Material transferring trolley for vehicle lamp

A technology for lamps and materials, applied in the field of material turnover trolleys for automotive lamps, can solve the problems of uncontrollable shape and size of lamps, time-consuming production efficiency, inconvenient placement, etc., to facilitate material turnover, improve production efficiency, and prevent bumps and scratches effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

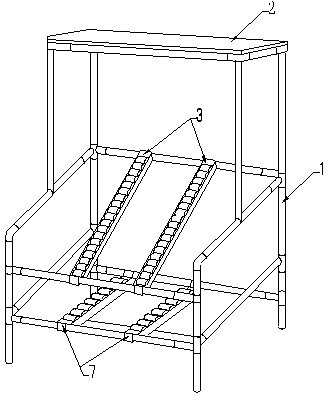

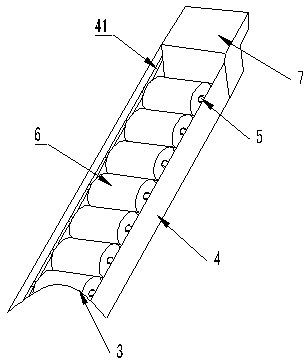

[0013] Depend on figure 1 , 2 Known, a kind of material turnover trolley of lamps and lanterns for vehicles, comprises the three-dimensional support 1 of frame structure, and the support board 2 is installed on the top frame above the three-dimensional support 1, can place some production auxiliary tools, Standard connectors, etc., save the working space of the console; two inclined guide frames 3 are installed in the middle of the three-dimensional support 1, and two inclined guide frames 3 are also installed at the bottom of the three-dimensional support 1. Two brackets with different heights form a certain inclination, the inclined guide frame 3 in the middle of the three-dimensional support 1 is high at the front and low at the rear, and the inclined guide frame 3 at the bottom of the three-dimensional support 1 is low at the front and high at the rear, so that no mechanical power transmission can be realized, which is convenient Workpiece transmission: There is also a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com