Industrial film winding machine and working method thereof

A film rolling machine, industrial technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems that affect the production progress, the filter screen is not easy to align, and unfavorable production, so as to improve the quality and yield, and ensure good quality The effect of improving efficiency and quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

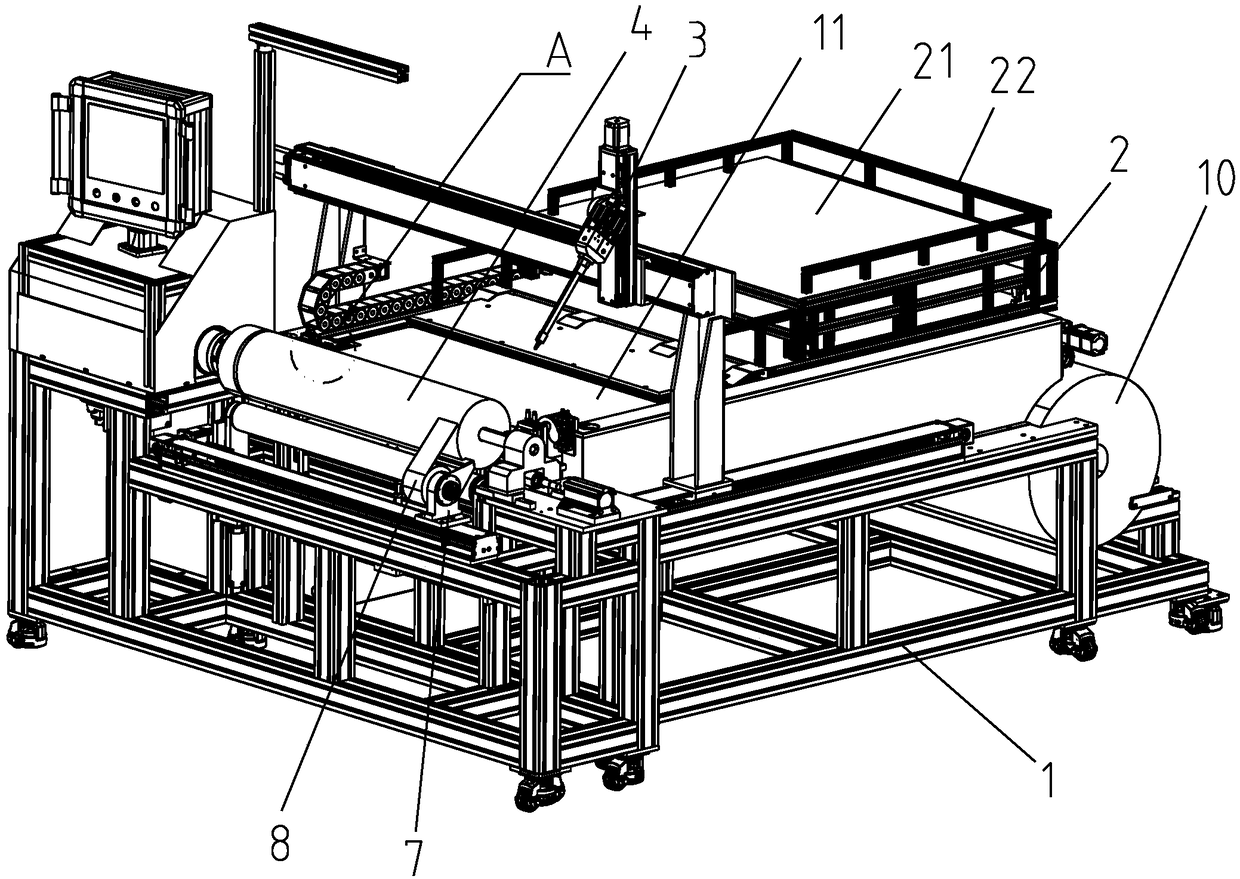

[0050] Such as Figure 1~5 As shown, an industrial film roll machine, it includes:

[0051] A frame 1, the frame 1 is provided with a fresh water network platform 11 for supporting the fresh water network;

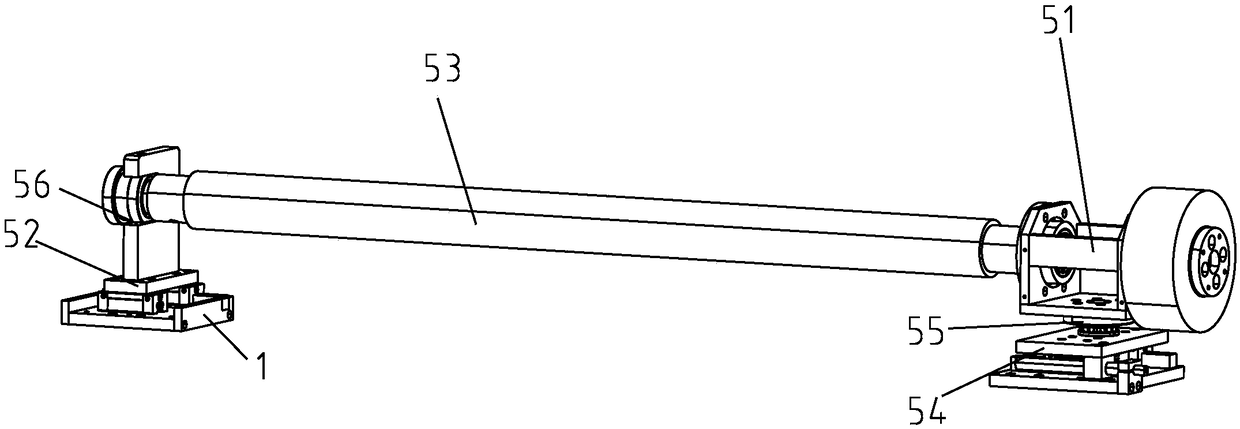

[0052] An unwinding mechanism for supporting the freshwater net roll 10 and unwinding the freshwater net roll 10, and the freshwater net unrolled by the unwinding mechanism is laid flat on the freshwater net platform 11;

[0053] A filter screen frame 2 for placing a filter screen, the filter screen frame 2 is slidably fitted on the frame 1;

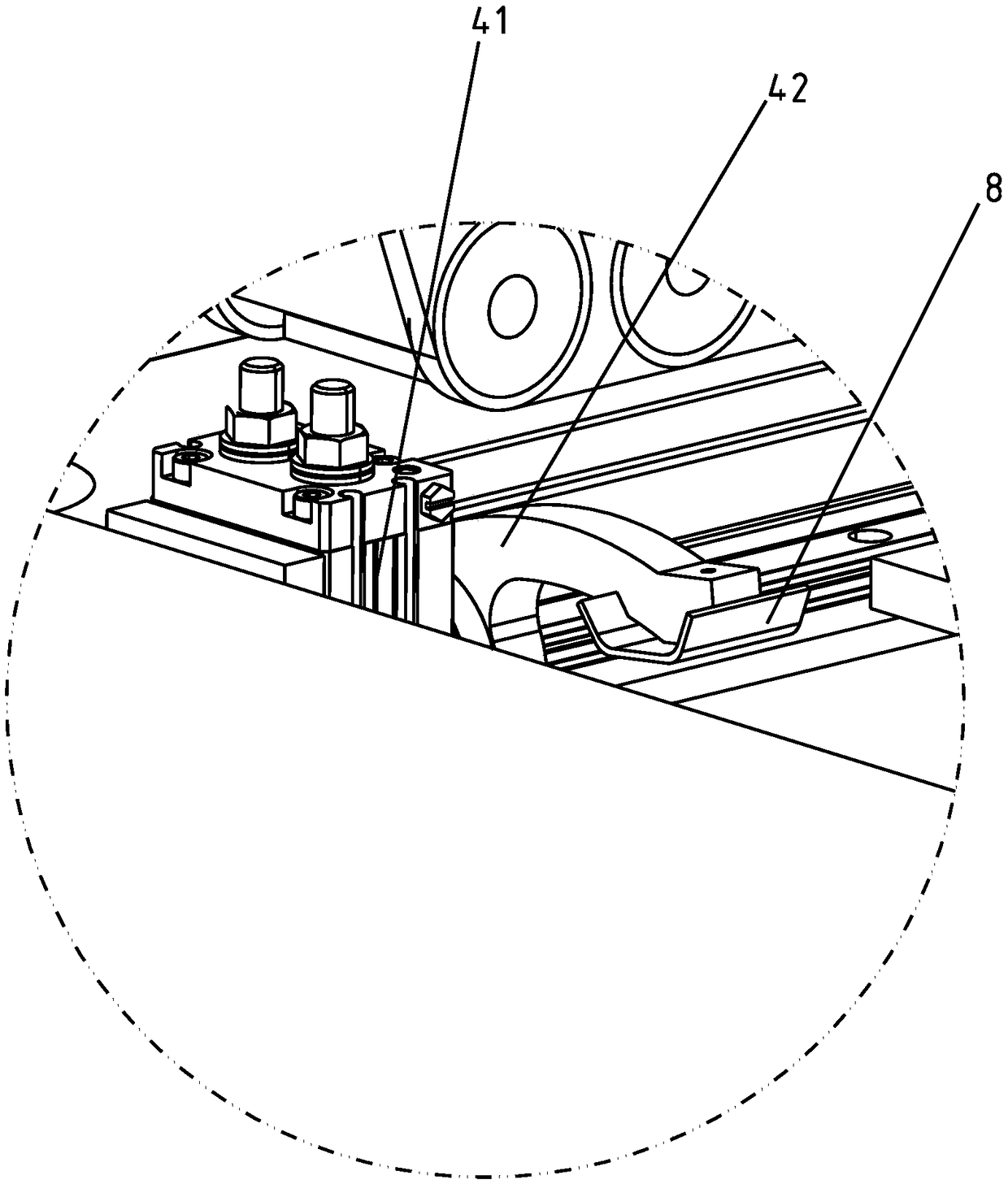

[0054] Gluing mechanism 3 for gluing the filter screen, so that the newly taken filter screen can be glued to the glued filter screen;

[0055] Mobile driving device, the mobile driving device is arranged between the frame 1 and the filter screen frame 2, so that the filter screen frame 2 is driven forward by the mobile driving device to facilitate the filter screen and put it into the fresh water net platform 11; and by moving Th...

Embodiment 2

[0076] A kind of working method of industrial film rolling machine as described in embodiment one, comprises in the method step:

[0077] Step S1, pulling the head of the fresh water net roll 10 on the unwinding mechanism, passing through the fresh water net platform 11, and then winding on the winding mechanism 4;

[0078] Step S2, the mobile drive device drives the filter frame 2 to move forward, the employee pulls the head of the filter screen, and then the mobile drive device drives the filter frame 2 to move back and reset, so that the filter screen falls on the fresh water net platform 11, and the fresh water net After moving to a suitable position, the glue-making mechanism 3 performs glue-making operations on the filter screen, and repeats this until the filter screen with a set number of layers is bonded;

[0079] Step S3, the winding mechanism 4 rewinds the fresh water net and the filter net on the fresh water net platform 11, and after finishing the winding, cuts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com