Multiple-chip array type chip-on-board (COB) inversely-installed eutectic packaging structure and method

A packaging structure and array technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of poor contact, chip defect luminous efficiency, poor heat dissipation effect, etc., to improve reliability performance, excellent heat dissipation effect, The effect of reducing the bonding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

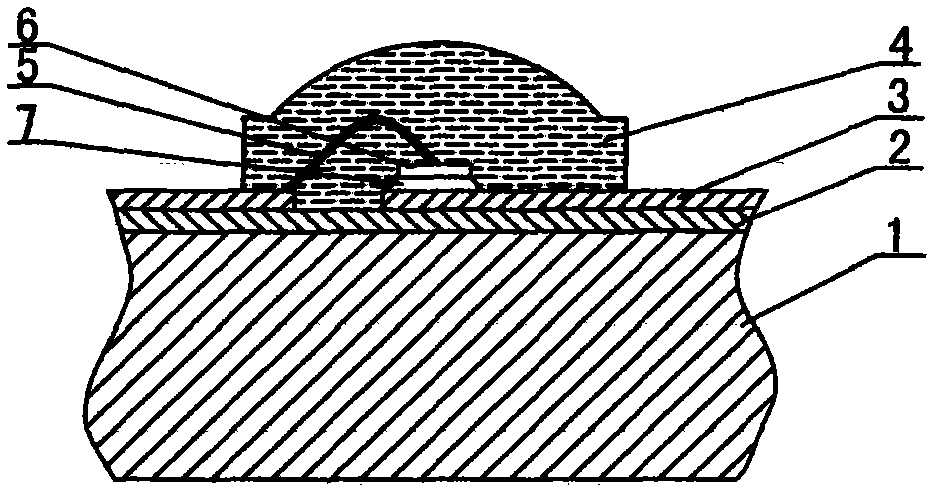

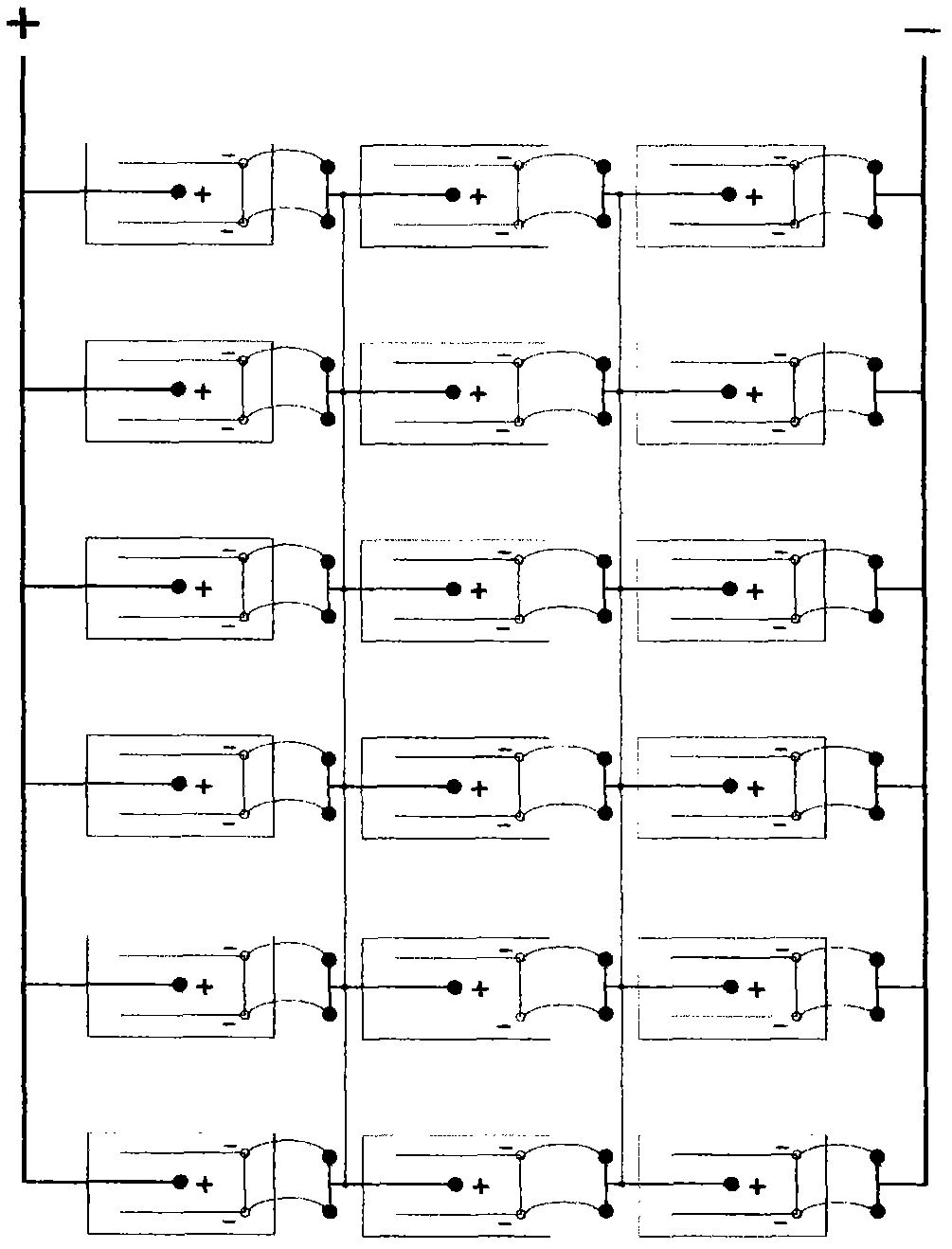

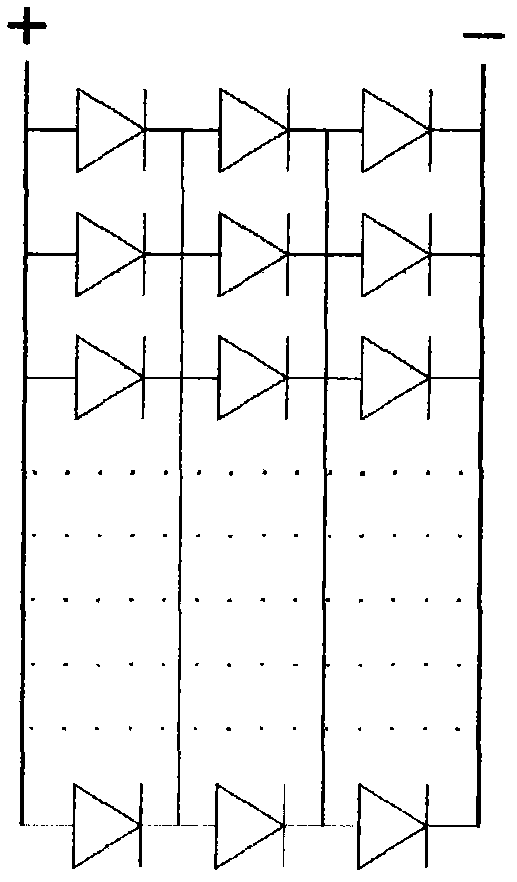

[0020] Such as figure 1 As shown, the multi-chip array COB flip-chip eutectic packaging structure described in the embodiment of the present invention includes a ceramic heat dissipation substrate 1, a phosphor powder and silica gel mixed packaging layer 4, and an LED chip 6. The ceramic heat dissipation substrate 1 is a high thermal conductivity rate, close to the LED chip expansion coefficient of the ALN ceramic substrate and its upper surface is provided with an insulating layer 2, the upper surface of the insulating layer 2 is provided with a circuit wire layer 3, and a plurality of LED chip connection units are installed on the upper side of the ceramic heat dissipation substrate 1; each Each LED chip connection unit is composed of a bonding layer 7, an LED chip 6, and a gold wire 5 for thermosonic bonding, wherein the LED chip 6 is set as a strip-shaped or other-shaped chip whose positive and negative electrodes have different faces and the substrate is transparent. And ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com