Patents

Literature

79results about How to "Shorten the cooling path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

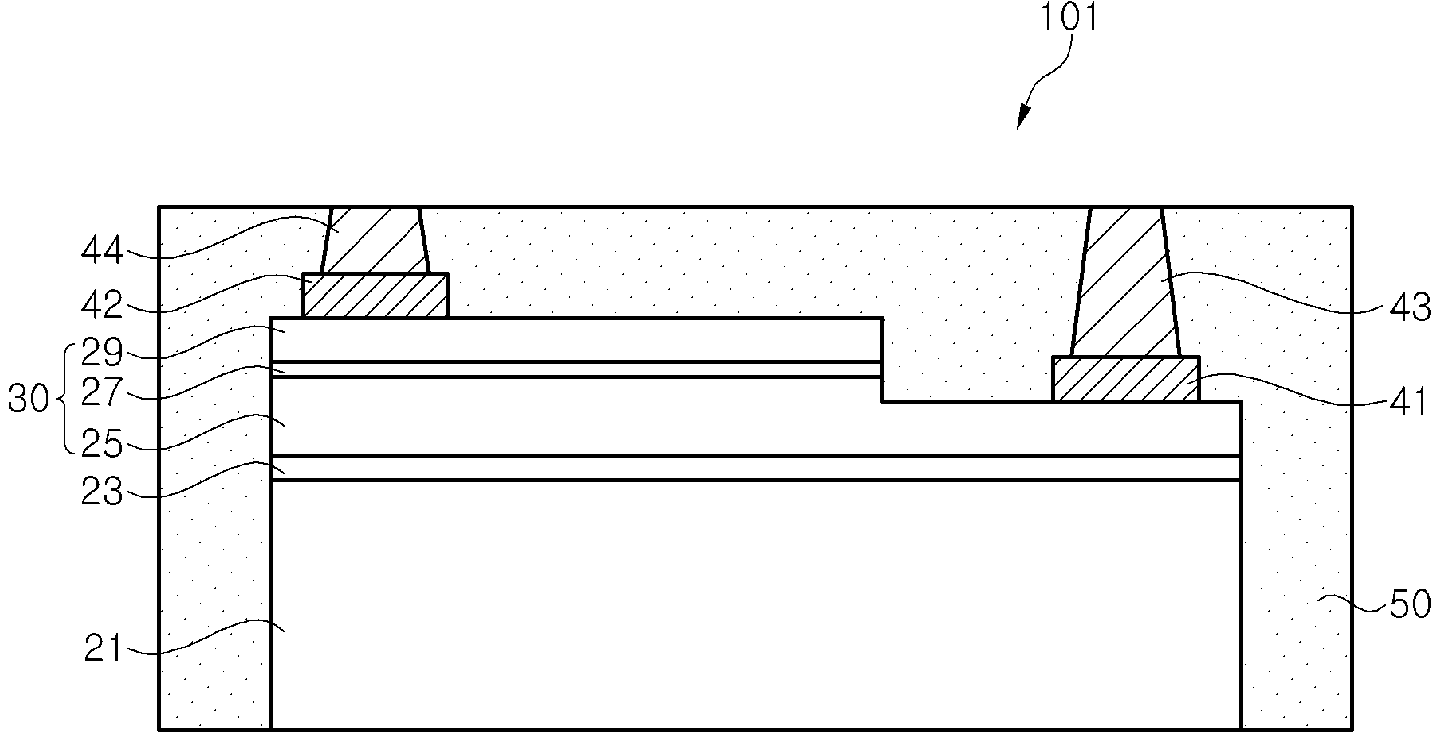

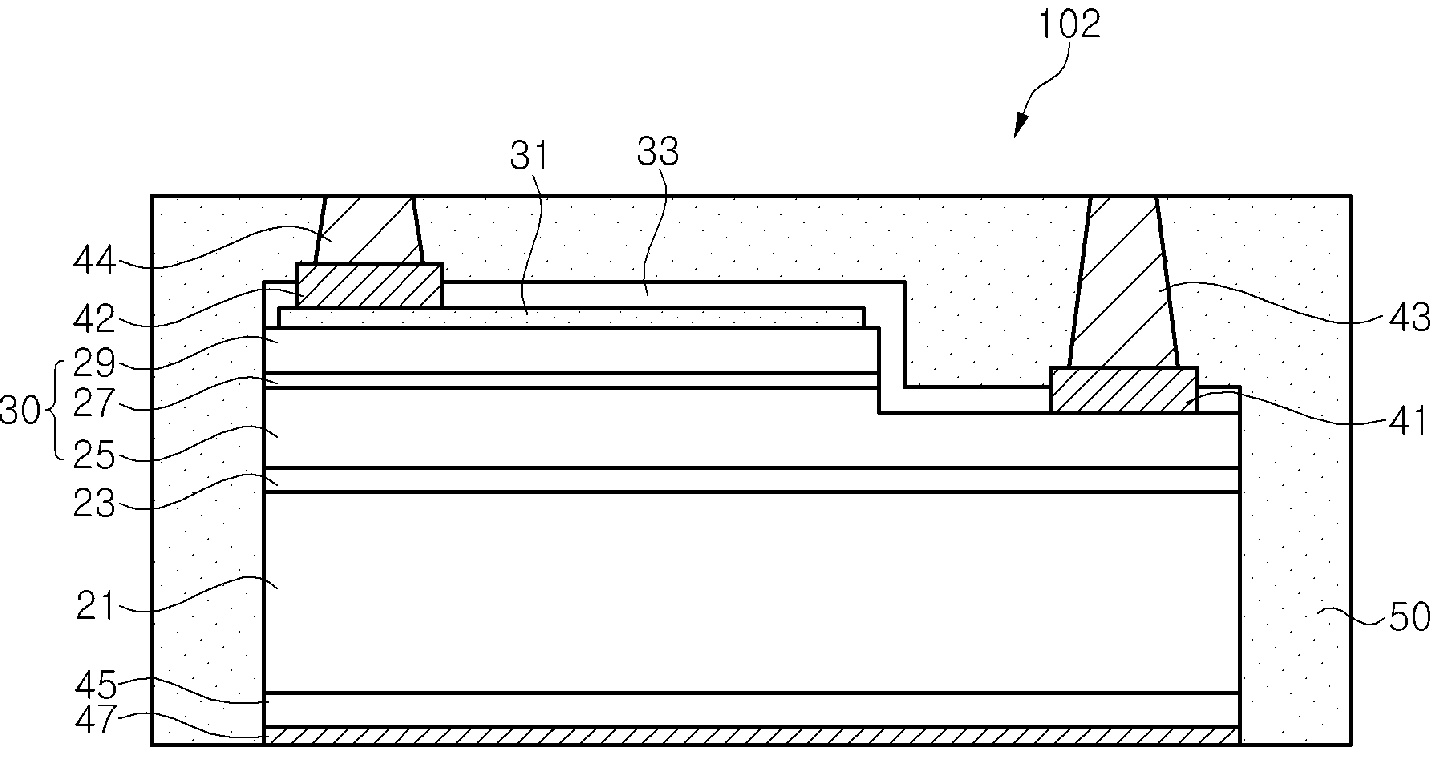

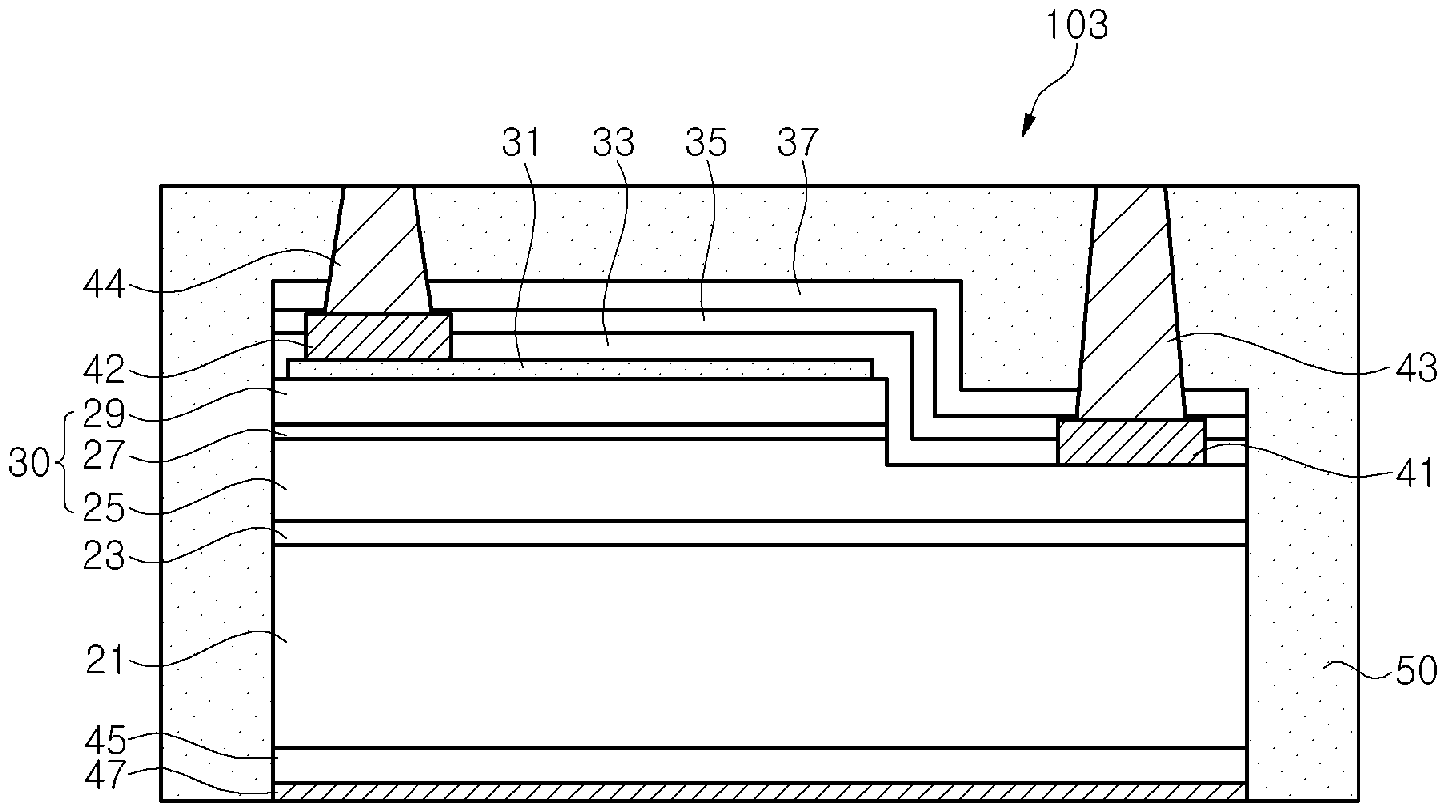

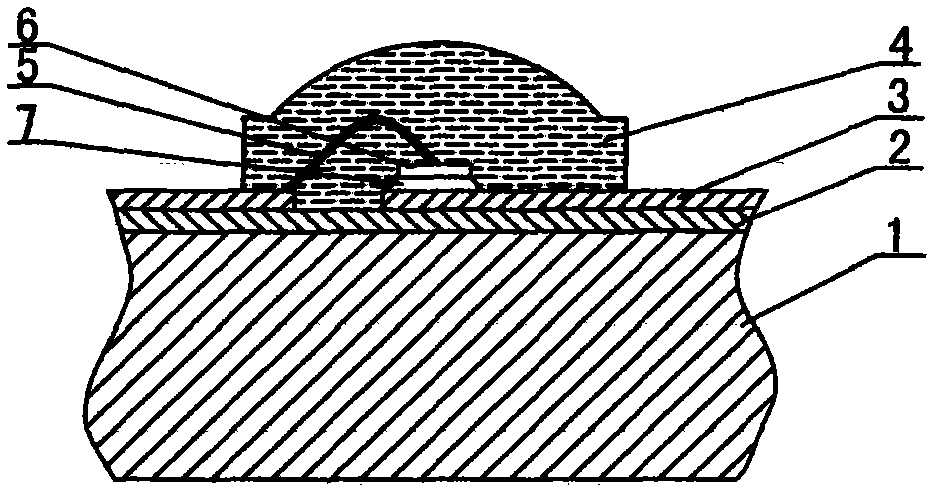

Light emitting diode chip having wavelength conversion layer and manufacturing method thereof, and package including same and manufacturing method thereof

ActiveCN103003966AEasy to bondShorten the cooling pathSolid-state devicesSemiconductor devicesGallium nitrideCompound semiconductor

Disclosed are a light emitting diode chip having a wavelength conversion layer, a method for manufacturing the same, and a package having the same. According to one aspect, the light emitting diode chip comprises: a substrate; a semiconductor stacked structure, which is located on an upper surface of the substrate and a gallium nitride-based compound semiconductor stacked structure including a first conductive semiconductor layer, an active layer, and a second conductive semiconductor layer; an electrode which is electrically connected to the semiconductor stacked structure; an additional electrode which is formed on said electrode; and a wavelength conversion layer which covers the upper part of the semiconductor stacked structure. Further, said additional electrode passes through the wavelength conversion layer. Thus, the invention is capable of performing wavelength conversion of light, and providing a light emitting diode chip which can easily bond a wire.

Owner:SEOUL SEMICONDUCTOR

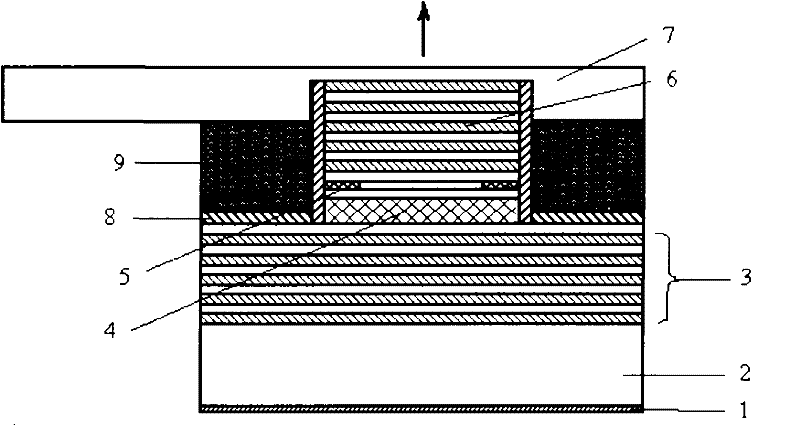

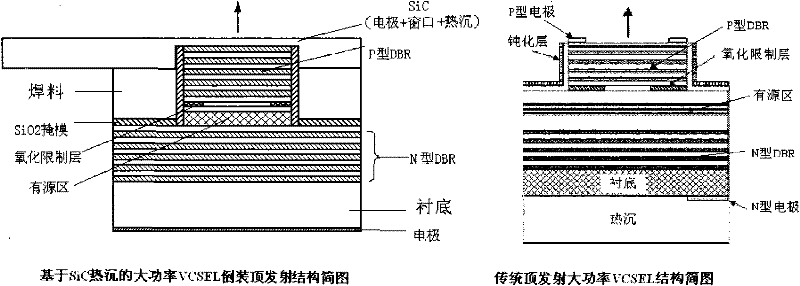

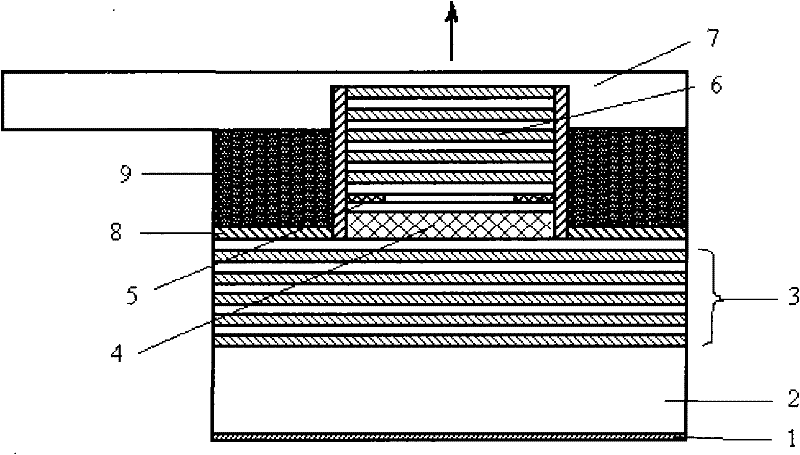

Single-mode high-power vertical-cavity surface-emitting laser based on sic heat sink

InactiveCN102263371AHigh thermal conductivityGuaranteed normal injectionLaser detailsSemiconductor lasersSic substrateHeat sink

The invention relates to a single-mode high-power vertical cavity surface-emitting laser based on a SiC heat sink. Including N electrode, SiC substrate, N-type DBR, active region, oxidation limiting layer, P-type DBR, SiC (electrode + window + heat sink), SiO2 mask, solder. The present invention is characterized by adopting a flip-chip top-emitting structure. The light output window is made on the P-type DBR, and the top light output method is adopted, and the heat sink is also placed at the end of the P surface. SiC wafers have high thermal conductivity, high electrical conductivity and high transmittance of near-infrared light after being modified by special technology. The P electrode, light window and heat sink in the traditional structure are replaced by SiC wafers, and the functions of the three are combined into one. The SiC wafer is used as an electrode, and the circular P electrode of the traditional VCSEL is replaced by a planar electrode or a non-uniform grid electrode; the SiC wafer is used as a heat sink material, and the thermal expansion coefficient is similar to that of GaAs materials, and it is directly flip-chip connected to the P surface in the epitaxial wafer; The SiC wafer simultaneously becomes the light exit window.

Owner:徐靖中

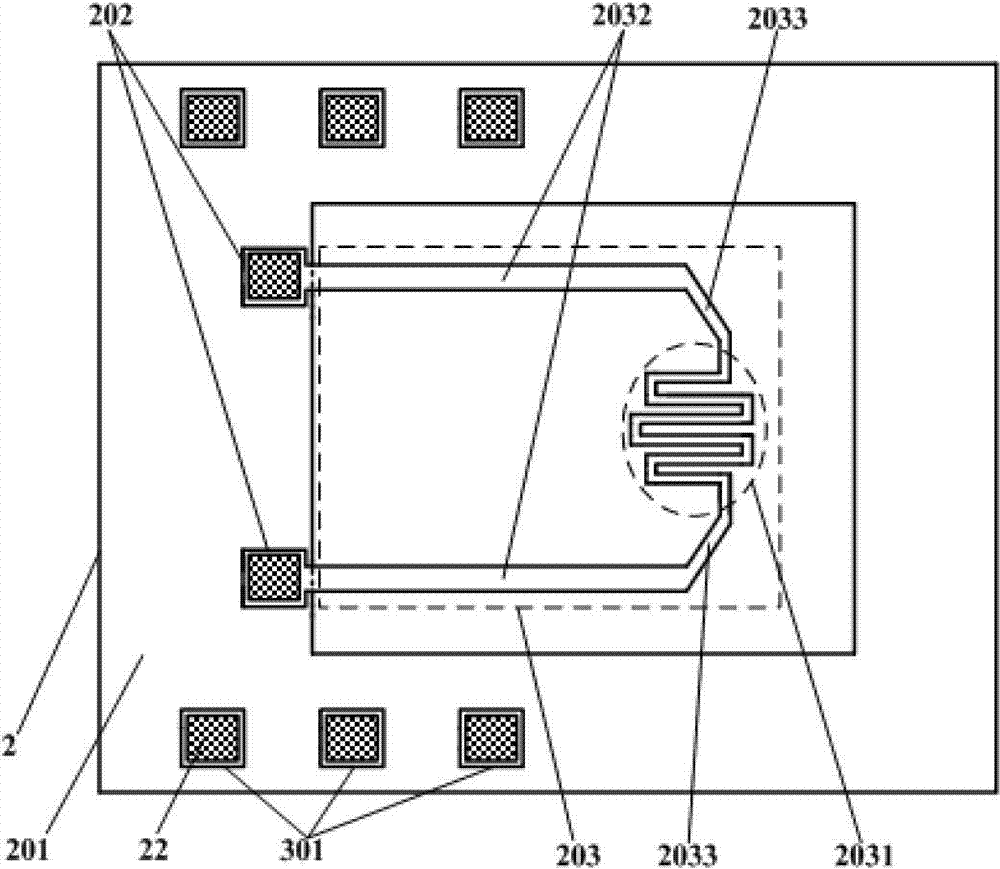

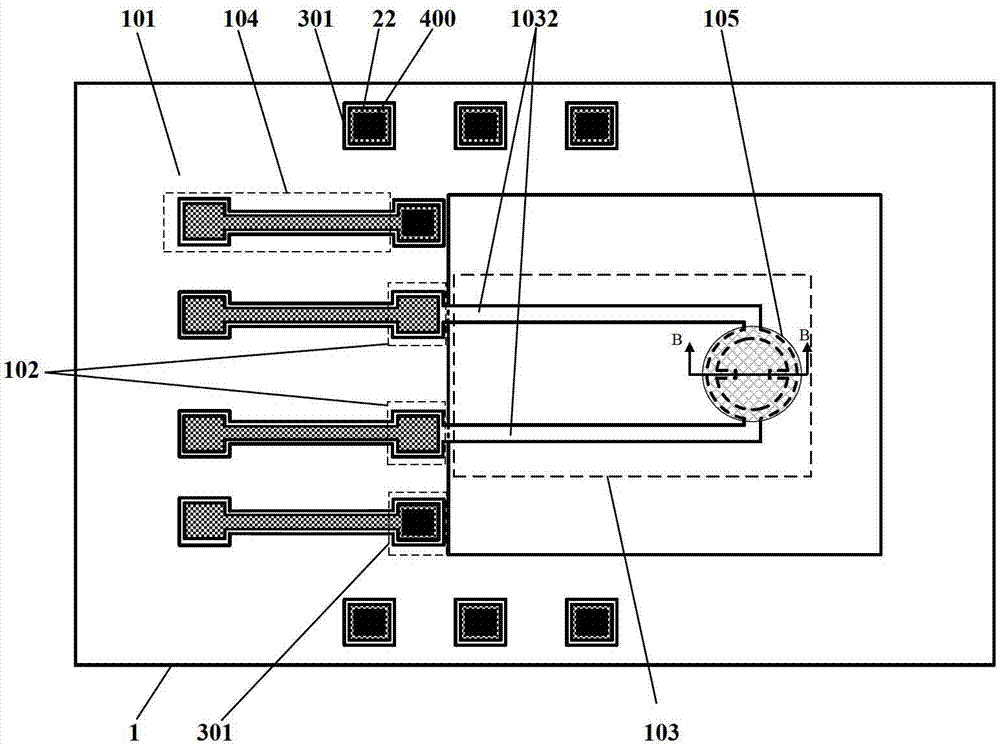

Micro gas sensor recoverable for repeated preparation and preparation method thereof

InactiveCN103472097AImprove performanceImprove electricity-heating efficiencyMaterial resistanceCMOSOhmic contact

The invention discloses a micro gas sensor recoverable for repeated preparation and a preparation method thereof, and belongs to micro gas sensors and preparation methods thereof. The silicon heater of the micro gas sensor is provided with a heat dissipation-support silicon block at the center; one ends of silicon cantilevers are connected with the silicon heater, and the other ends of the silicon cantilevers are connected with fixing ends of a silicon bearer; the fixing ends are arranged on silicon oxide buried layer of the silicon bearer; the silicon layer of each fixing end is provided with a doped silicon layer; a metal layer contacts the doped silicon layer of each fixing end via the window of the silicon oxide layer for formation of ohmic contact; the silicon heater is completely embedded in a catalyst carrier, and the catalyst carrier penetrates the center of the silicon heater and forms an own integrated structure. The MEMS processing technology is employed for the low-energy-consumption gas sensor for detecting gas concentration in coal mines, the preparation technology is compatible with the CMOS technology, and batch production can be realized; the catalyst carrier and the catalyst can be prepared repeatedly after the gas sensor is recovered; and the micro gas sensor is long in service life, stable in performance, small in volume and low in cost.

Owner:CHINA UNIV OF MINING & TECH

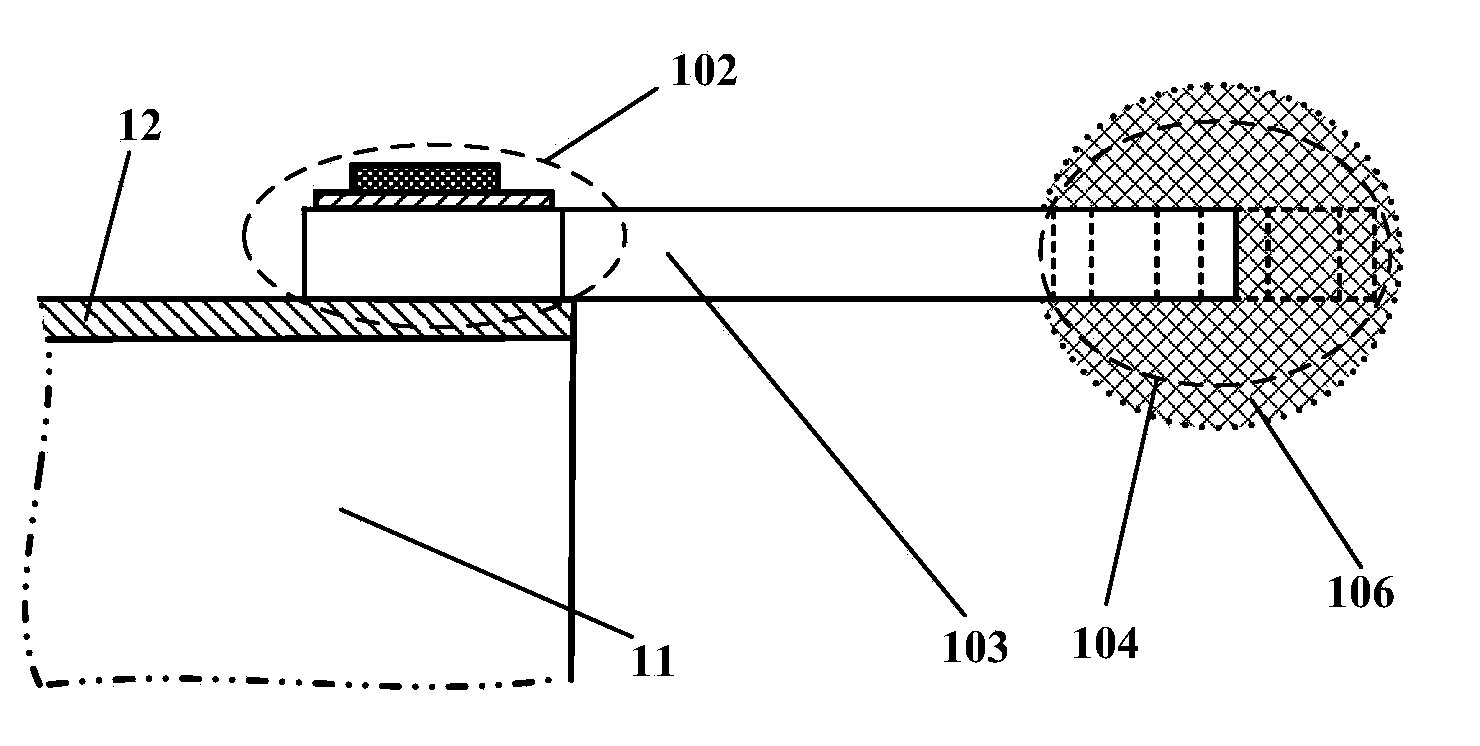

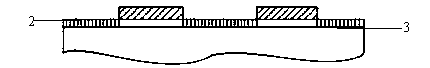

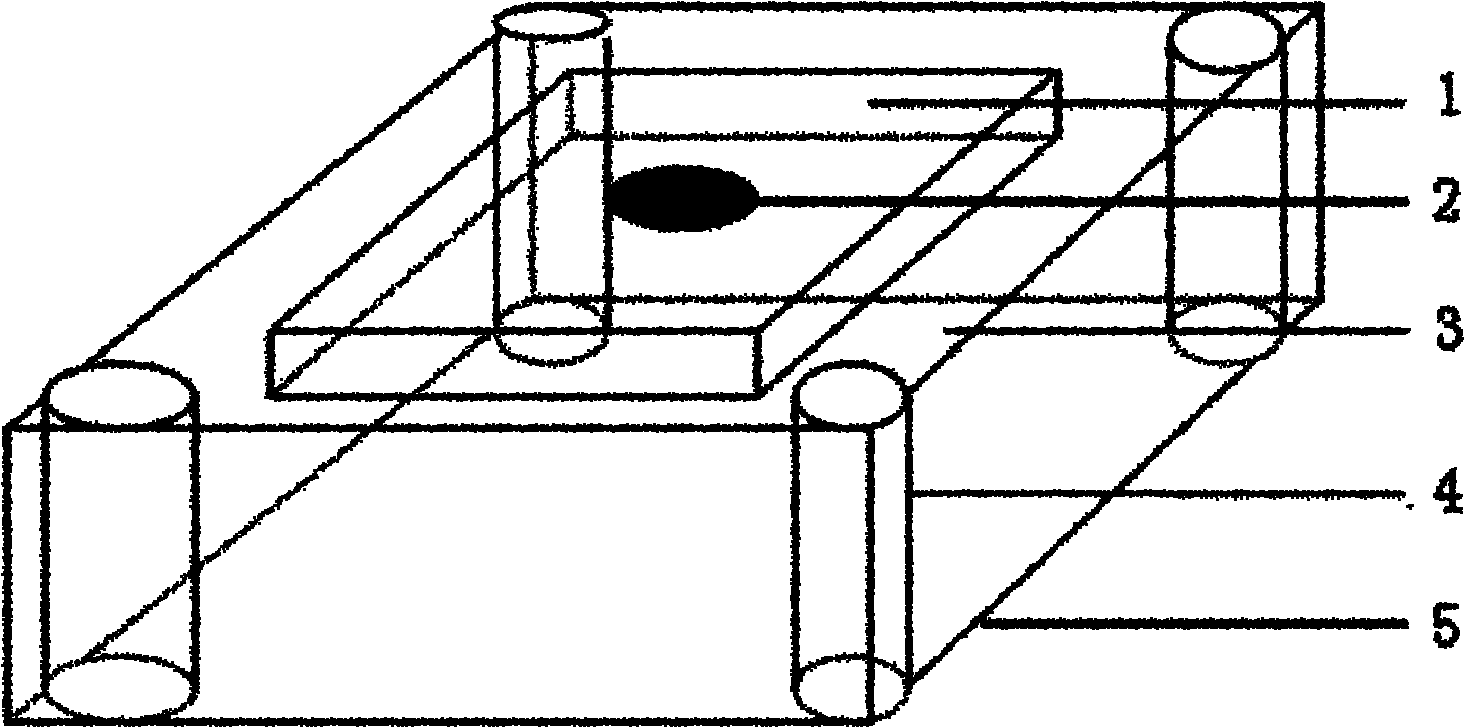

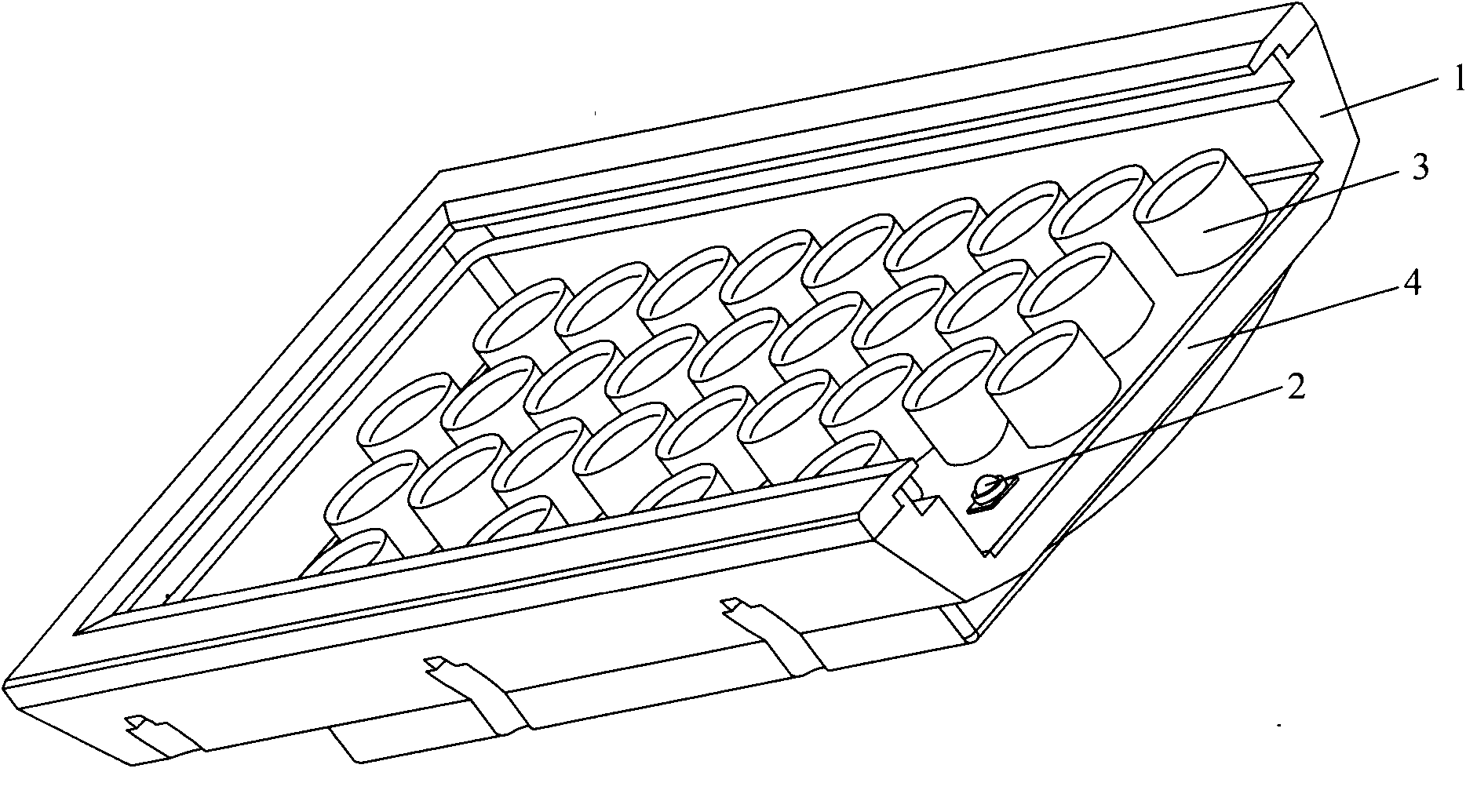

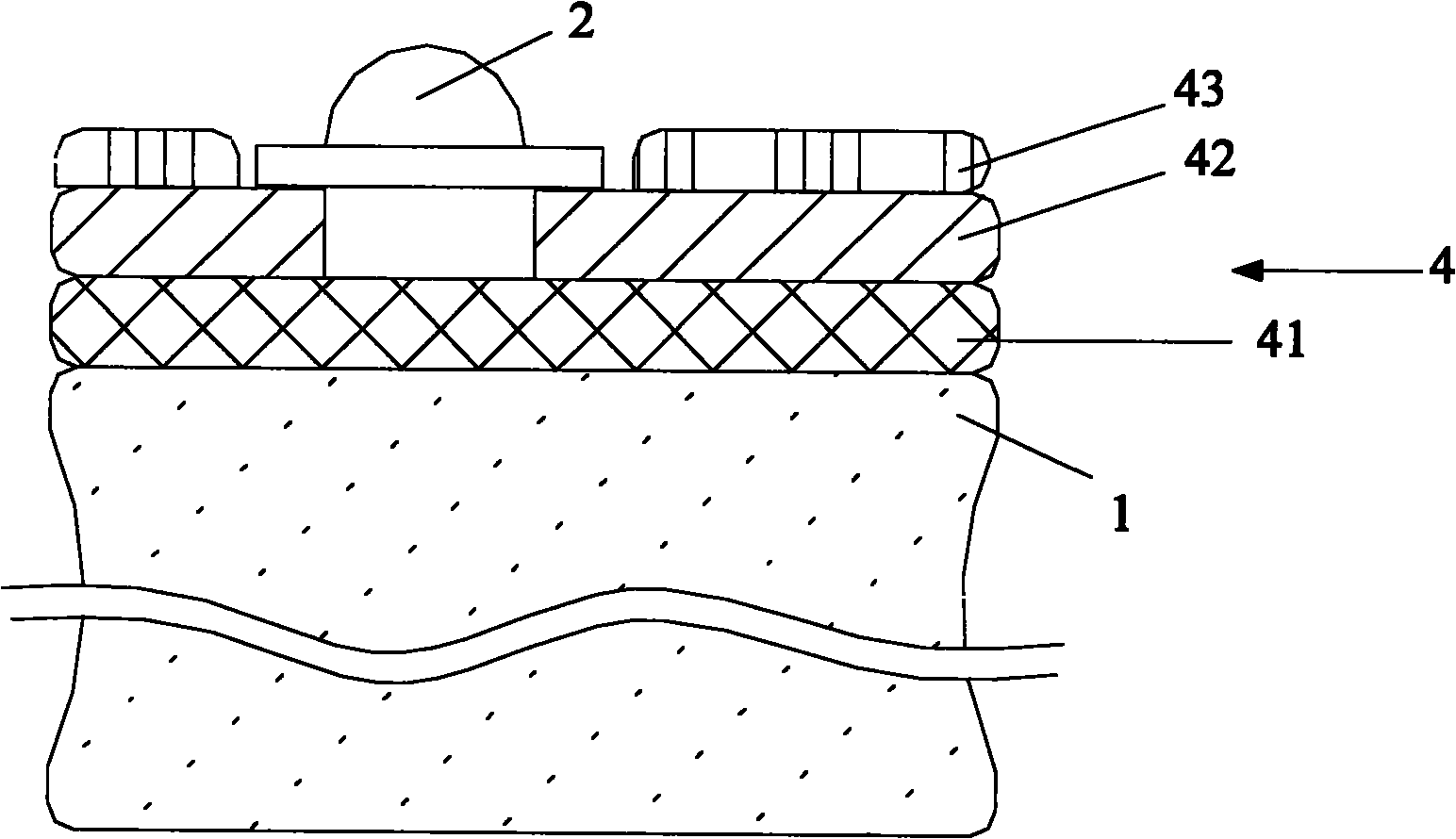

Multi-chipset high-power LED encapsulation structure

InactiveCN102130110AShorten the cooling pathReduce thermal resistanceSolid-state devicesSemiconductor devicesInsulation layerEngineering

The invention relates to a multi-chipset high-power LED encapsulation structure, belonging to the technical field of LED encapsulation and solving the problem on heat radiation of the multi-chipset high-power LED illumination modules. The multi-chipset high-power LED encapsulation structure comprises a substrate, a plurality of encapsulation units and a circuit lead, wherein the encapsulation units are uniformly distributed on the front side of the substrate; the circuit lead is printed on the front side of the substrate; and the substrate comprises a copper heat-radiating substrate on the lower layer and an insulation layer on the upper layer. Each encapsulation unit comprises a reflecting cup, a bonding layer, an LED chip, fluorescent powder, a silica gel lens and gold wires used for bonding wire balls, wherein the reflecting cup is arranged on the front side of the substrate; the LED chip is bonded on the center of the bottom of the reflecting cup in an eutectic way; the fluorescent powder is coated on the upper surface of the LED chip; silica gel is injected in the reflecting cup for fixing the LED chip; the silica gel lens is fix on the outer side of the mouth of the reflecting cup; and the anode and the cathode of the LED chip are respectively connected with the circuit lead on the front side of the substrate through the gold wires for bonding the wire balls. The invention relates to an encapsulation structure of the LED chips.

Owner:HARBIN INST OF TECH

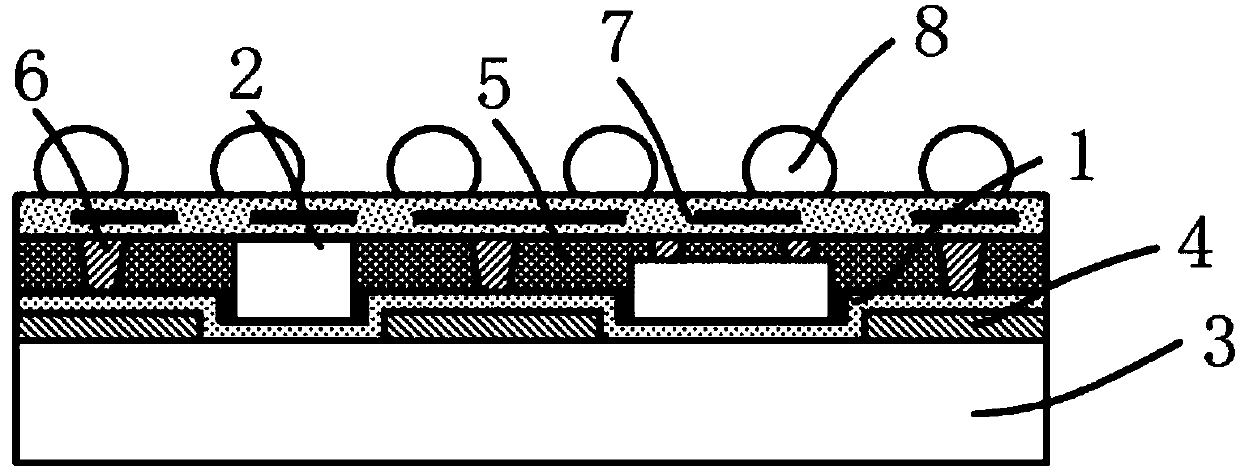

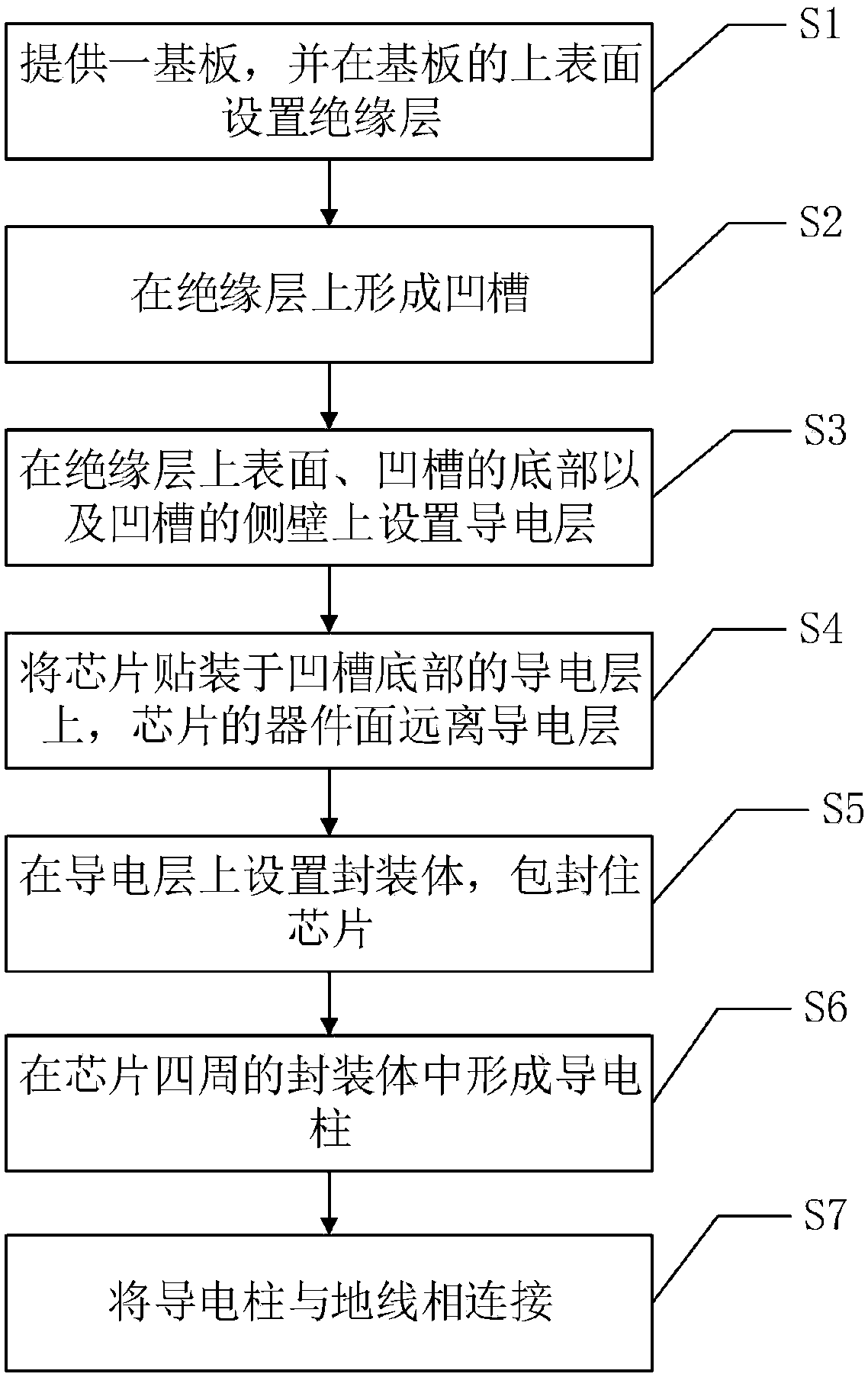

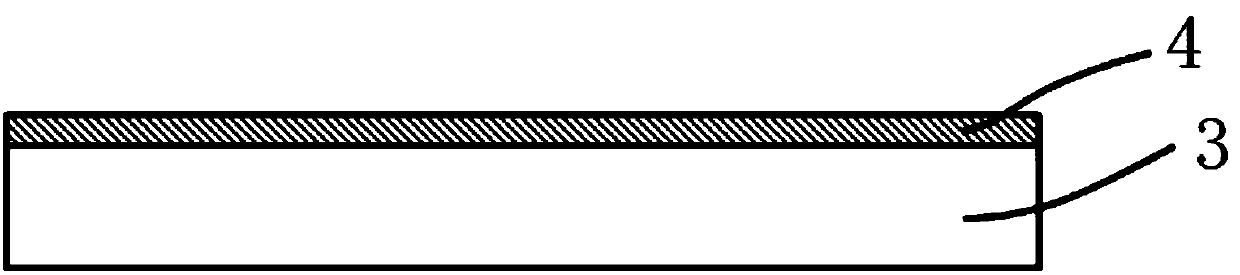

Fan-out wafer-level chip packaging structure and method

ActiveCN107946249AFast heat conductionImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

The present invention provides a fan-out wafer-level chip packaging structure and method. The fan-out wafer-level chip packaging structure comprises: a conducting layer, wherein one groove configuredto arrange one chip is formed on the conducting layer, and the conducting layer is arranged on a substrate; an insulation layer arranged between the conducting layer and the substrate and configured to fill a gap between the conducting layer and the substrate; a packaging body arranged at the upper surface of the conducting layer, wherein the chip is packaged in the packaging body, one bonding padof each chip is exposed out of the packaging body; a conducting column arranged in the packaging body, wherein one end of the conducting column is coupled to the conducting layer, the other end of the conducting column is exposed out of the packaging body, and the conducting column is connected with a ground wire. The chip is arranged in the groove on the conducting layer, and the conducting layer is connected with the ground wire through the conducting column to form an electromagnetic shielding structure located in the fan-out wafer-level chip packaging structure, and therefore, the possibility can be reduced that the chip is subjected to electromagnetic wave interference by devices in the packaging structure and external devices, the preparation difficulty is small and the production cost is low.

Owner:NAT CENT FOR ADVANCED PACKAGING

Multi-chip LED packaging method based on aluminum matrix composite substrate

InactiveCN104183683AGuaranteed Thermal MatchingShorten the cooling pathSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorOptoelectronics

The invention relates to a multi-chip LED packaging method based on an aluminum matrix composite substrate. The method comprises the steps that aluminum matrix composite material with high heat conductivity is adopted to act as a substrate. A layer of aluminum film is grown on the substrate, and a multi-hole type aluminum oxide layer is generated via performance of selective anodic oxidation on the substrate. Then a conductor wiring and electrode welding region is manufactured via a thin film technology, and then micro assembling and micro interconnection of LED chips are performed and finally packaging of a transparent shell is performed. A heat radiation problem of the LED chips is solved. Heat can be directly transmitted to the aluminum matrix composite substrate to be radiated out via a multi-hole type heat-radiating channel so that a heat-radiating path is greatly shortened and heat radiation effect is great.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

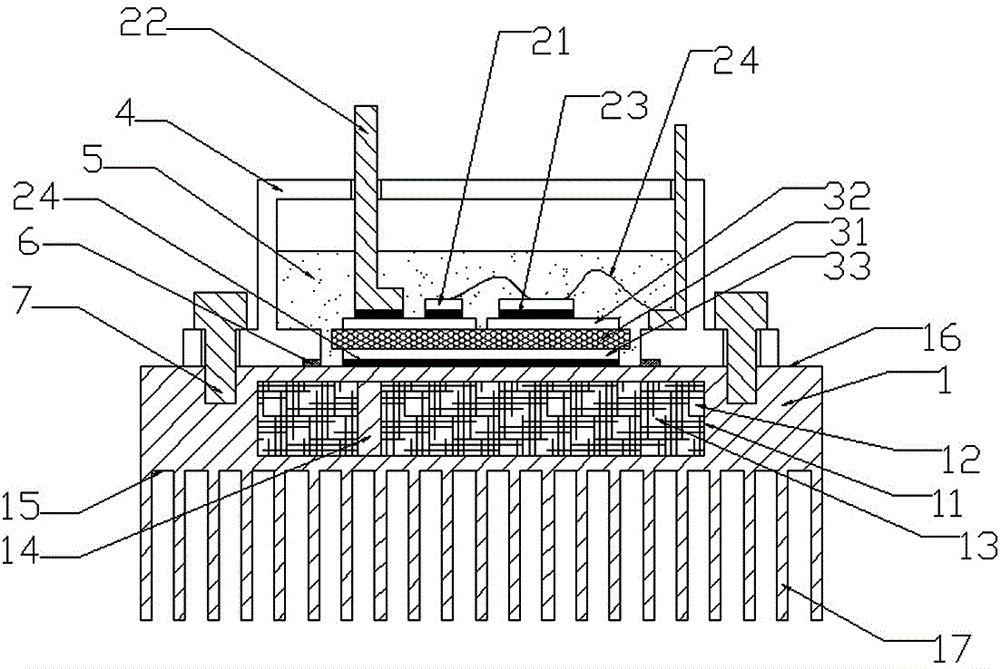

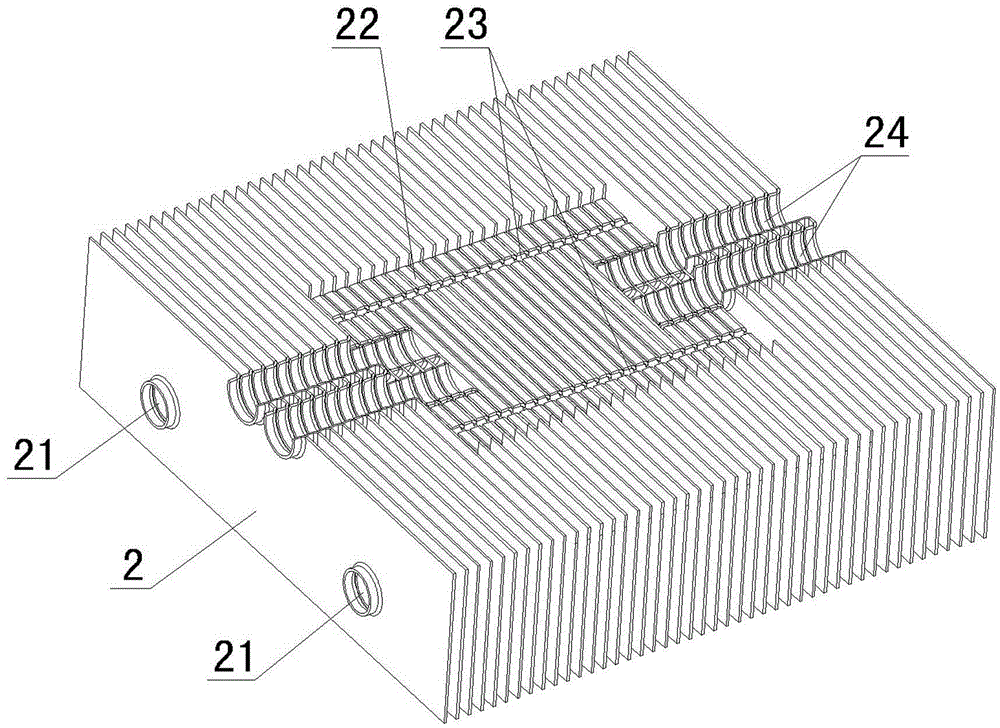

Power module structure with vapor chamber heat radiation substrate

InactiveCN105655307AFast deliveryRapid divergenceSemiconductor/solid-state device detailsSolid-state devicesFine structureOptoelectronics

A power module structure with a vapor chamber heat radiation substrate comprises the vapor chamber heat radiation substrate with a vapor chamber heat radiation system. The vapor chamber heat radiation system is formed by a vacuum cavity with a fine structure in the vapor chamber heat radiation substrate and a certain number of cooling fins connected with the vacuum cavity. A certain number of supporting blocks for supporting the upper face and the lower face of the vacuum cavity are arranged in the vacuum cavity, and a proper quantity of heat radiation media is injected into the vacuum cavity. A copper coated ceramic substrate is welded to the vapor chamber heat radiation substrate through solder and formed by sintering copper layers to the upper face and the lower face of an insulation ceramic layer, power devices are welded to the copper layer on the upper face through solder and connected through a wire to form a circuit structure, and the copper layer on the lower face of the copper coated ceramic substrate is welded to the vapor chamber heat radiation substrate through solder. The power module structure has the advantages of being high in heat radiation efficiency, compact in structure, high in reliability and the like.

Owner:SHANGHAI DAOZHI TECH CO LTD

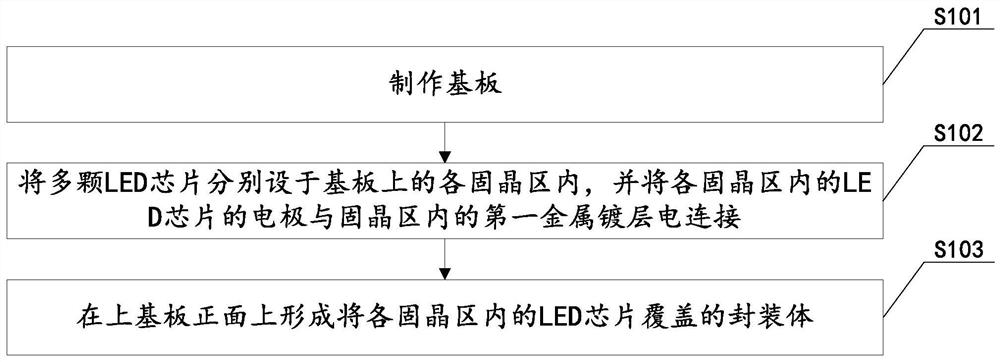

LED encapsulation method

InactiveCN103545423AShorten the cooling pathLight attenuation is smallSemiconductor devicesFluorescenceColor temperature

The invention discloses an LED encapsulation method. The method comprises the following steps: fixing insulation materials onto a radiator to form an insulating layer, and reserving a plurality of through holes in the insulating layer so as to expose the radiator; adopting solid crystal glue to fix an LED wafer onto the exposed radiator on the insulating layer; placing the LED wafer fixed by the solid crystal glue and the radiator into an oven, and baking the LED wafer and the radiator so as to enable the solid crystal glue to be solidified; connecting the positive electrode and the negative electrode of the LED wafer fixed on the radiator through a guide line to form series connection or parallel connection; mixing silica gel and fluorescent powder to obtain fluorescent glue, controlling the color temperature of the fluorescent glue to be 2000K-8000K; pointing the fluorescent glue in the center of the LED wafer, and enabling the fluorescent glue to cover the through holes in the insulating layer; placing the radiator going through glue pointing into the oven for baking, and enabling the fluorescent glue to be solidified. The method simplifies encapsulation processes, is good in heat dissipating effect, and improves the high-pressure resisting performance of an LED encapsulation structure.

Owner:广州荣基能亮节能科技有限公司

Manufacturing method of novel gallium nitride LED (light emitting diode) chip electrode structure

InactiveCN102064249AImprove stabilityImprove cooling efficiencySemiconductor devicesGallium nitrideVacuum coating

The invention relates to a manufacture method of a novel gallium nitride LED (light emitting diode) chip electrode structure. The method comprises the following steps: taking a gallium nitride epitaxial wafer with a sapphire substrate, selectively etching according to the chip architecture to remove a P type layer 1 in the epitaxial layer and expose an N type epitaxial layer 3; forming an ITO (indium tin oxide) diffusion layer in ohmic contact with the P type layer, on the surface of the P type epitaxial layer 1 of the epitaxial wafer, punching a hole in the exposed N type epitaxial layer region; thinning the epitaxial wafer, so that the punched hole becomes a through hole 4 communicating the substrate surface with an N type region; coating a Cr layer on the surface of the epitaxial layer by vaporization through an vacuum coating technology firstly, then coating an Au layer by vaporization, forming a required weld line electrode 2 of the LED by photoetching and etching technologies; depositing an AL metal layer 5 on the surface of the thinned substrate, and forming a reflector of the LED chip; and splitting the epitaxial wafer to form LED chips which can be directly packaged and applied. The manufacture method in the invention is suitable for preparing high-power LED chips of a gallium nitride luminescent material.

Owner:JIANGXI LIANCHUANG OPTOELECTRONIC SCIENCE AND TECHNOLOGY CO LTD

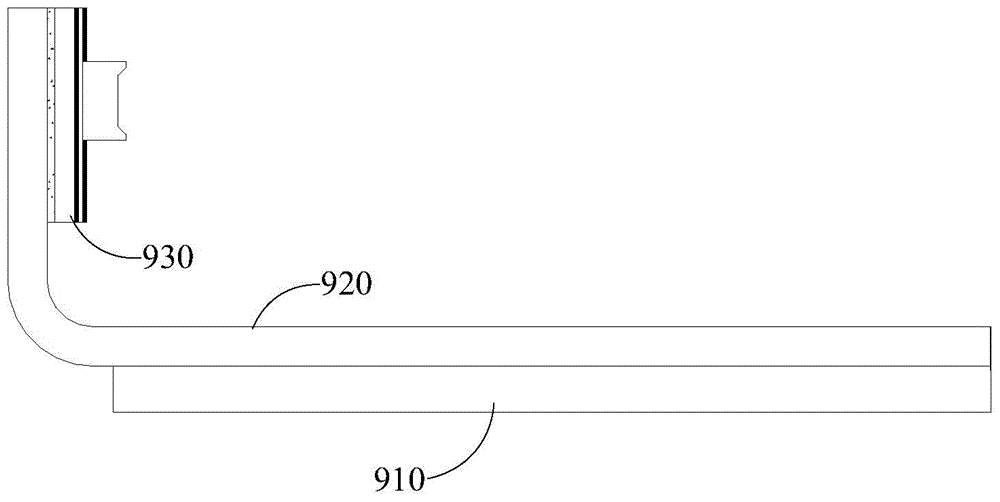

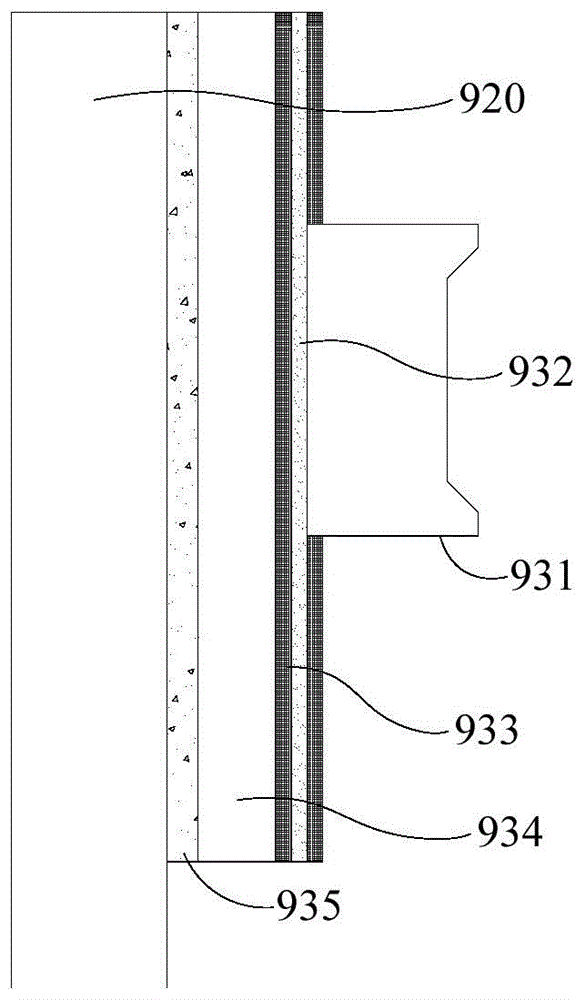

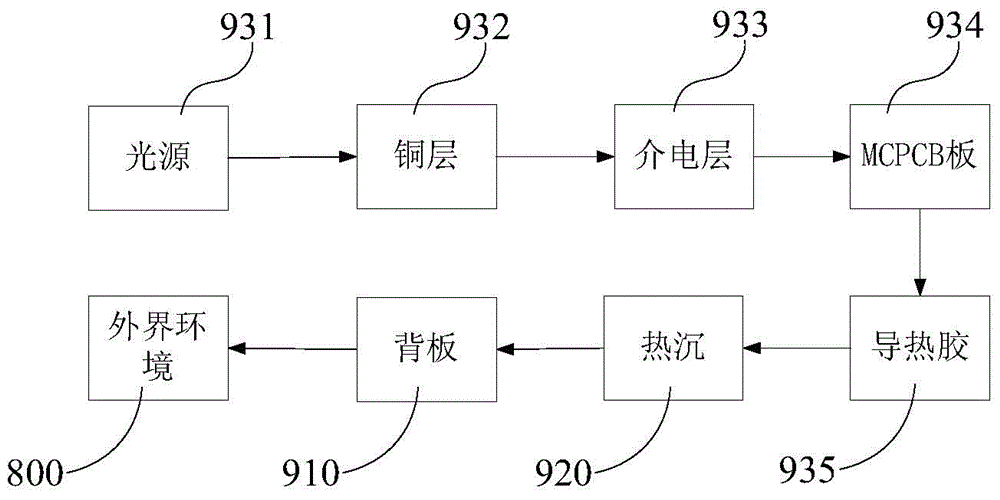

Backlight component and liquid crystal display thereof

ActiveCN104062806AShorten the cooling pathImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsHeat sinkLiquid-crystal display

The invention provides a backlight component and a liquid crystal display thereof. The backlight component comprises a light source, a conductive copper layer, a dielectric layer, a metal base printed circuit board and a heat sink, wherein the dielectric layer is attached to the surface on one side of the metal base printed circuit board, the conductive copper layer is arranged on the dielectric layer, the light source and the heat sink are respectively connected to the conductive copper layer, the light source is subjected to electric conduction through the conductive copper layer and transfers heat to the heat sink through the conductive copper layer, and the heat sink is used for radiating the heat of the backlight component. According to the backlight component provided by the invention, the heat sink is connected to the light source through the conductive copper layer, so that a radiating path of the light source is shortened, the radiating efficiency is improved, and furthermore, by applying the bending type metal base printed circuit board, the heat sink can be directly welded to radiate the heat on the premise of guaranteeing the design requirement of a narrow side of the display.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Light source

InactiveCN104251388AShorten the cooling pathImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention relates to a light source, which comprises a lamp body, a lamp shade, a lamp head, an LED (light emitting diode) and a substrate, wherein the lamp shade is connected with the lamp body, the lamp head is connected with the lamp body, the LED is arranged on the substrate, the light rays of the LED are emitted out of the lamp shade, the interior of the lamp body is provided with a heat radiating cavity for containing the substrate, the part, corresponding to the heat radiating cavity, of the lamp body is provided with heat radiating holes, and the heat radiating holes are used for communicating the heat radiating cavity with outside space. Compared with the prior art, the light source has better heat radiating effect.

Owner:OPPLE LIGHTING

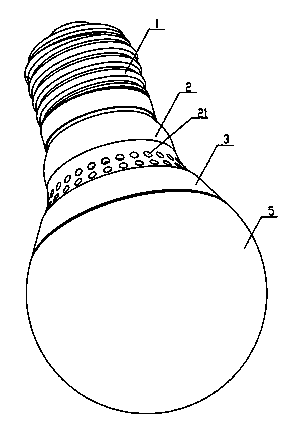

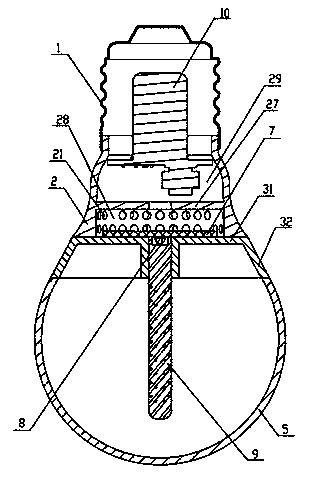

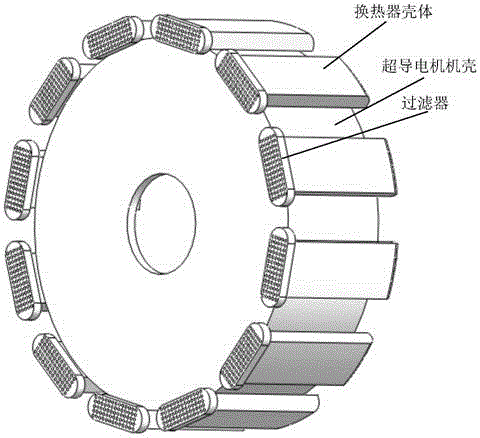

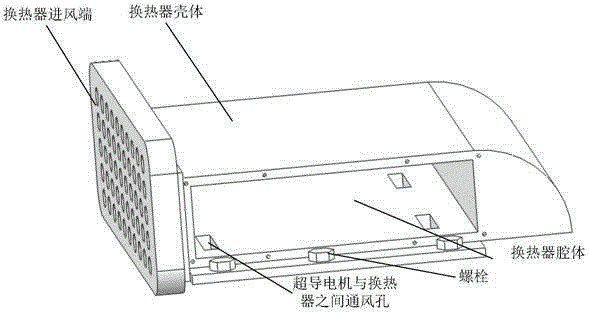

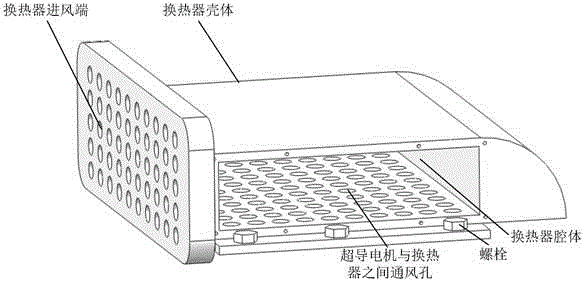

Rotary cooling system of wind driven generator and wind driven generator with same

ActiveCN103956883AShorten the cooling pathImprove efficiencyDynamo-electric machinesSuperconductor elements usageWind drivenEngineering

The invention discloses a rotary cooling system of a superconducting wind driven generator. The system comprises at least one heat exchange unit attached to the outer peripheral wall of an iron core cylinder of an outer rotor of the superconducting wind driven generator. Each heat exchange unit comprises a filter, a cooling fan, a heat exchanger and a heat exchanger shell, wherein the filter is arranged at the end of the heat exchange shell, a plurality of filter holes are evenly distributed in the surface of the filter, the cooling fan is arranged at the rear end of the filter and communicated with an inner cavity of the heat exchanger shell, the heat exchanger shell is axially attached to the outer wall of the iron core cylinder, a plurality of heat dissipation holes are formed in the surface of the heat exchanger shell and can be communicated with through holes formed in the outer wall of the iron core cylinder, heat is exhausted out of an outlet in the other end of the heat exchanger shell, and then convection cooling is achieved. The invention further discloses the wind driven generator with the cooling system. Forced ventilation caused by rotation of superconducting motor blades can be fully utilized, a cooling path inside a superconducting motor is shortened to a certain degree, and efficiency of cooling fans of the superconducting motor and efficiency of the whole superconducting motor are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

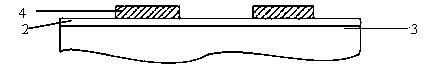

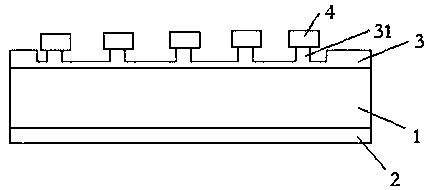

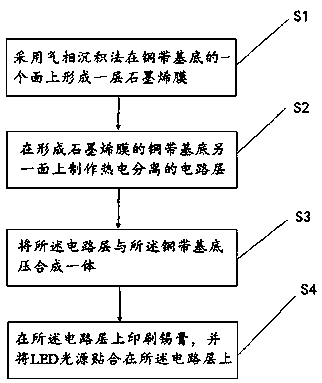

Flexible LED (light-emitting diode) light-emitting structure based on graphene material and manufacturing method thereof

The invention provides a flexible LED (light-emitting diode) light-emitting structure based on graphene material. The flexible LED (light-emitting diode) light-emitting structure based on the graphenematerial is characterized in that the flexible LED light-emitting structure comprises a copper tape substrate, a graphene film arranged on one side of the copper tape substrate, and a circuit layer disposed on the other side of the copper tape substrate; a plurality of LED light sources are attached to the circuit layer; due to the excellent thermal and thermal radiation properties of the graphene film, thermal conductivity becomes easy; the flexible LED light structure of the whole being light and thin can be used directly and achieve a certain degree of free bending with no metal radiatorsneeded to be attached; thus, directly through the heat sink of the LED light sources, all the heat is directly transferred to the copper tape substrate provided with the graphene film, and the graphene film on one side of the copper tape substrate can quickly dissipate the heat generated by the LED light sources. The flexible LED light-emitting structure has the advantage of having good heat dissipation effect. Further provided is a manufacturing method of the flexible LED light-emitting structure based on the graphene material.

Owner:SHENZHEN GUANGMAO ELECTRONICS

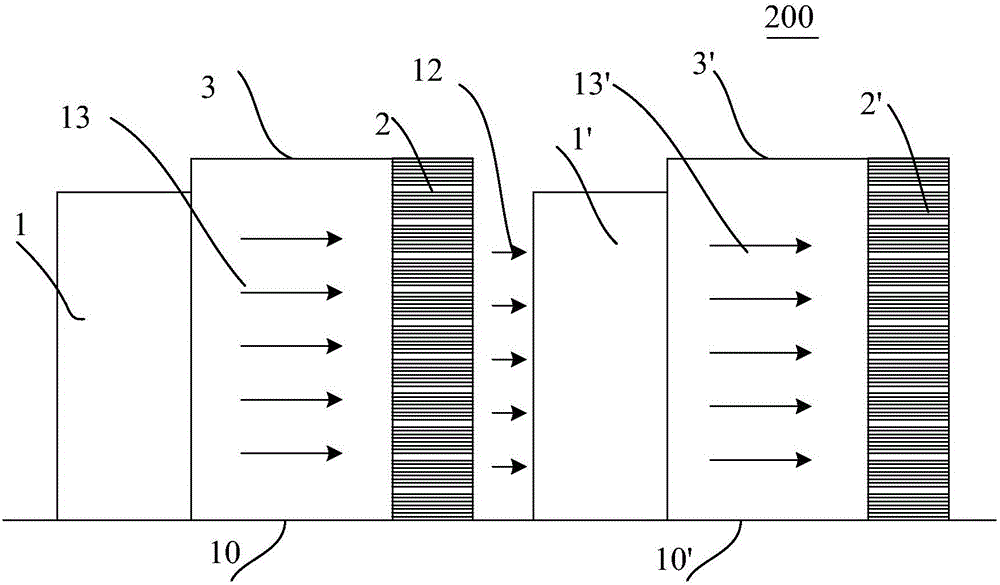

Combined modular backlight unit for flat panel display and helmet

InactiveCN102011969AAchieve serializationShorten the cooling pathPoint-like light sourceLighting heating/cooling arrangementsDisplay deviceEngineering

The present invention discloses a combined modular backlight unit for a flat panel display and a helmet. The present invention aims to provide a combined modular backlight unit for a flat panel display and a helmet. The present invention is characterized in that: it comprises LED chips packaged by ceramic, a heat spreader and cooling fins, a LED module packaged by resin is equipped on the heat spreader and cooling fins are equipped below the heat spreader, and the LED module packaged by resin is consists of at least one piece of LED chip packaged by ceramic. The present invention is mainly applicable to the display device.

Owner:江苏捷诚车载电子信息工程有限公司

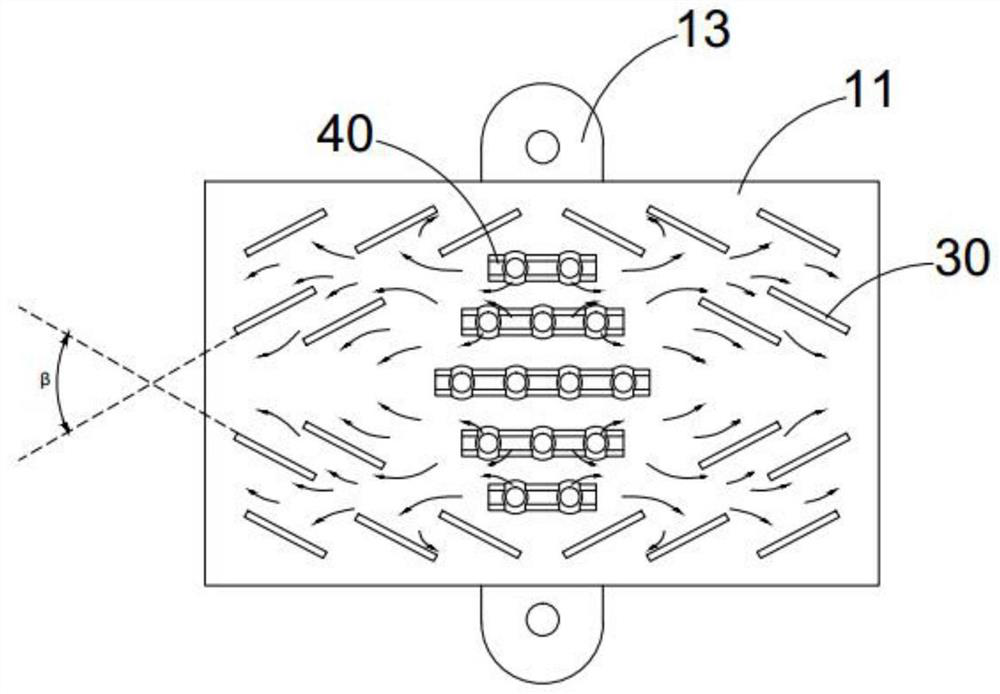

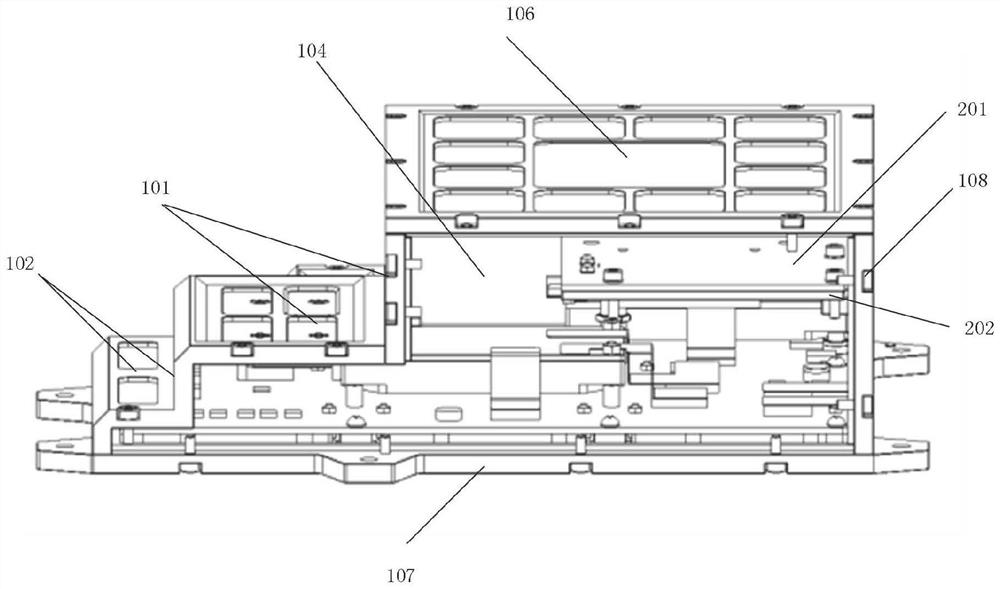

Intelligent motor controller

ActiveCN111696933AImprove reliabilityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsElectric machinery

The invention discloses an intelligent motor controller, and belongs to the technical field of motor control. The intelligent motor controller comprises a control panel, wherein heat dissipation pieces are arranged at the upper end and the lower end of the control panel, each heat dissipation piece comprises a heat dissipation shell, and the control panel is arranged in the heat dissipation shell;the heat dissipation shell is provided with a heat dissipation surface, heat dissipation strips are arranged in the middle of the heat dissipation surface; the heat dissipation strip in the middle ofthe heat dissipation surface are horizontally arranged at intervals, the lengths of the heat dissipation strips decrease progressively, the heat dissipation surface is provided with heat dissipationfins perpendicular to the heat dissipation surface, the heat dissipation fins are symmetrically arranged on the sides of the heat dissipation strips and are obliquely arranged relative to the heat dissipation strips, the heat dissipation fins are used for guiding airflow on the two sides of the heat dissipation surface to the heat dissipation strips in the middle of the heat dissipation surface, and the height of the heat dissipation fins is greater than that of the heat dissipation strips. According to the invention, the motor controller has the advantages of fast heat leading-out speed, highheat conduction efficiency, high heat dissipation efficiency, balanced heat dissipation and strong external interference resistance, and effectively prevents dust from entering the controller and electromagnetic noise pollution.

Owner:江门市力丰电机有限公司

LED automobile lamp, manufacturing method of LED automobile lamp and automobile headlamp assembly

InactiveCN104197262AShorten the cooling pathReduce volumeVehicle headlampsPoint-like light sourceEngineeringHeadlamp

The invention provides an LED automobile lamp, a manufacturing method of the LED automobile lamp and an automobile headlamp assembly. The LED automobile lamp comprises a lamp body center post, a radiator, LED chips and a strip-shaped circuit board. An installing hole is formed in the radiator, the lower section of the lamp body center post is fixed into the installing hole, and the circuit board is embedded into the side wall of the lamp body center post in the extension direction of the lamp body center post and comprises a body part and a welding part connected with the body part. The LED chips are directly packaged on the side wall of the upper section of the lamp body center post and electrically connected with the welding part. According to the LED automobile lamp and the manufacturing method of the LED automobile lamp, the heat radiation path can be effectively shortened, the heat radiation effect is effectively improved, and due to the fact that the heat radiation performance is improved, the LED chips can be more compactly installed, the overall size of the LED automobile lamp can be reduced, the effect of luminous points can be formed, the requirements for lighting patterns of automobile lighting standards are met, and application and popularization of the LED automobile lamp are improved.

Owner:杨道达

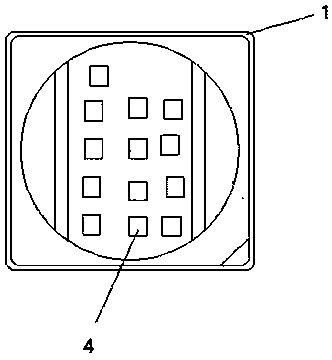

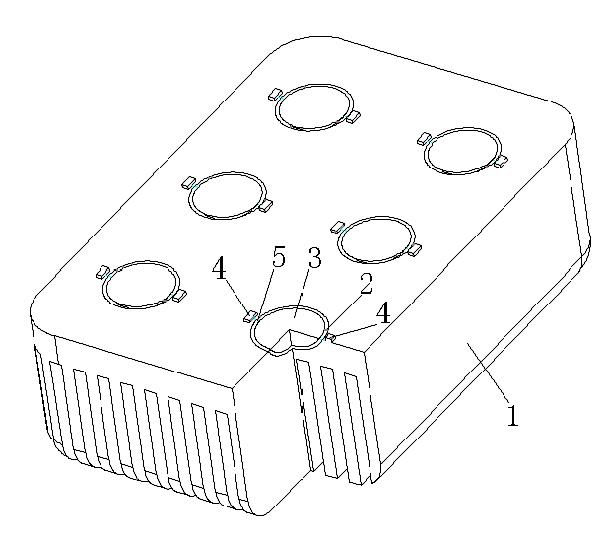

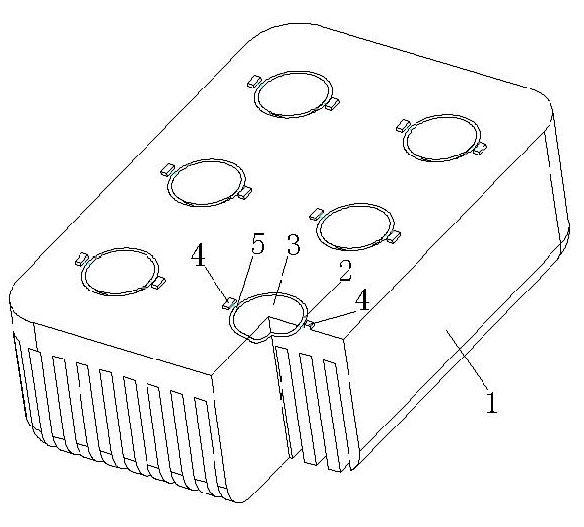

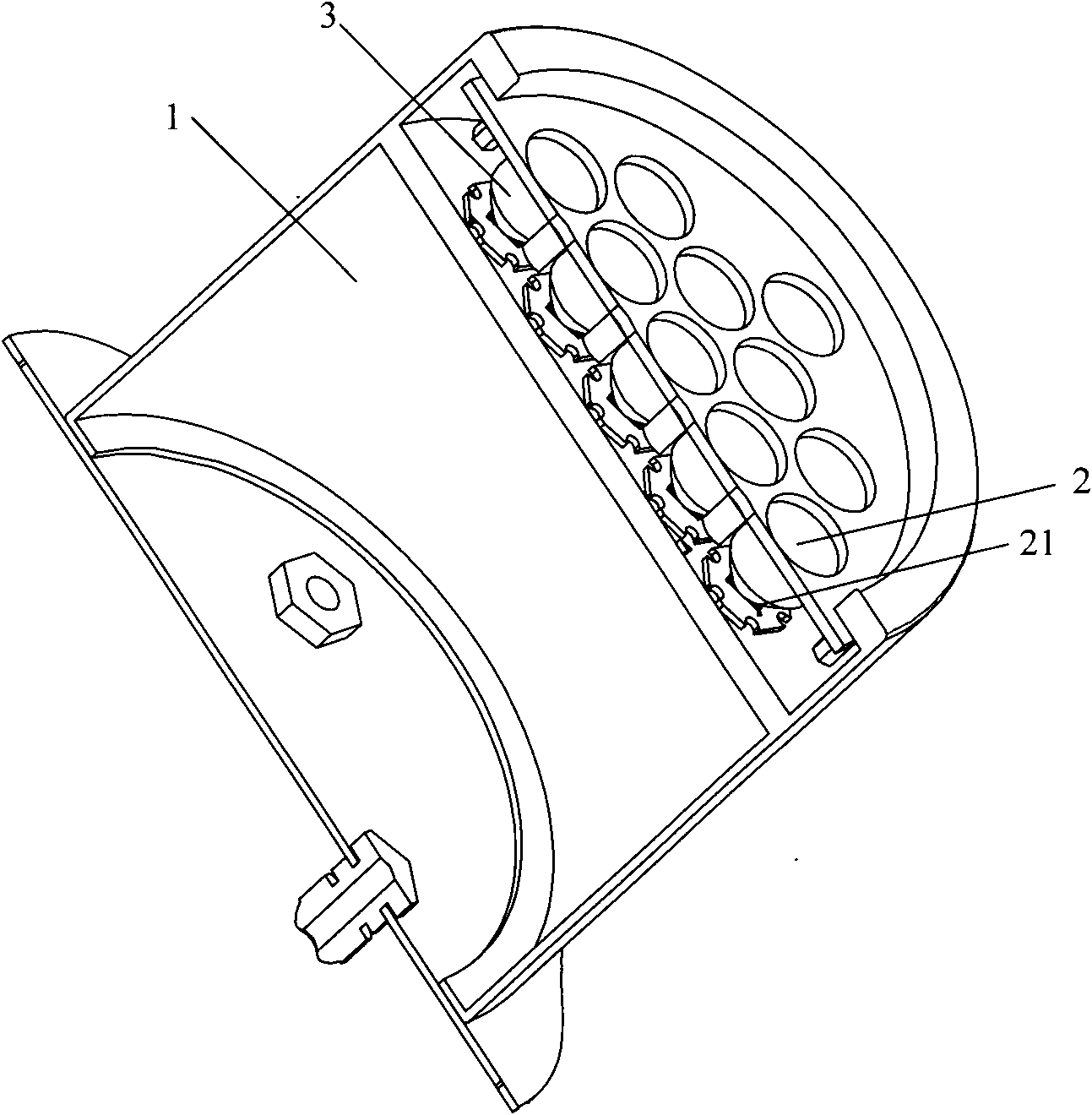

LED (light emitting diode) illumination device with high lighting effect and high color rendering properties

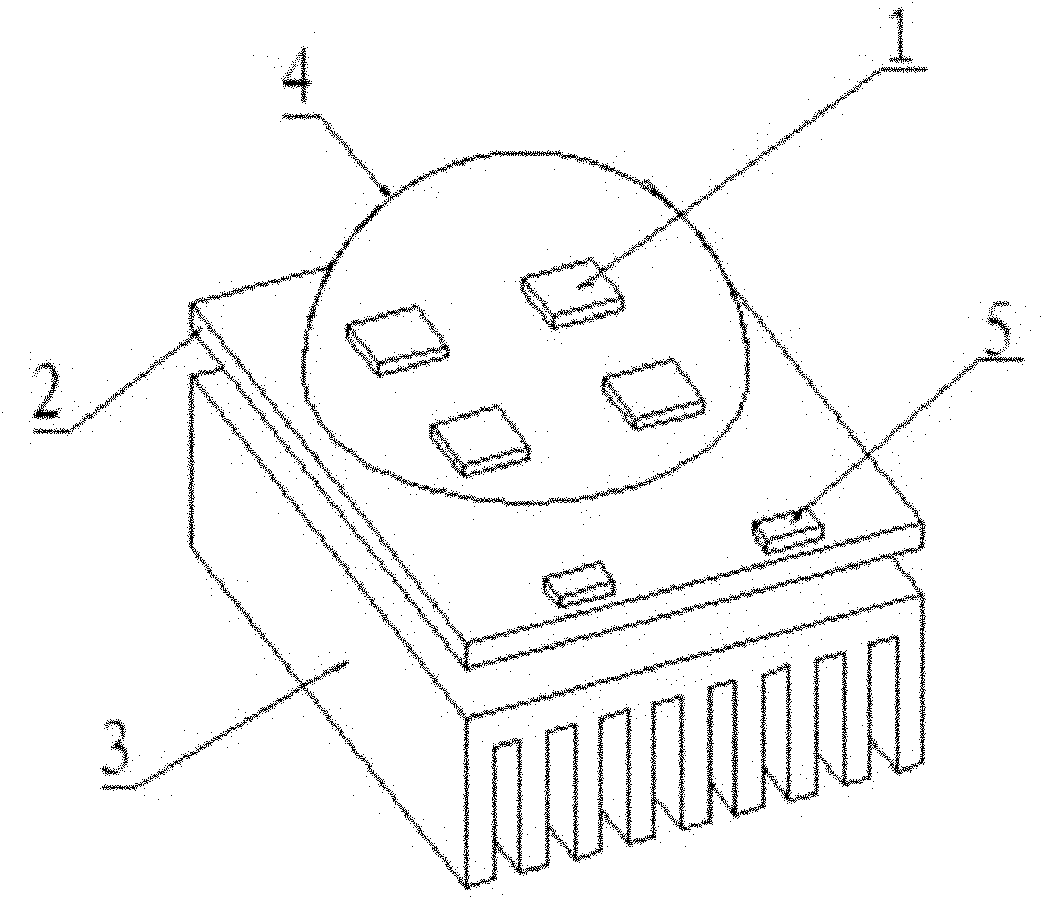

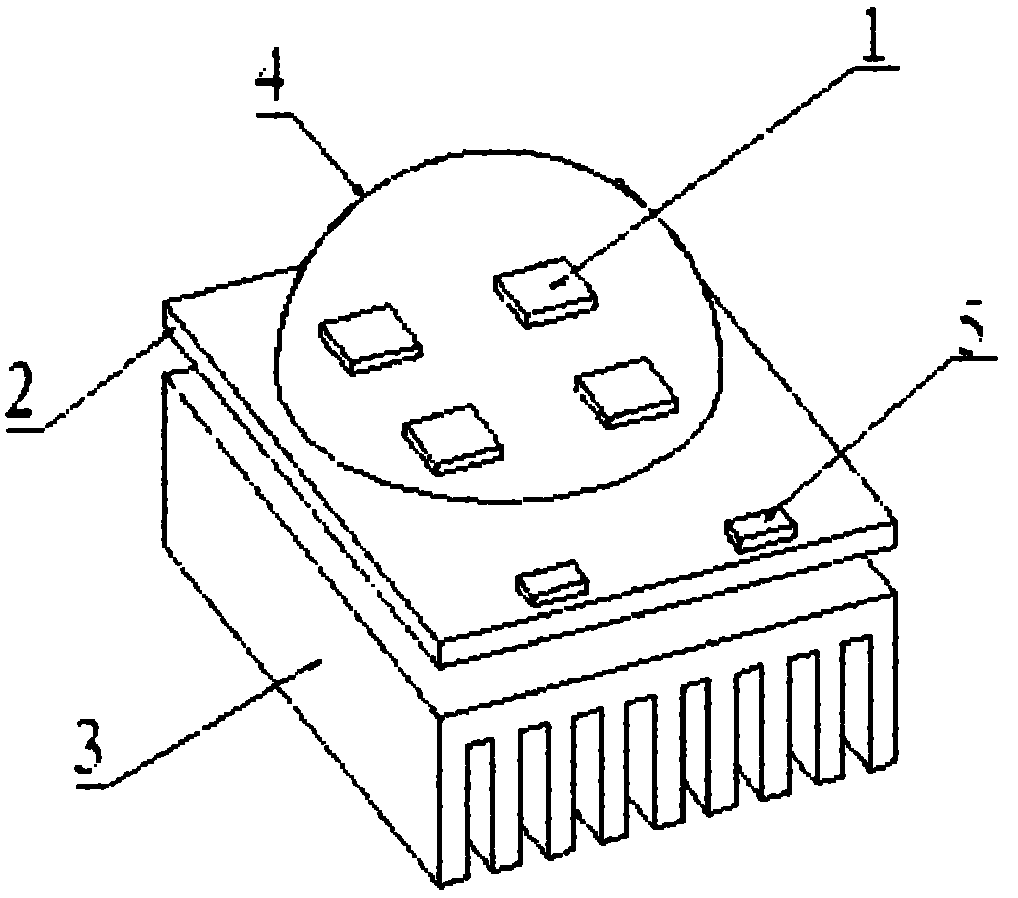

InactiveCN102121613AHigh light efficiencyHigh color rendering indexPoint-like light sourceElectric circuit arrangementsElectricityEffect light

The invention discloses an LED (light emitting diode) illumination device with a high lighting effect and high color rendering properties. The device comprises a metal radiating piece (1) and a plurality of LED chips (3) of RGB (red, green and blue) three primary colors, wherein the frontage of the metal radiating piece (1) is provided with a circuit layer and a plurality of grooves (2); the LED chips (3) of RGB three primary colors are packaged in the grooves (2); two sides of each groove (2) of the metal radiating piece (1) are provided with LED chip welding points (4) which are electrically connected with the circuit layer; and the LED chip welding points (4) are electrically connected with two electrodes of each LED chip (3) of RGB three primary colors through lead wires (5). According to the invention, the LED chips of RGB three primary colors are packaged in the metal radiating piece, a solidification body of the LED and the metal radiating piece is formed, the radiating steps are reduced, and the lighting effect and color rendering properties of the LED lamp are improved.

Owner:东莞市远大光电科技有限公司

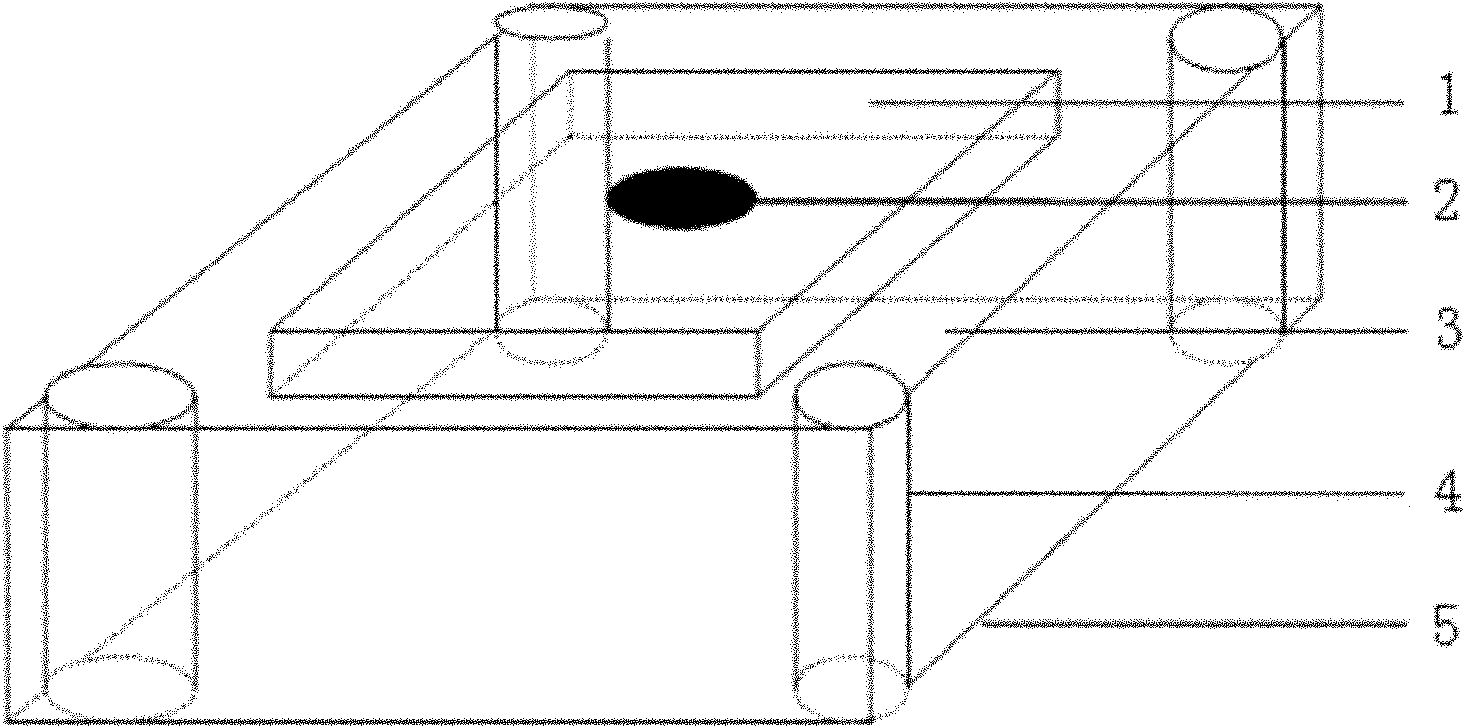

Tiny gas sensor of laminated structure and preparation method of micro-gas sensor

ActiveCN103482562AImprove performanceReduce heating power consumptionTelevision system detailsImpedence networksCMOSPower flow

The invention relates to a micro-gas sensor of a laminated structure and a preparation method of the micro-gas sensor, and belongs to gas sensors and preparation method thereof. The gas sensor comprises a single-chip gas micro-reactor and a single-chip temperature detector, and the single-chip gas micro-reactor and the single-chip temperature detector are processed by MEMS (micro electro mechanical systems) technology and form the micro-gas sensor of the integral laminated structure through bonding. The single-chip gas micro-reactor independently heats a catalyst carrier, the single-chip temperature detector independently detects temperature rise of the single-chip gas micro-reactor due to gas catalytic combustion reaction and is not influenced by voltage or current on the single-chip gas micro-reactor during measuring, and the single-chip gas micro-reactor and the single-chip temperature detector are not electrically connected and independent to each other. The preparing process of the micro-gas sensor is compatible with CMOS (complementary metal oxide semiconductors) process. The sensor can respectively and independently regulate the single-chip gas micro-reactor and the single-chip temperature detector, and therefore, the sensor can have various operating modes, is simple in configuration, easy to operate, low in power consumption, high in sensitivity and stable in performance.

Owner:CHINA UNIV OF MINING & TECH

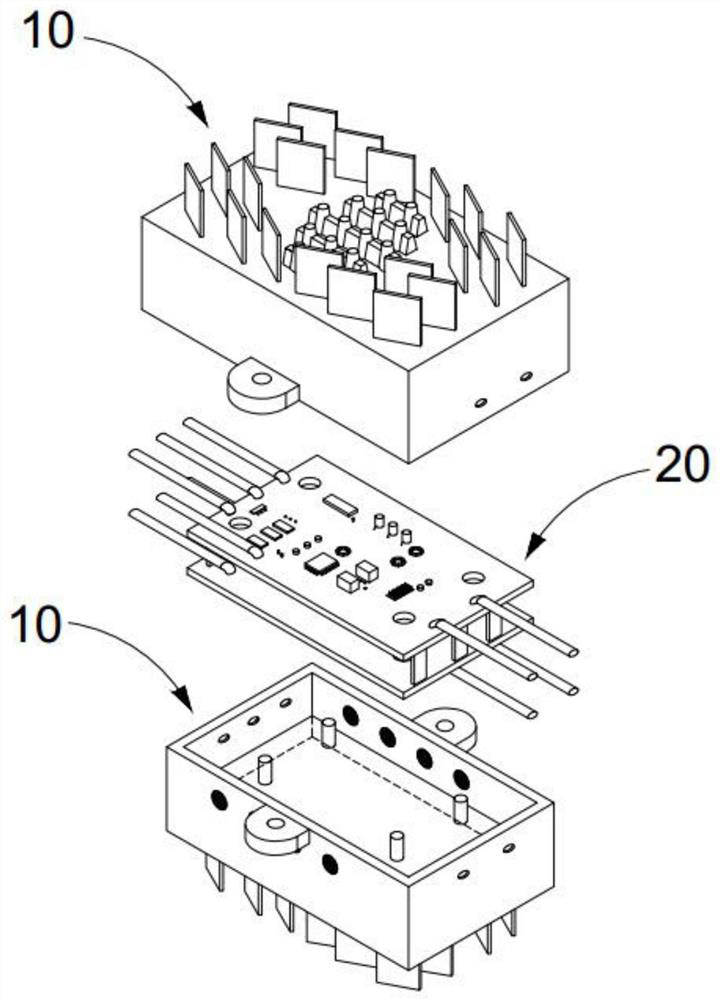

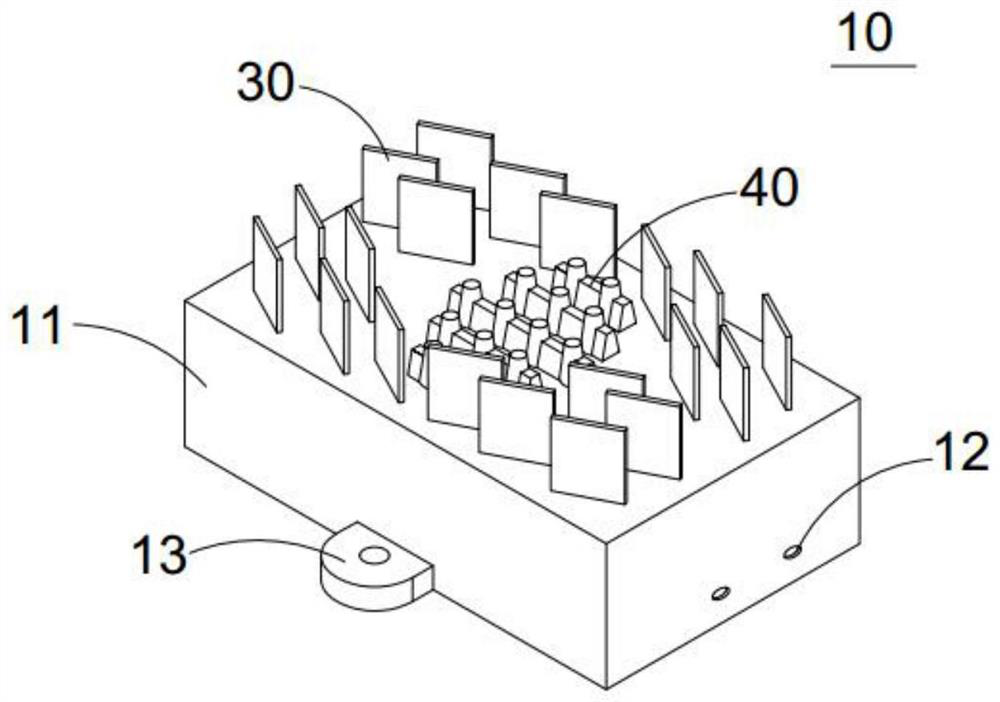

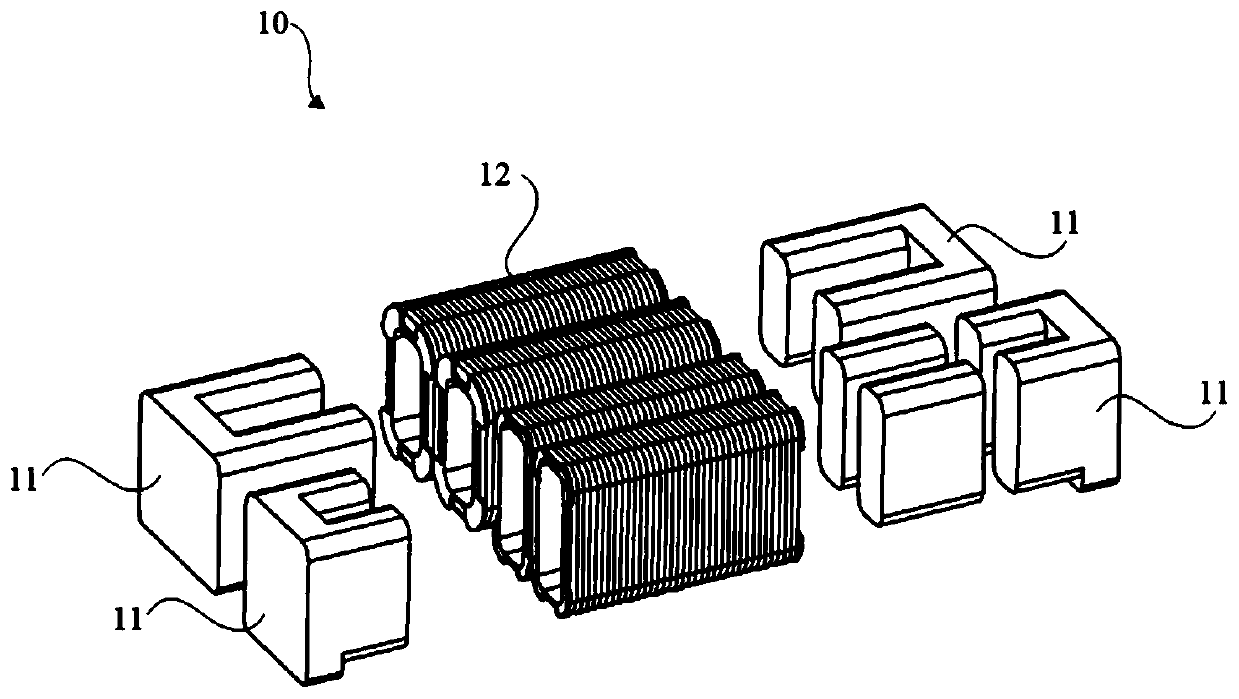

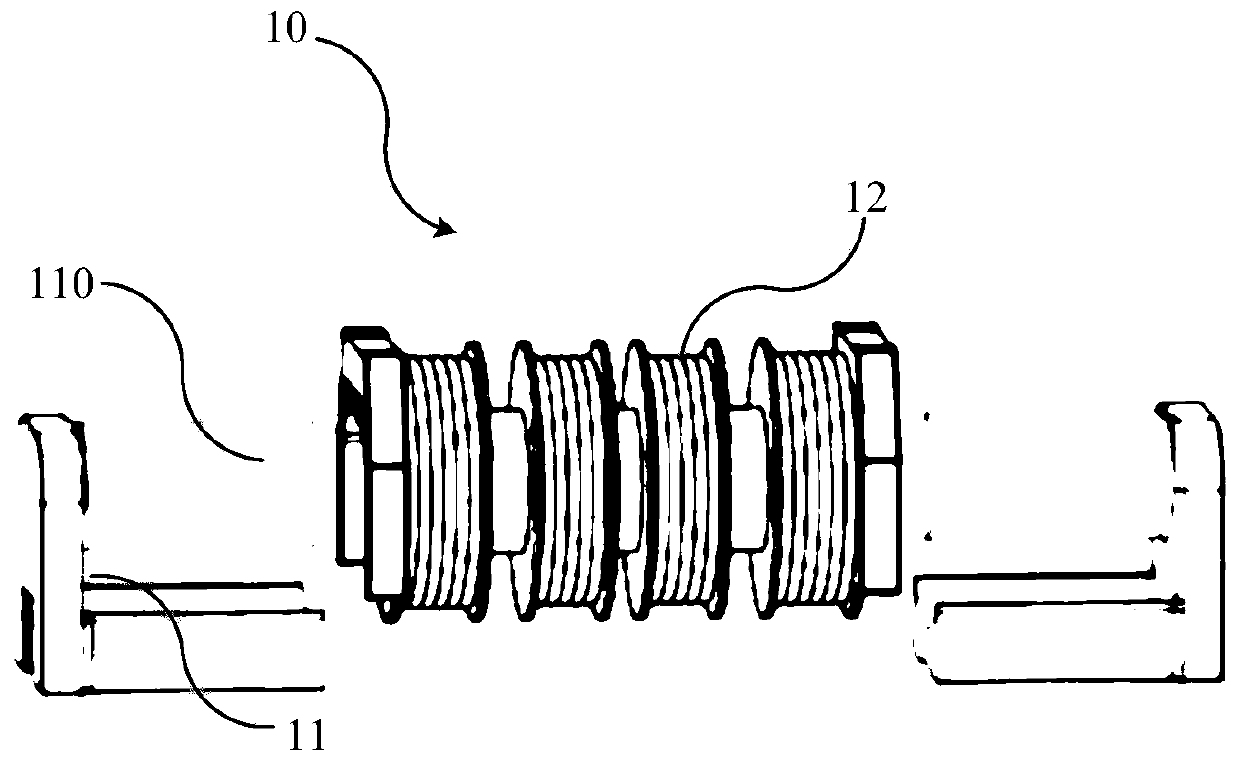

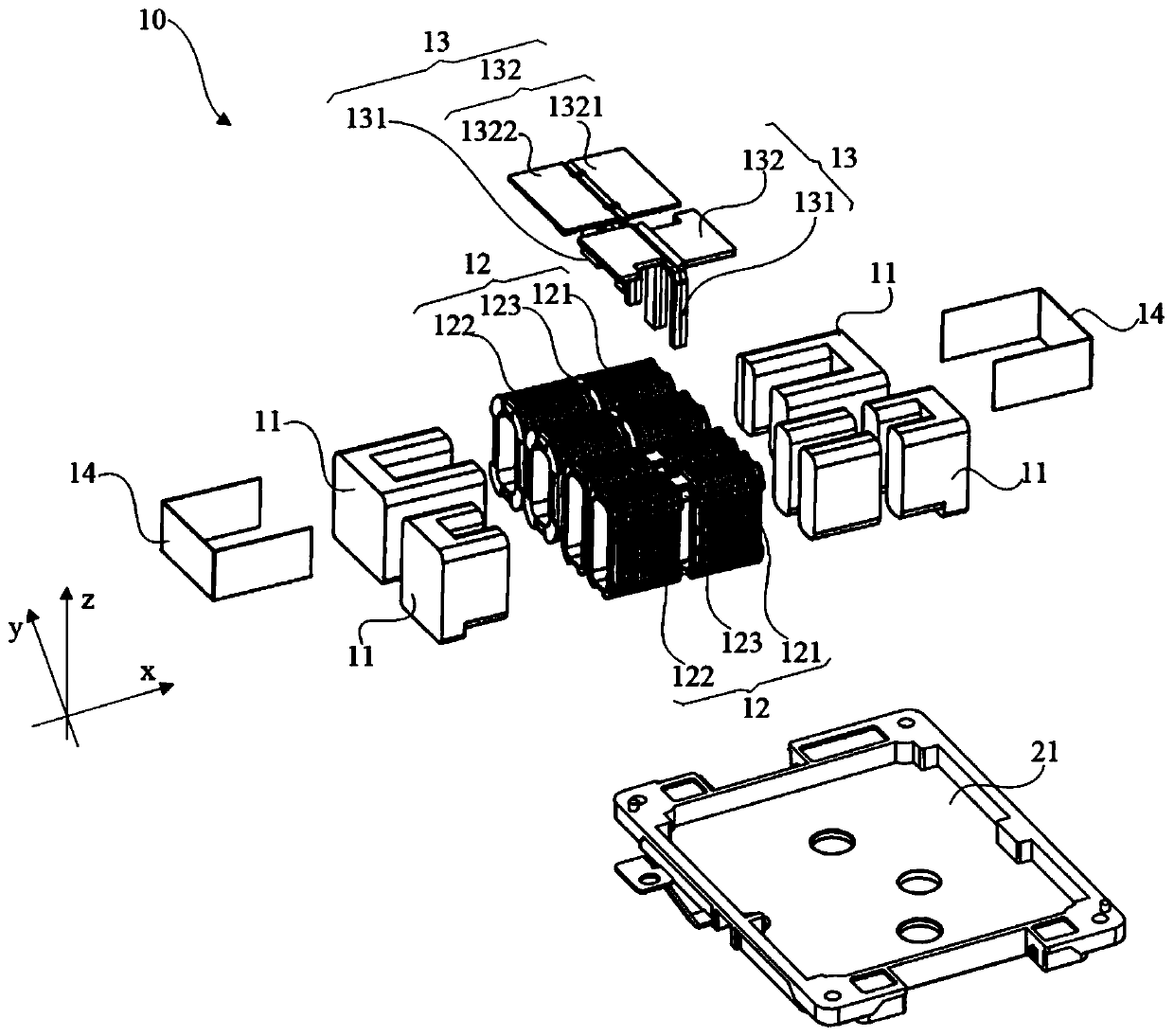

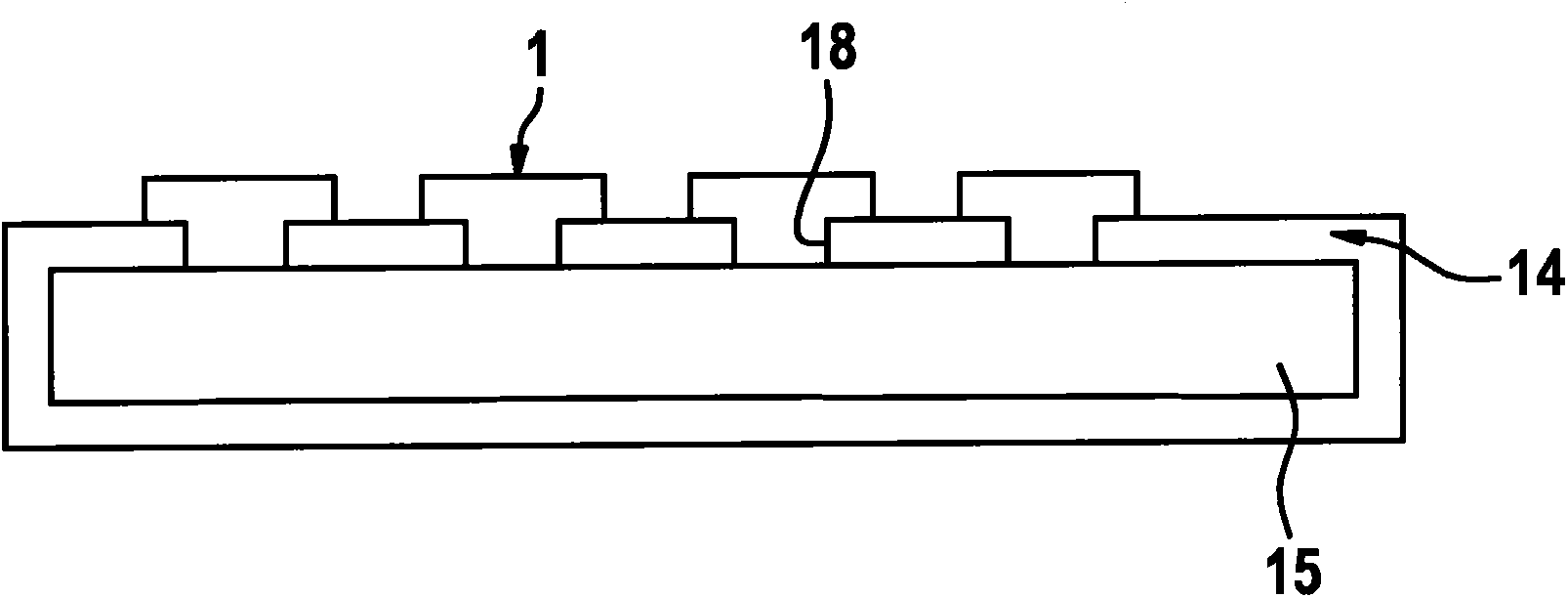

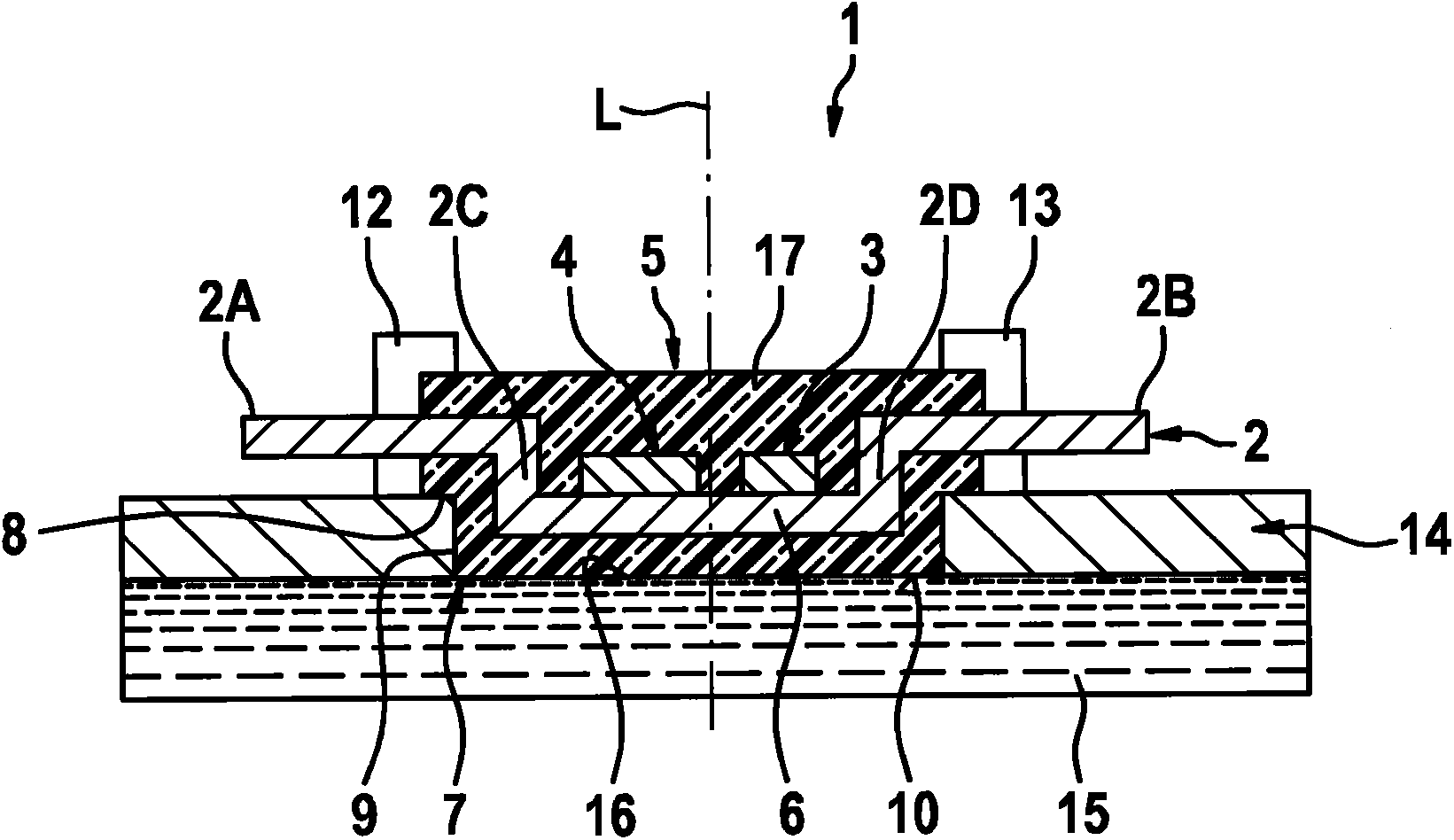

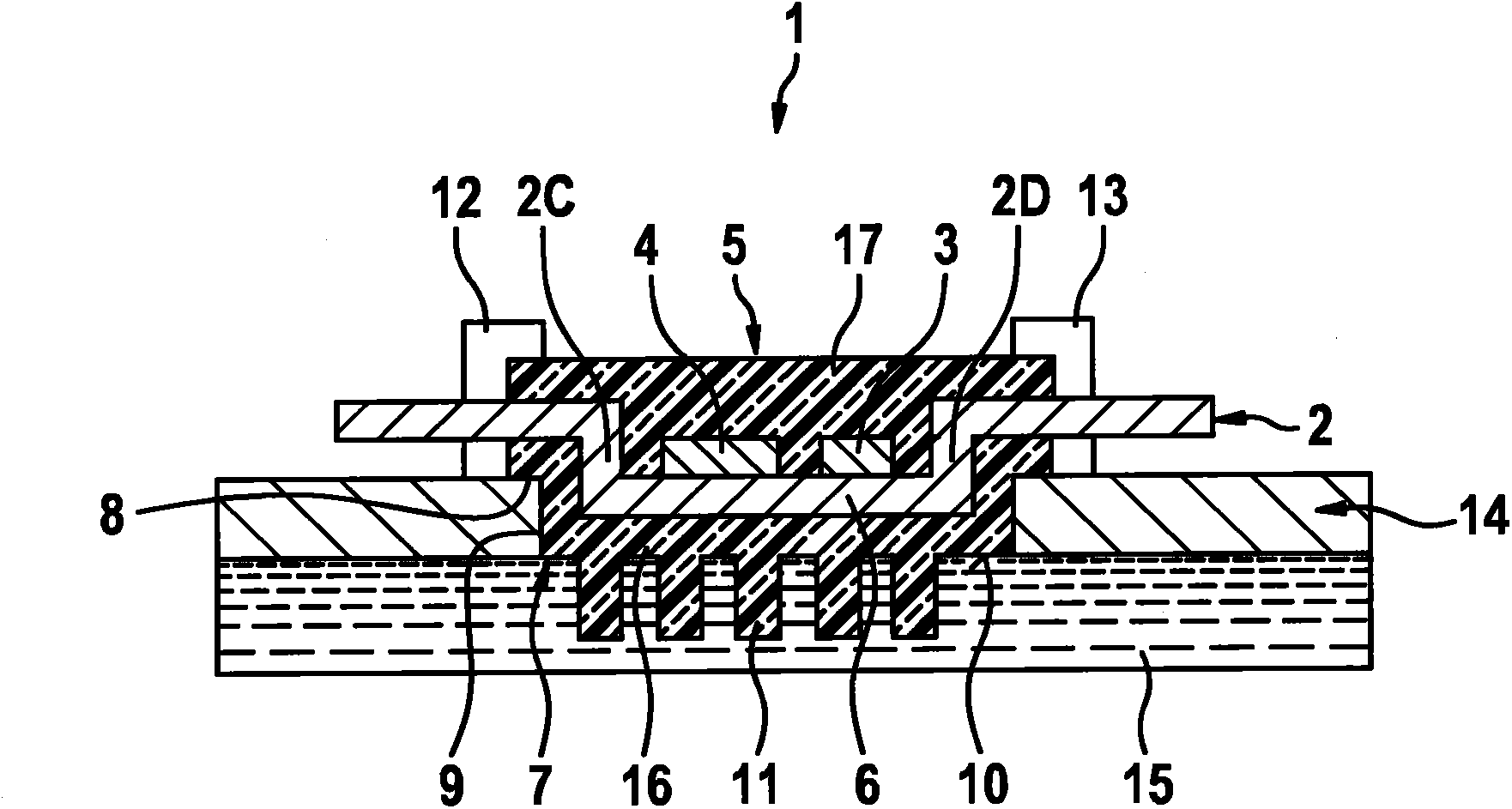

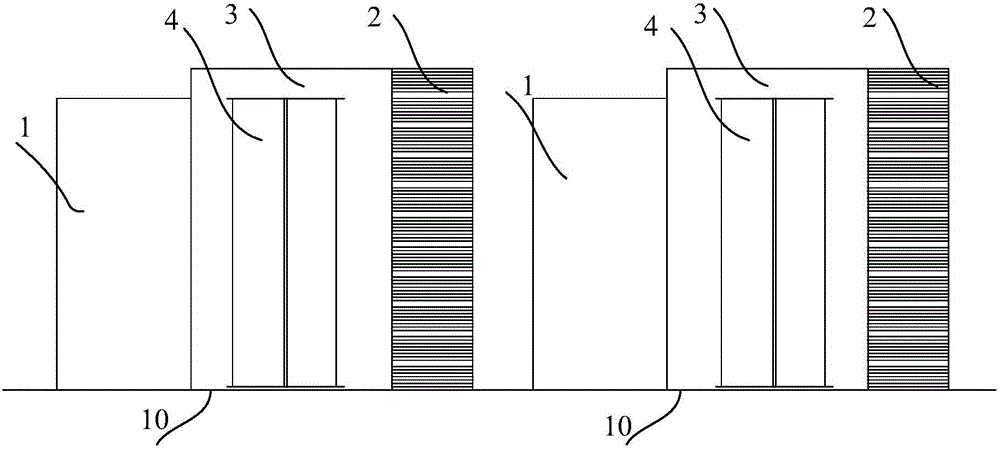

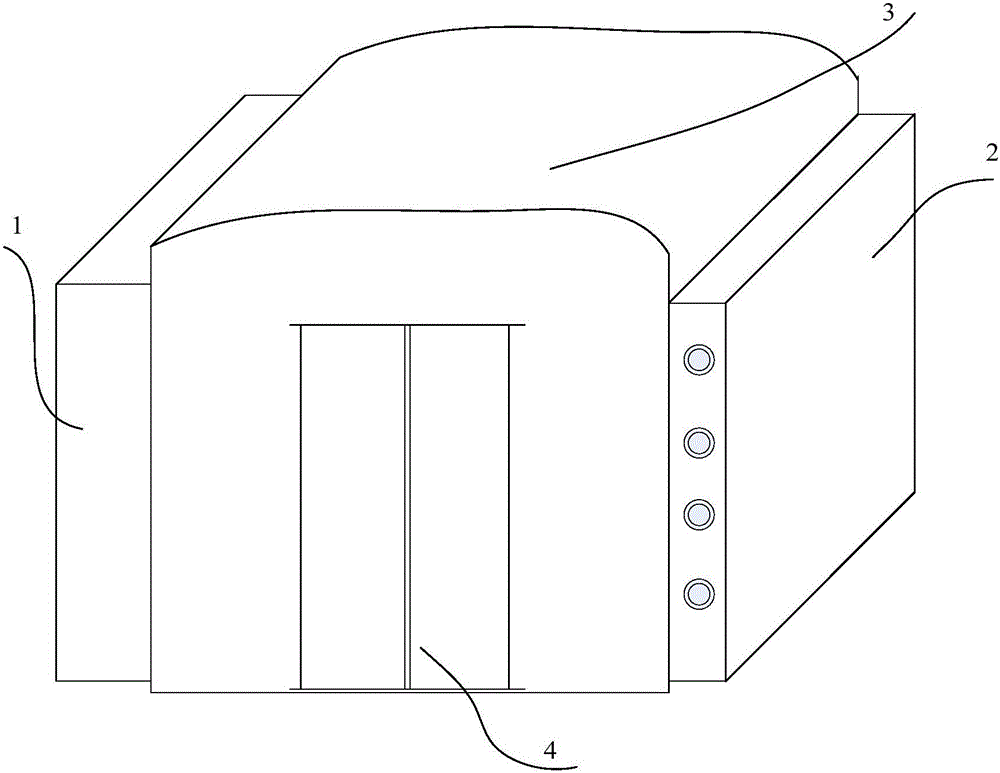

Magnetic assembly and power supply module

PendingCN111354543AImprove cooling effectShorten the cooling pathTransformers/inductances coolingCharging stationsEngineeringThermal contact

The invention provides a magnetic assembly and a power supply module and relates to the technical field of power electronics. The magnetic assembly comprises a first heat dissipation structure, a magnetic core extending in the transverse direction and a winding structure arranged on the magnetic core in a winding mode. The winding structure at least comprises a first winding package and a second winding package which are adjacently arranged in the transverse direction. A gap is formed between the first winding package and the second winding package; at least a part of the first heat dissipation structure is arranged in the gap; the first heat dissipation structure is in thermal contact with the first winding package, the second winding package and the magnetic core such that the first heatdissipation structure can help the magnetic core, the first winding package and the second winding package dissipate heat in the vertical direction and the longitudinal direction at the same time, the heat dissipation path is shortened, the thermal resistance is reduced, and the heat dissipation effect of the magnetic assembly is improved.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

Electronic module and method for the production thereof

ActiveCN103460362ALow costEasy to assembleSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

The invention relates to an electronic module (1) comprising a carrier plate (2), at least one electronic component (3, 4), which is arranged on the carrier plate (2), and a molded housing (5), which encases the carrier plate (2) and the at least one electronic component (3, 4), wherein the carrier plate (2) has a central region (6).

Owner:ROBERT BOSCH GMBH

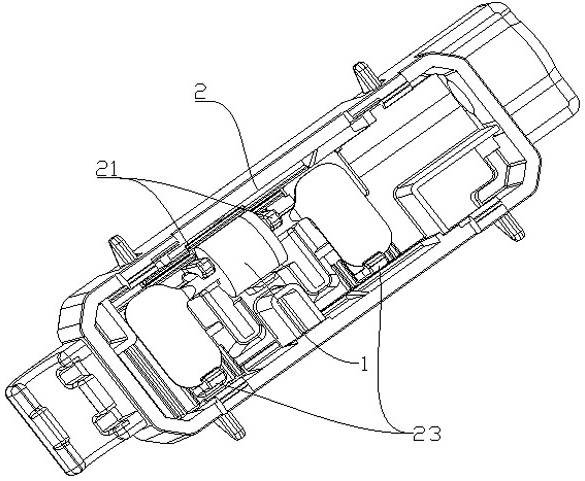

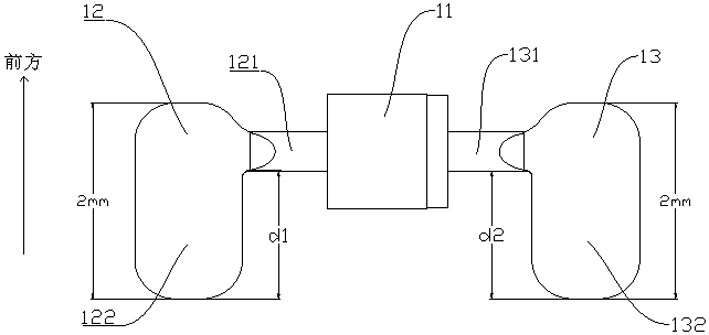

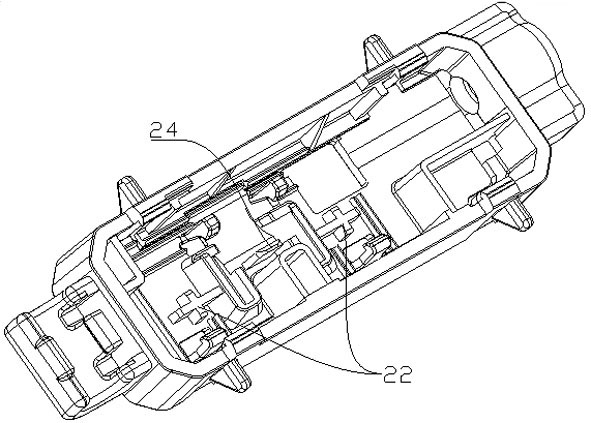

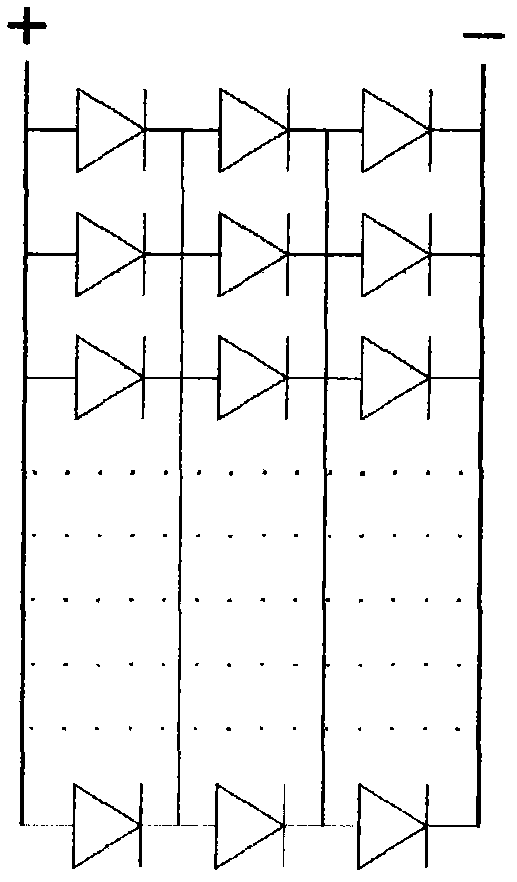

Axial diode junction box and manufacturing method thereof

ActiveCN113328698BIncrease cooling areaShorten the cooling pathElectrically conductive connectionsPhotovoltaicsProduction lineEngineering

The invention discloses an axial diode junction box and a manufacturing method thereof, comprising an axial diode and a junction box body, wherein the axial diode is installed inside the junction box body; the axial diode includes a diode body, a first pin and a second pin Two pins, one end of the diode body is connected to the first pin, and the other end of the diode body is connected to the second pin; the direction where the diode body is close to the junction box body is defined as the front, and the first pin includes the first connecting part and The first flat part, one end of the first connecting part is connected to one end of the diode body, the other end of the first connecting part is connected to the first flat part, the second pin includes the second connecting part and the second flat part, and the second connecting part One end of the second connecting portion is connected to the other end of the diode body, and the other end of the second connecting portion is connected to the second flat portion; the diode body is clamped with the junction box body. The invention simplifies the production process, reduces the product cost, improves the product reliability and improves the production efficiency of the production line.

Owner:ZERUN CO LTD

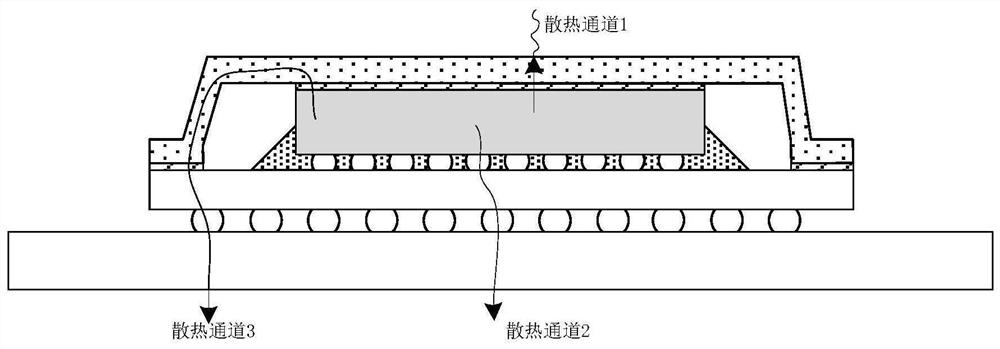

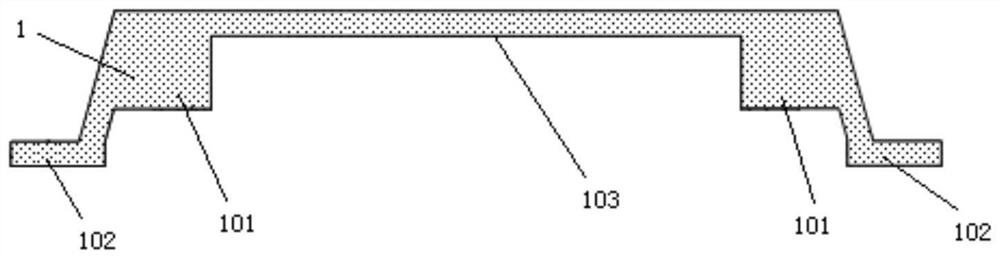

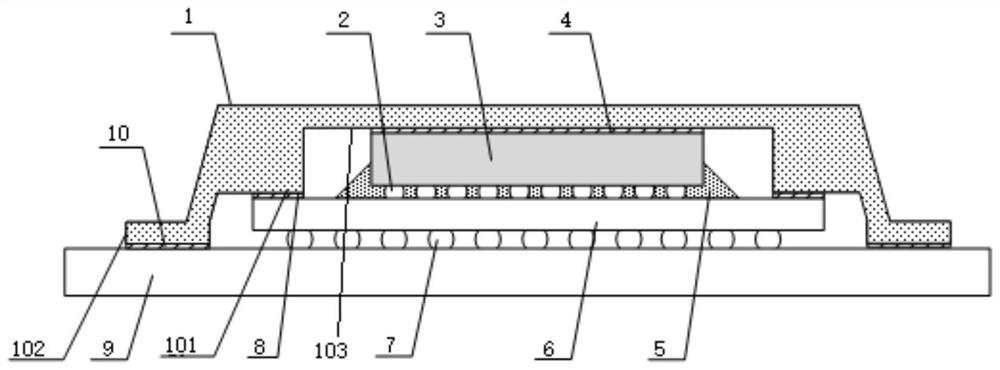

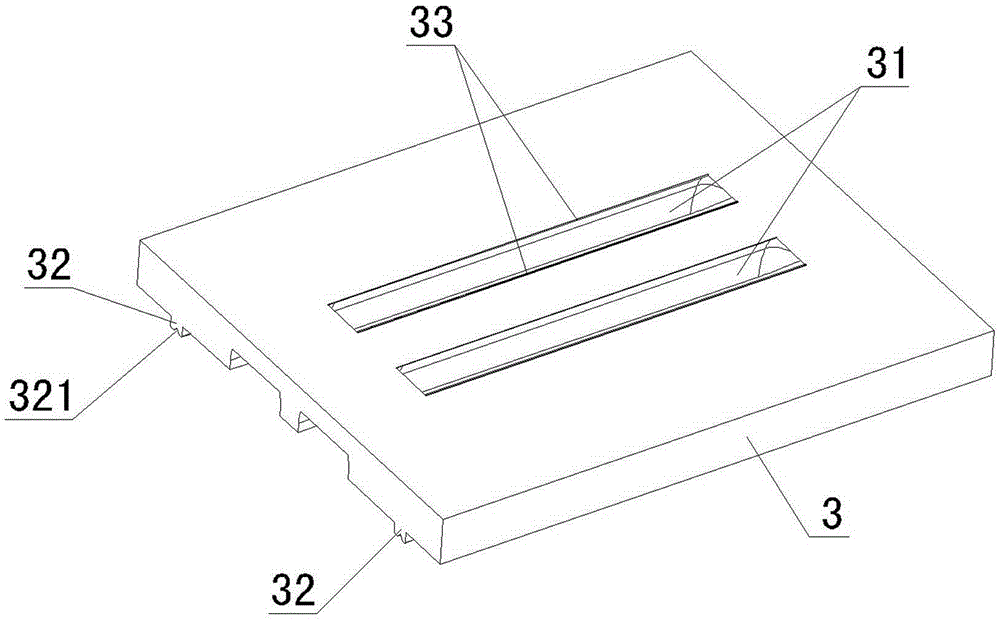

Heat dissipation cover plate and chip

PendingCN113629028AImprove cooling effectReduce the maximum junction temperatureSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsJunction temperature

The invention provides a heat dissipation cover plate and a chip, and belongs to the technical field of integrated circuit packaging. The chip comprises a chip body, a PCB and a heat dissipation cover plate arranged on the PCB. The heat dissipation cover plate comprises a cover plate body, the cover plate body is provided with a groove, and the groove and the PCB form an accommodating groove. The chip body is arranged in the accommodating groove and is in contact with the cover plate body. The cover plate body is in contact with the PCB to form a second heat dissipation surface, and the second heat dissipation surface is used for transmitting heat generated by the chip body to the PCB. According to the chip, the heat dissipation path of the chip is changed, the heat dissipation effect is improved, and the maximum junction temperature of the chip is reduced.

Owner:XI AN UNIIC SEMICON CO LTD

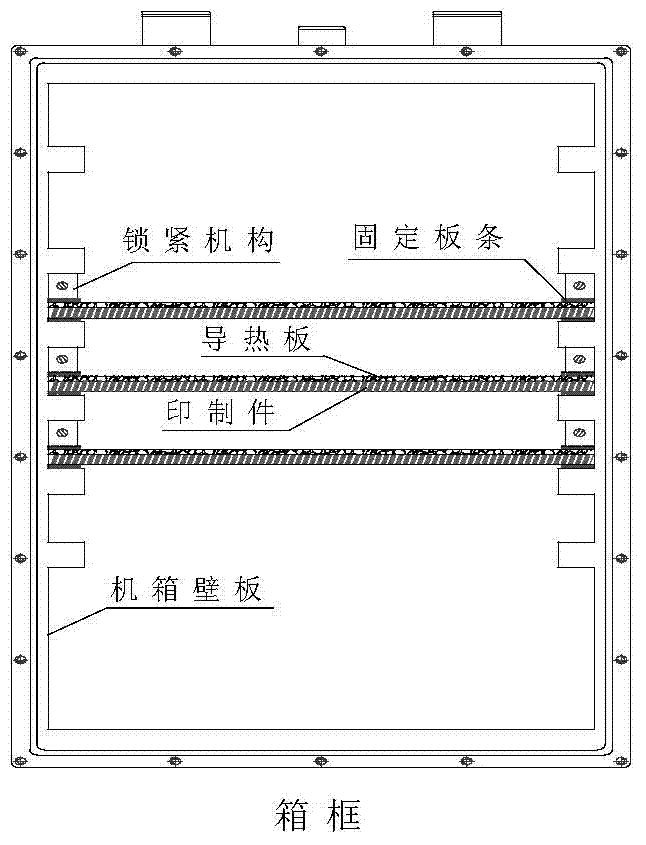

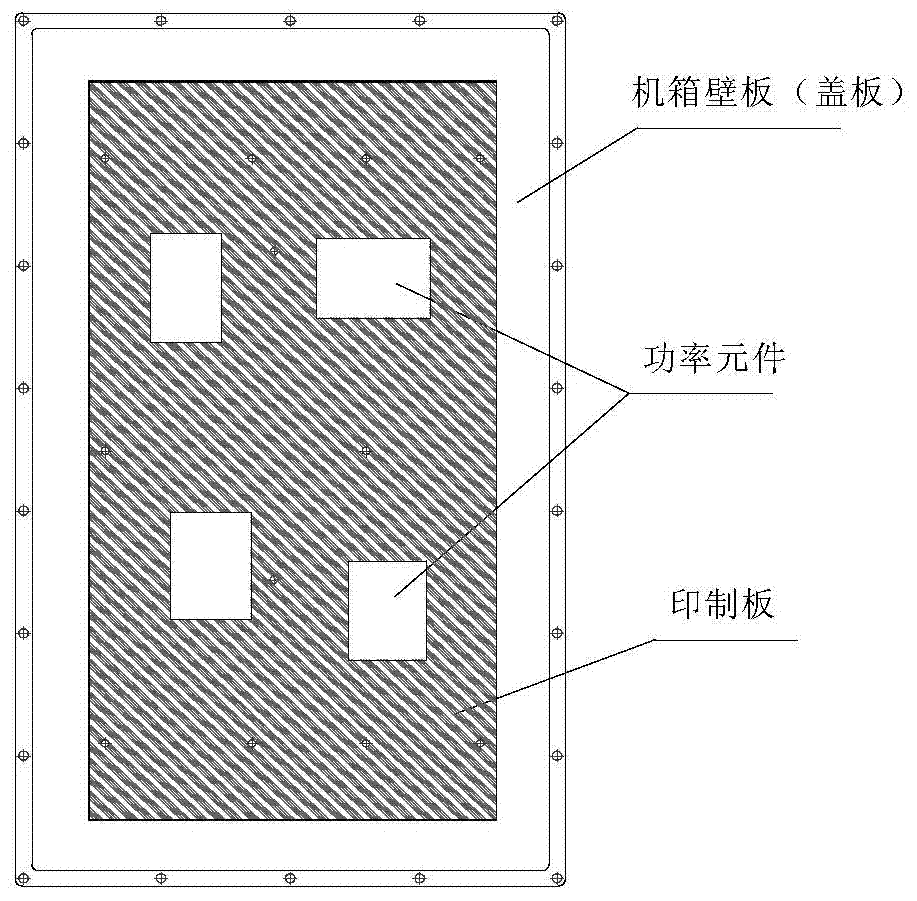

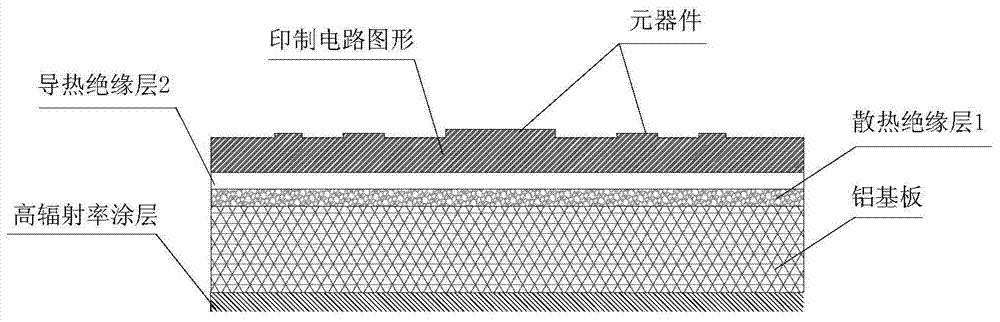

Preparation method of embedded printed structural parts

ActiveCN103702545AAvoid high temperature effectsDistribute quicklyCooling/ventilation/heating modificationsEngineeringCopper foil

The invention discloses a preparation method of embedded printed structural parts. The method comprises the following steps: taking one surface of a case cover plate as a reference surface, confirming frames of a fixing position and a circuit pattern on the reference surface according to a circuit pattern negative plate, leveling the reference surface, then performing insulating treatment on the surface of the case cover plate, forming a heat dissipation insulating layer on the surface of the case cover plate, coating a heat conduction insulating layer on the heat dissipation insulating layer of the reference surface, loading copper foils on the heat conduction insulating layer, manufacturing a circuit pattern on surfaces of the copper foils, then coating a protection layer on the circuit pattern on the surfaces, performing shape processing on the case cover plate, performing surface protection treatment on an exposed surface of the case cover plate, and coating thermal control material on the exposed surface. Heat emitted by the high-power elements connected with a printed circuit is directly conducted to the case cover plate, and then is radiated to external environment through the case cover plate, heat is rapidly emitted to external space, other devices in a case are prevented from being affected by high temperature, and the method provides guarantee for the stable and reliable operation of a complete machine.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

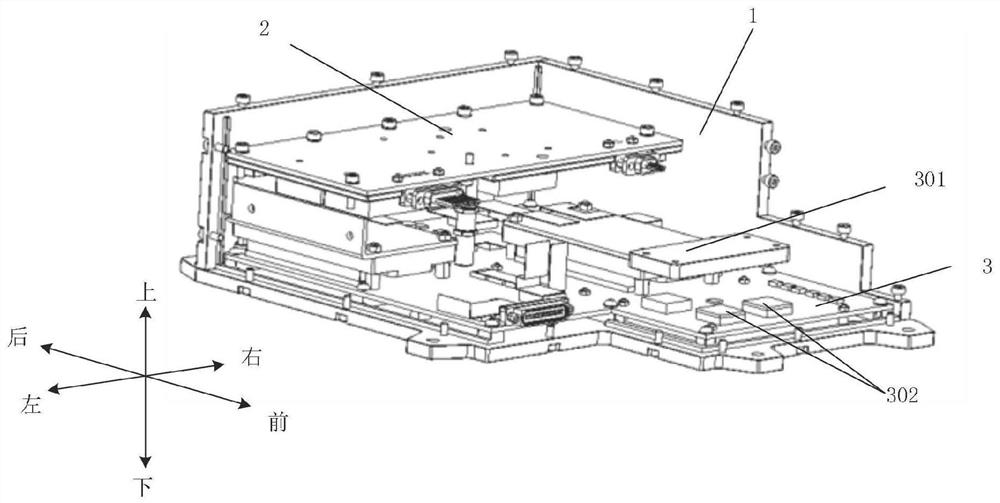

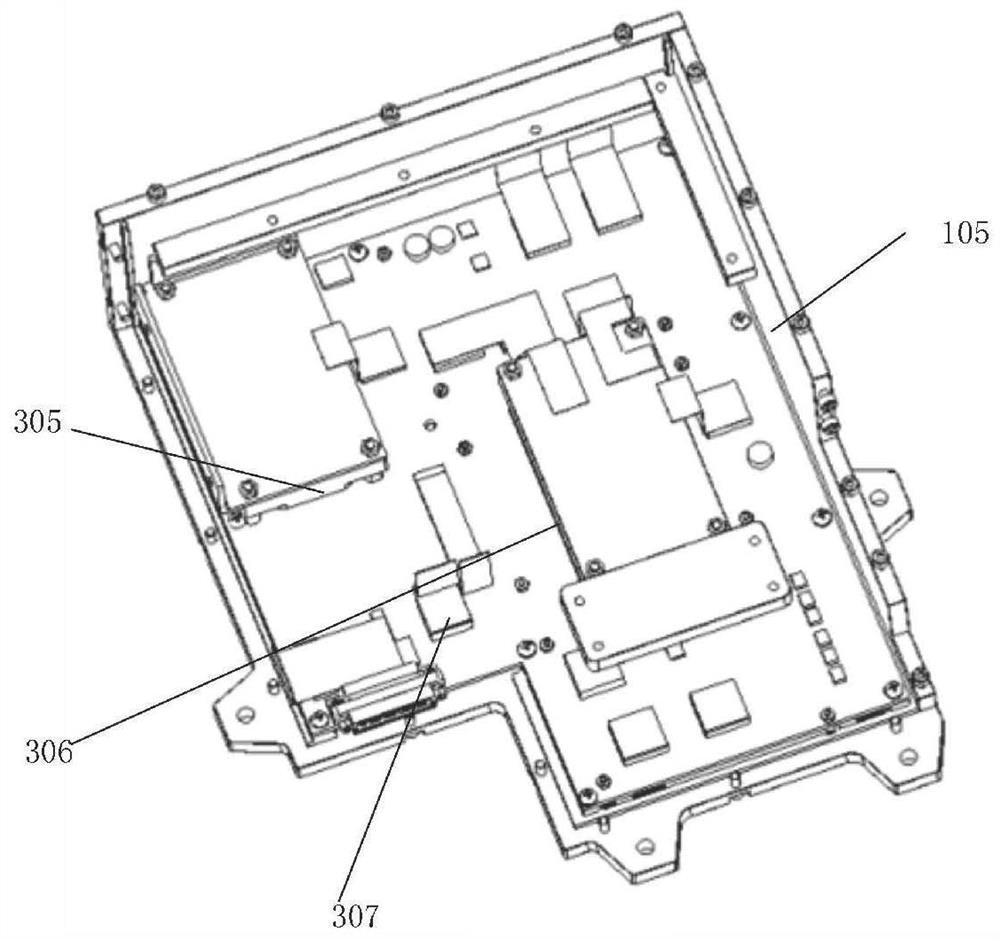

Thermal control structure and device for satellite-borne on-orbit information processing and service load

ActiveCN114173540AShorten the cooling pathReduce accumulationModifications by conduction heat transferPhysicsSatellite

The invention relates to a thermal control structure and device for satellite-borne on-orbit information processing and service load, and relates to the field of mechanical thermal design, a power panel and a control panel are arranged close to a top plate and a bottom plate of a box body respectively, the area of the power panel is smaller than that of the control panel, and three side edges of the power panel are fixedly connected with three adjacent side walls at one end of the box body; the middle part of the box body is provided with an in-board device heat dissipation part close to the control board, one side of the in-board device heat conduction plate is fixedly connected with a large-size device in the middle of the top surface of the control board, and the other side of the in-board device heat conduction plate abuts against the in-board device heat dissipation part. The device has the beneficial effects that under weight constraint, size constraint, cost constraint and sensitive constraint of the device to temperature, heat of the device in the middle of the control panel is conducted to the device-in-plate heat dissipation part nearby through the device-in-plate heat conduction plate, the device-in-plate heat dissipation part conducts heat in a radiation mode, and the heat can also be conducted to a satellite top plate for heat exchange. Heat dissipation paths of devices in the middle of the control panel are shortened, heat dissipation efficiency is improved, and heat accumulation in the middle of the box body is reduced.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

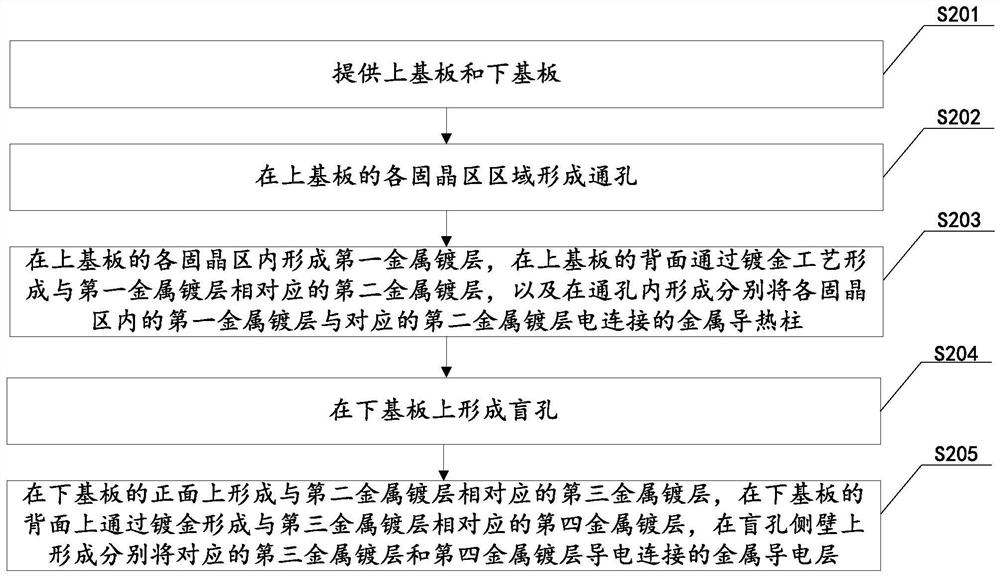

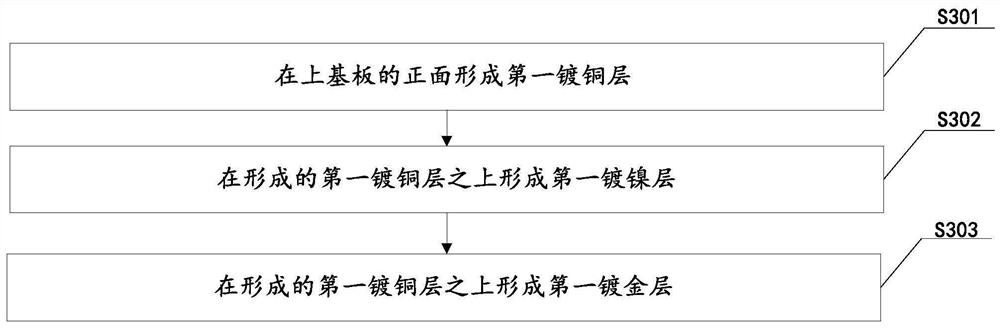

LED lamp bead plate, manufacturing method thereof and display panel

PendingCN112331637AImprove overall brightnessLight mixing distance between lights is reducedSolid-state devicesSemiconductor devicesElectrically conductiveStructural engineering

The invention provides an LED lamp bead board and a manufacturing method thereof, and a display panel. An upper substrate and a lower substrate are combined to form a substrate; through holes are independently formed in the upper substrate, blind holes are independently formed in the lower substrate, a mature process can be adopted, metal heat conduction columns are arranged in the through holes,the metal conducting layers are formed in the blind holes and the corresponding metal coatings are formed on the upper substrate and the substrate. the universality is good, implementation is easy, efficiency and yield are high, cost is low, and mass production, popularization and application are easy; compared with a single-layer substrate with the same thickness, the substrate formed by the upper substrate and the lower substrate has the advantages that the height of the metal heat conduction columns is only half of or even smaller than the height of the metal heat conduction columns, used for enabling heat generated by the LED chips to be generated everywhere, in the single-layer substrate, so that heat dissipation paths can be greatly reduced, and the heat dissipation performance is better.

Owner:HUIZHOU JUFEI OPTOELECTRONICS CO LTD

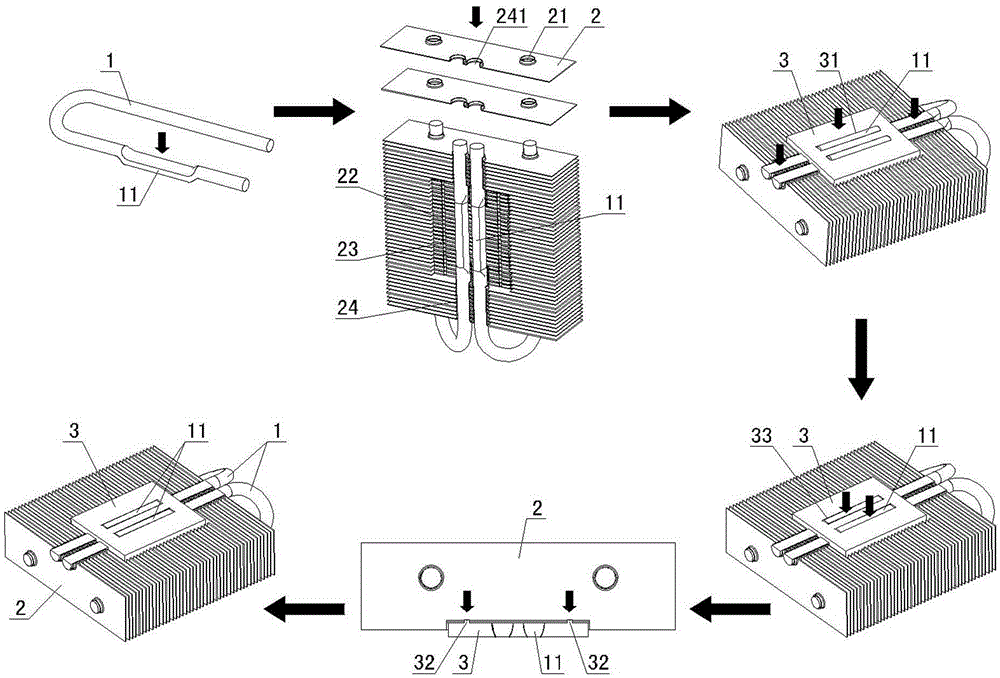

Manufacturing method of cooler

InactiveCN105382124ASimple processIncrease productivityHeat exchange apparatusHeat resistanceCooling effect

The invention provides a manufacturing method of a cooler. The method includes the steps that one strut of each U-shaped heat conductive pipe is pressed on a boss; cooling fins are riveted to the other strut of each U-shaped heat conductive pipe one by one; a bottom board and the boss are preliminarily riveted and fixed and meanwhile the two ends of each strut with the corresponding boss are riveted and fixed to the cooling fins; the boss is riveted, so that the boss is flush with the bottom board; and finally the bottom board and the cooling fins are riveted and fixed. The riveting process is adopted for manufacturing the cooler, no electroplating or welding process is needed, the process is simple, production efficiency is improved, production cost is reduced, energy is saved, and environmental friendliness is achieved. Meanwhile, the heat conductive pipes are flattened and then embedded in the bottom board, one side of each heat conductive pipe can make direct contact with a heat source, the other side of each heat conductive pipe makes direct contact with the cooling fins, heat resistance of an aluminum board is reduced, the heat conductive performance is effectively improved, a cooling path is shortened, heat generated by the heat source can be rapidly conducted and dissipated out, the cooling effect is improved, and the service life of the heat source is effectively prolonged.

Owner:SIHUI HONGYI ELECTRONICS TECH CO LTD

Data center

InactiveCN106163229AReduce energy consumptionReduce wind resistanceCooling/ventilation/heating modificationsData centerEngineering

The application discloses a data center. The data center comprises a plurality of cabinet assemblies arranged in the same direction. The cabinet assemblies include cabinet columns, heat exchange bodies, and sealing parts. The cabinet columns and the heat exchange bodies are alternatively arranged in parallel. The sealing parts are arranged between the cabinet columns and the heat exchange bodies for sealing spaces between air outlets at back sides of the cabinet columns and the heat exchange bodies. The embodiment improves the heat exchange efficiency of the cabinet assemblies of the data center, shortens a cold-feeding path, and greatly reduces the data center energy consumption.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

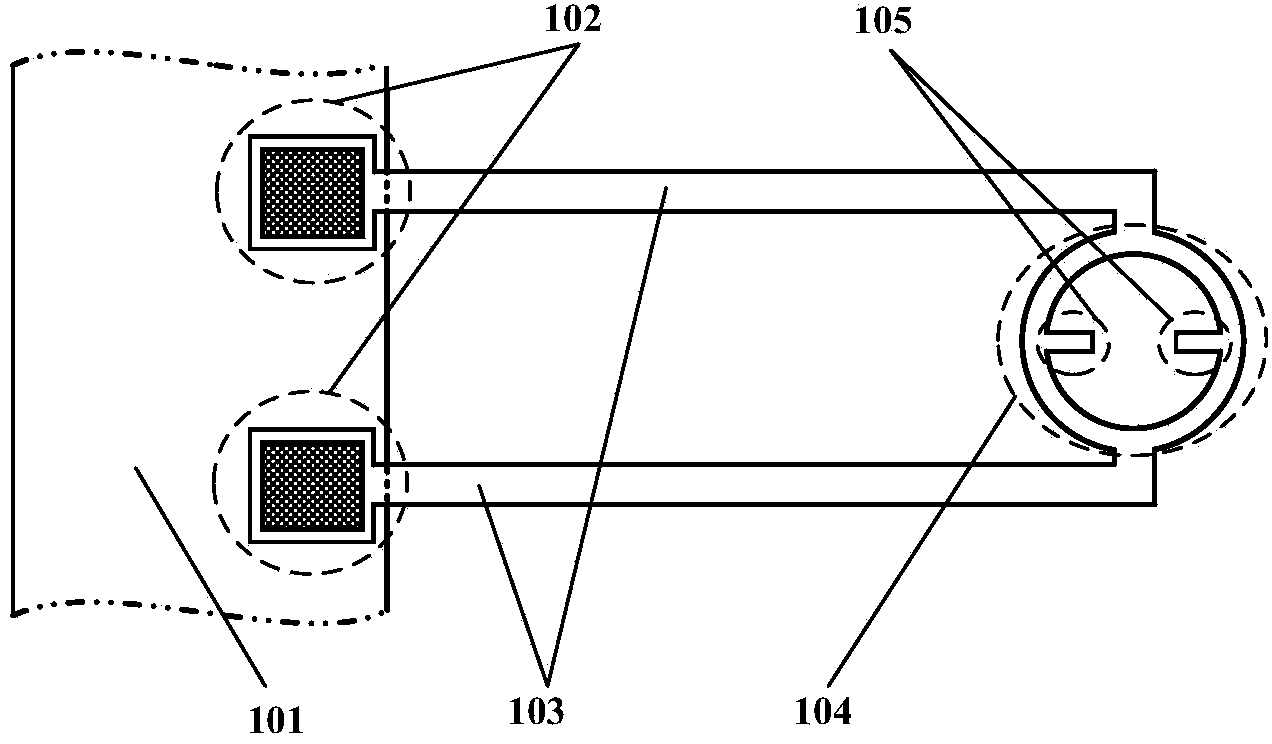

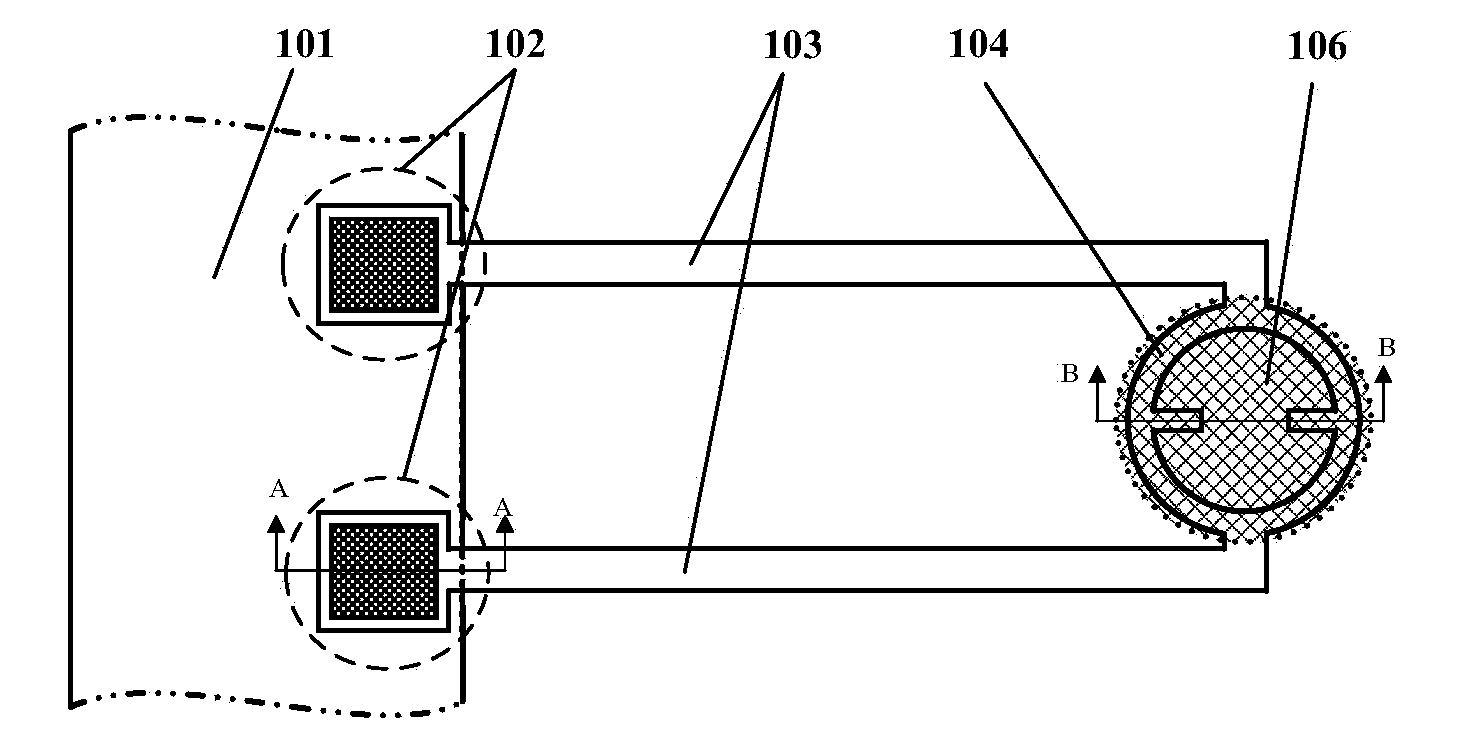

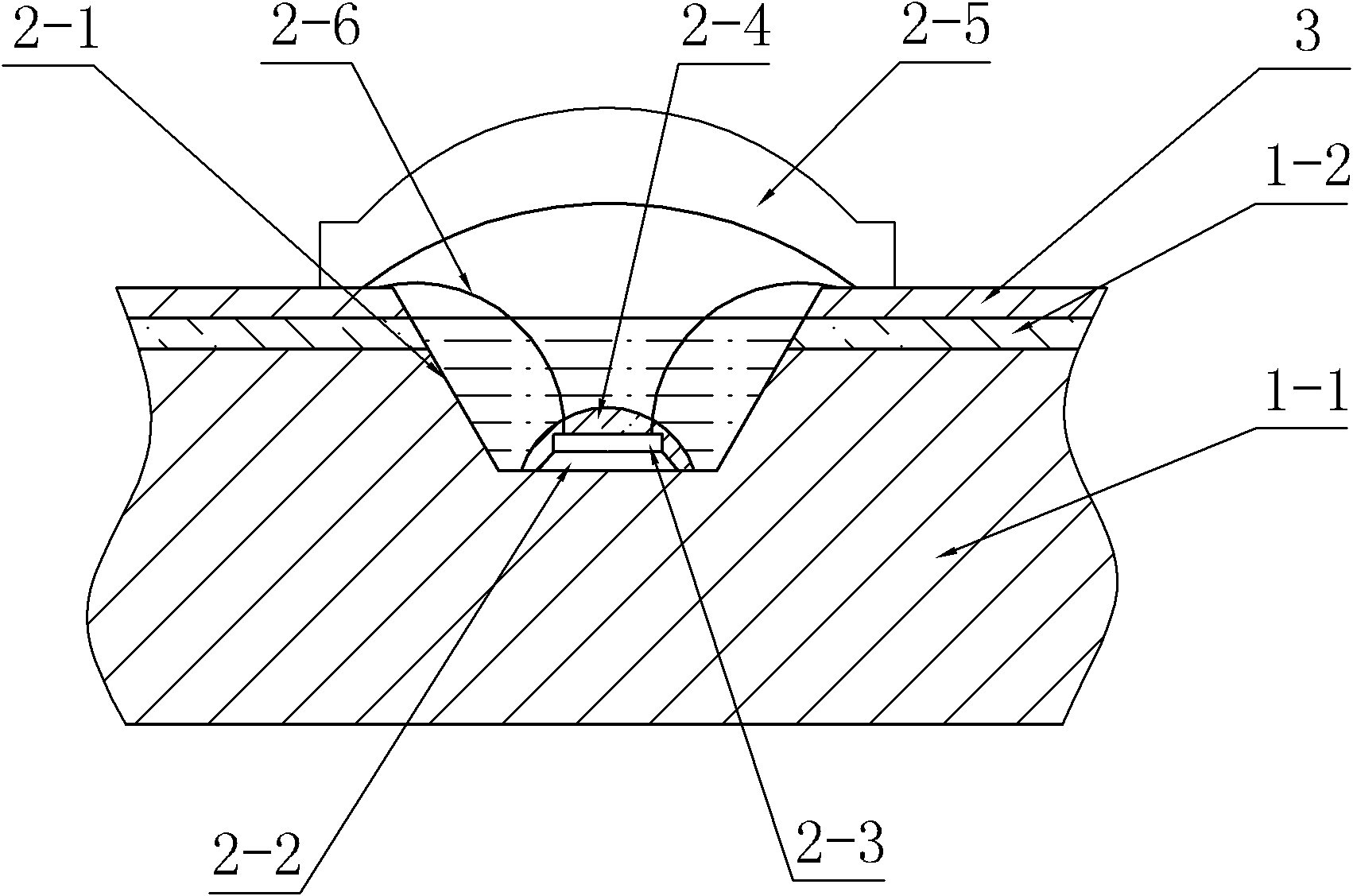

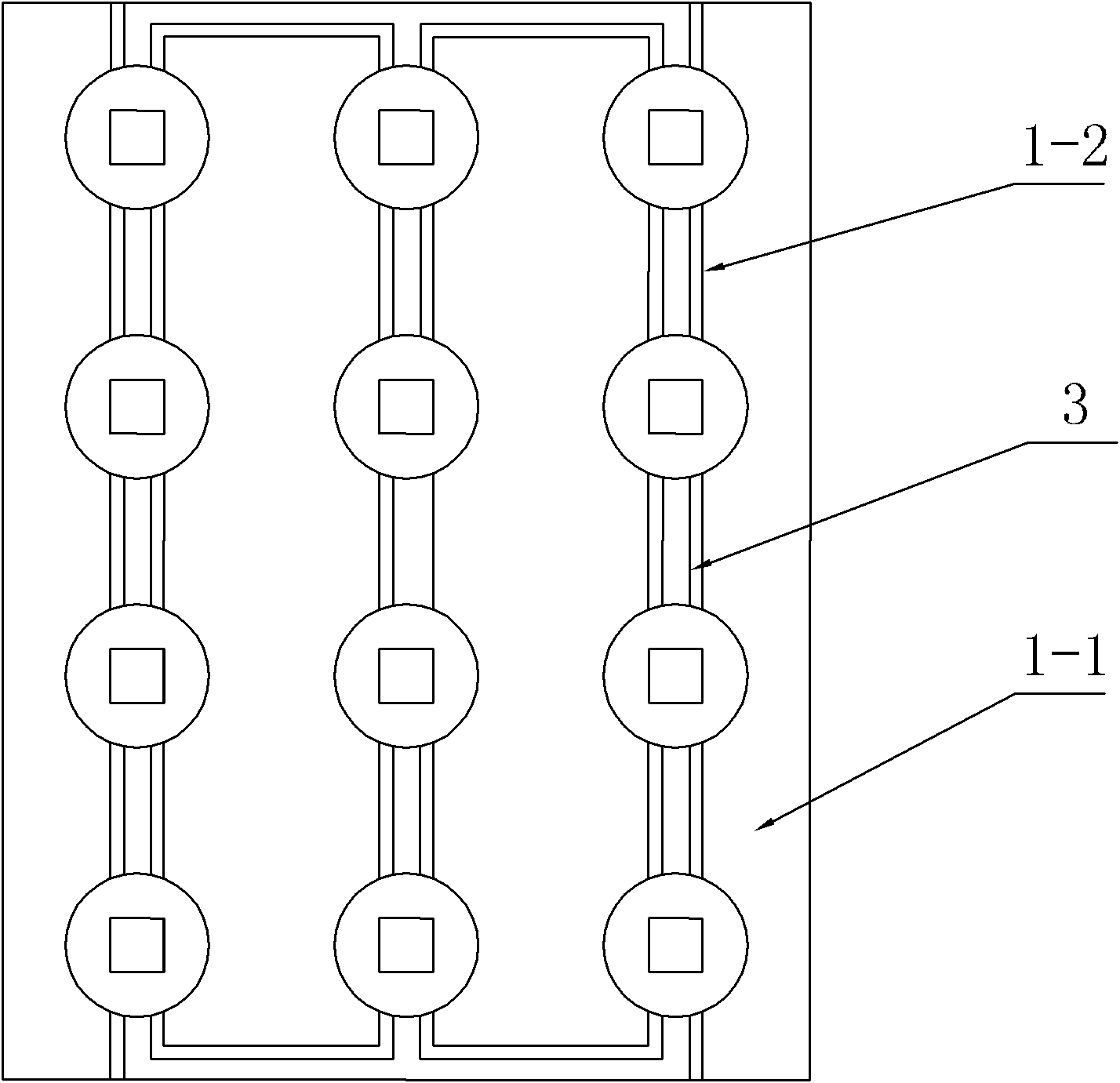

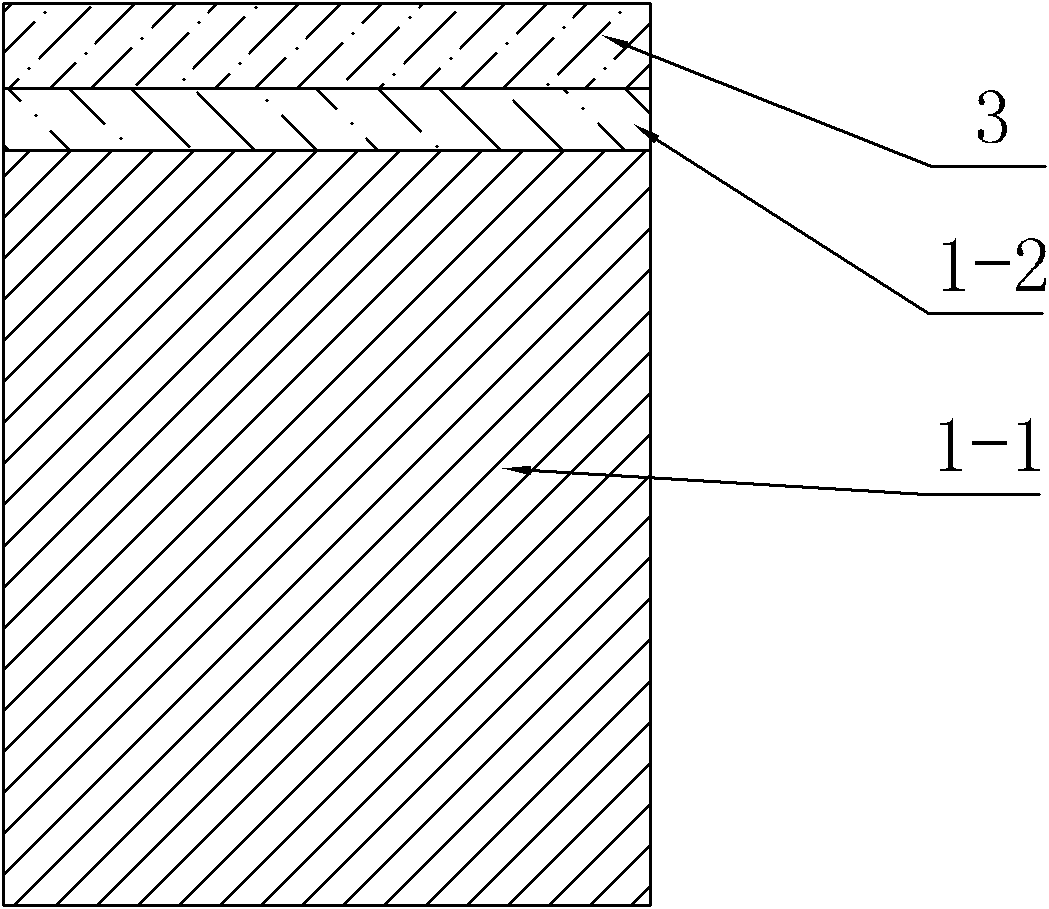

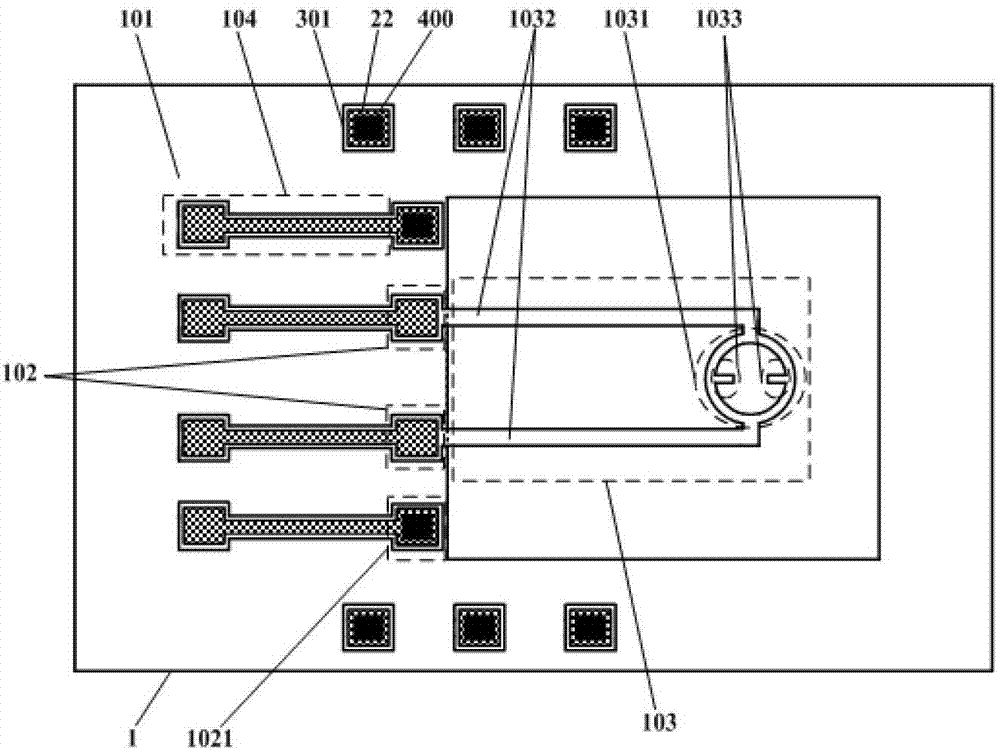

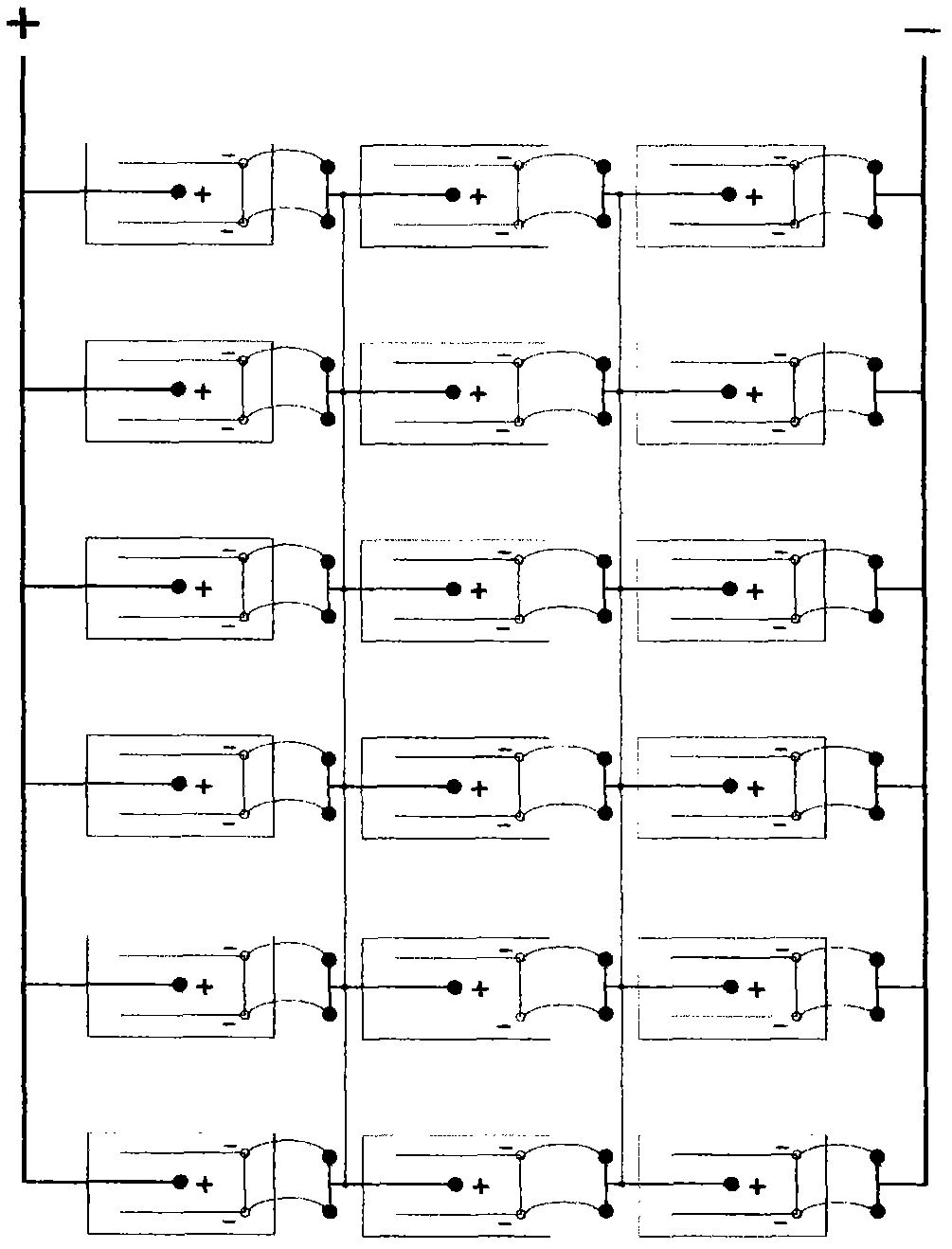

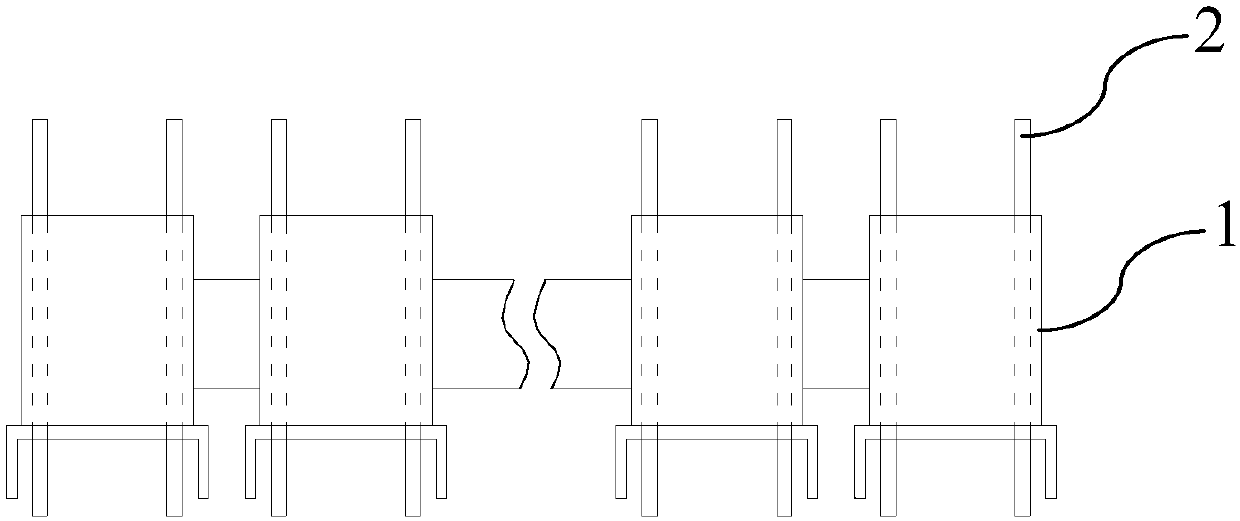

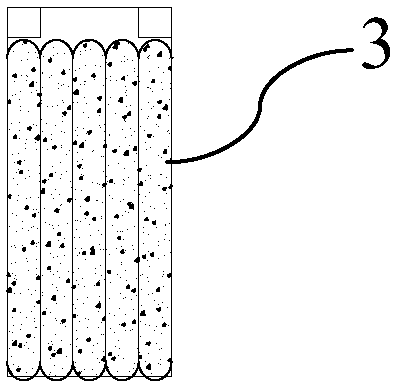

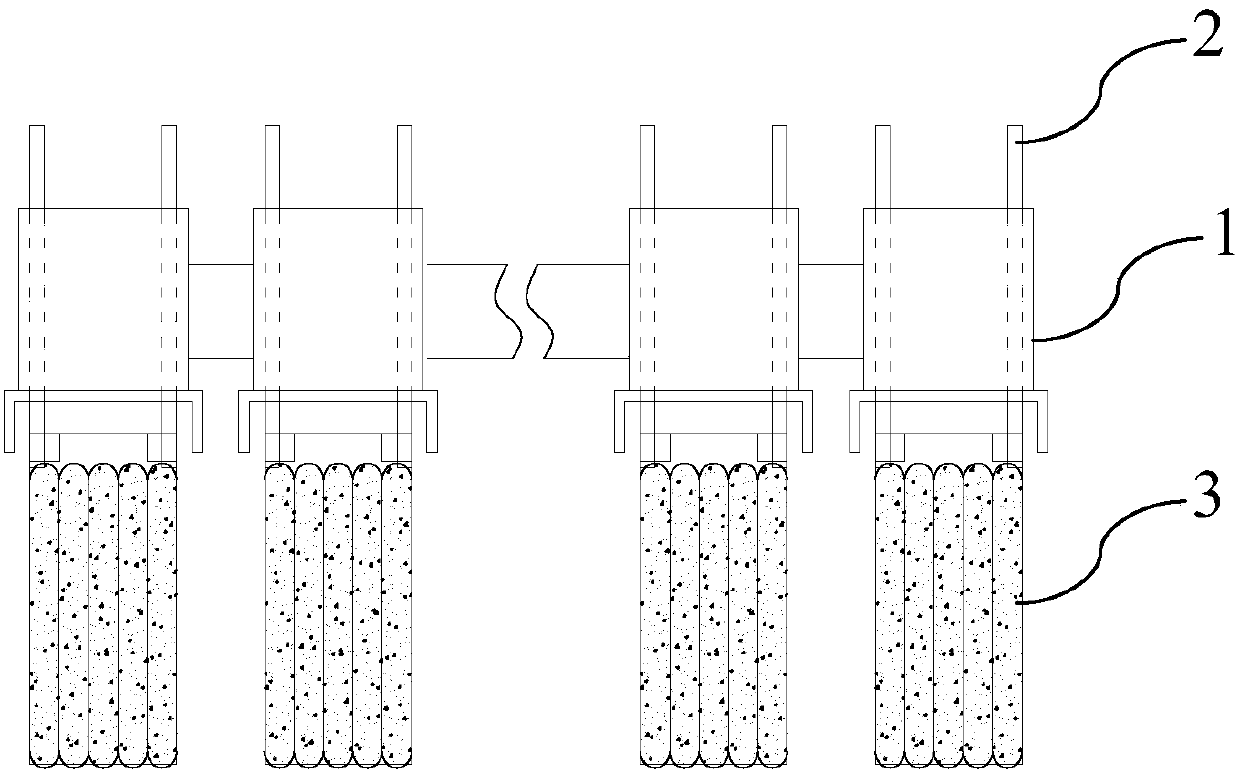

Multiple-chip array type chip-on-board (COB) inversely-installed eutectic packaging structure and method

InactiveCN103378079AShorten the cooling pathReduce thermal resistanceSolid-state devicesSemiconductor devicesEutectic bondingOn board

The invention relates to a multiple-chip array type chip-on-board (COB) inversely-installed eutectic packaging structure and method. The multiple-chip array type COB inversely-installed eutectic packaging structure comprises a ceramic heat-radiating substrate, a fluorescent powder and silica gel mixed packaging layer and light-emitting diode (LED) chips, wherein an insulating layer is arranged on the upper surface of the ceramic heat-radiating substrate, a circuit conductor layer is arranged above the insulating layer, and multiple LED chip connecting units are installed on the upper side of the ceramic heat-radiating substrate. Each LED chip connecting unit consists of a bonding layer, an LED chip and a gold wire shared by thermo-sonic keys, wherein the positive pole ends of the chips are in eutectic bonding with the bonding layers and connected with the circuit conductor layer, and the negative pole ends of the LED chips are connected with one end of the circuit conductor layer on the front side of the substrate through the gold wires. The multiple-chip array type COB inversely-installed eutectic packaging structure and method has the advantages of being excellent in heat-radiating effect and capable of avoiding the problems including chip defects or reduced luminous efficiency and the like caused by the different expansion degree of the chip and the substrate with heat, facilitating wire arrangement, reducing bonding temperature, improving the reliability performance and solving the problems of false welding and unsoldering of wires.

Owner:GUANGDONG JINYUAN LIGHTING TECH

Power type G9 LED bulb and manufacturing method thereof

InactiveCN107830429AShorten the cooling pathImprove heat dissipationLighting heating/cooling arrangementsProtective devices for lightingEngineeringAnode

The invention discloses a power type G9 LED bulb comprising LED lamp slices, metal pins, a connecting plate insulation cover and silica gel, wherein the metal pins are fixed in the connecting plate insulation cover, and both ends of each metal pin are exposed out of the connecting plate insulation cover; the LED lamp slices are connected to the connecting plate insulation cover, and one end of each metal pin is connected to the positive and negative anodes of the LED lamp slices; the other end of the metal pin is connected to an external power supply; the silica gel covers the LED lamp slices,and the surface area of the connecting plate insulation cover is larger than the surface area of the LED lamp slices. The invention further discloses a manufacturing method of the power type G9 LED bulb. The power type G9 LED bulb disclosed by the invention meets the market requirements for high-power LED G9 bulbs, and the heat dissipation of the LED G9 bulbs is optimized; and the high-power LEDG9 bulbs can be achieved, and the market requirements are met.

Owner:JIANGSU WENRUN OPTOELECTRONICS

LED (light-emitting diode) lamp and manufacturing method thereof

InactiveCN102563399AShorten the cooling pathAvoid the influence of thermal resistancePoint-like light sourceLighting heating/cooling arrangementsHeat resistanceEngineering

The invention discloses an LED (light-emitting diode) lamp. The LED lamp comprises an attached lamp shell and an LED, wherein an attached composite layer is laid on the attached lamp shell, and comprises a substrate insulating layer and a conducting wire layer which are arranged in sequence from bottom to top; and the LED or an electronic element are attached on the attached surface of the conducting wire layer. The LED lamp has the advantages that the shell of the LED lamp is directly used as the attached lamp shell of the LED, the radiating way is reduced to have fewest links, and the influences of various heat resistances are avoided, so that the radiating performance is greatly improved, the structure form is simplified and the assembling cost and the product-manufacturing cost are saved.

Owner:SHANGHAI GRANDAR LIGHT ART & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com