Machining method and special hinged tool post for ultra-long and deep vertical turning

A processing method and vertical lathe technology, which are applied in metal processing equipment and other directions, can solve the problems of inaccurate repeated positioning of processing, cumbersome tool loading process, laborious removal of workpieces, etc., achieving simple structure, convenient picking/putting of workpieces, and quick installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The processing method of the ultra-long depth vertical turning of the present invention comprises the following steps:

[0034] (1) Set the processing program of the workpiece to be processed on the control panel of the lathe;

[0035] (2) Pull the bottom of the cutter bar upwards to the direction where the axis of the cutter bar is perpendicular to the axis of the main shaft, and at the same time make the gear pin socket on the main shaft connector at the position below the tool bar, and then The gear pin is inserted into the gear pin socket to realize the lateral fixation of the knife rod, and install the required tools on the tool mounting frame;

[0036] (3) Move the main shaft, after being adjusted to the processing position of the workpiece to be processed, unplug the gear pin that is positioned at the bottom of the tool bar at this time, so that the tool bar will naturally sag again under the action of gravity;

[0037] (4) Adjust the axis of the cu...

Embodiment 2

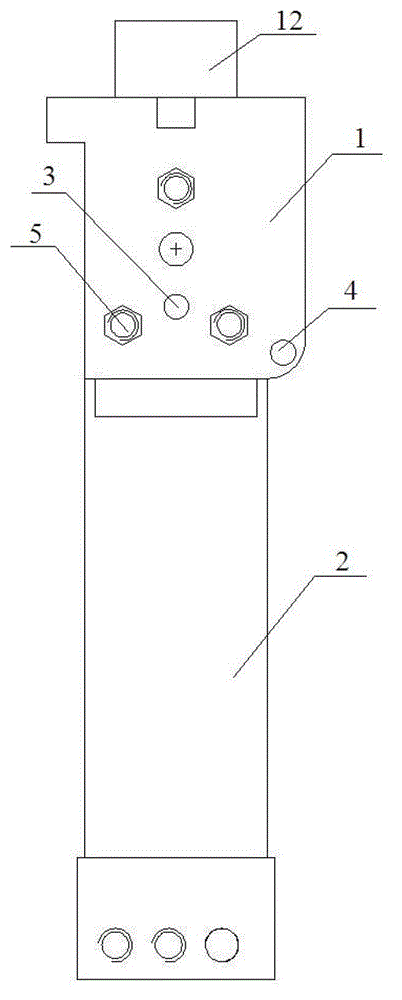

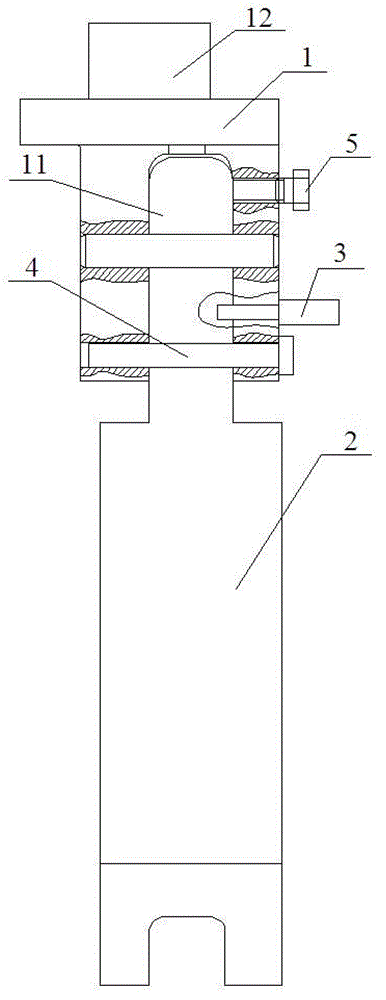

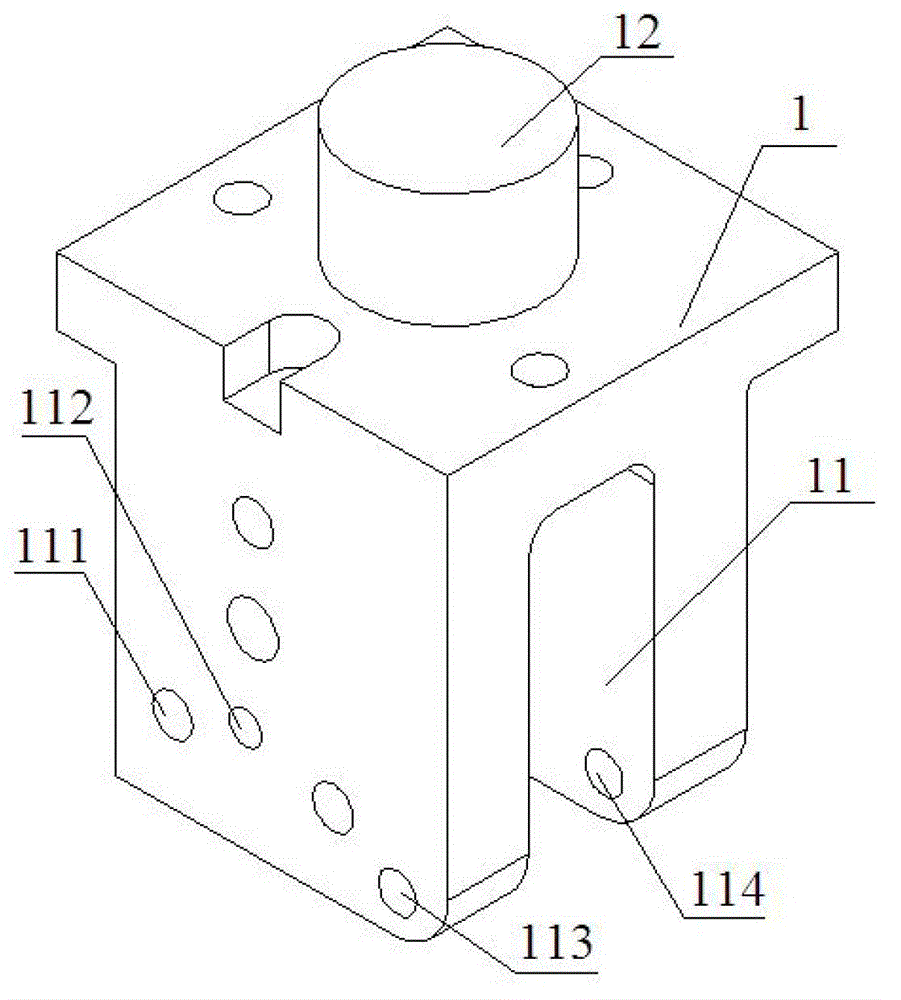

[0040] Embodiment 2 A special hinged tool post constructed according to the processing method described in the present invention, including a main shaft connector 1, a tool bar 2, a positioning plunger 3, a gear pin 4 and a positioning bolt 5, and the upper end of the main shaft connector 1 is Fixed on the main shaft of the lathe, the lower end of the main shaft connector 1 is provided with a strip-shaped tool bar installation groove 11, and a positioning part communicating with the tool bar installation groove 11 is provided on the rib of the tool bar installation groove 11. Bolt holes 111, positioning sockets 112, first gear pin holes 113 and second gear pin holes 114, and the first gear pin holes 113 and the second gear pin holes 114 are respectively located on the cutter bar The same position of the different ribs of the installation groove 11;

[0041] Described cutter bar 2 comprises cutter bar shaft 21 and the tool mounting frame 22 of installing cutter, and described t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com