Construction method for prefabricated building shear wall conversion layer

A technology of shear walls and transfer floors, applied in the direction of buildings, building components, building structures, etc., to achieve the effect of convenient disassembly, installation and turnover, convenient turnover, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

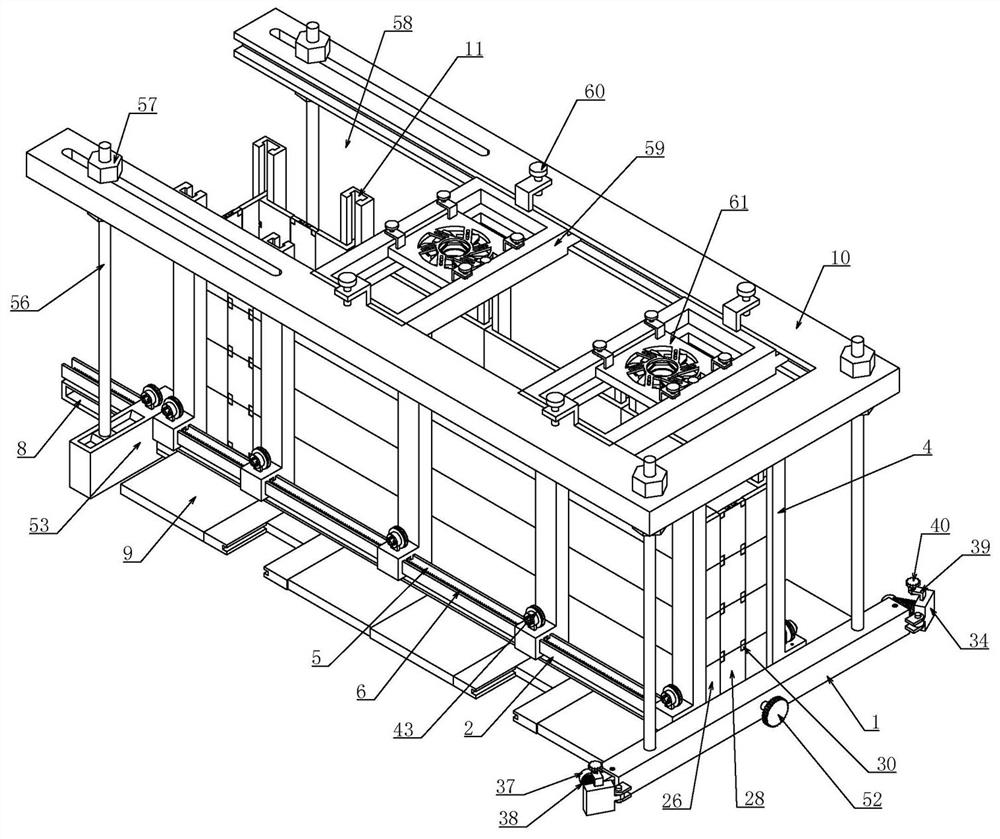

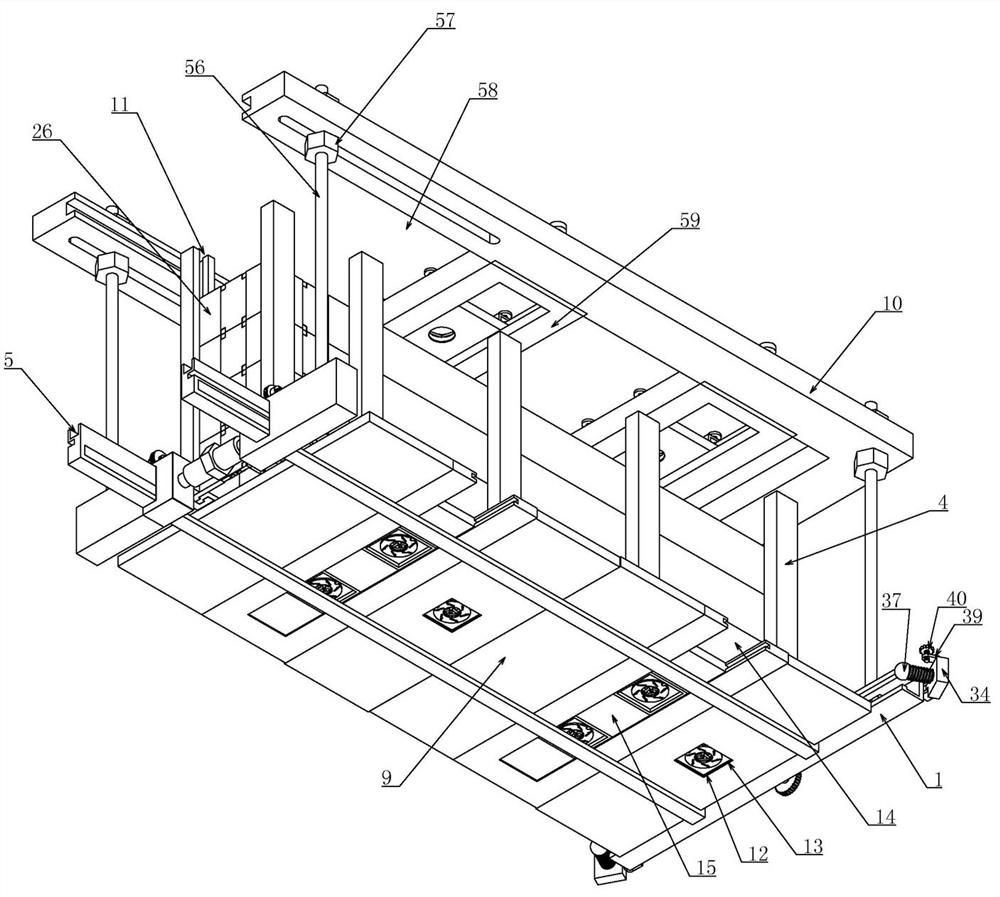

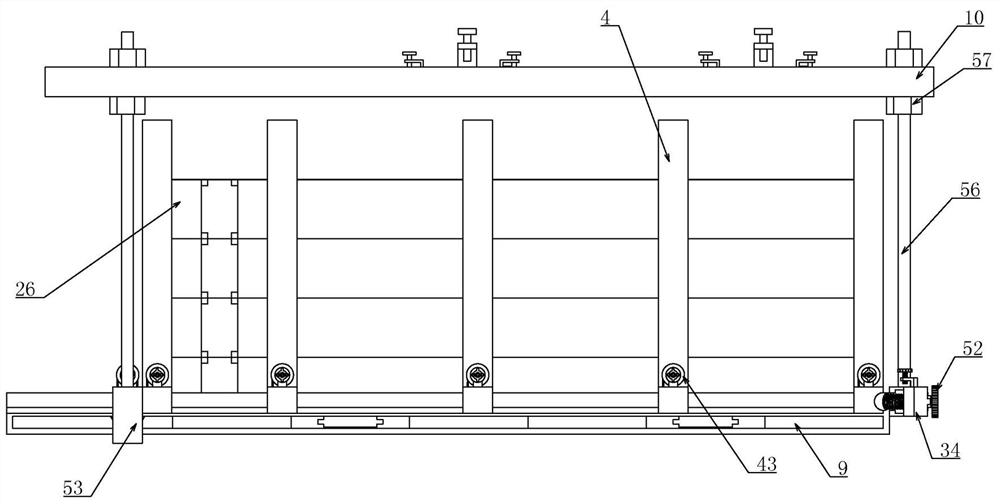

[0064]Embodiment 1, the device applying the above-mentioned prefabricated building shear wall transfer layer construction method includes a longitudinal bar 1, and the left end of the longitudinal bar 1 is open, and there are two sets of transverse bars 2 sliding longitudinally in the longitudinal bar 1, and the longitudinal bar 1 There is a groove structure with a T-shaped cross-section at the left end, and the groove structure is transparent along the front and rear directions. The end of the transverse rod 2 is a slider-shaped structure with a T-shaped cross-section. The cooperation of the two makes the two transverse rods It can move along the longitudinal direction of the longitudinal bar 1. Since the front and rear ends of the longitudinal bar 1 are in a penetrating state, the transverse bar 2 can be smoothly disengaged from the longitudinal bar 1. The longitudinal bar 1 is rotatably connected with a Two-way lead screw 3, the two-way lead screw 3 relies on the support fra...

Embodiment 2

[0067] Embodiment 2, on the basis of Embodiment 1, wherein the longitudinal board 9 provided with one or more groups of movable positioning hole structures includes the body of the longitudinal board 9, and the longitudinal board 9 can adopt a wooden structure. There is a square hole 12 on the body of the longitudinal bar 1, the lower end of the square hole 12 is connected with a limit frame 13, and a positioning hole structure with a radius adjustment is placed in the square hole 12, forming a group of openings on the longitudinal plate 9. Positioning hole structure, when only one set of positioning holes is required at the lower end of the formwork structure, the positioning holes can be positioned at the corresponding positions by moving the position of the longitudinal plate 9 and according to the position of the sleeve 55 on the drawing;

[0068] The body of the longitudinal plate 9 is provided with a longitudinally transparent sliding hole 14. The sliding hole 14 is longi...

Embodiment 3

[0070] Embodiment 3, on the basis of Embodiment 1, the board structure with adjustable lateral spacing or the board structure with adjustable longitudinal spacing includes a connecting plate that cooperates with the slide rail 11 of the vertical bar 4 on the corresponding side 26. The connecting plate 26 opens in the direction of the vertical rod 4, and its interior is a box structure. The connecting plate 26 is opened with a rectangular groove 27 at one end facing the other connecting plate 26, and two sets of rectangular grooves 27 slide horizontally. Cooperate with a clamping plate 28 placed between two groups of connecting plates 26, so that the clamping plate 28 can only move along the transverse direction of the rectangular groove 27. Two sets of Us are connected to the upper and lower ends of the clamping plate 28 respectively. Shaped plate 29, the upper and lower ends of the clamp plate 28 are respectively horizontally slidably fitted with a top tightening block 30 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com