Floor tile laying and pasting device

A technology of floor tiles and suction cups, which is applied in the direction of construction and building construction, can solve the problems of time-consuming and labor-intensive laying of floor tiles, and achieve the effects of reducing work intensity, increasing contact area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

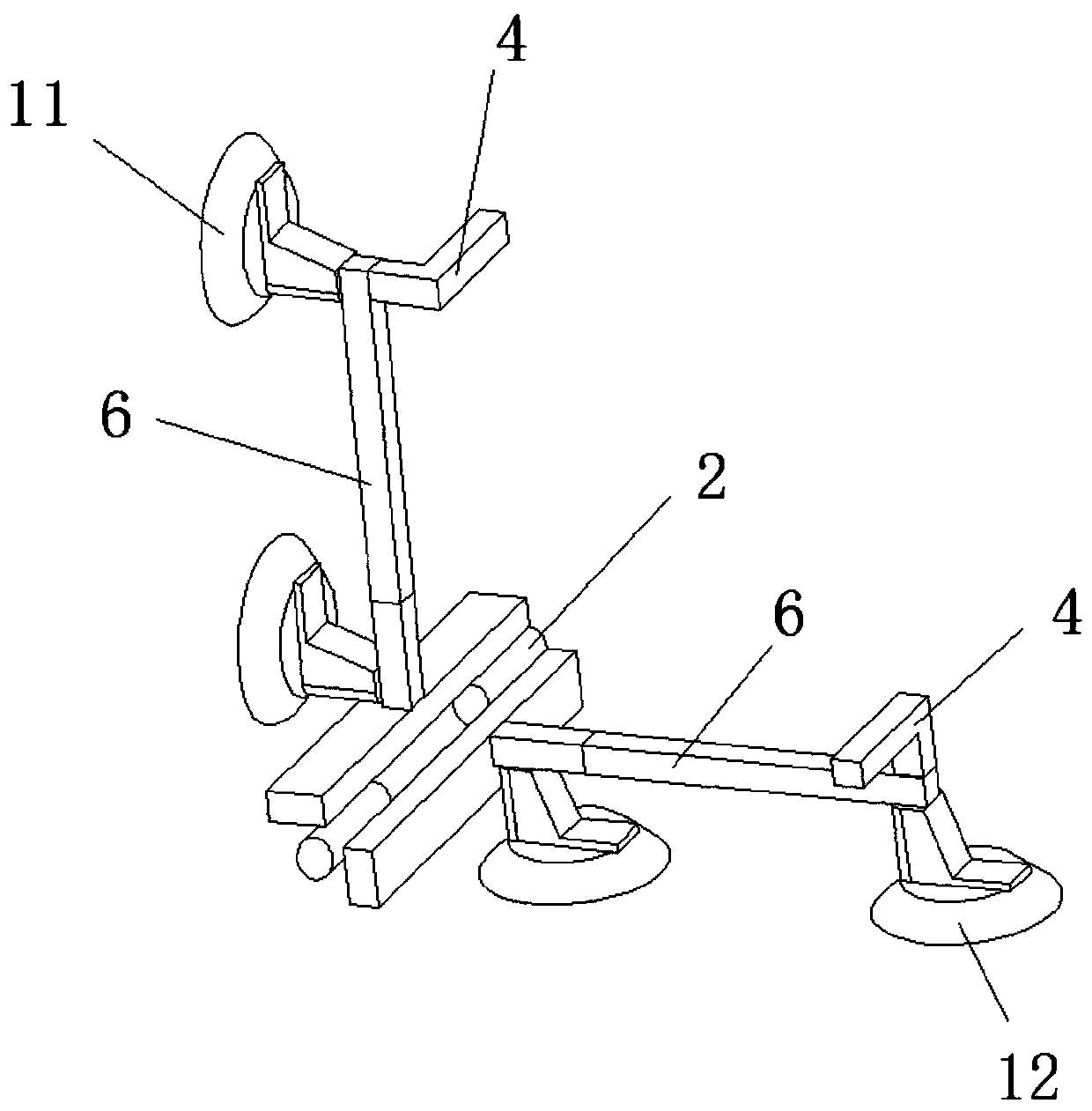

[0031] A floor tile laying device, such as figure 1 As shown, it includes a first suction cup group 11, a second suction cup group 12 and a hinge assembly, the first suction cup group 11 and the second suction cup group 12 are hinged by the hinge assembly, and when the hinge assembly is in an unfolded state, the first suction cup group 11 The orientation of the adsorption surfaces of the second suction cup set 12 is the same, and when the hinge assembly is in the closed state, the orientations of the adsorption surfaces of the first suction cup set 11 and the second suction cup set 12 are opposite.

[0032] Through a floor tile laying device with the above structure, when in use, the worker can use the first suction cup group 11 and the second suction cup group 12 to respectively absorb a floor tile, and then move the two floor tiles to the position where they need to be pasted. At this time, The worker just can realize the trial placement of floor tiles by pulling the first s...

Embodiment 2

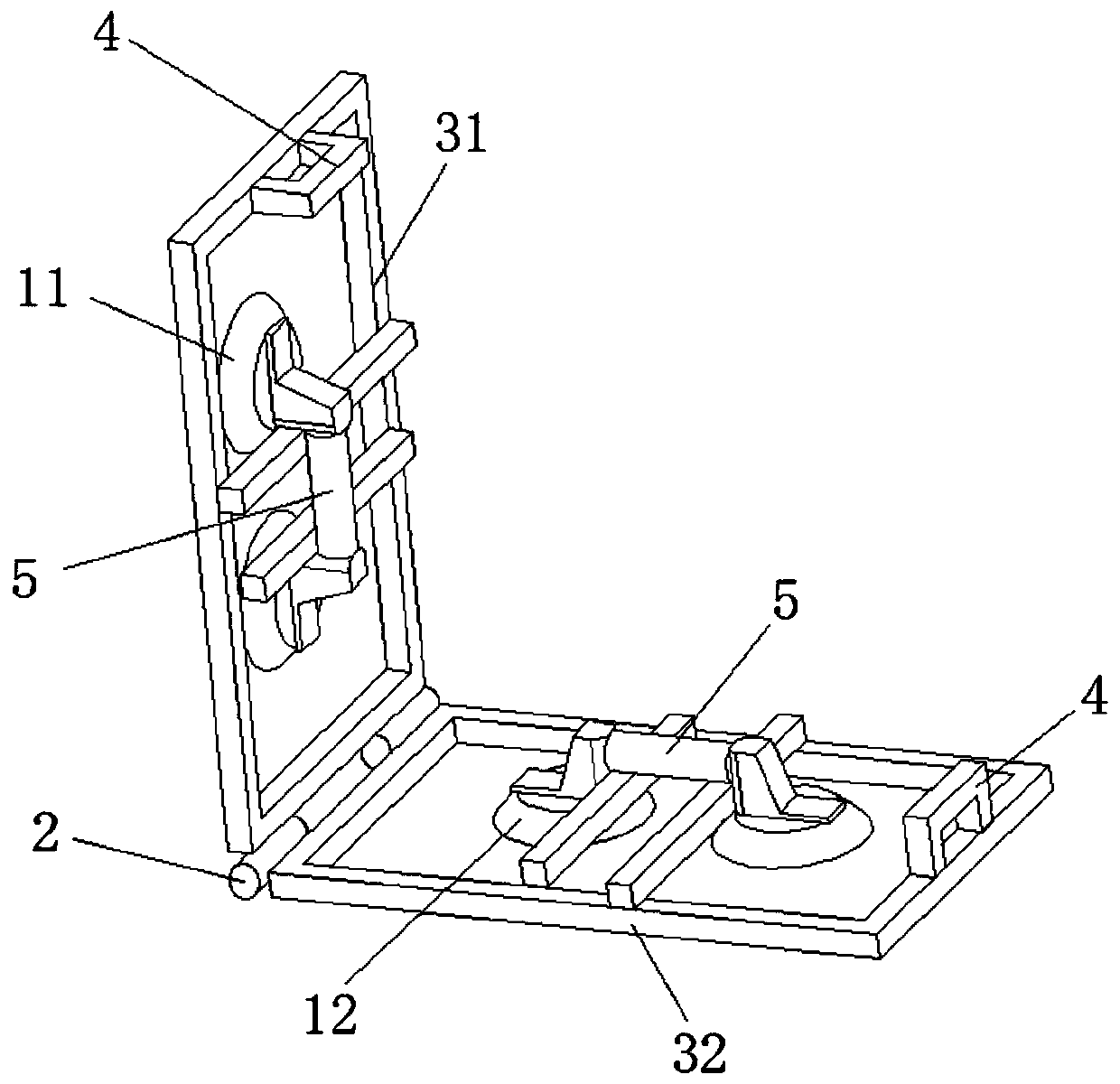

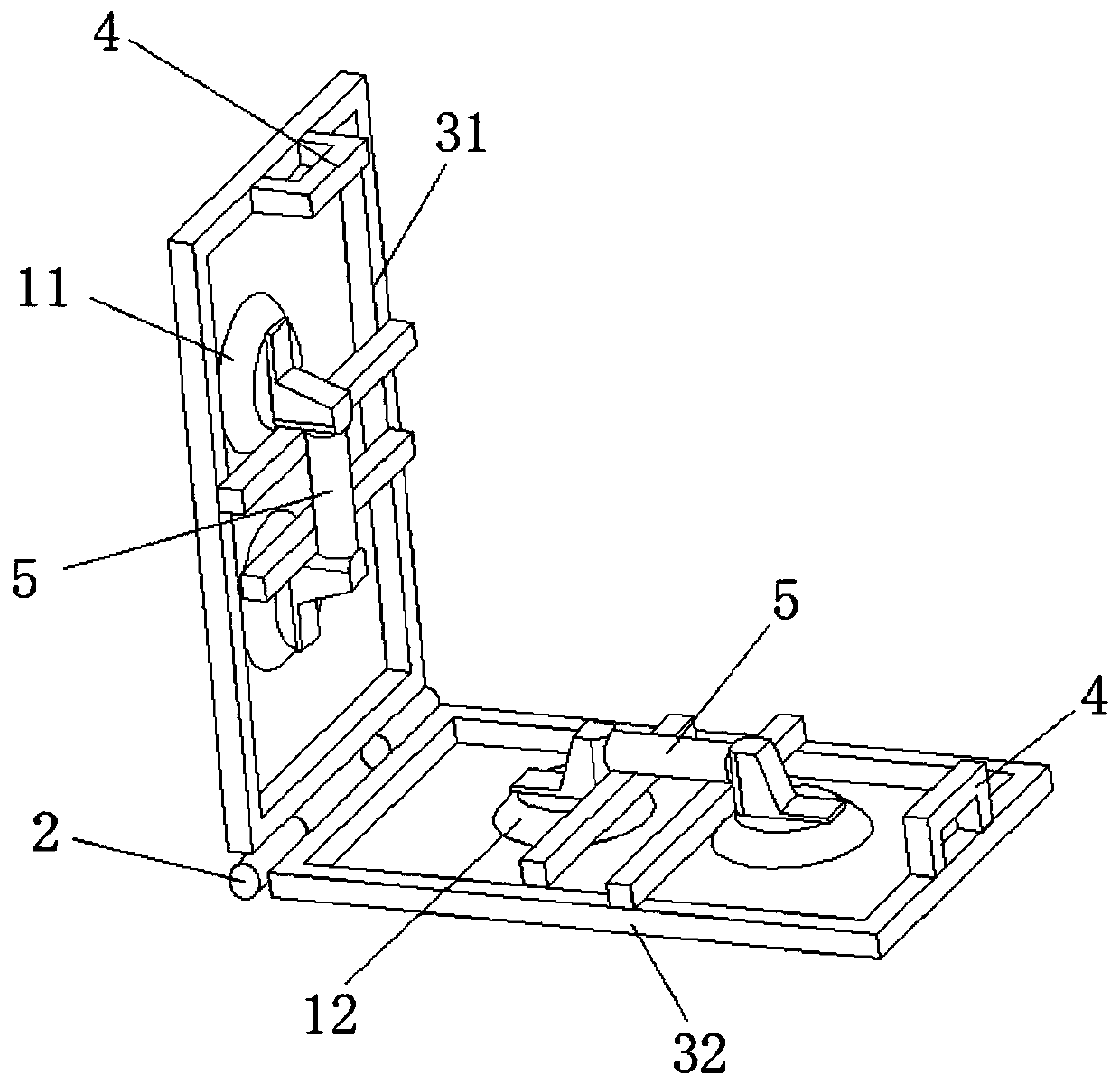

[0040] As another specific structure of the present invention, such as figure 2 As shown, the floor tile laying device includes a first suction cup group 11, a second suction cup group 12 and a hinge assembly, the first suction cup group 11 and the second suction cup group 12 are hinged by the hinge assembly, and when the hinge assembly is in an unfolded state, the second suction cup assembly The suction surfaces of the first suction cup set 11 and the second suction cup set 12 have the same orientation, and when the hinge assembly is in the closed state, the suction surfaces of the first suction cup set 11 and the second suction cup set 12 have opposite orientations.

[0041] Optimally, the hinge assembly includes a first frame 31, a second frame 32 and a hinge 2; wherein,

[0042] Both the first frame 31 and the second frame 32 are quadrangular frames, one of the action ends of the hinge 2 is connected to one side of the first frame 31, and the other action end of the hinge 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com