Combined modular backlight unit for flat panel display and helmet

A modular and backlight technology, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of inability to meet the needs of batch products, lack of mature heat dissipation modules, and increase design costs, so as to shorten product maintenance time and shorten R & D cycle, the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

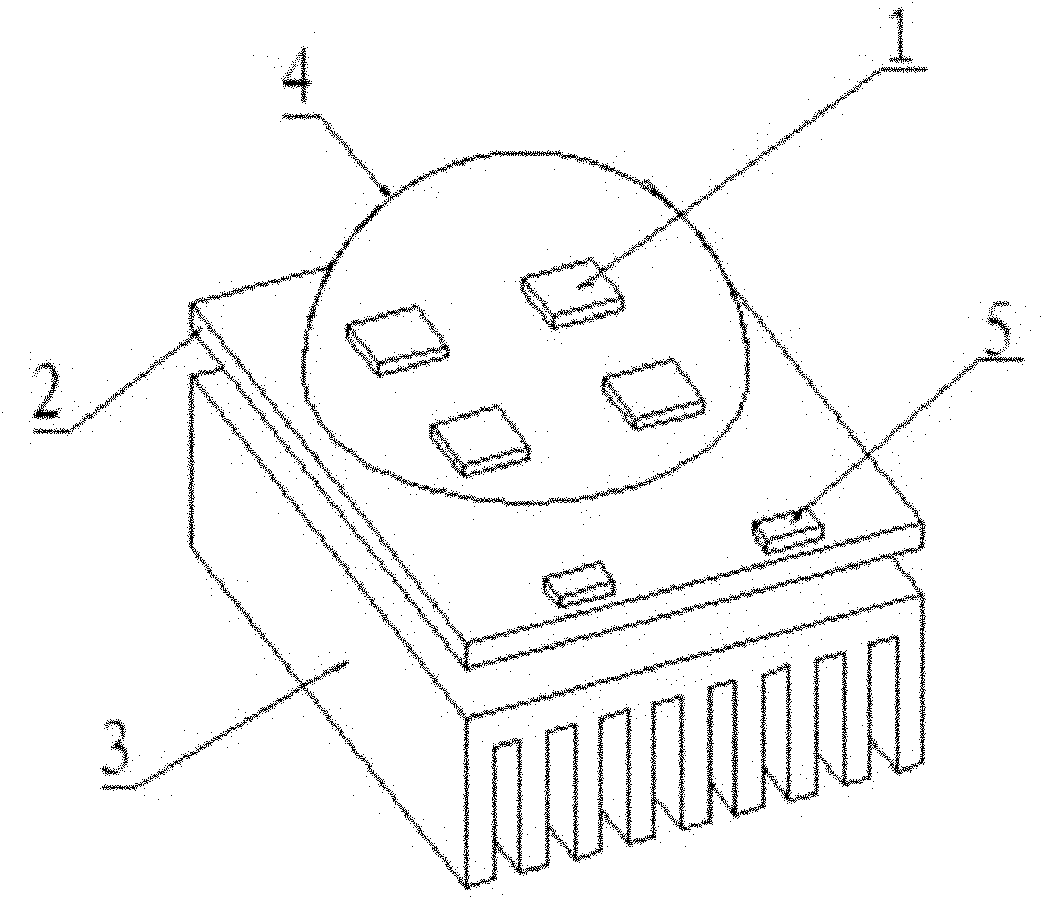

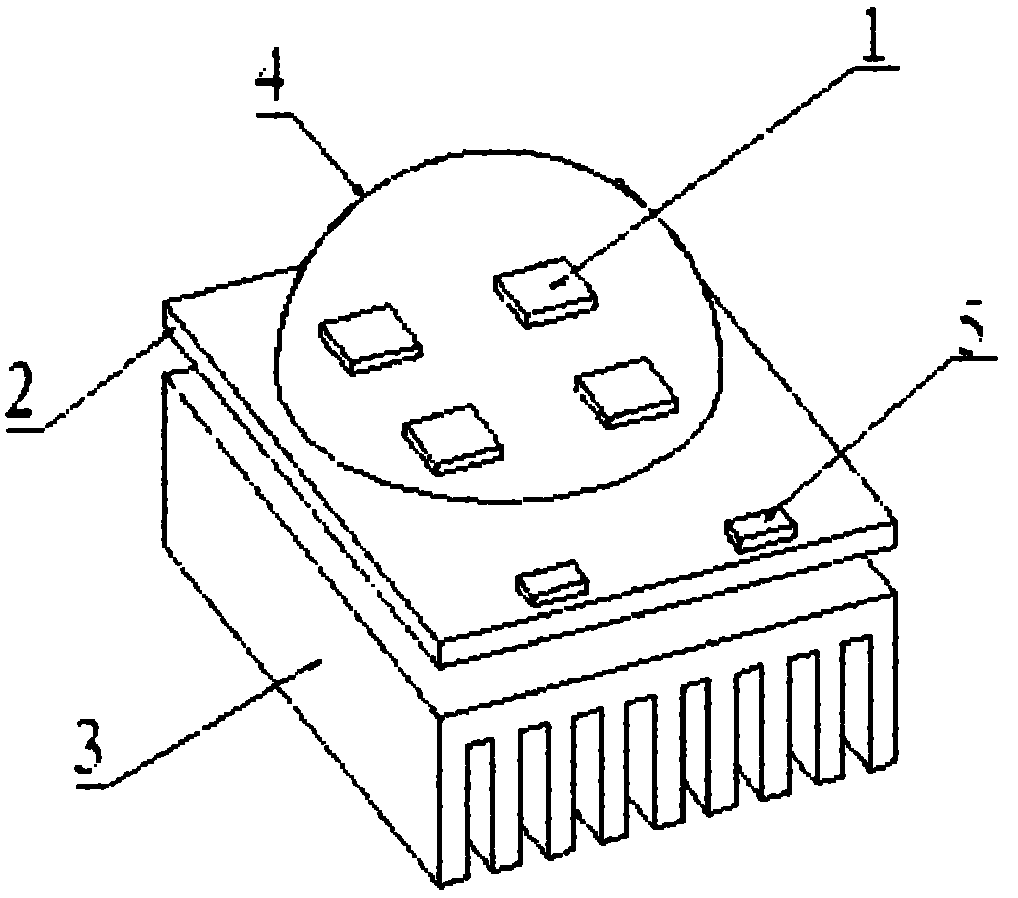

[0009] Referring to the accompanying drawings, the present invention is characterized in that it includes a ceramic-packaged LED chip 1, a vapor chamber 2, and heat dissipation fins 3. On the top of the vapor chamber 2, there is a resin-encapsulated LED module 4. Heat dissipation fins 3 are provided, and the resin-encapsulated LED module consists of at least one ceramic-encapsulated LED chip.

[0010] The invention adopts single or multiple LEDs with small volume and good heat dissipation performance as the backlight module, and the circuit board adopts a uniform temperature plate with a thermal conductivity of 800W / mK or more, and conducts heat dissipation according to the power consumption and quantity of LEDs used in the backlight of a single module. Simulation, design heat dissipation fins that meet the heat dissipation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com