Silicon-wafer transport trolley

A transportation tool and silicon wafer technology, which is applied in the direction of transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems of easy bumping, inconvenient picking and placing of silicon wafer boxes, etc., and achieves good firmness, simple structure, and easy placement. Take out the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be clearly and completely described below with specific embodiments and accompanying drawings.

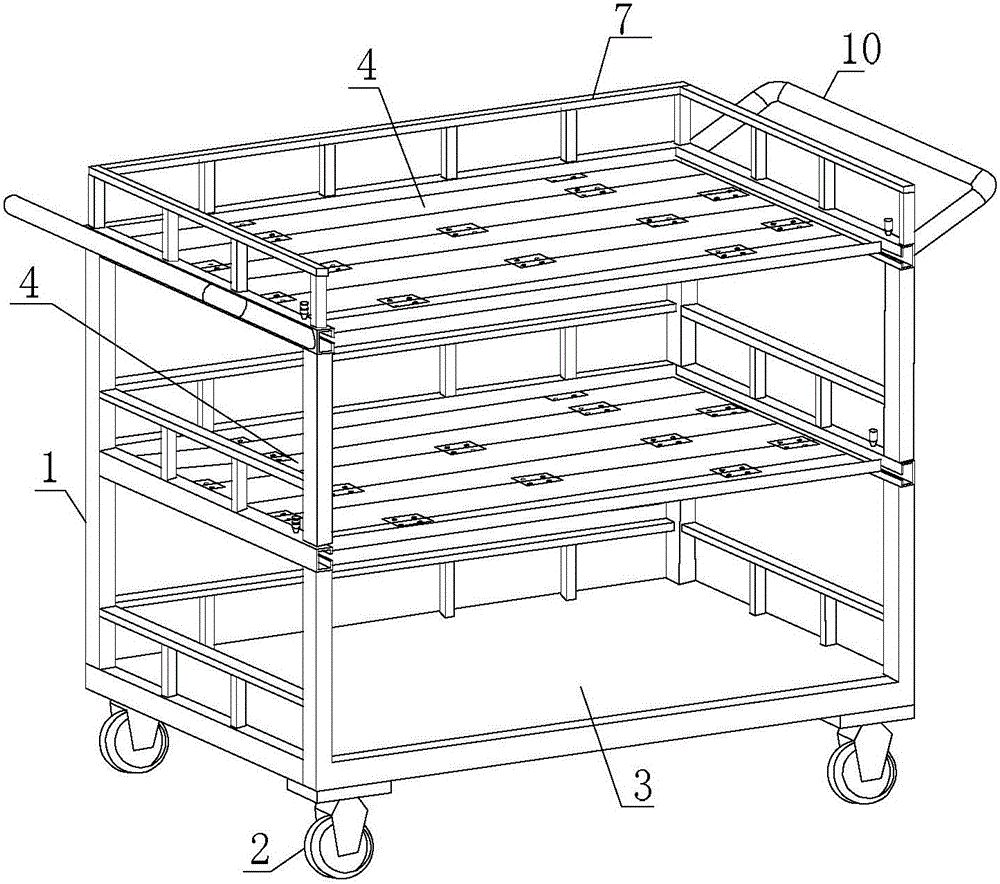

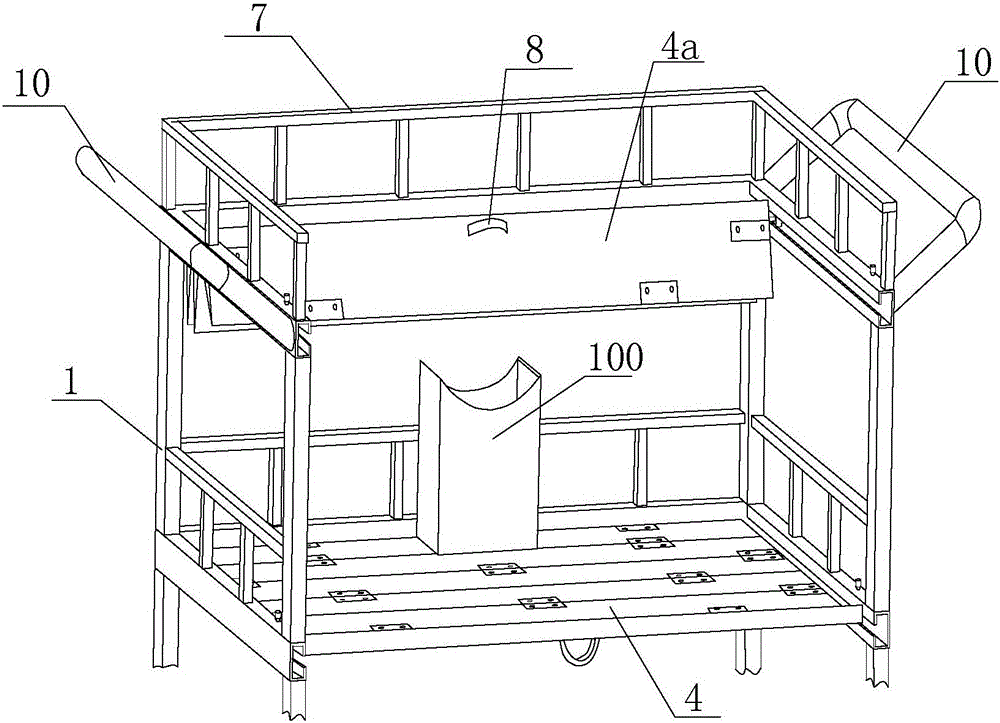

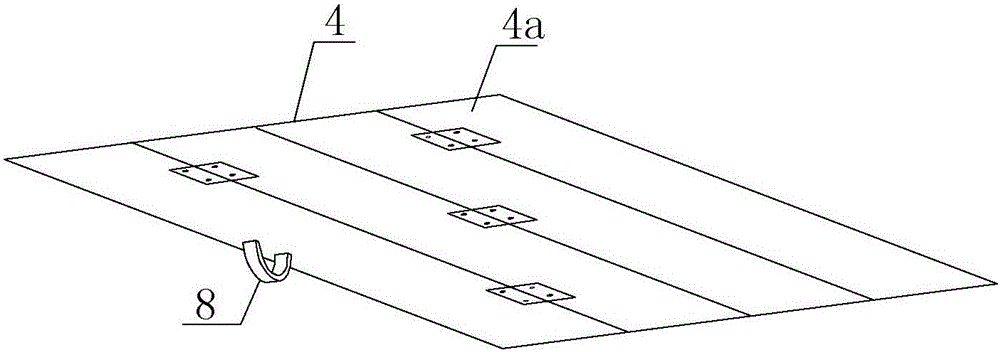

[0023] Such as Figure 1-4 As shown, the silicon wafer transportation tool of the present invention includes a vehicle frame 1 and several layers of partitions arranged on the vehicle frame for placing the silicon wafer box 100. The bottom of the vehicle frame 1 is provided with rollers 2, and the partition includes a The base plate 3 at the bottom and several upper dividing plates 4 positioned above the base plate. In the present embodiment, the upper dividing plates 4 are two pieces, and each upper dividing plate includes several folding plates 4a that can be overlapped and unfolded. 4a are connected in a rotatable manner. In this embodiment, the folding plates 4a are connected by hinges, such as image 3 shown. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com