Grinding device for parts and components

A technology of parts and turntables, which is applied in the field of parts processing to avoid loosening and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

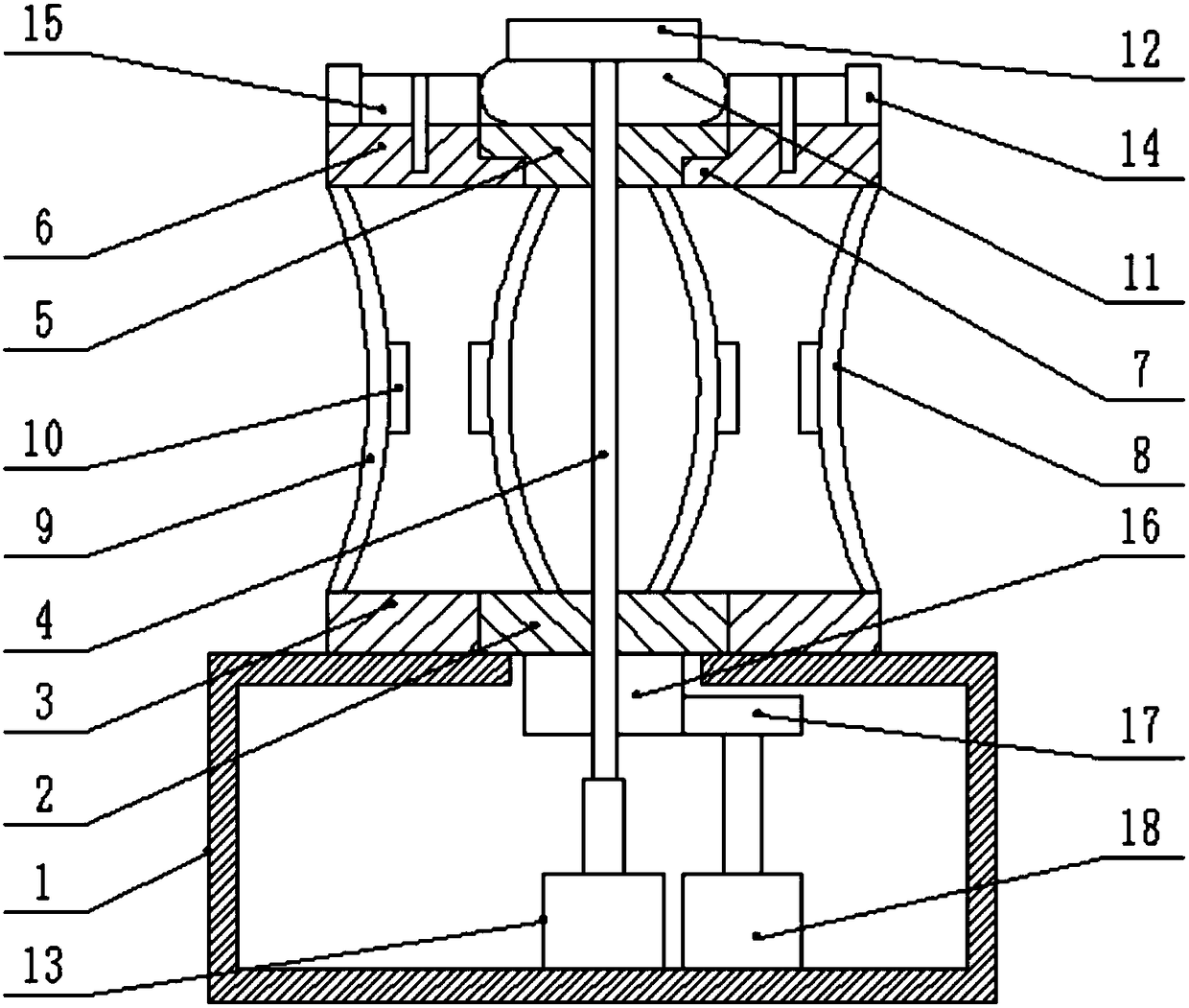

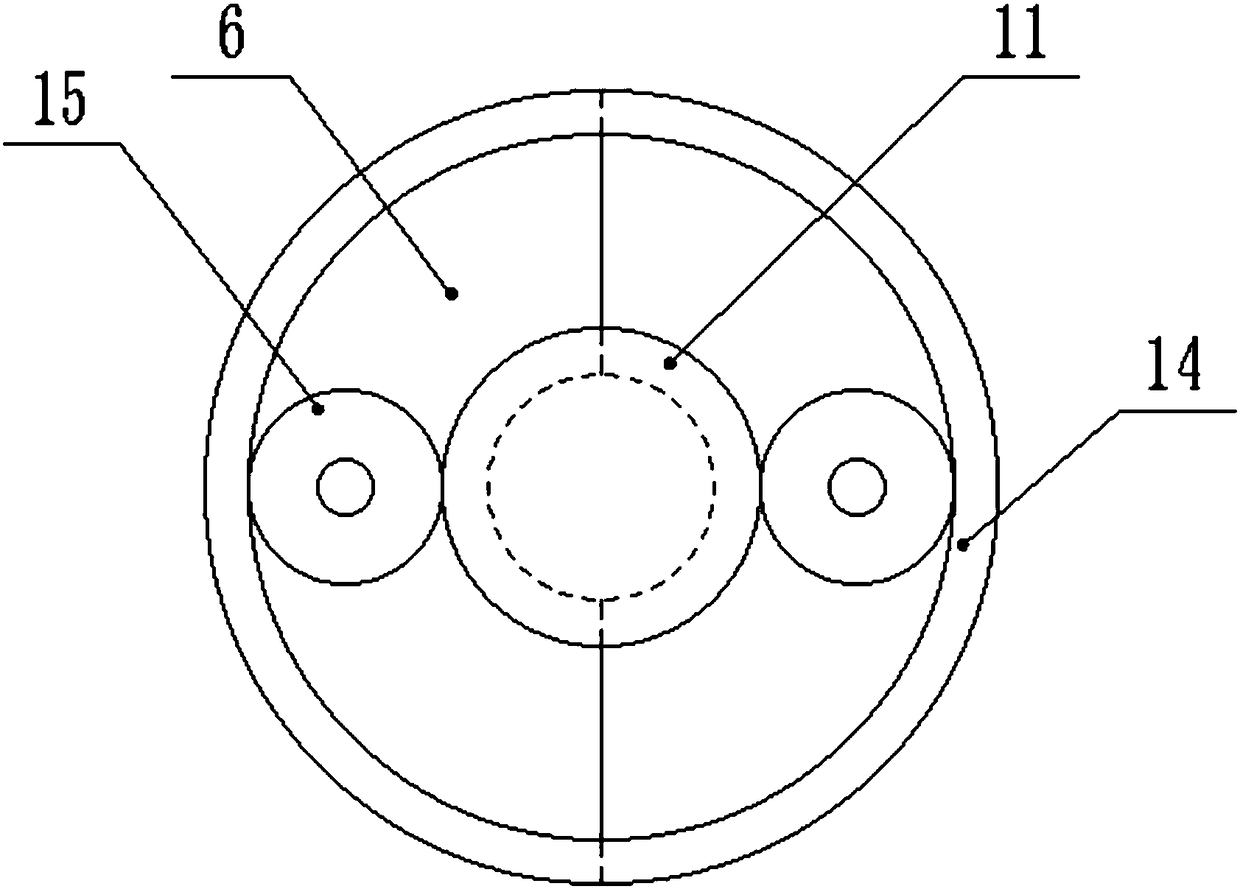

[0018] The reference signs in the drawings of the description include: frame 1, first turntable 2, first ring 3, telescopic rod 4, second turntable 5, second ring 6, limiter 7, convex strip 8, Concave strip 9, grinding block 10, active air bag 11, limit block 12, cylinder 13, friction ring 14, transmission wheel 15, ring gear 16, gear 17, motor 18.

[0019] This embodiment is basically as attached figure 1 , figure 2 Shown:

[0020] The parts grinding device includes a frame 1, on which a concentric first turntable 2 and a first ring 3 are rotatably connected, and the lower end surfaces of the first turntable 2 and the first ring 3 are all offset against the frame 1, And the first turntable 2 is located inside the first ring 3, and the lower end surfaces of the first turntable 2 and the first ring 3 are bonded with gaskets; the center of the first turntable 2 is slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com