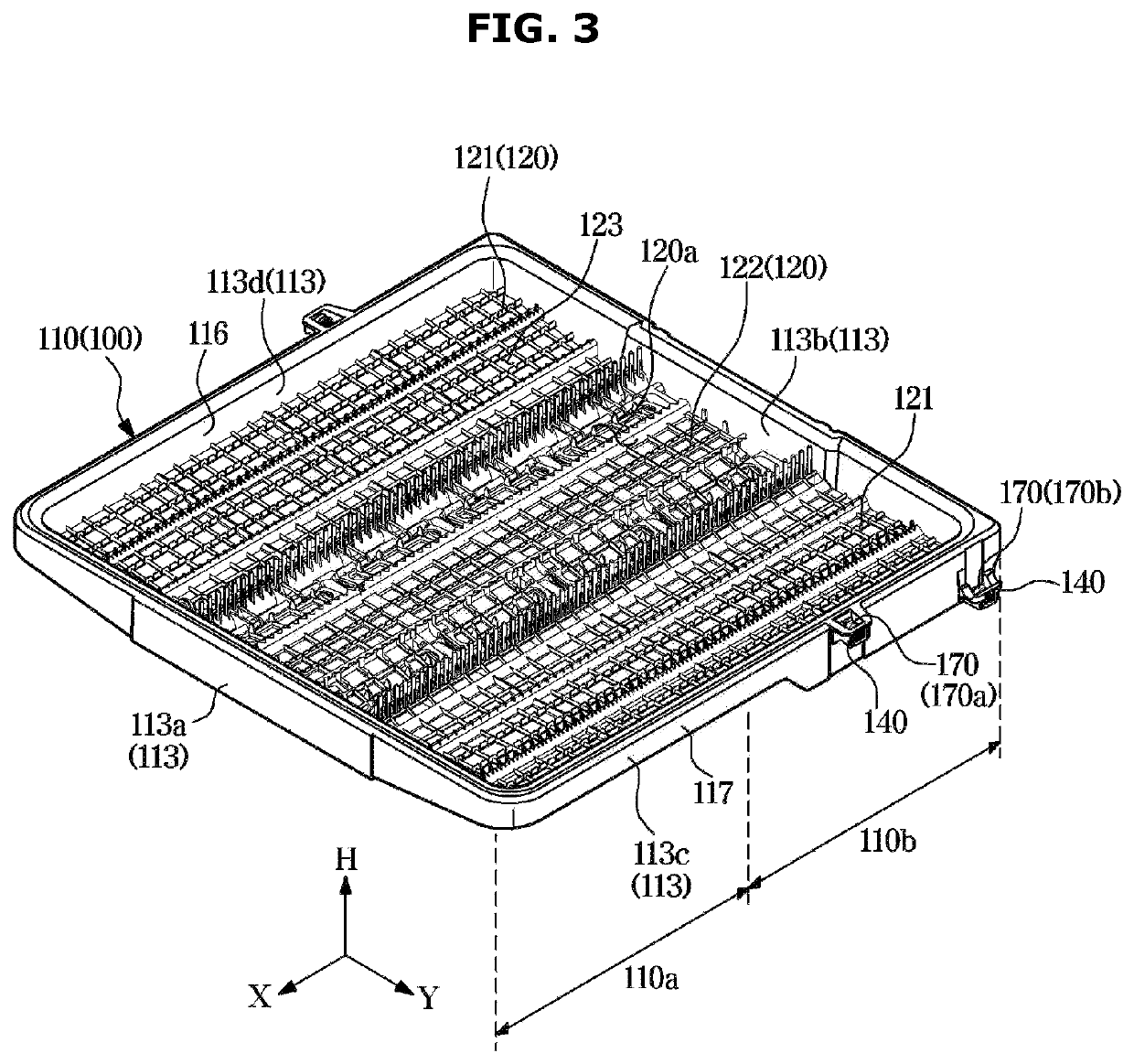

Dish washer with loading frame

ActiveUS11412915B2Simple structureEasy to take and putTableware washing/rinsing machine detailsStructural engineeringWasher

A dish washer includes: a main body; a tub positioned in the inside of the main body, wherein an object that is to be washed is washed in the tub; and an accommodating container positioned in the inside of the tub and accommodating the object that is to be washed, wherein the accommodating container includes: a frame forming an accommodating space in which the object that is to be washed is accommodated; and a shaft rotatably supporting a roller configured to move the accommodating container, wherein both ends of the shaft are supported on the frame.

Owner:SAMSUNG ELECTRONICS CO LTD

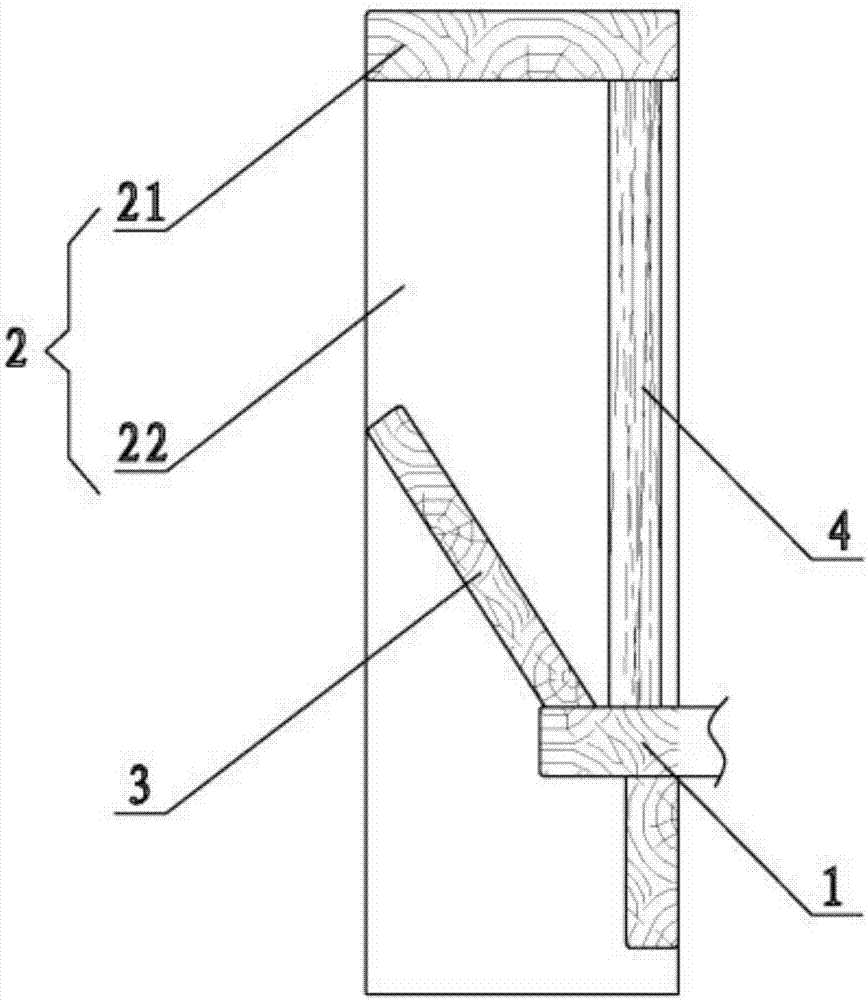

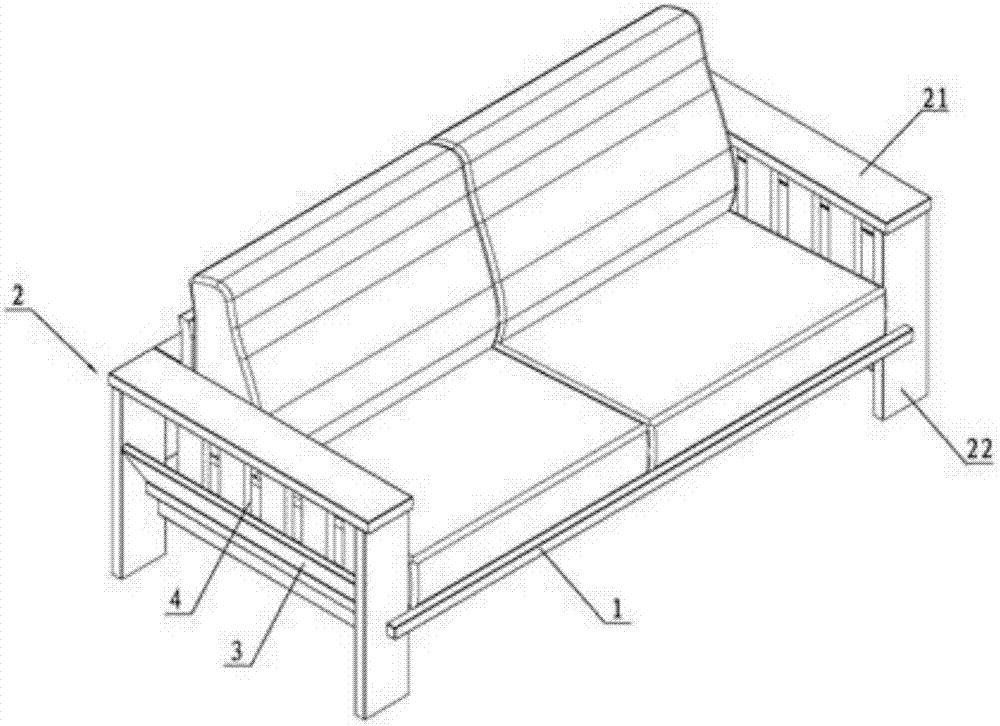

Furniture armrest capable of conveniently storing periodicals

The invention relates to the technical field of furniture, in particular to a furniture armrest convenient for storing publications, comprising an armrest body fixed to a furniture base, the armrest body comprising an armrest plate and two armrest support plates for supporting the armrest plate, the armrest The support plates are respectively connected to the lower surfaces of the armrest plates, and a slant plate whose bottom surface is connected to the furniture base is arranged under the armrest plates, and the slant plates are sandwiched between two armrest support plates, and the orthographic projection of the armrest plates The surface covers the orthographic projection surface of the inclined plate, and the angle between the plane where the inclined plate is located and the plane where the armrest plate is located is an acute angle; The space is convenient for publications such as newspapers or magazines to lean against on the slant plate, effectively avoiding the publications from being prone to dumping during storage, making it easy to take / put the publications, and providing convenience for users.

Owner:白正辉

Jet washer

InactiveCN1847505BSimple structureEasy to take and putWashing machine with receptaclesTextiles and paperControl systemJet washer

The jet washer includes one shell, one cover, one control system and transmission mechanism. It has one sandwich formed with the housing and the inner container of the shell, one basket inside the inner container and with one clothing entrance and one end connected through the transmission mechanism inside the sandwich to the side wall of the inner container, one water holder in the bottom of thesandwich and communicated with the water outlet of the inner container, one water pump inside the water holder, one jetting pipe connected to the water pump and stretched into the inner container, andone jet in the upper end of the jetting pipe and opposite to the basket.

Owner:刘登华

Folding type dual-purpose process trolley wheel with compact structure

ActiveCN107776332AEasy to take and putMeet the needs of switching walking modes at any timeWheelsEngineeringDual purpose

The invention discloses a folding type dual-purpose process trolley wheel with the compact structure. The wheel comprises a support, an axle mounted on the support, a walking wheel assembled with theaxle and fasteners, wherein a magnet fixedly assembled with the support is arranged on the support; each fastener is made of a ferromagnetic material; a structural body is arranged on one side of thewalking wheel; mounting holes are formed in the walking wheel; fan blades are arranged on the periphery of the structural body, one side of each fan blade is movably connected with the structural body, and through holes are formed in the fan blades; each fan blade comprises a first position and a second position, and each fan blade is located on one side, away from the walking wheel, of the structural body when located in the first position; the through holes in each fan blade are in one-to-one correspondence to and connected with mounting holes in the walking wheel through the fasteners wheneach fan blade is located in the second position, all the fan blades cooperate with one another to form a wheel body coaxial with the walking wheel, and the diameter of the wheel body is larger than that of the walking wheel. The wheel is compact and attractive in whole structure and can be switched randomly between two walking modes.

Owner:安徽星凯龙客车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com