Highly effective brake based on magnetic rheology technique

A brake, magnetorheological technology, applied in the direction of brake type, mechanical equipment, etc., can solve problems such as bulky, achieve the effect of small structure, light weight and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

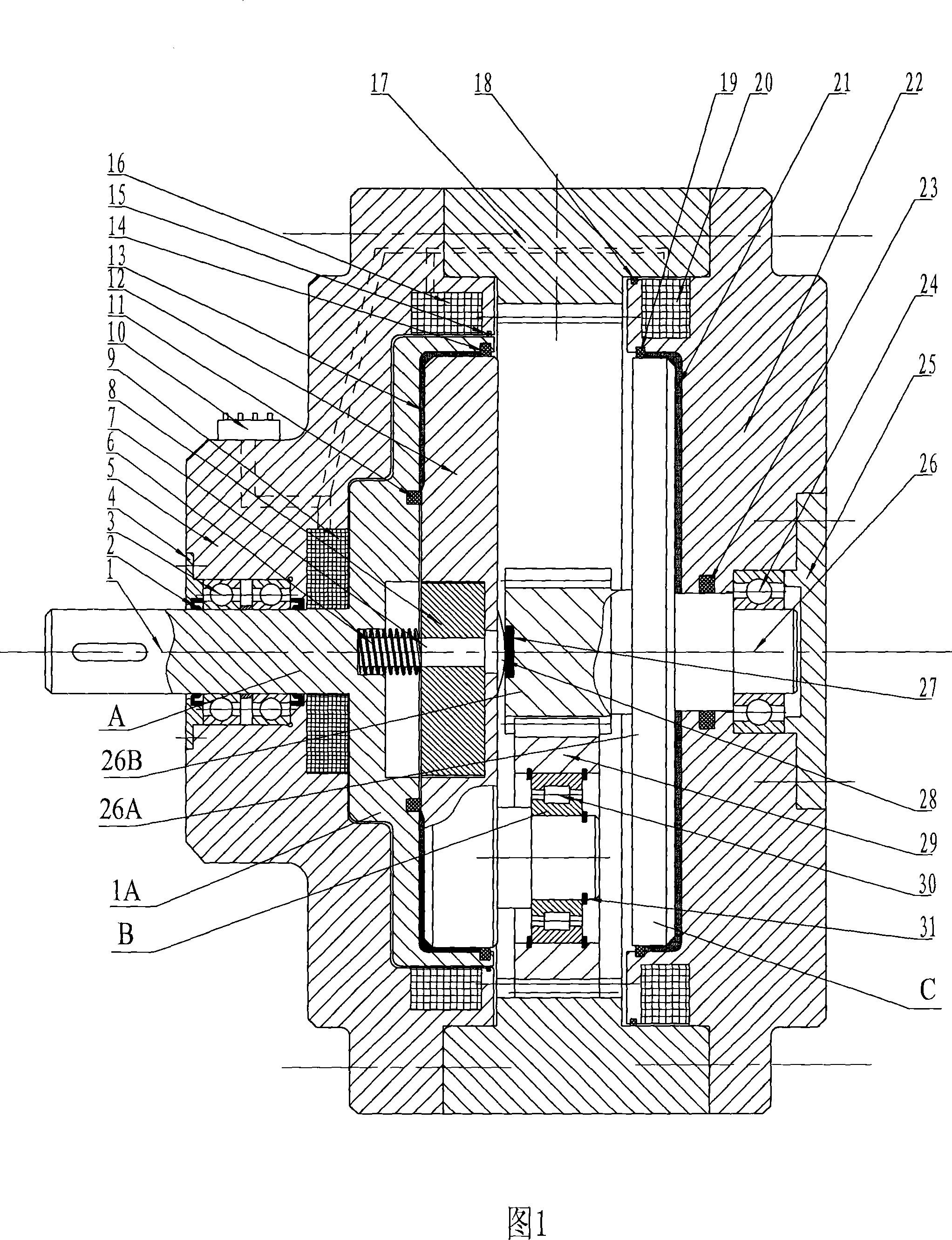

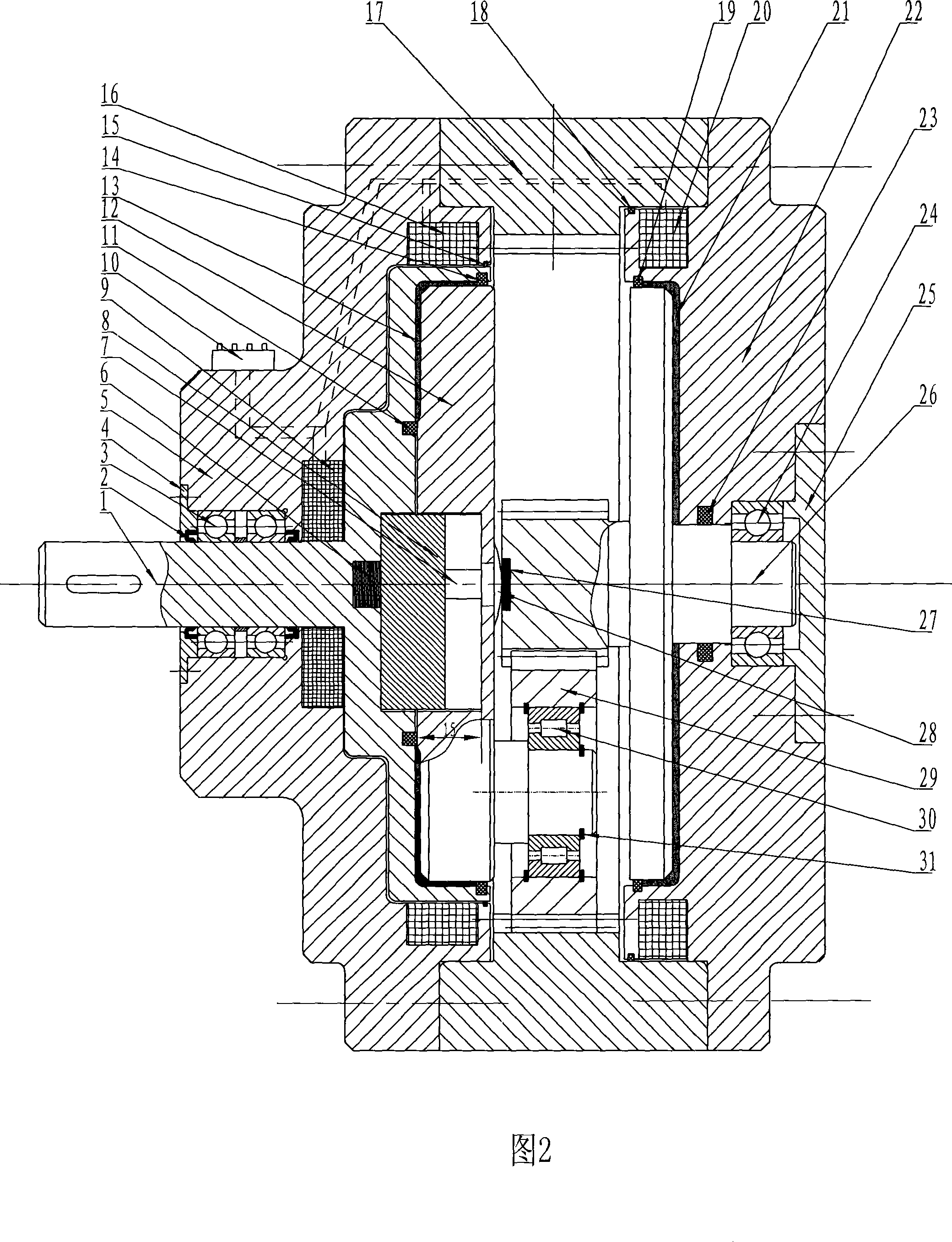

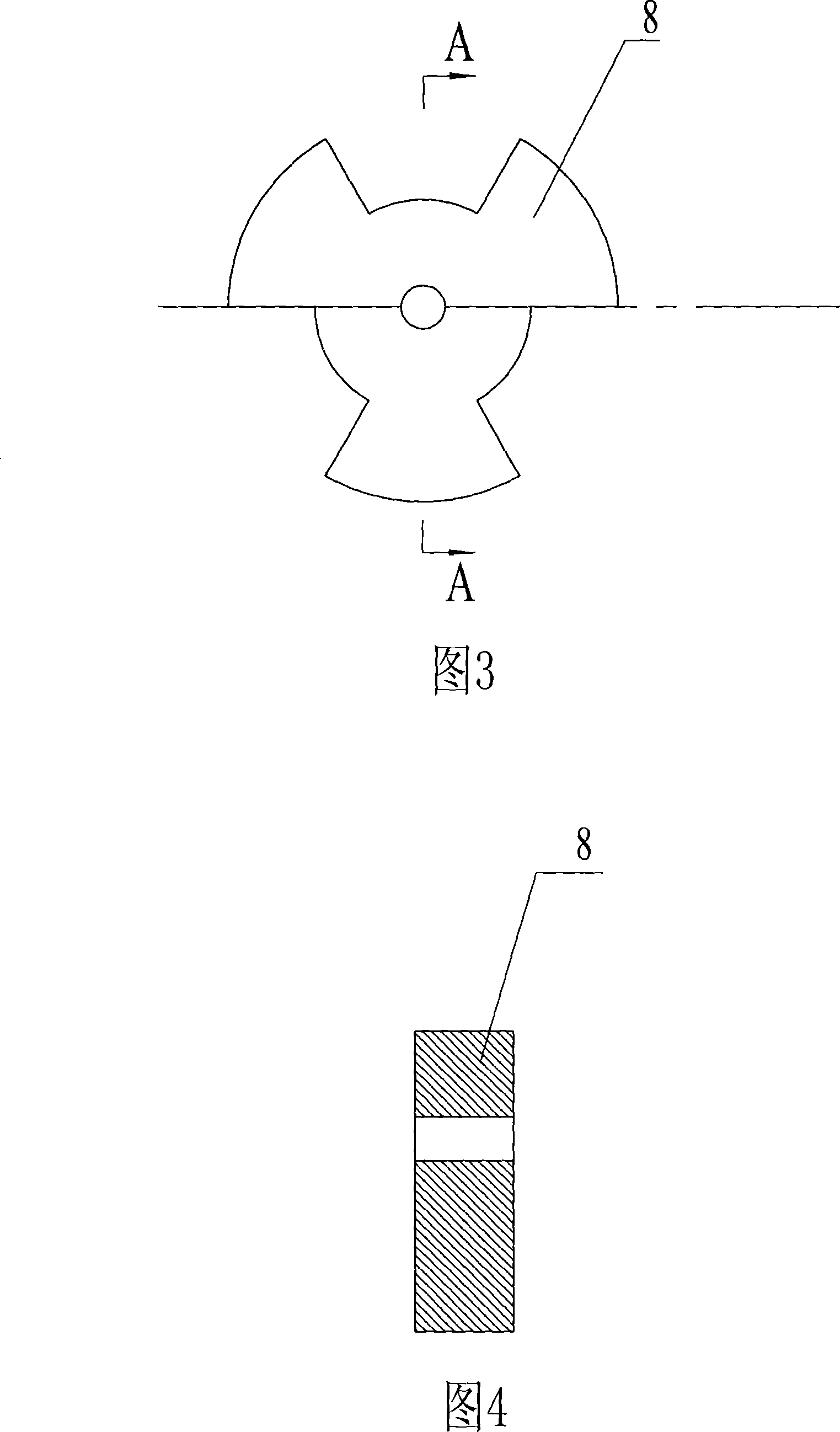

[0023] The structure schematic diagram of the present invention is shown in Figure 1, including the electromagnetic clutch mechanism A and the electromagnetic brake mechanism B that generate the damping torque, wherein a planetary speed increaser that amplifies the damping torque is arranged between the electromagnetic clutch mechanism and the electromagnetic brake mechanism c.

[0024] In this embodiment, the above-mentioned electromagnetic clutch mechanism A includes an input shaft 1 having a disc structure 1A, a left end cover 5 is set on the input shaft 1, and an input excitation coil 9 is set on the contact surface between the input shaft 1 and the left end cover 5 , the contact surface between the disc structure 1A and the left end cover 5 is set with a left excitation coil 16; the electromagnetic brake mechanism B includes a central shaft 26 with a disc structure 26A, and a right end cover 22 is set on the central shaft 26, and the right end cover The outer side of 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com