Acoustic emission inspection device for storage tank base plate corrosion

A technology of acoustic emission detection and storage tank bottom plate, which is applied in the use of acoustic emission technology for material analysis and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. Problems, to achieve the effect of convenient positioning, fast installation of sensors, and convenient pick-and-place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

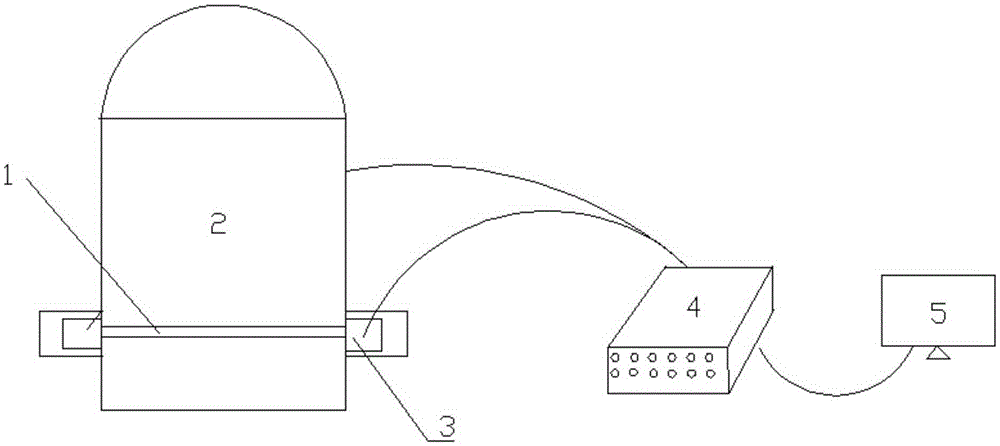

[0015] see figure 1 , an acoustic emission detection device for storage tank floor corrosion, comprising an acoustic emission detection sensor 3 adsorbed near the bottom of a storage tank 2 by a magnetic base 1, an acoustic emission detection instrument 4 connected to the acoustic emission detection sensor by a data line . A display 5 connected to the acoustic emission detector for displaying the analysis results recorded by the acoustic emission detector.

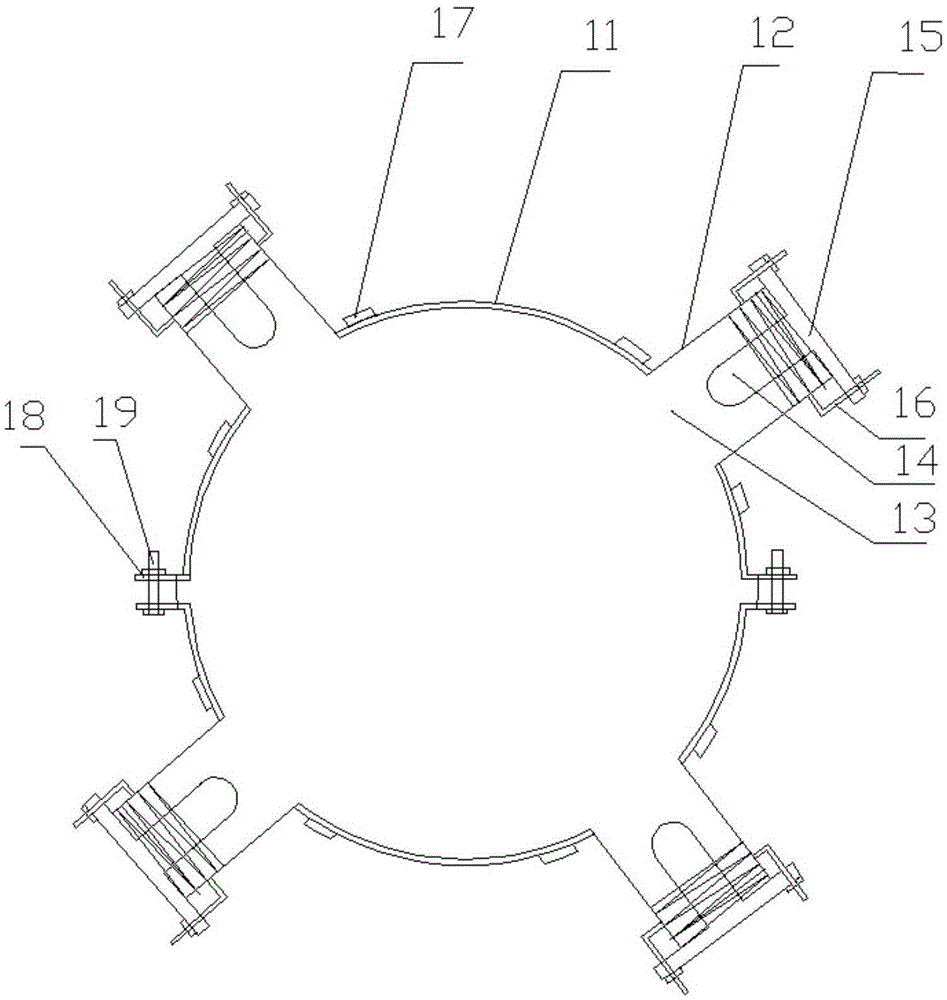

[0016] like figure 2 As shown, the magnetic base 1 includes a hoop 11 set near the bottom of the storage tank. The hoop is spliced by two semi-circular hoops in a detachable connection, and is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com