Patents

Literature

44results about How to "Solve Welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent electronic spot welder and spot welding method thereof

ActiveCN101890565ASolve only spot weldingSolve quality problemsElectrode featuresWelding monitoring devicesMicrocontrollerAviation

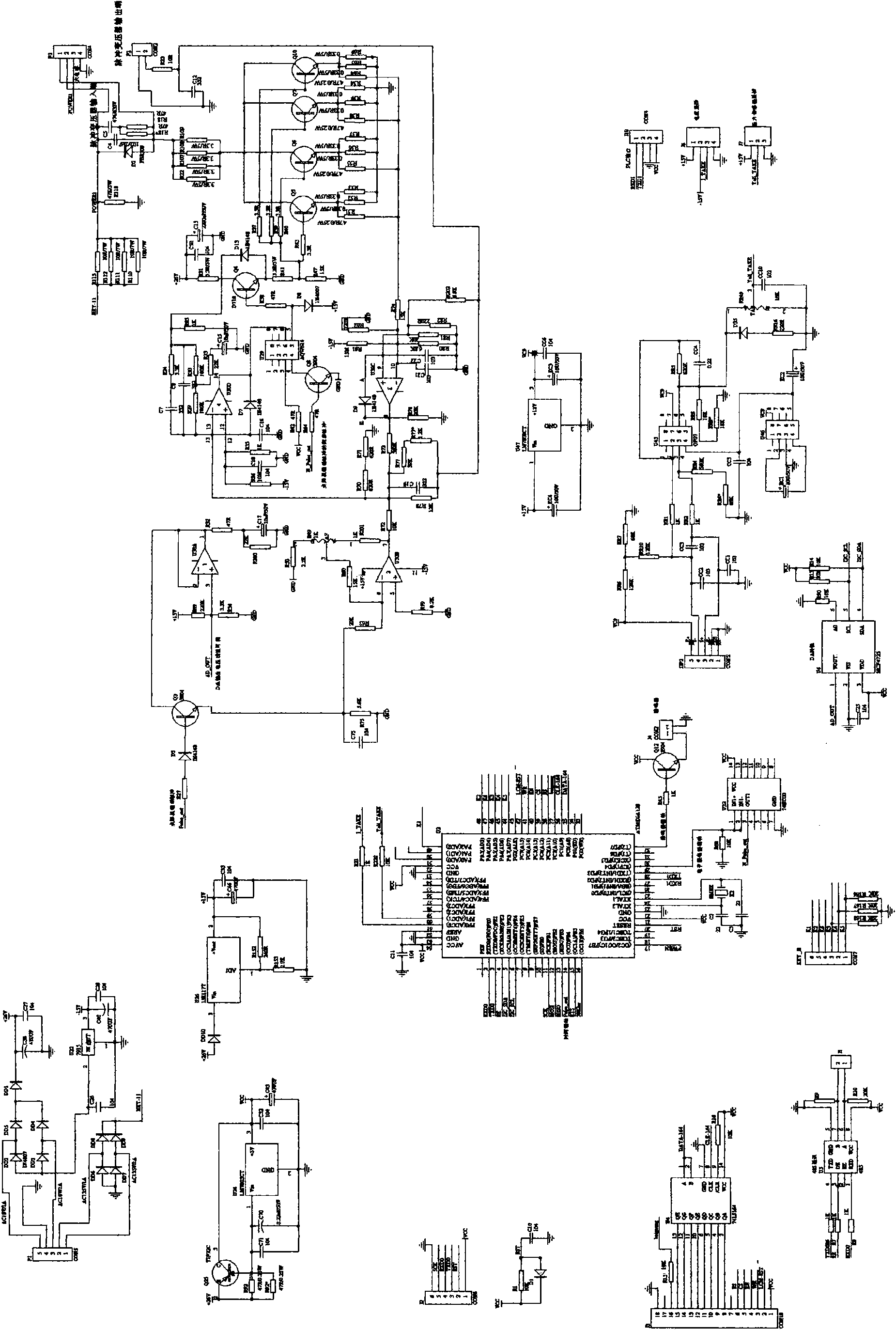

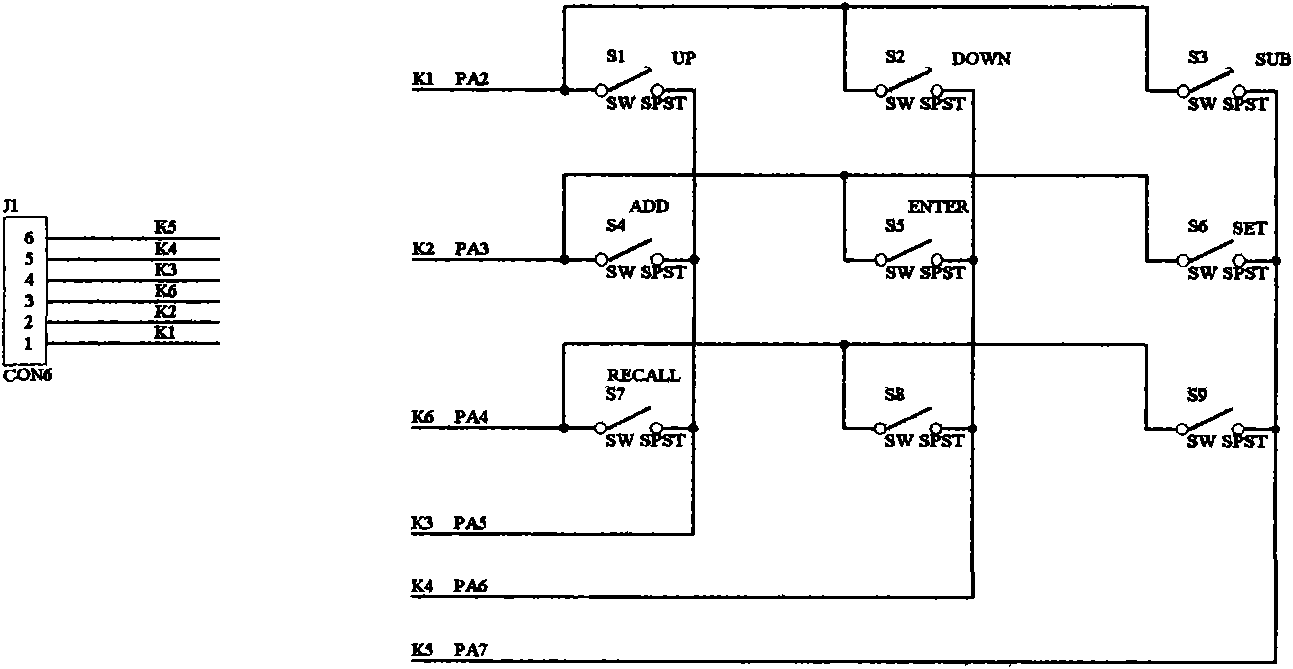

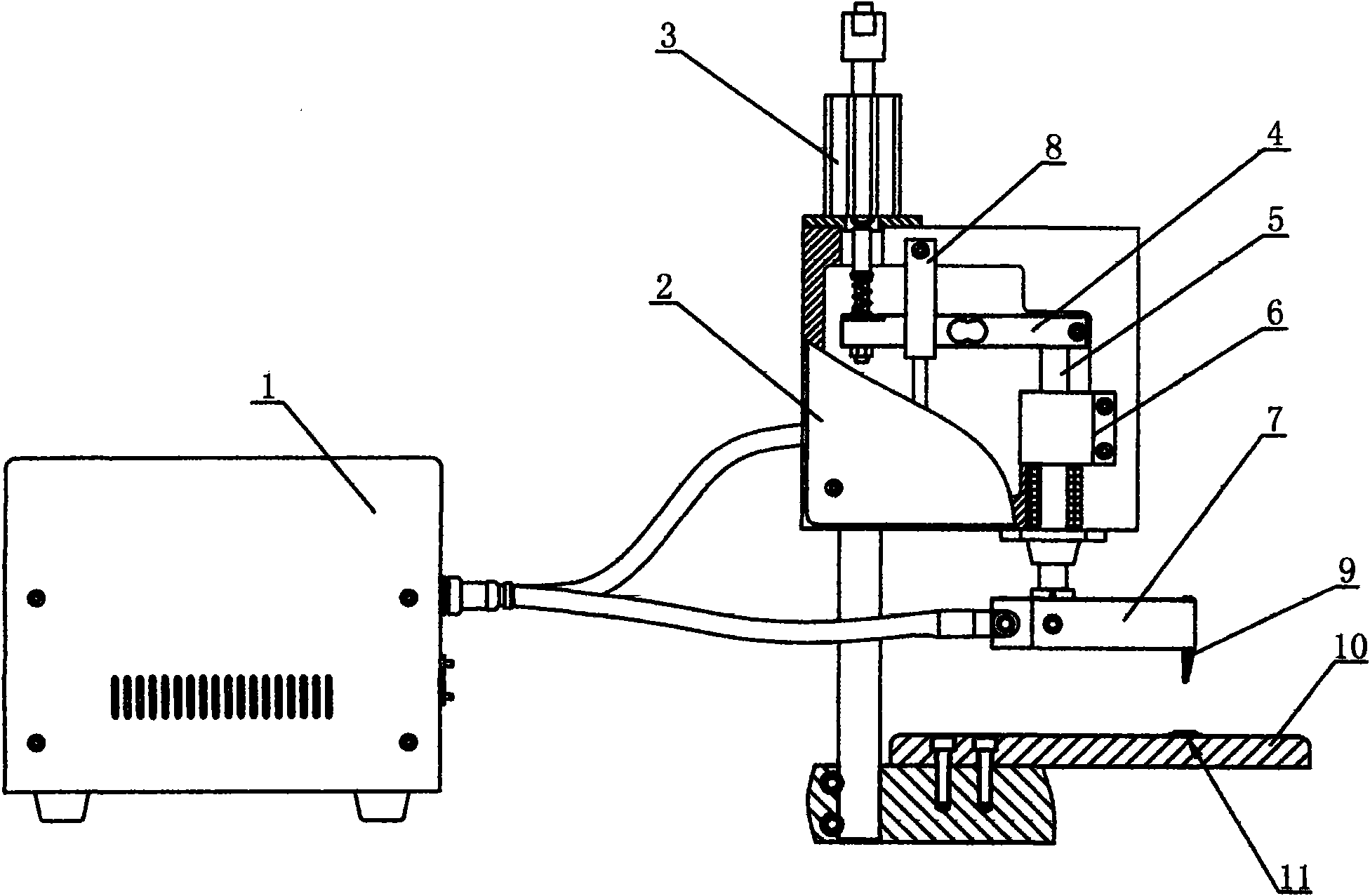

The invention relates to an intelligent electronic spot welder and a spot welding method thereof. The spot welder comprises a host machine provided with a singlechip and a welding database, and a machine head; the machine head comprises a driving device, a front shaft and a welding head; and a detector and a braking device are respectively connected with the front shaft. The detector transmits the acquired data to the singlechip so as to make the welding head automatically perform welding action through the host machine. The intelligent electronic spot welding method comprises the following steps of: (1) establishing a welding parameter database; (2) measuring the diameter of an enameled wire to be processed; (3) outputting a paint-removing pulse for paint removal; (4) outputting a welding pulse for welding; (5) and measuring or performing repair welding. The Intelligent electronic spot welder has real-time detection and repair welding function, namely synchronously welds and detects welding spot quality, and detects a welding spot once the welding spot is welded to form a closed-loop automatic detection system, solves the problems of no detection of the welding spot quality afterwelding, and insufficient welding and wire break during spot welding of the conventional spot welder, and improves the reliability of processing electronic components in the industries of communication, aviation and aerospace and advanced medical equipment.

Owner:珠海精易焊接设备有限公司

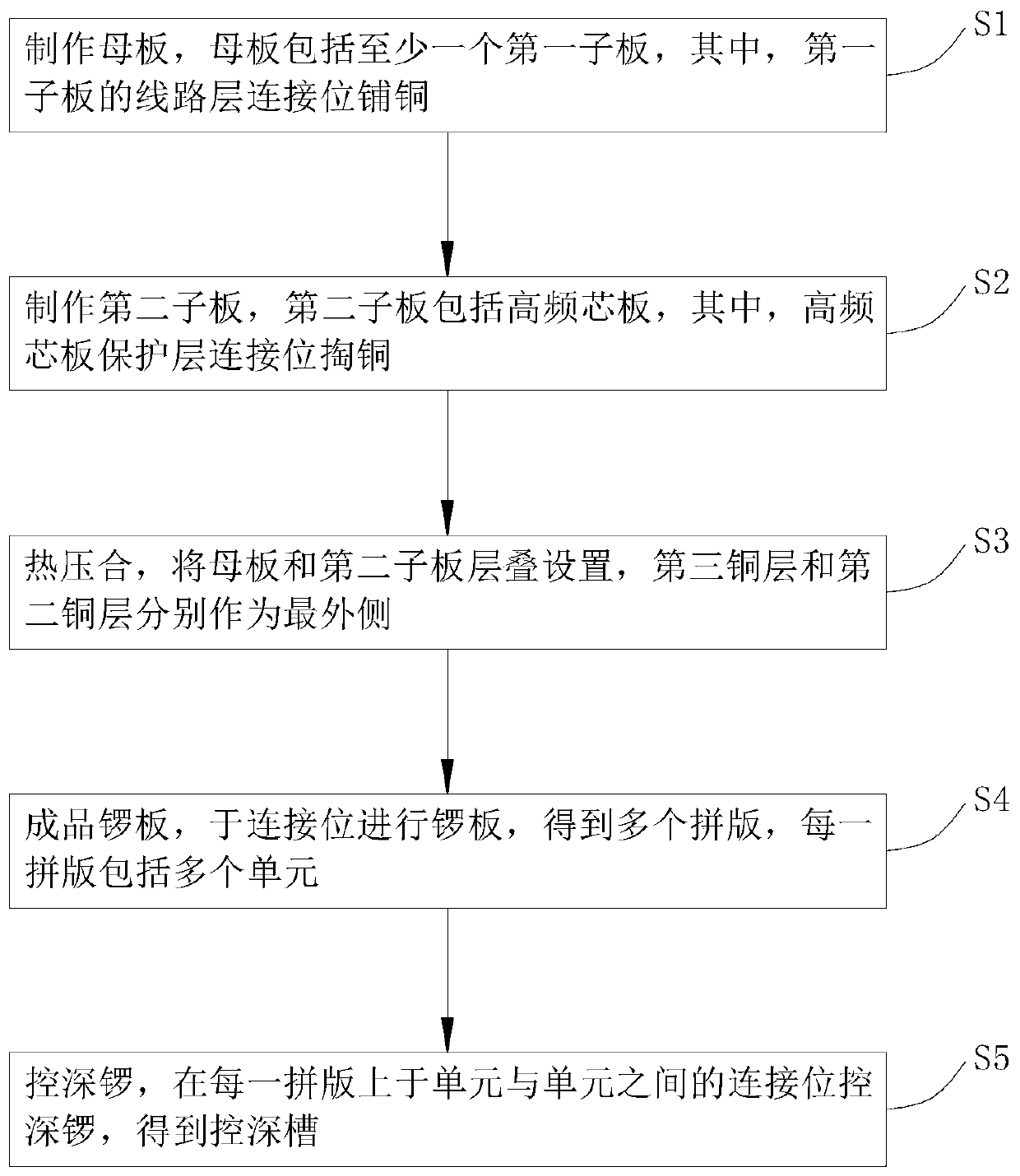

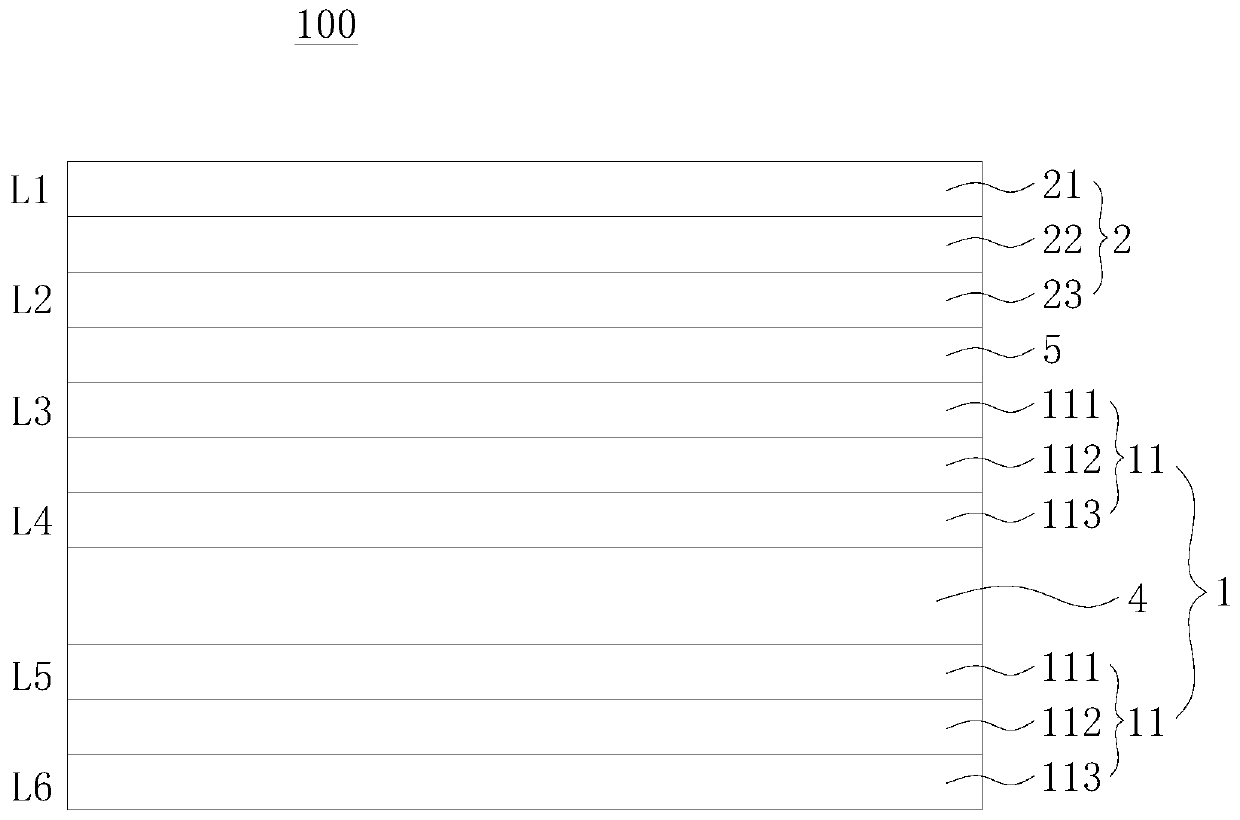

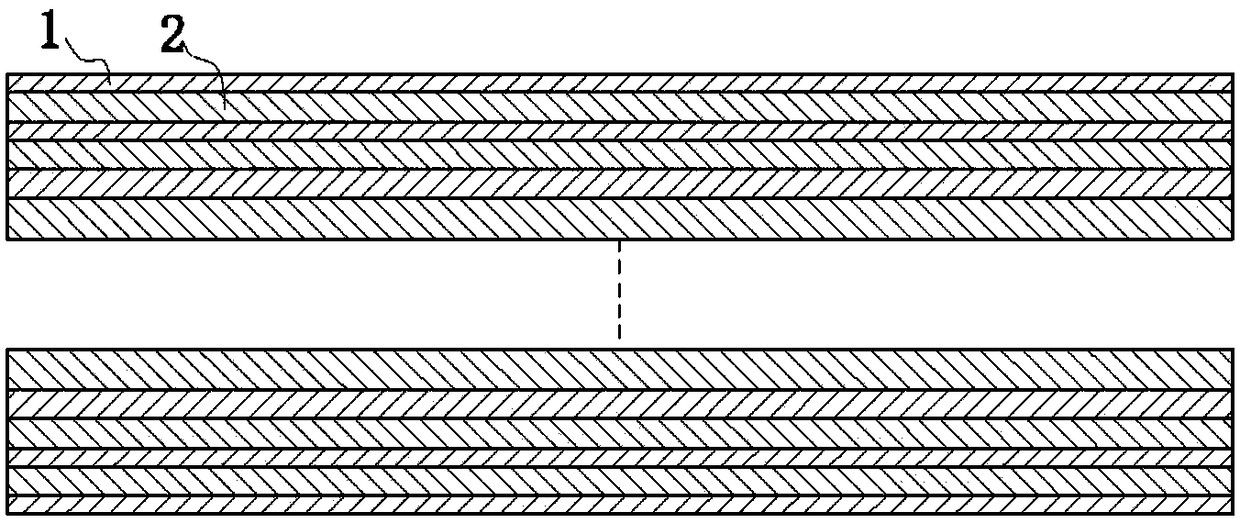

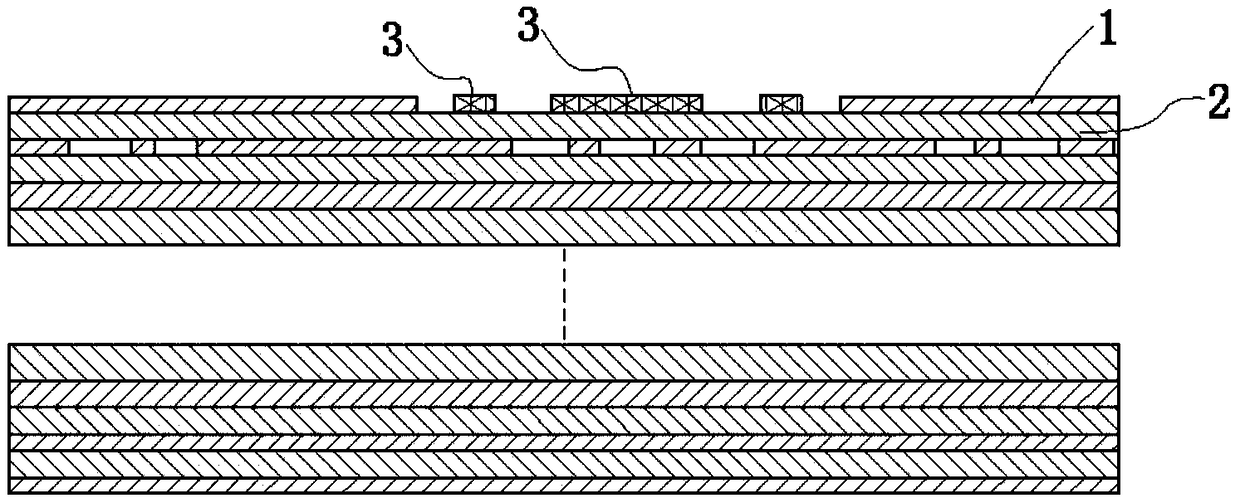

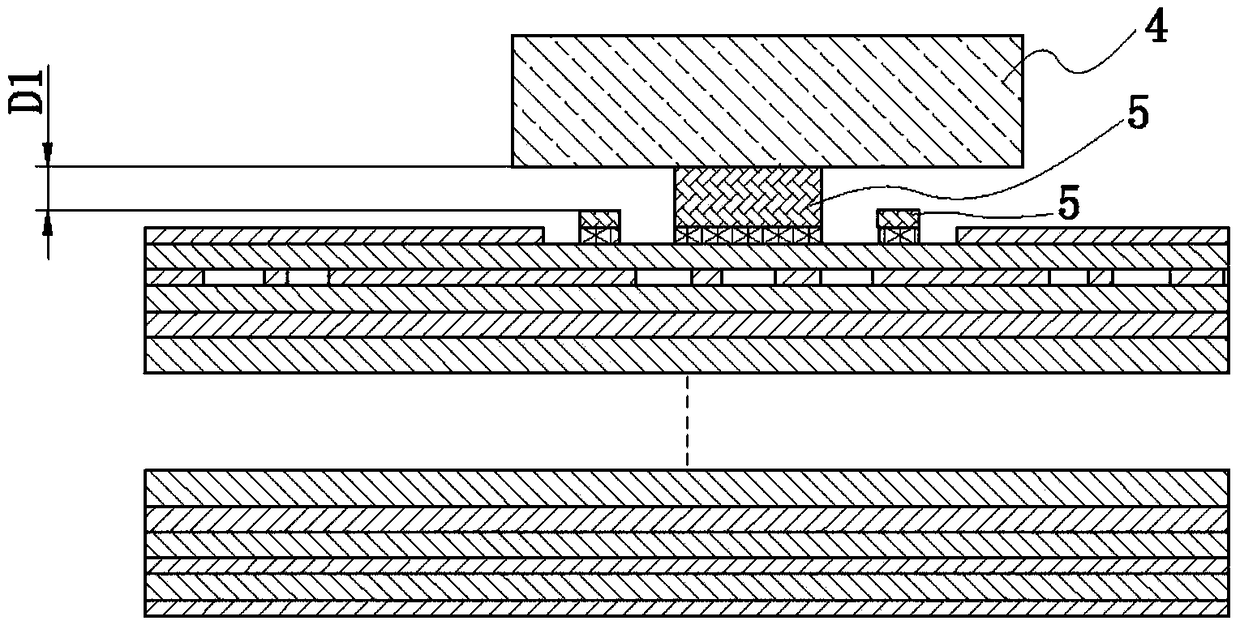

Manufacturing method of asymmetric plate

ActiveCN111511129AReduce warpageSolve WeldingPrinted circuit aspectsPrinted circuits stress/warp reductionDaughterboardSoldering

The invention is applicable to the technical field of circuit plate manufacturing, and provides a manufacturing method of an asymmetric plate. The manufacturing method of the asymmetric plate comprises the steps of manufacturing a mother plate, manufacturing a second daughter plate, carrying out thermal compression bonding on the mother plate and the second daughter plate, finished plate milling,and further comprises at least one of the three steps of laying copper on the connection positions, except the second copper layer on the outermost layer, of the mother plate to obtain a copper layingarea, digging copper at the connection position of a third copper layer protection layer when the second daughter plate is manufactured and performing depth control milling on each spliced plate fromone side of the second core plate at the connection position to obtain a depth control groove after the finished plate is milled.Any one of the three steps is beneficial to reducing the warping degree of the asymmetric plate after being heated, so that the problems of pseudo soldering and desoldering of a customer after a circuit plate finished product is assembled are solved, and the reliabilityof the product is improved.

Owner:SHENZHEN KINWONG ELECTRONICS

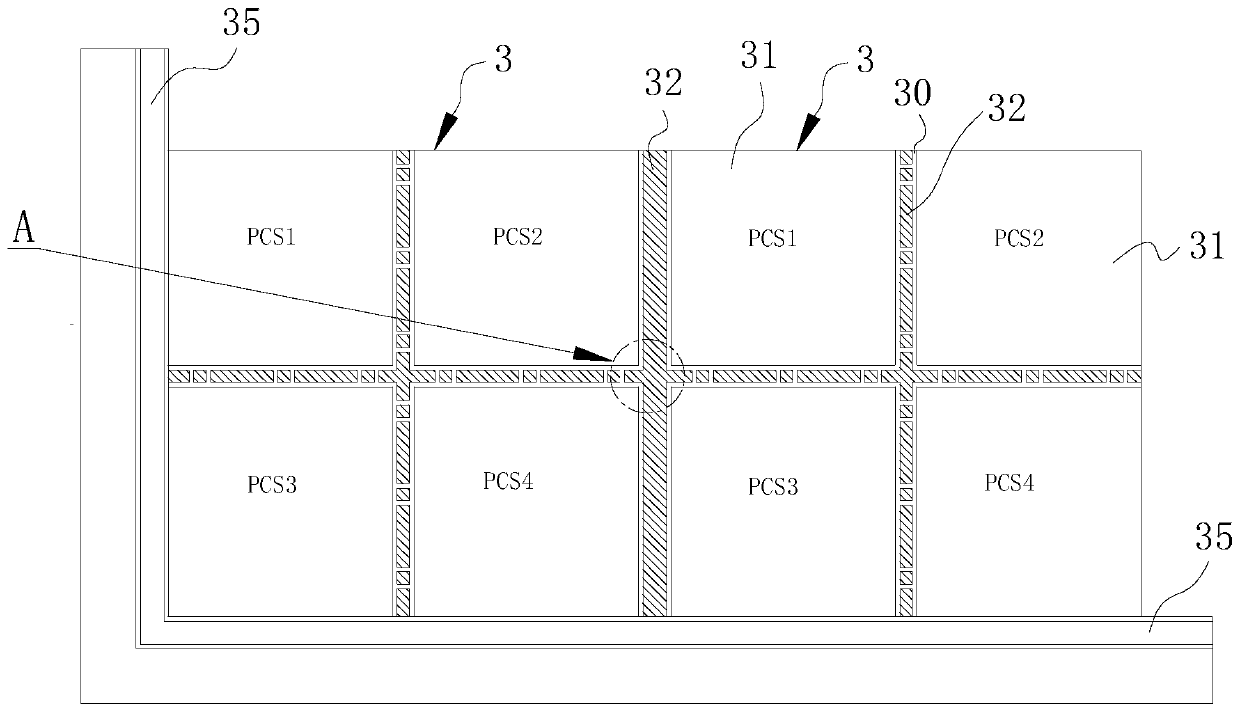

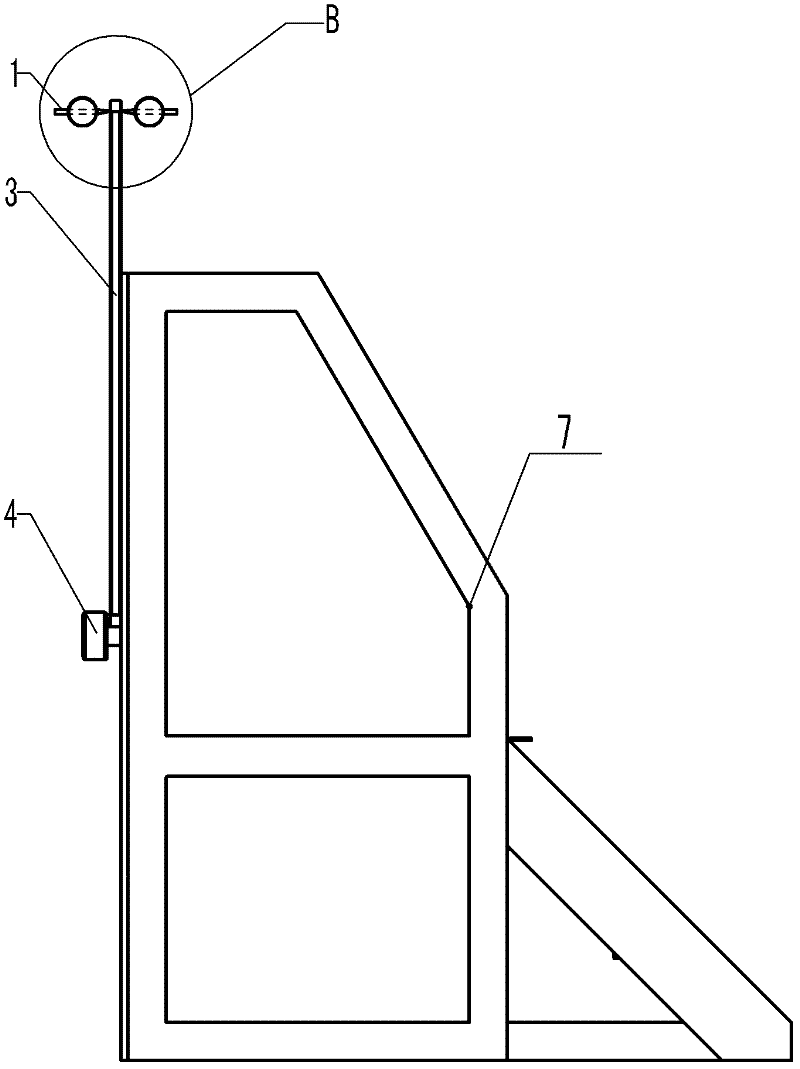

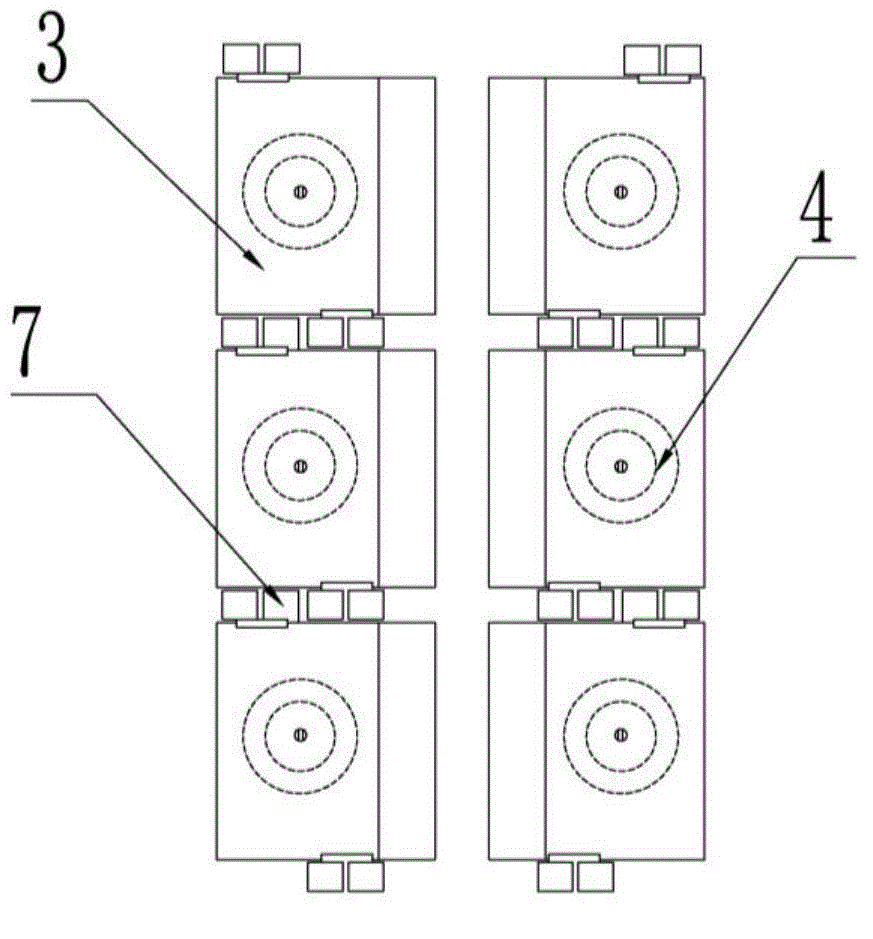

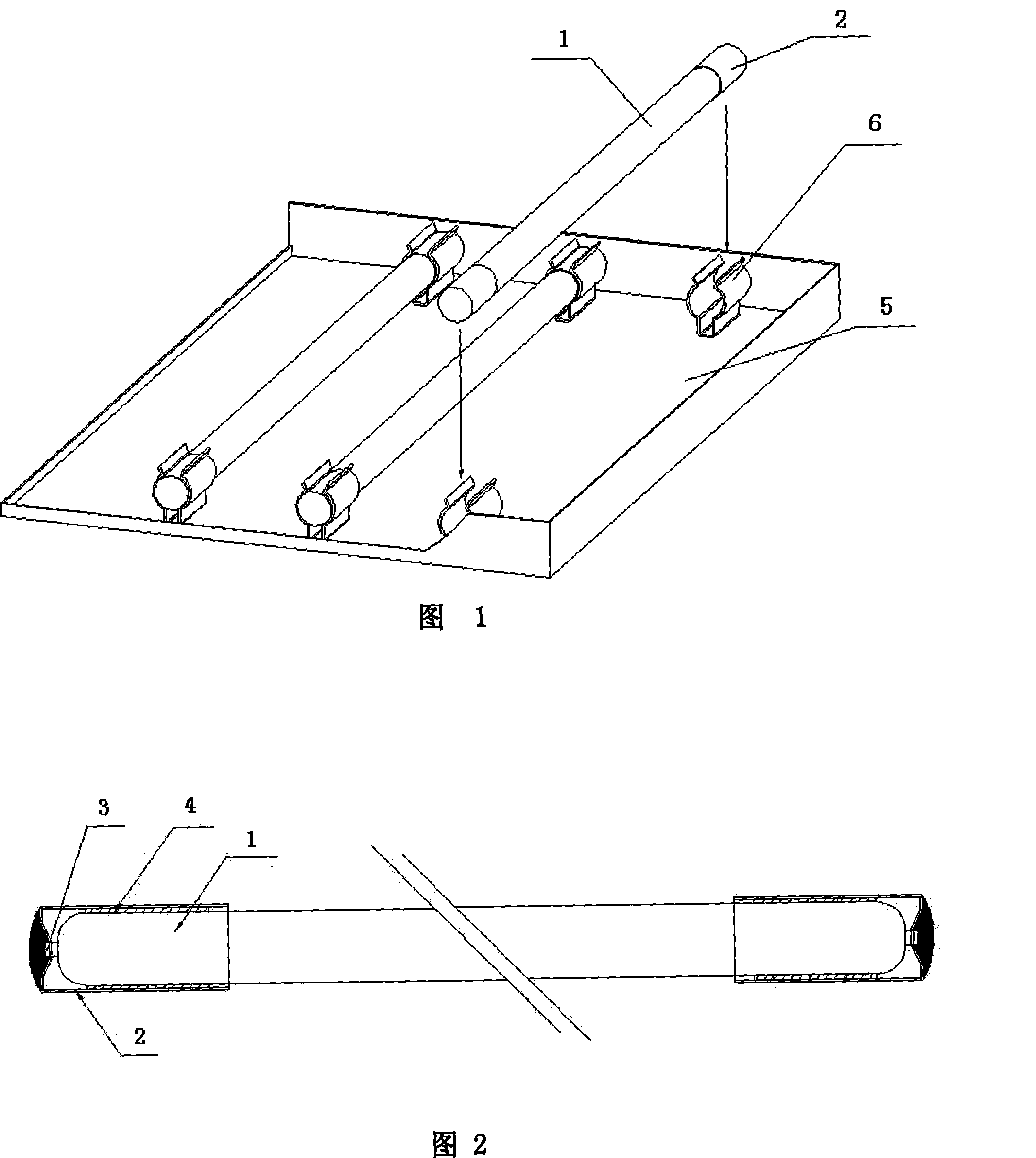

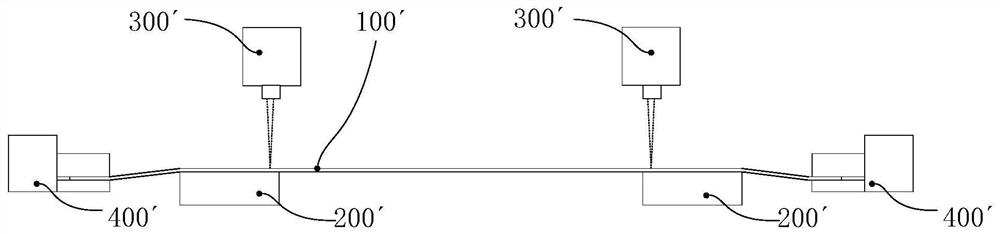

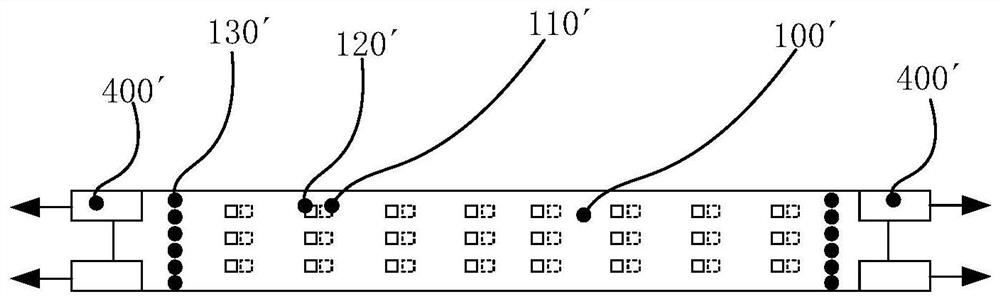

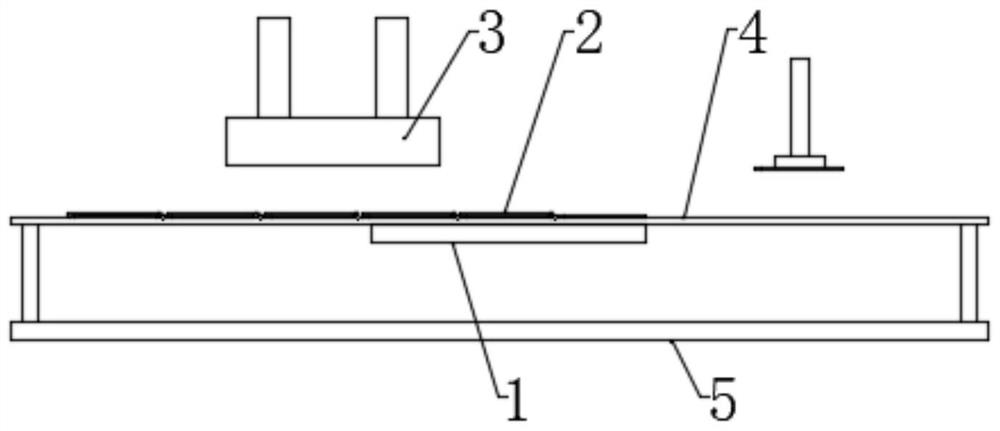

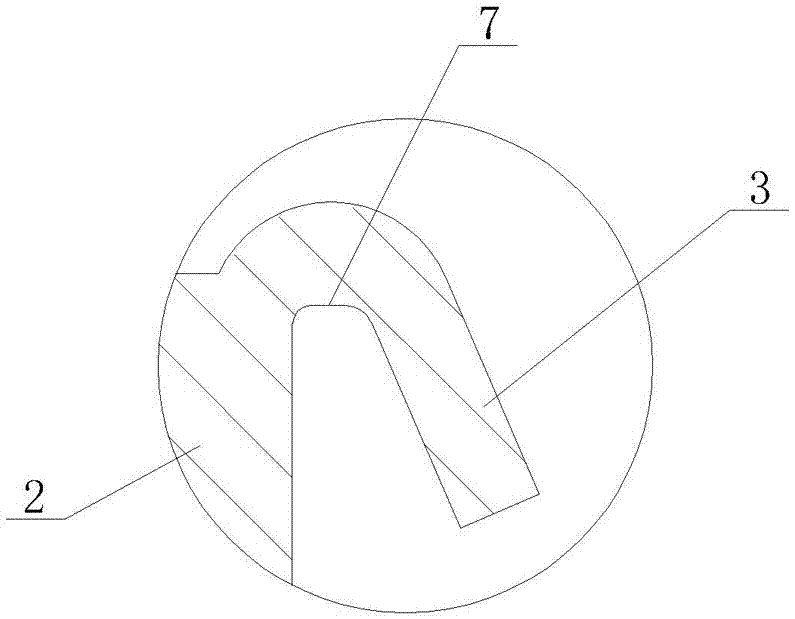

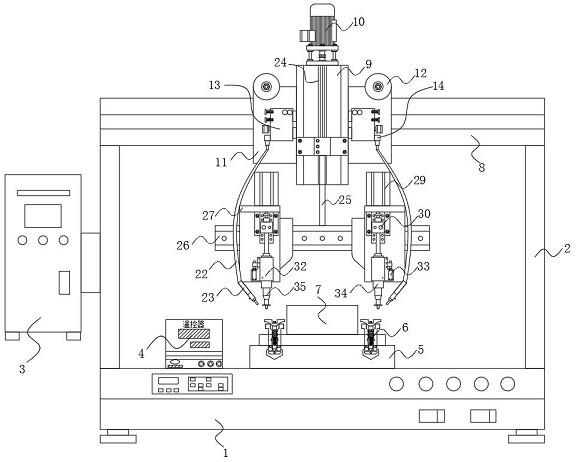

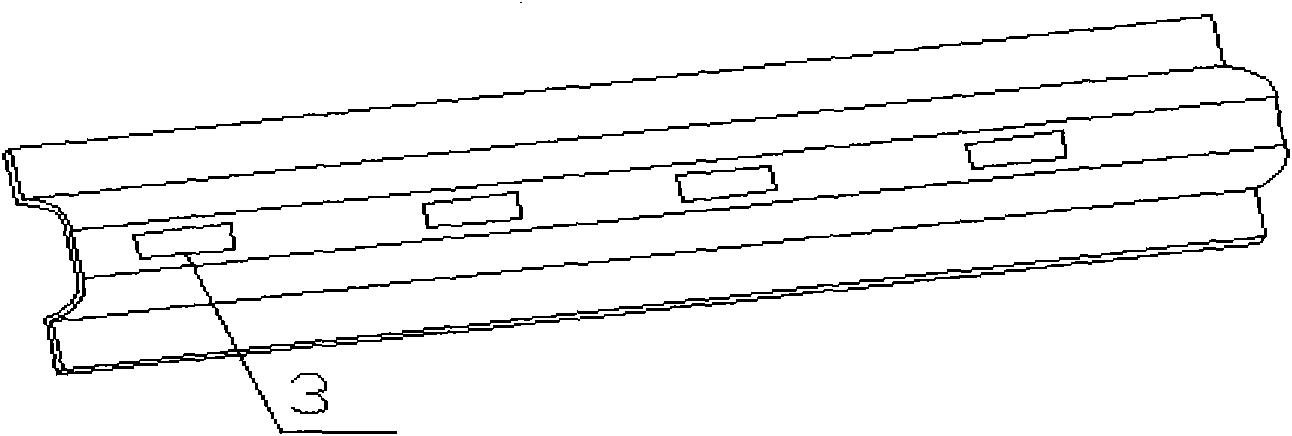

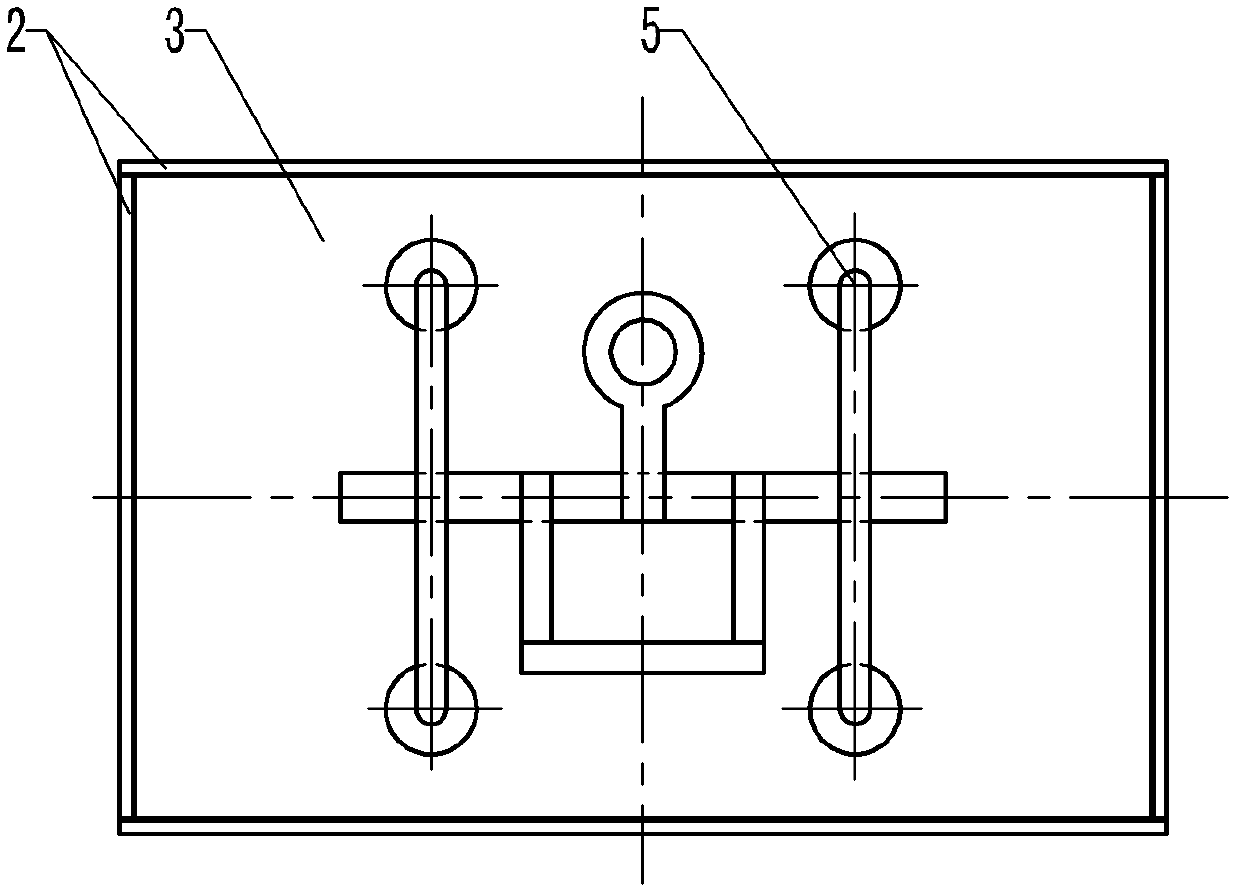

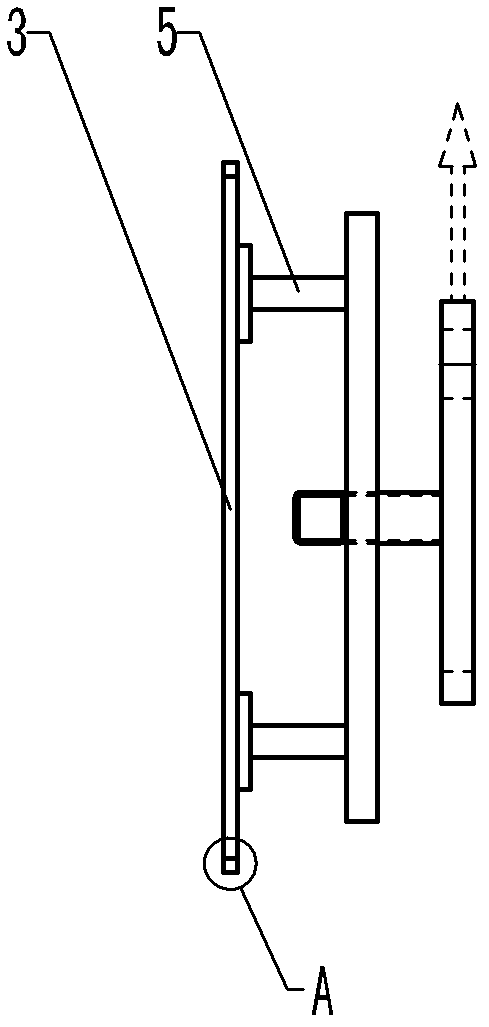

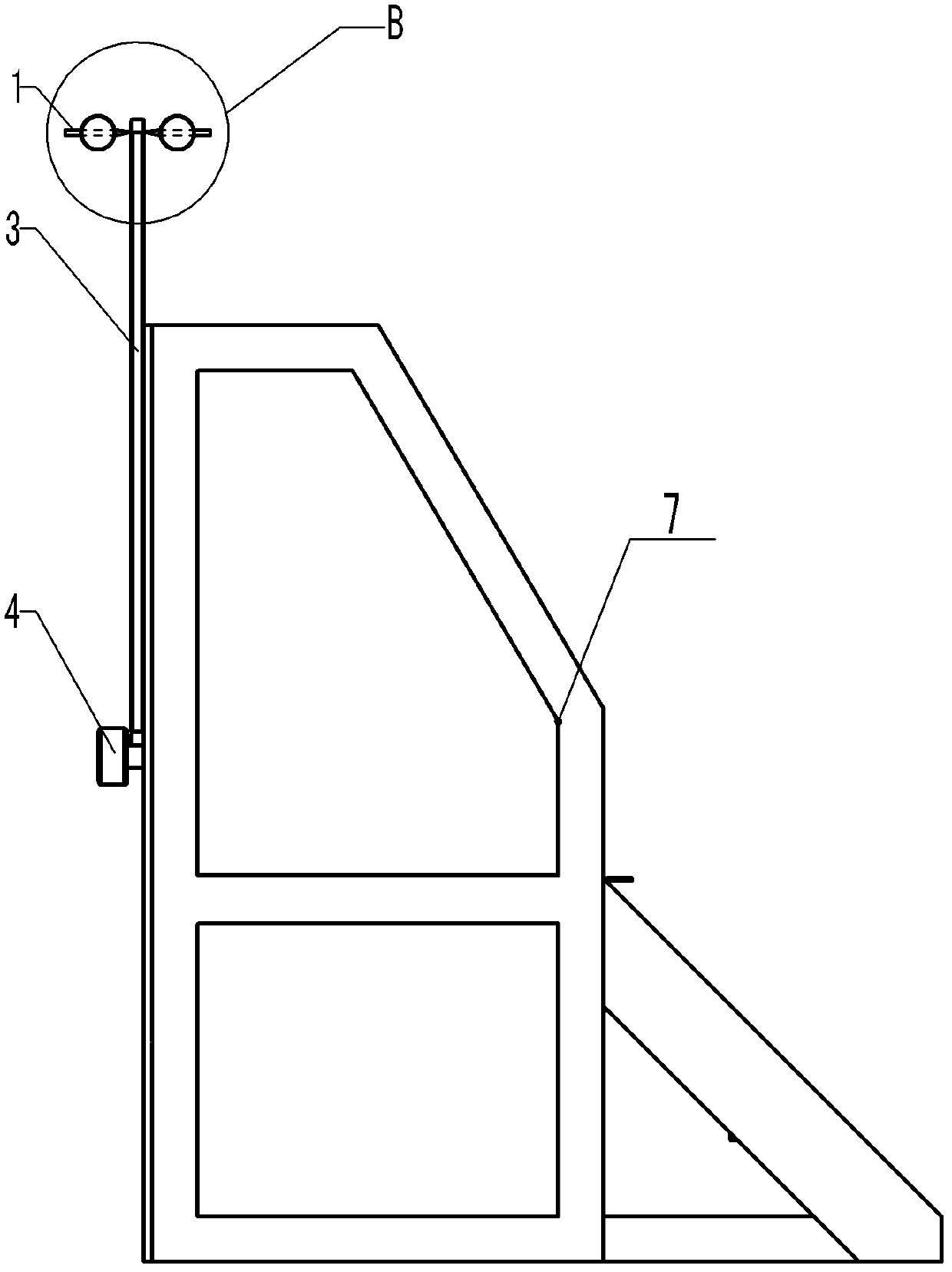

Technology and device for welding periphery of plate layer of vacuum freeze dryer

ActiveCN102357743APracticalSolve scrapWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a technology and a device for welding the periphery of a plate layer of a vacuum freeze dryer, belonging to the technical field of pharmaceutical machinery welding. The technology comprises the following steps of: 1.1, welding and fixing a plate layer (3) and edge steel (2) by using an argon arc point welding mode; 1.2, moving a movable workbench (7) to a proper position, and tightly pressing the plate layer (3) through a pressing mechanism (11); 1.3, carrying out fine-adjusting on the height of welding guns (1), and moving the welding guns (1) to the outside of the plate layer (3) through a welding gun moving unit (9); 1.4, igniting the two welding guns (1) arranged at two sides of the plate layer (3) at the same time, carrying out self-fusing welding at first andthen carrying out wire filling welding; 1.5, hoisting the plate layer (3) again, and welding another welded wire in the same way; and 1.6, repeating the welding process in step 1.3 for a plurality oftimes until gradual welding is completed. The invention has the advantages that the technology process is simple, the plate layer is not easy to deform, the welded wire is even, the technology and the device are suitable for welding different specifications and sizes of plate layers and the like.

Owner:山东浩器生物装备技术有限公司

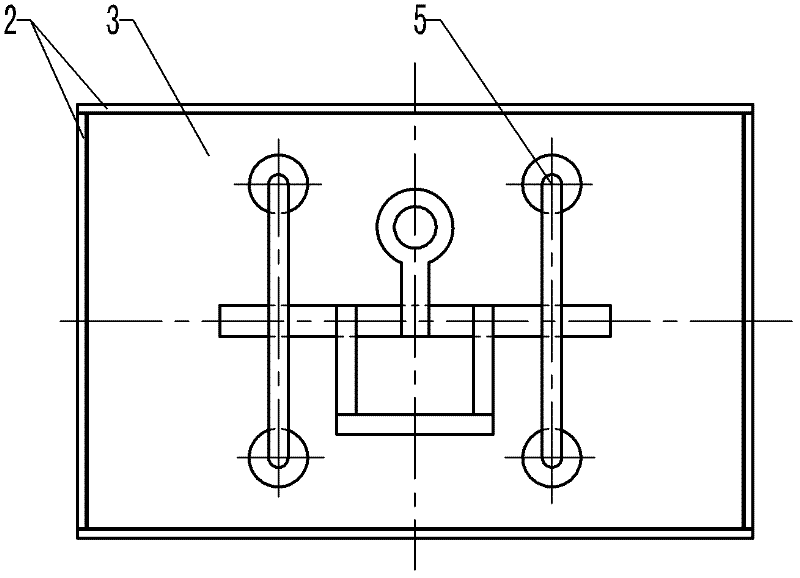

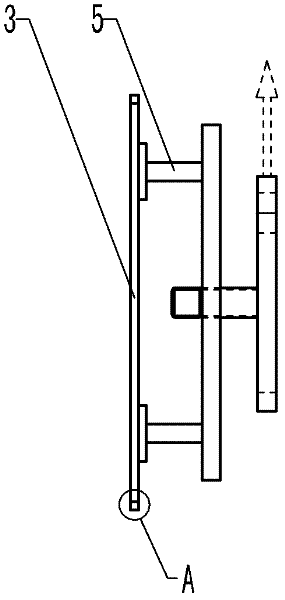

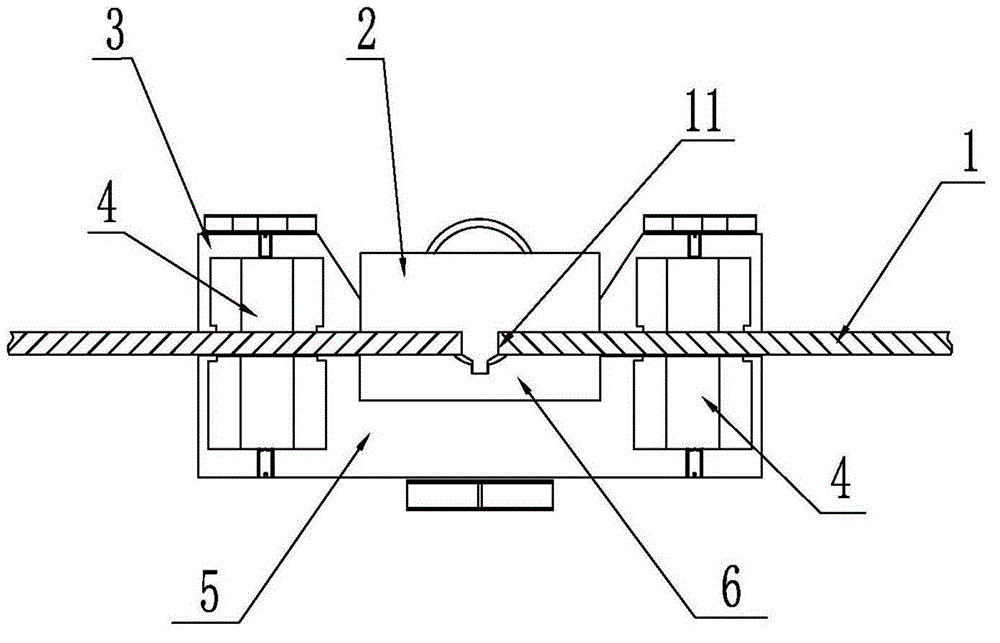

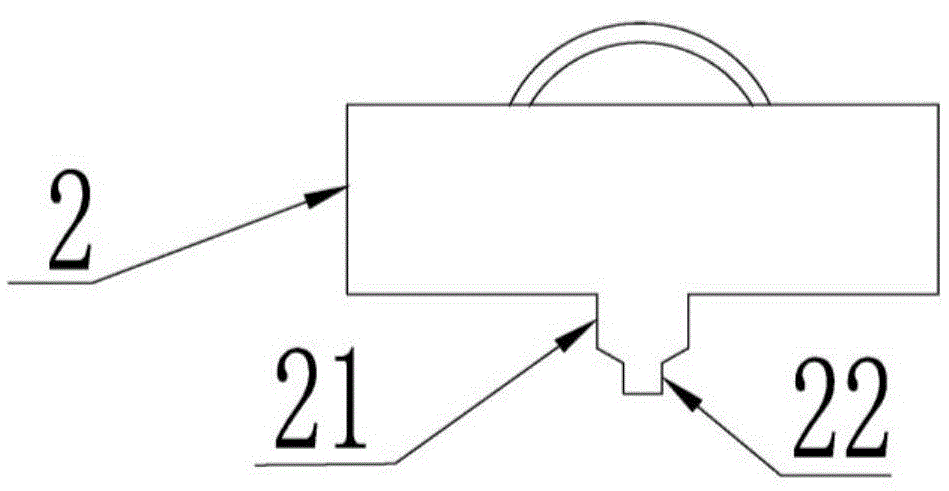

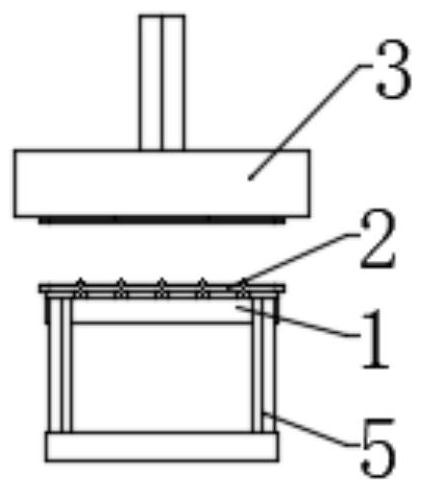

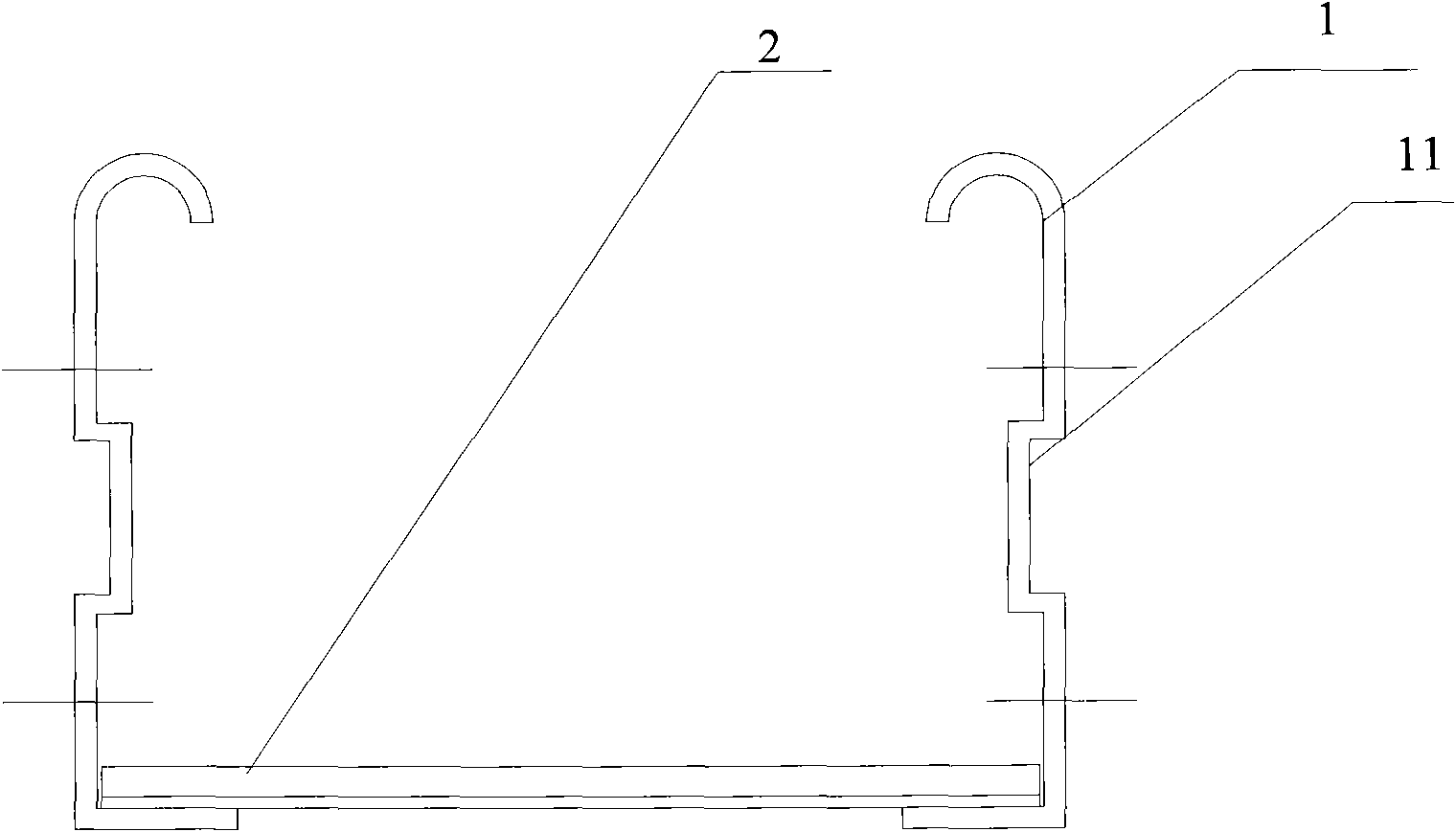

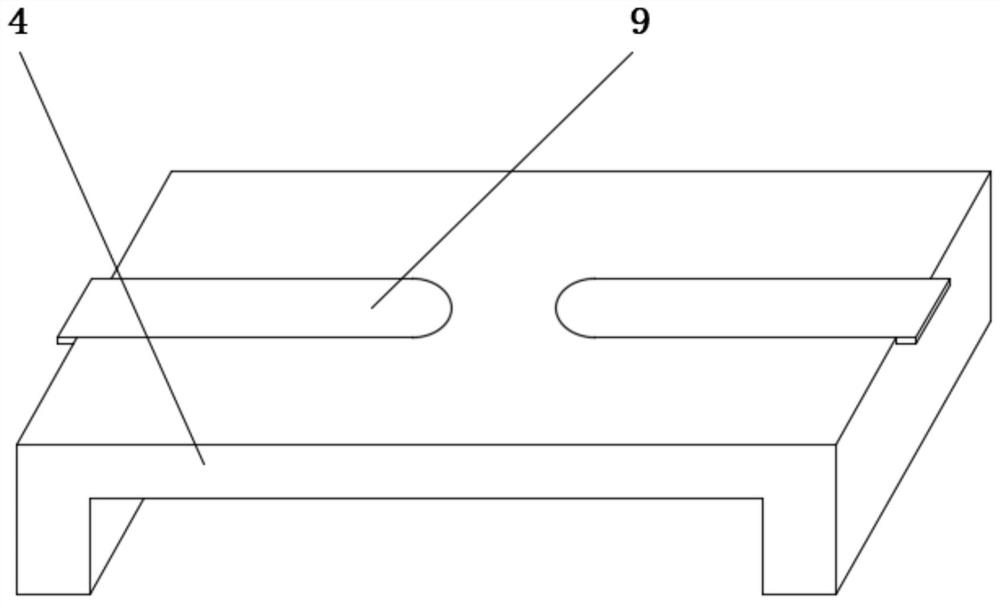

Device and method for controlling suspension welding seam root gap and welding deformation in self-supporting mode

ActiveCN104625318AWell formedEasy to useWelding/cutting auxillary devicesArc welding apparatusEngineeringWeld seam

The invention discloses a device and method for controlling a suspension welding seam root gap and welding deformation in a self-supporting mode. The device comprises a positioning block, upper rigid press blocks, a lower rigid press block and a forming groove. The positioning block comprises a positioning block body and a positioning part, wherein the positioning part penetrates through the seam root gap and is embedded in the forming groove. The upper rigid press blocks are symmetrically installed on the two sides of the positioning block body, the lower rigid press block is provided with provided with an inward-concave part matched with the forming groove, and the forming groove is formed in the inward-concave part. Magnets are installed in the upper rigid press blocks and the lower rigid press block. The invention further discloses the method with the device for controlling the suspension welding seam root gap and the welding deformation in the self-supporting mode used. The device for controlling the suspension welding seam root gap and the welding deformation in the self-supporting mode is convenient to use, low in cost and high in adaptation, the transverse retraction and staggered edges of a welding seam can be controlled, the welding deformation can be reduced, and it can be ensured that the back face of the welding seam is good in formation.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

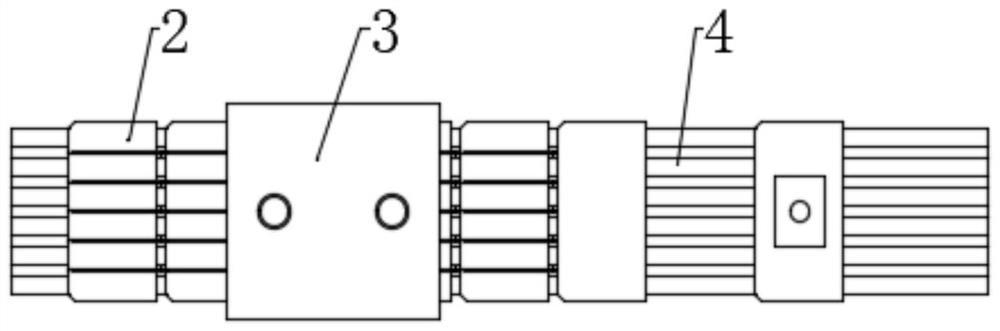

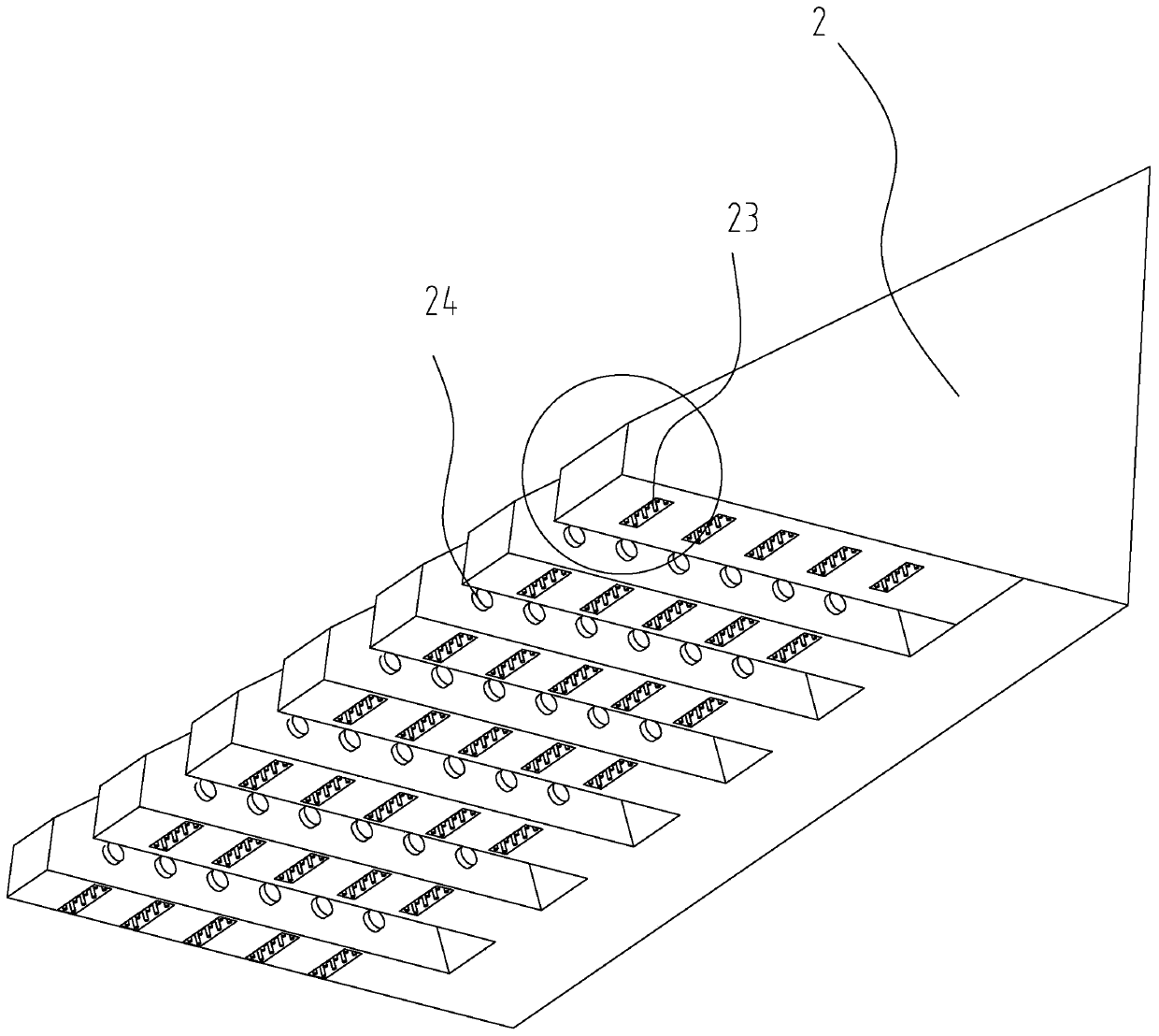

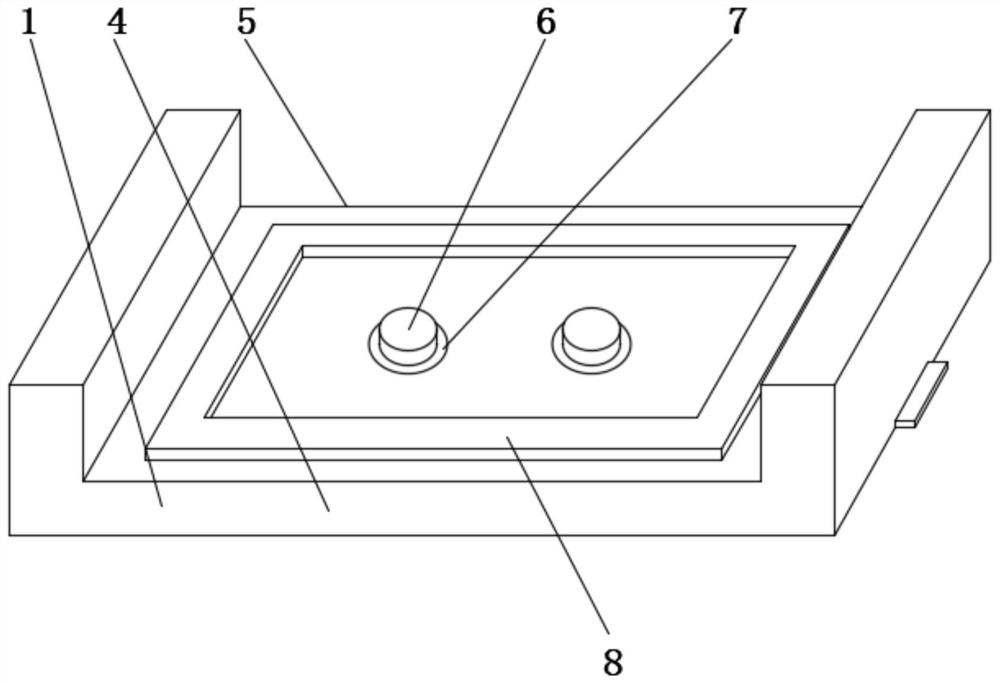

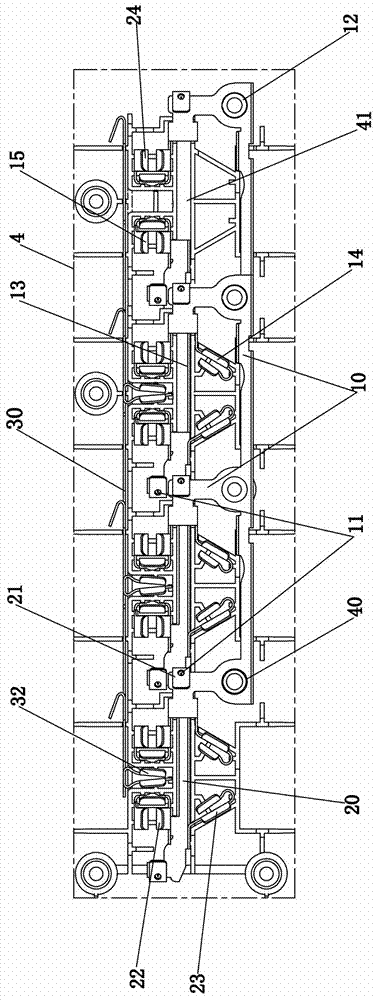

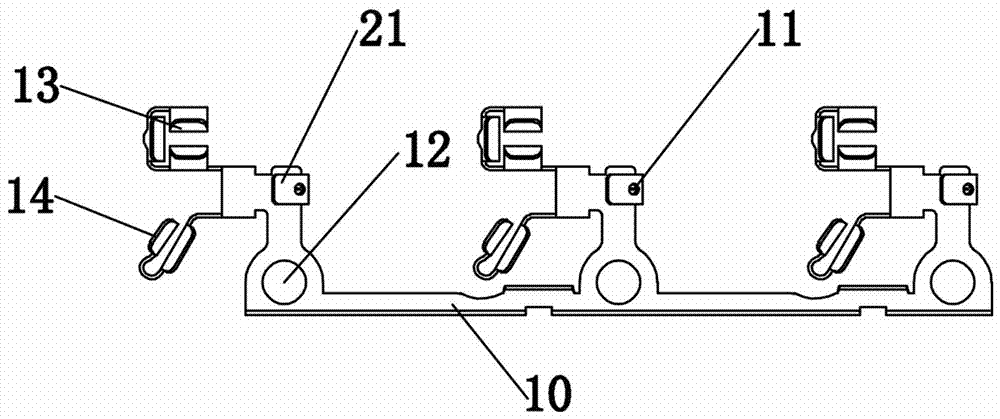

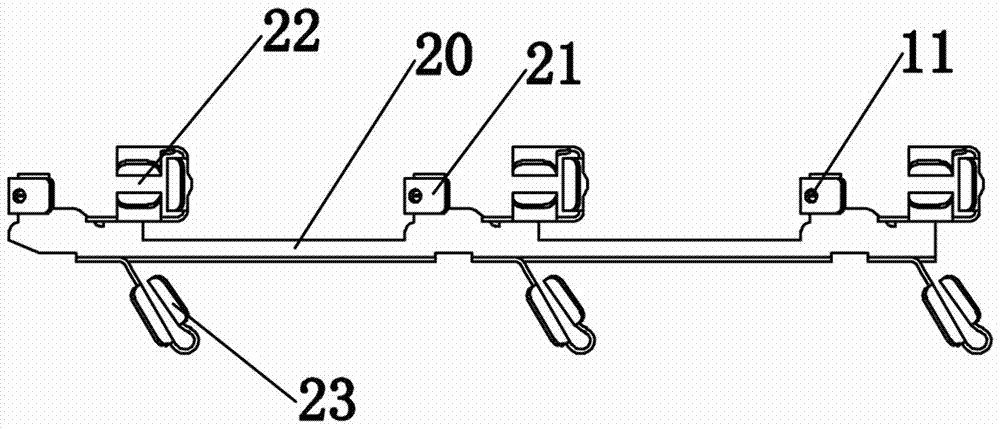

Backflow carrier

ActiveCN111940863AControl compressionFirmly connectedMetal working apparatusSoldering auxillary devicesEngineeringLead frame

The invention discloses a backflow carrier, and relates to the technical field of automobile-level intelligent power semiconductor module manufacturing. The problem that pins of a high-hardness lead frame are prone to cold solder joint due to uneven heights of the pins is solved. The backflow carrier comprises a backflow carrier bottom plate and a backflow carrier metal cover plate; the backflow carrier bottom plate comprises a substrate limiting groove, a frame limiting groove, a coarse positioning groove and a fine positioning pin; the substrate limiting groove is used for arranging a heat dissipation substrate, the frame limiting groove is used for arranging a high-hardness lead frame, and the coarse positioning groove and the fine positioning pin are used for arranging the backflow carrier metal cover plate; the backflow carrier metal cover plate comprises an operation handle, first protruding blocks and a first pressure connecting piece; the position of the operation handle corresponds to the position of the coarse positioning groove; the plurality of first protruding blocks are in contact with the upper surfaces of pin wires included in the high-hardness lead frame respectively; and the first pressure connecting piece is matched with a second pressure connecting piece arranged on the backflow carrier bottom plate to fix the backflow carrier metal cover plate to the backflow carrier bottom plate.

Owner:华羿微电子股份有限公司

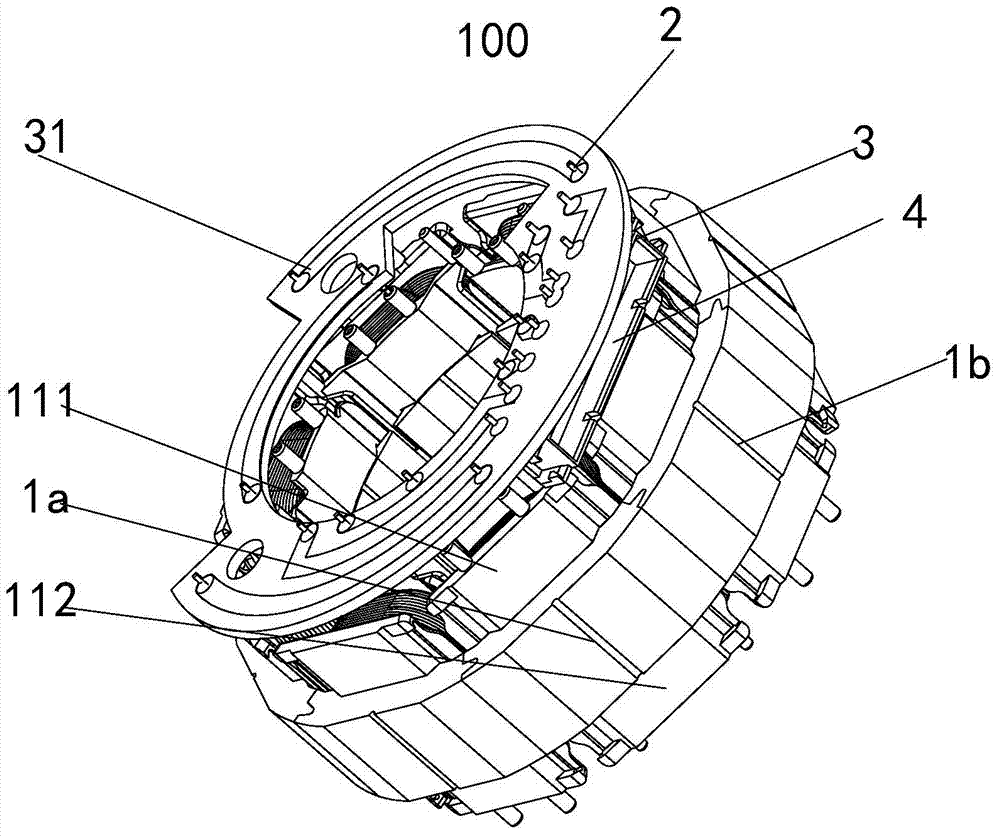

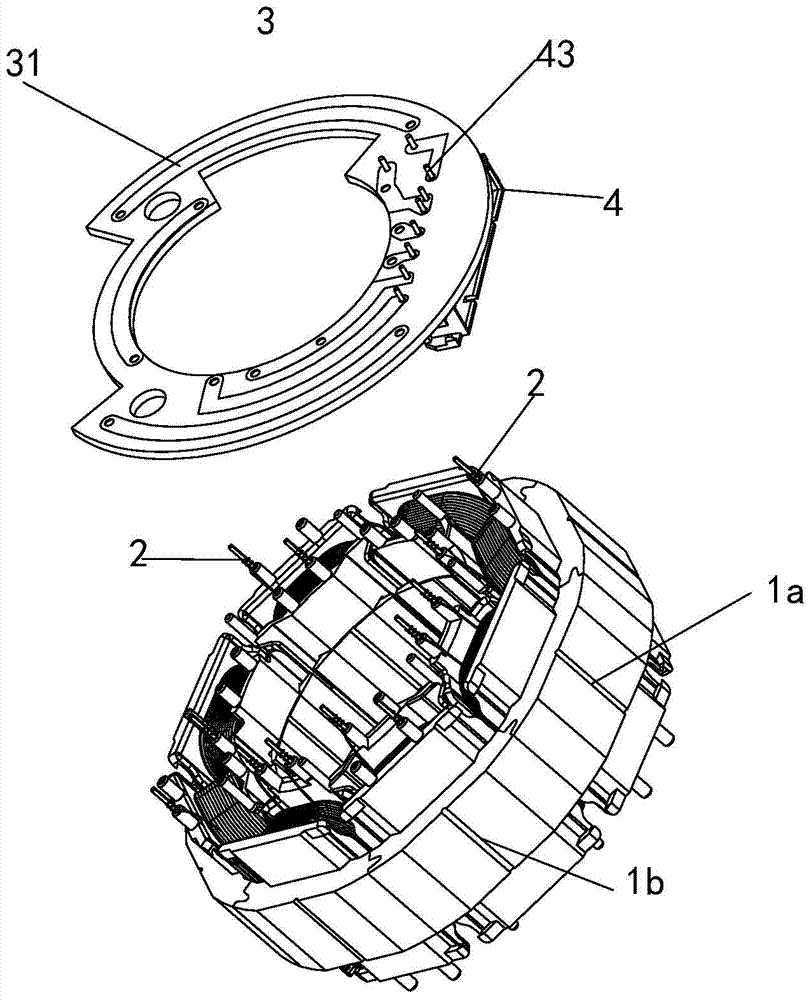

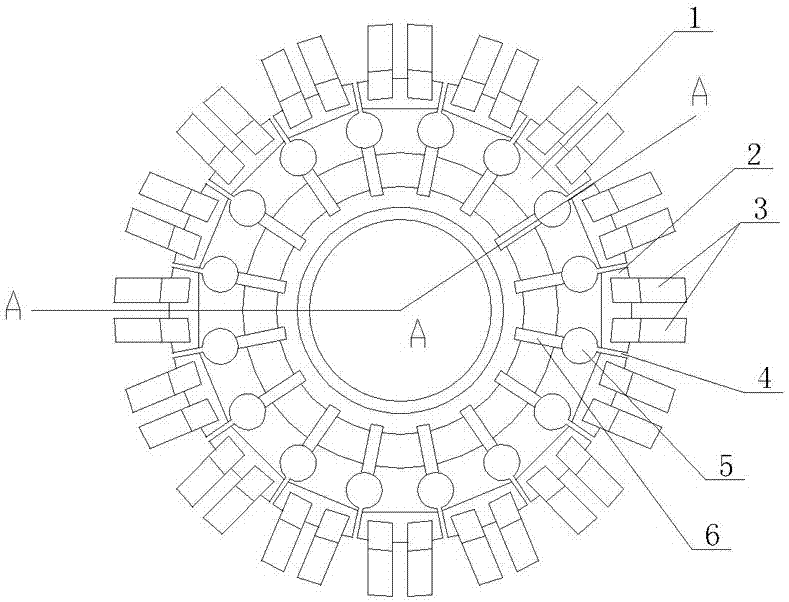

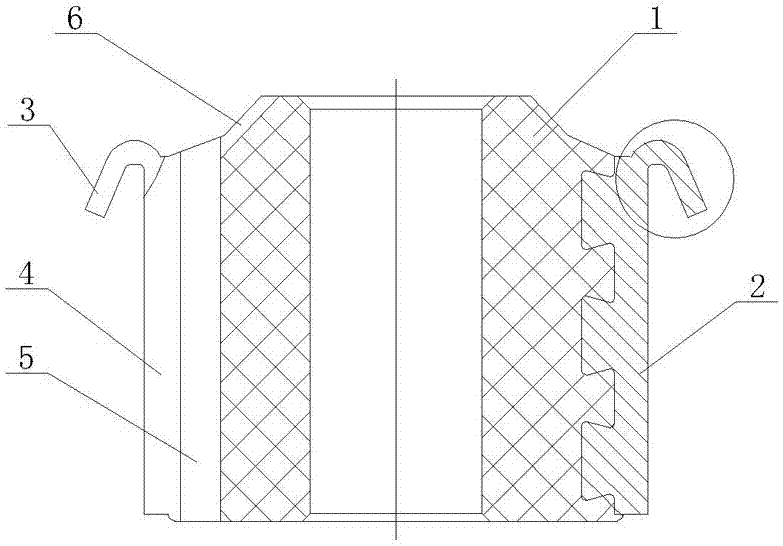

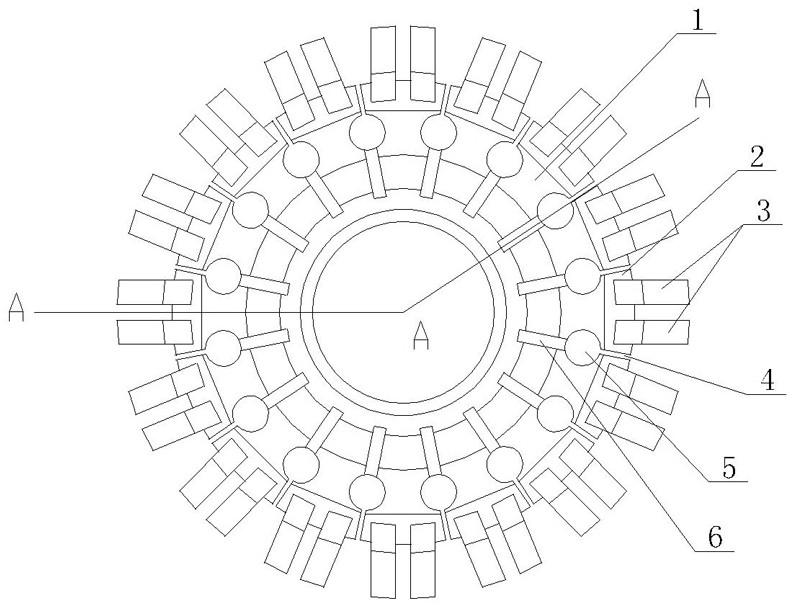

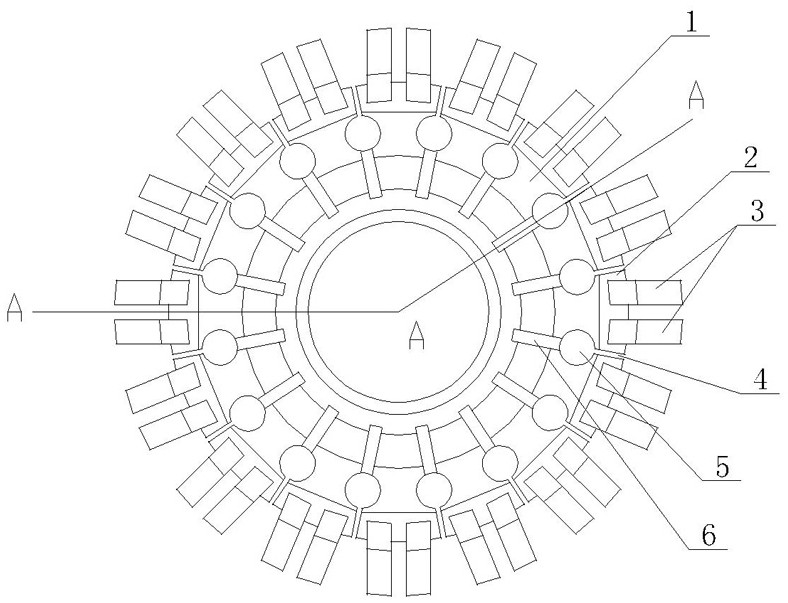

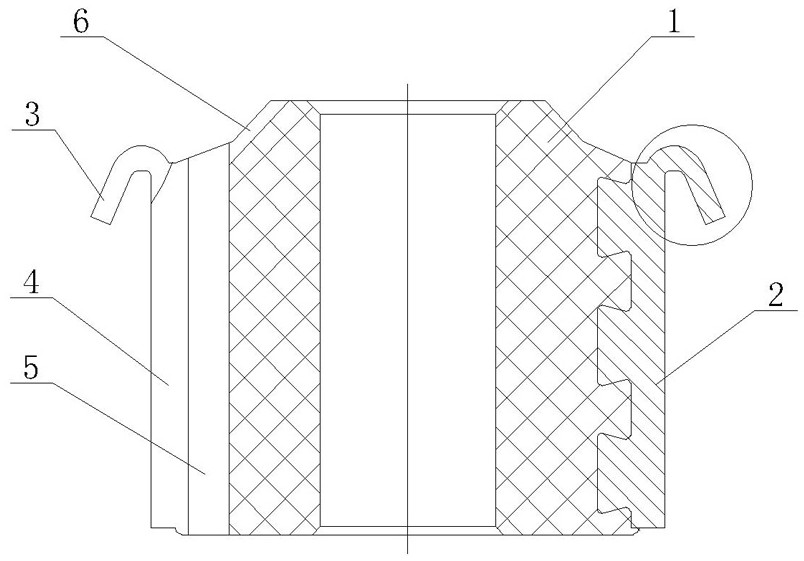

Block stator and motor with the same

ActiveCN104734388ASolve WeldingAvoid warpingMagnetic circuit stationary partsWindings conductor shape/form/constructionEngineeringExternal circuit

The invention discloses a block stator and a motor with the block stator. The block stator comprises a plurality of main windings, a plurality of auxiliary windings, a plurality of wire winding needles, a wiring board, a female connector and a male connector, wherein block iron cores of the main windings and block iron cores of the auxiliary windings are connected in a staggered mode into an annular shape in the circumferential direction, the wire winding needles are arranged on a plurality of wire winding frames respectively, the wiring board is installed on the main windings and the auxiliary windings, the upper ends of the wire winding needles penetrate through the wiring board, the female connector is arranged on the side, facing the main windings and the auxiliary windings, of the wiring board, and the male connector is used for being electrically connected with an external circuit. According to the block stator, the firmness and the reliability of the male connector are ensured, and the problem that a traditional connector is warped and disengaged due to stress is solved; furthermore, the wave soldering technology can be achieved, and the defects such as cold joints and solder skips in the soldering process of the wiring board are effectively overcome.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

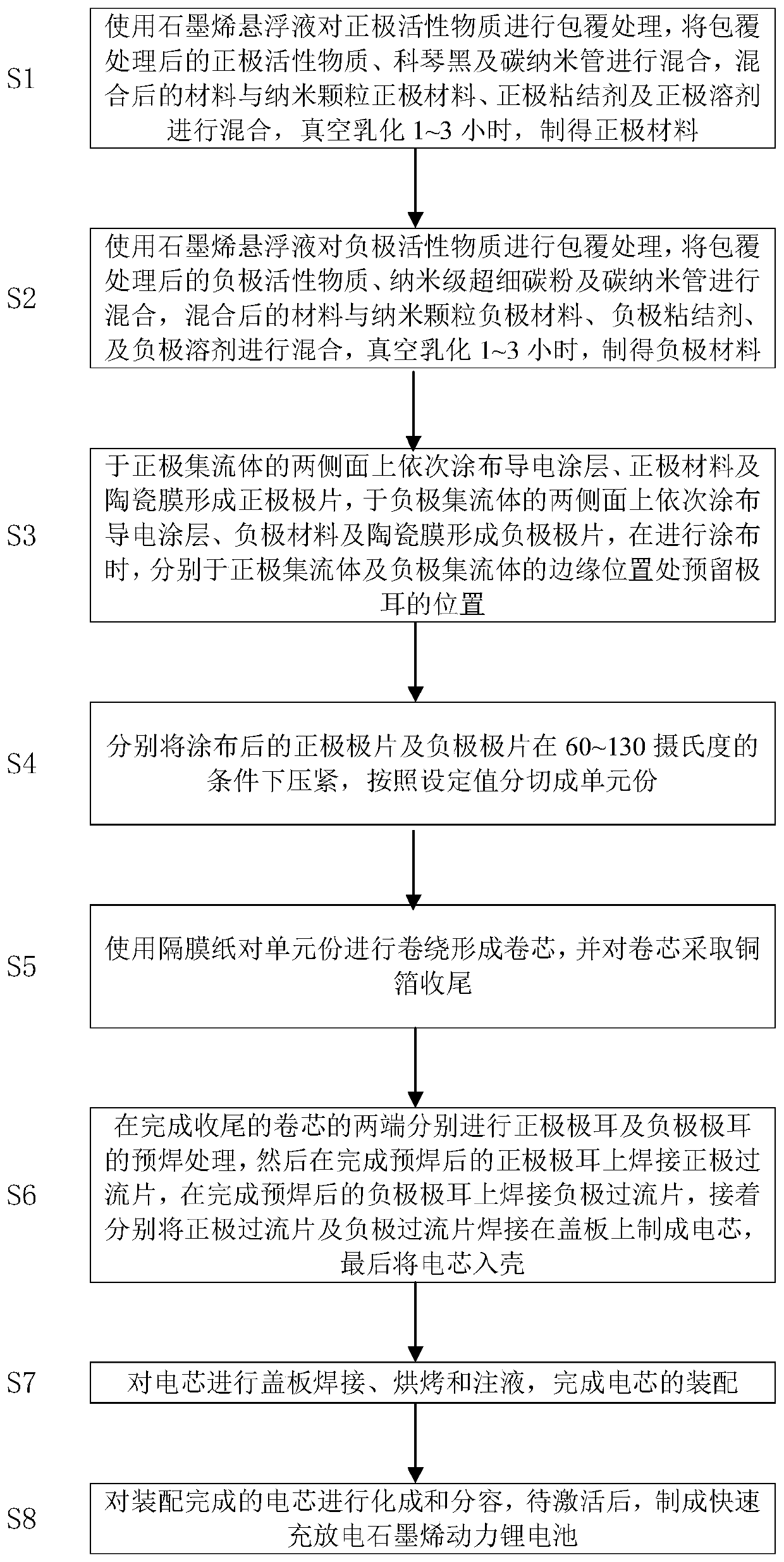

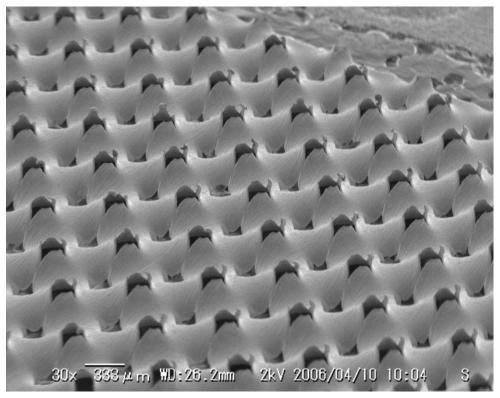

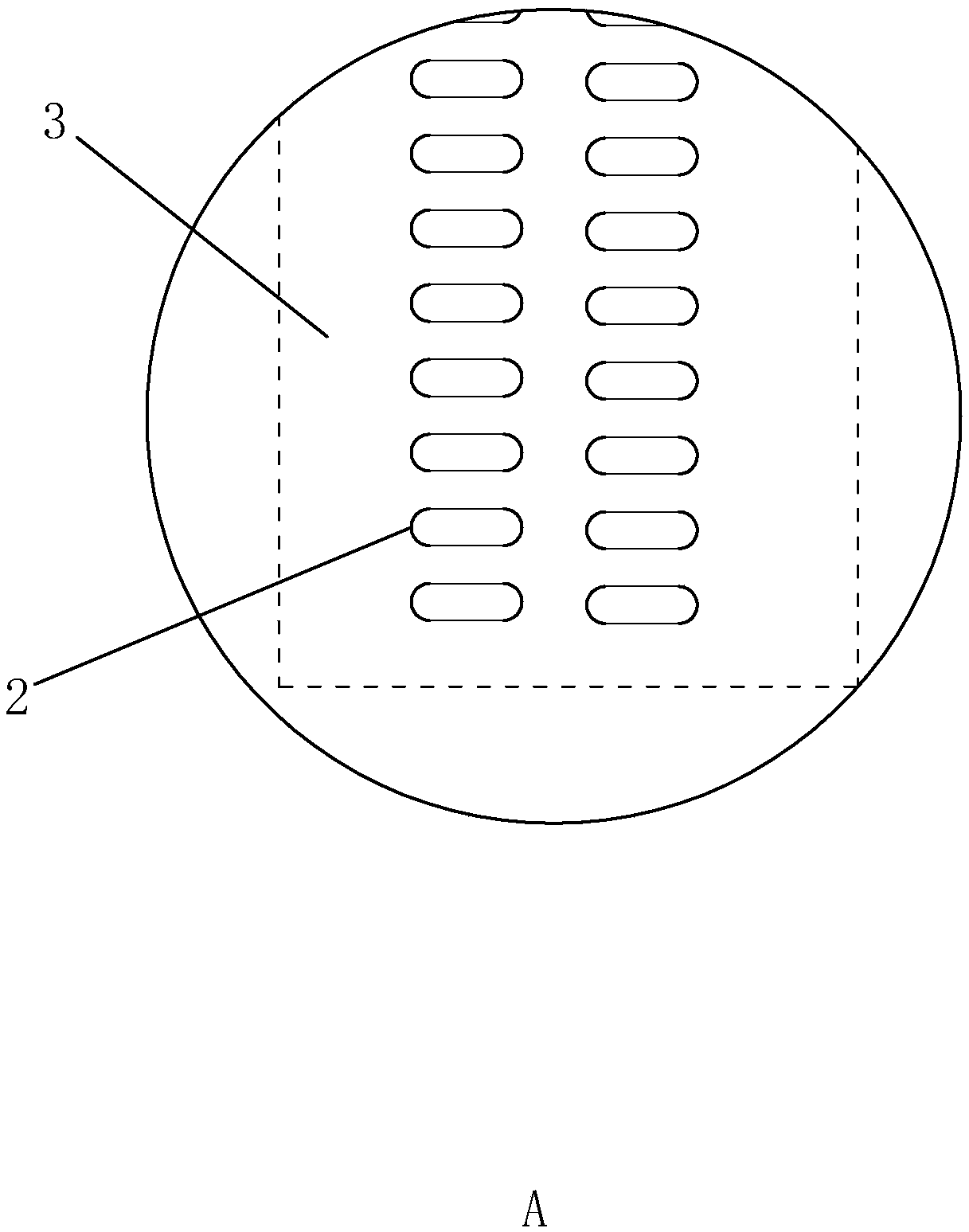

Rapid charging and discharging graphene power lithium battery and preparation method thereof

PendingCN111180730AImprove conductivityHigh resistivityFinal product manufactureElectrode carriers/collectorsGraphene coatingConductive coating

The invention discloses a rapid charging and discharging graphene power lithium battery and a preparation method thereof. The battery comprises a battery housing and a battery core accommodated in thebattery housing. The battery core comprises a positive pole piece, a negative pole piece and a diaphragm; the positive pole piece comprises a positive pole current collector and positive pole material coatings respectively coated on two side surfaces of the positive pole current collector; the negative pole piece comprises a negative pole current collector and negative pole material coatings respectively coated on two side surfaces of the negative pole current collector; a conductive coating and a ceramic membrane are coated between the positive pole current collector and the positive pole material coating, a conductive coating and a ceramic membrane are coated between the negative pole current collector and the negative pole material coating, and the conductive coating is a CNT / graphenecoating; a positive pole active substance in a positive pole conductive agent in the positive pole material coating and a negative pole active substance in a negative pole conductive agent in the negative pole material coating are respectively subjected to coating treatment by graphene suspension liquid; and the positive and negative pole current collectors comprise a plurality of through holes which are arranged in a matrix and penetrate through the upper and lower surfaces of the substrate.

Owner:王立军

Cold cathode fluorescent lamp tube for dismountable LCD TV

InactiveCN101241832AReduce the chance of breakageAvoid damageLighting support devicesElectric discharge tubesFluorescenceCold cathode

The invention discloses a cold cathode fluorescent lamp tube for a detachable liquid crystal television, having a metal cap whose surface is silver layer, tin layer or other conductive metal layer. A metal cap is sleeved on the top of the lamp tube. The lamp tube electrode tip wire is welded with the metal cap tip. The installation panel is designed into the metal spring clip or metal spring clamp. The lamp tube is installed in the middle of the metal spring clamp. The installation is finished. The inventive operation is simple and detachable, reduces the damage of the lamp tube during installation, improves the work efficiency. The original space occupied by the wire materials is completely unnecessary. The metal which is made of silver layer, tin layer or other conductive metal layer is easy to weld and has a good conductivity.

Owner:YICHANG JINSEN OPTRONICS TECH +1

A technology for bon a dual-row QFN integrated circuit

InactiveCN109152231AReduce volumeIncrease the tin climb heightPrinted circuit assemblingConductive pattern formationPeak valueEngineering

The invention relates to a welding process of a dual-row QFN integrated circuit, Circuit board weld field, The process comprises the following steps: S1) screen printing: brushing solder paste on thebonding pad of the circuit board by a screen printer, wherein the ratio of the area of the aperture in the fine pitch area to the area of the bonding pad of the circuit board is 0.85 to 0.95, the thickness of the steel plate is 0.09 to 0.11 mm, and the ratio of the thickness of the fine pitch area to the thickness of the steel plate is 0.85 to 0.95; The printing speed of screen printer is 30-40mm / s, the pressure of front and back scraper is 2.5-3.5 kg, the demoulding length is 1.4-1.6 mm, and the demoulding speed is 0.4-0.6 mm / s. 2) mount: mounting with a mount machine; S3) reflow soldering: reflow soldering is carried out by using a reflow soldering equipment, wherein the temperature peak value of the reflow soldering is 240 + / - 5 DEG C, the reflow time when the temperature is higher than217 DEG C is 30 to 60 seconds, and the temperature rise slope is less than or equal to 3 DEG C / s; S4) testing: testing the soldering quality and assembly quality of the assembled circuit board; S5) repairing: repairing the circuit board which is detected to be out of order, so as to improve the qualification rate of the double-row QFN integrated circuit.

Owner:成都京蓉伟业电子有限公司

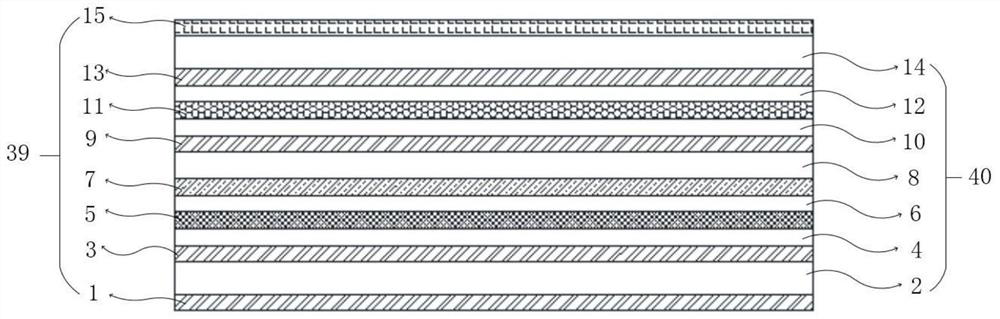

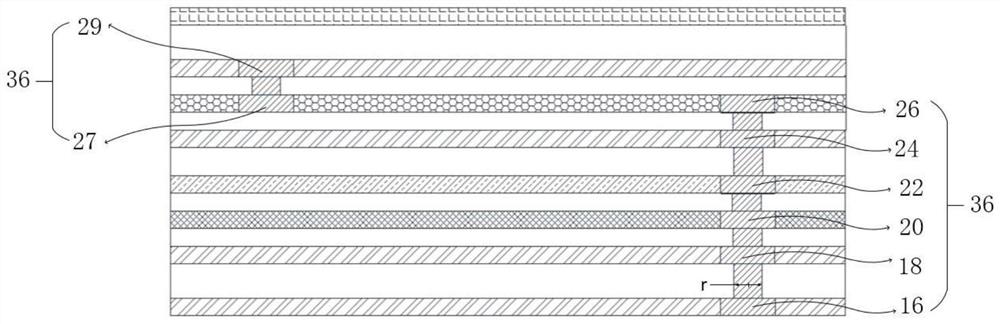

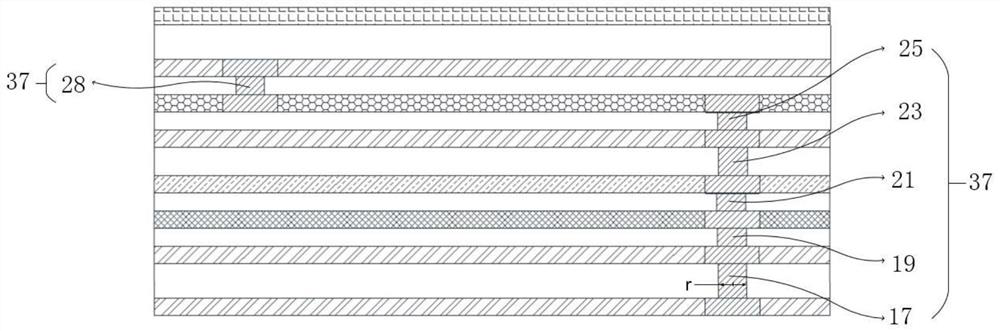

W-band millimeter wave chip multilayer dielectric substrate

ActiveCN113079623AImprove stabilitySolve WeldingCross-talk/noise/interference reductionPrinted circuit aspectsDielectric substrateEngineering

A W-band millimeter wave chip multilayer dielectric substrate comprises a first ground layer, a first dielectric layer, a second ground layer, a second dielectric layer, a control layer, a third dielectric layer, a power supply layer, a fourth dielectric layer, a third ground layer, a fifth dielectric layer, a radio frequency layer, a sixth dielectric layer, a fourth ground layer, a seventh dielectric layer and an antenna layer. The fourth ground layer is connected with the second end of the radio frequency layer through a vertical through hole; the first end of the radio frequency layer is connected with the third ground layer, the power supply layer, the control layer, the second ground layer and the first ground layer through vertical through holes; the radio frequency layer is of a multi-section microstrip line structure with different impedances. The structure of the metal layer is reasonably planned, the radio frequency layer is arranged between the two ground layers, and the shielding columns are arranged around the signal transmission structure, so that high-density wiring is carried out between the same layer or different layers while the anti-interference performance of radio frequency signals is guaranteed, and the dielectric substrate is suitable for the application scene of the antenna and chip integrated packaging interconnection structure. And the requirements of complex functions, high integration level and light weight at present are met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

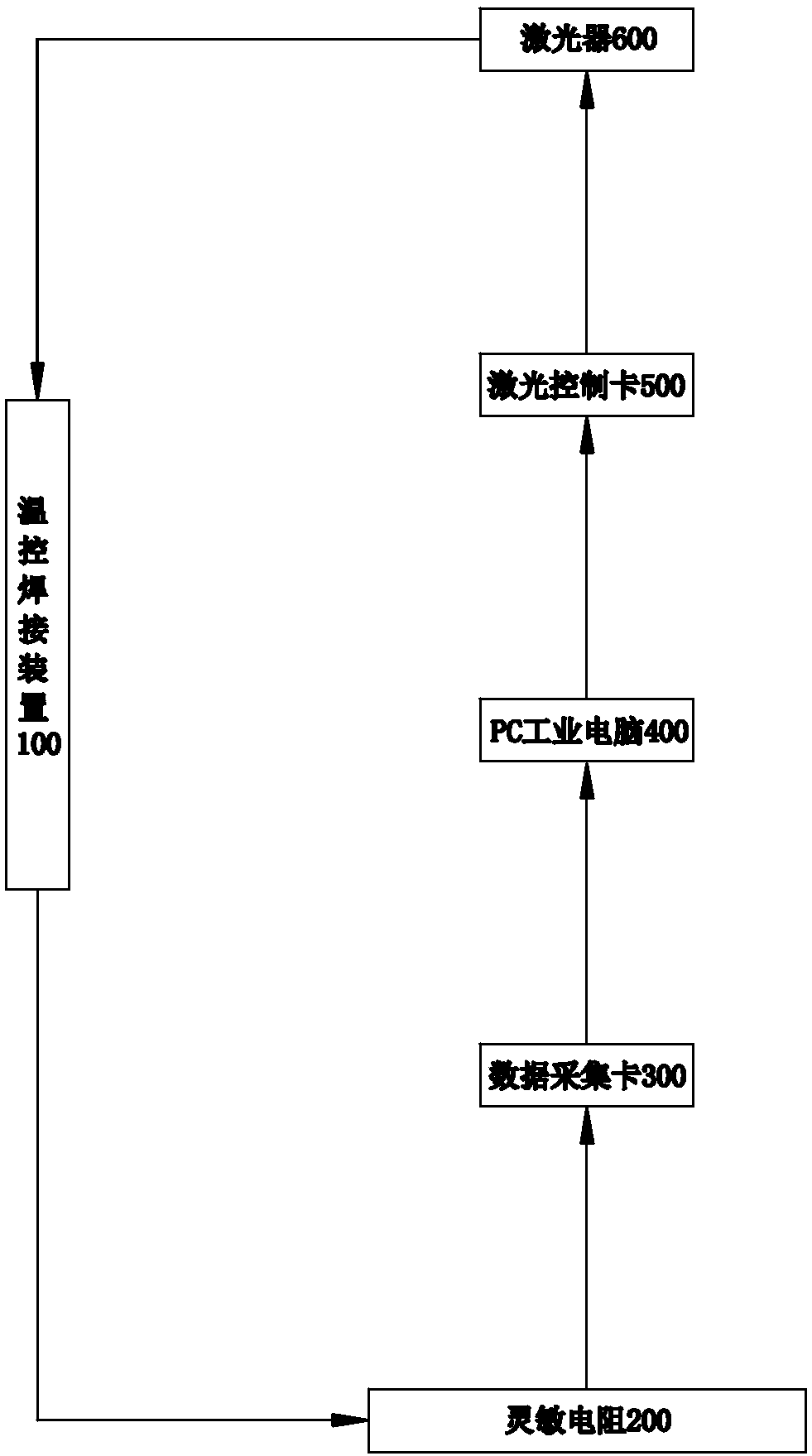

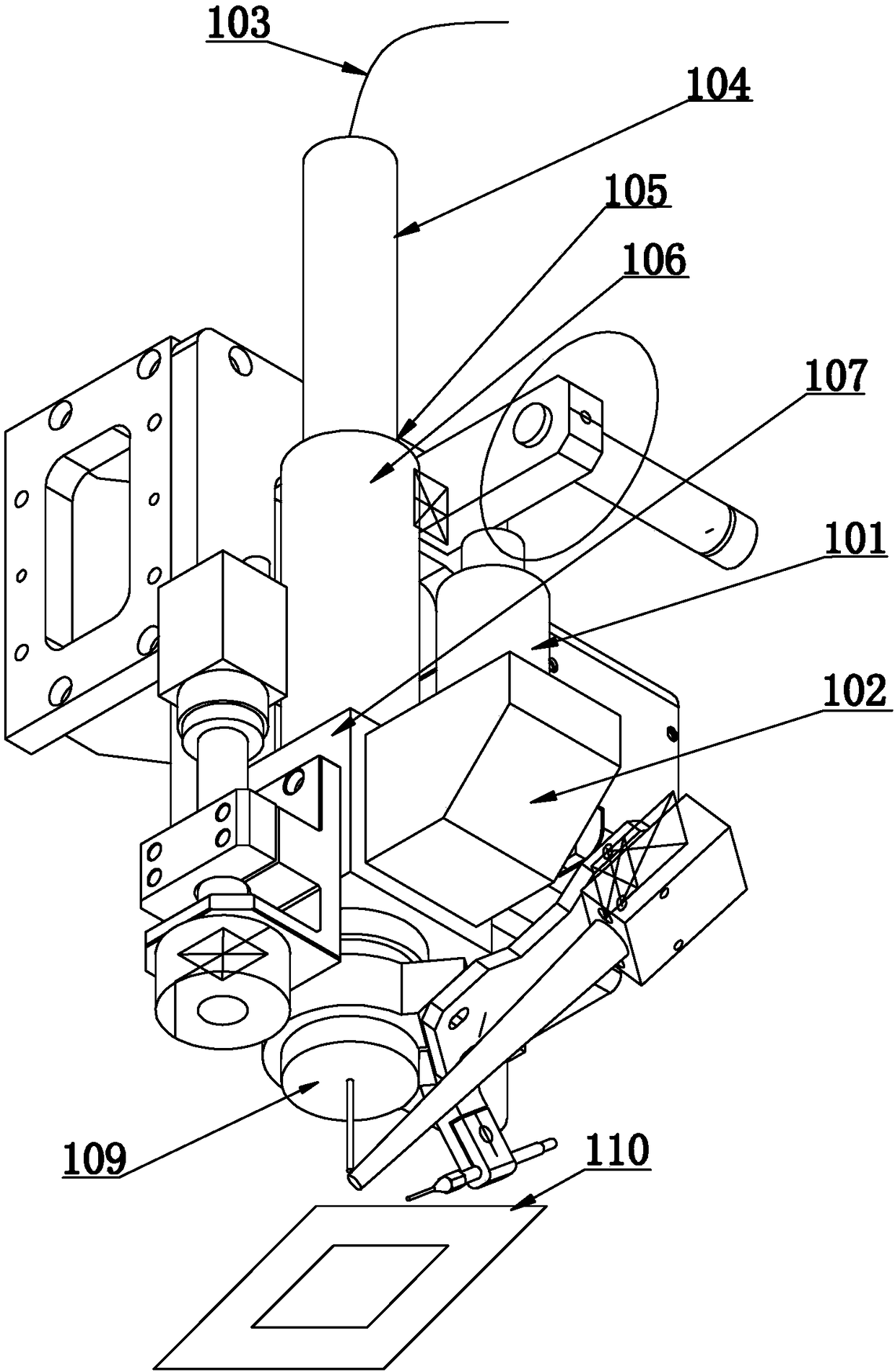

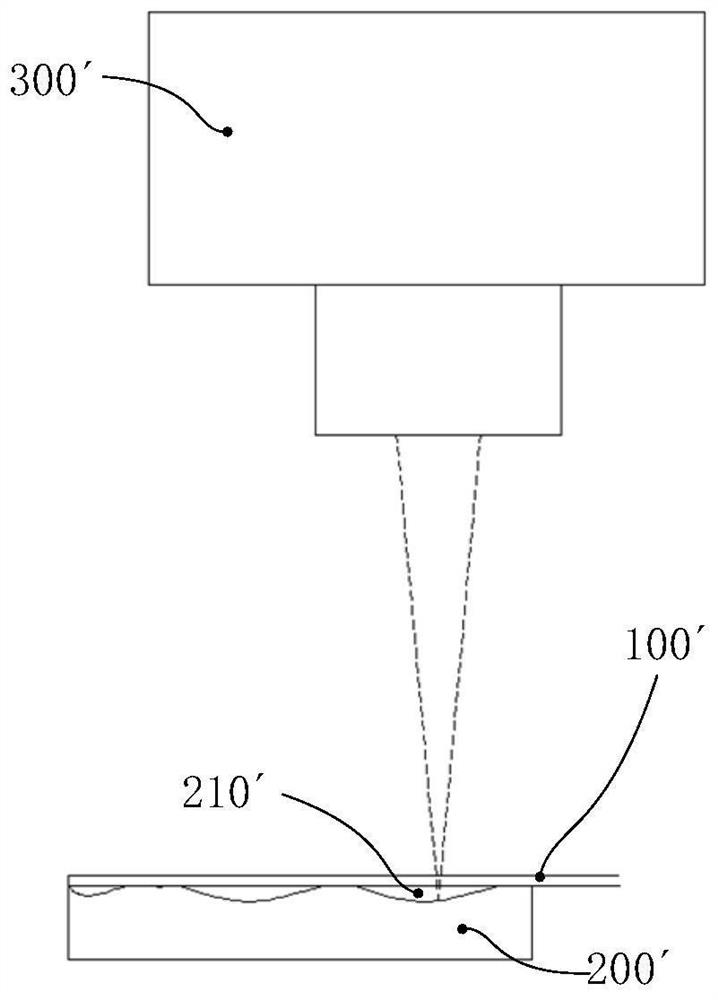

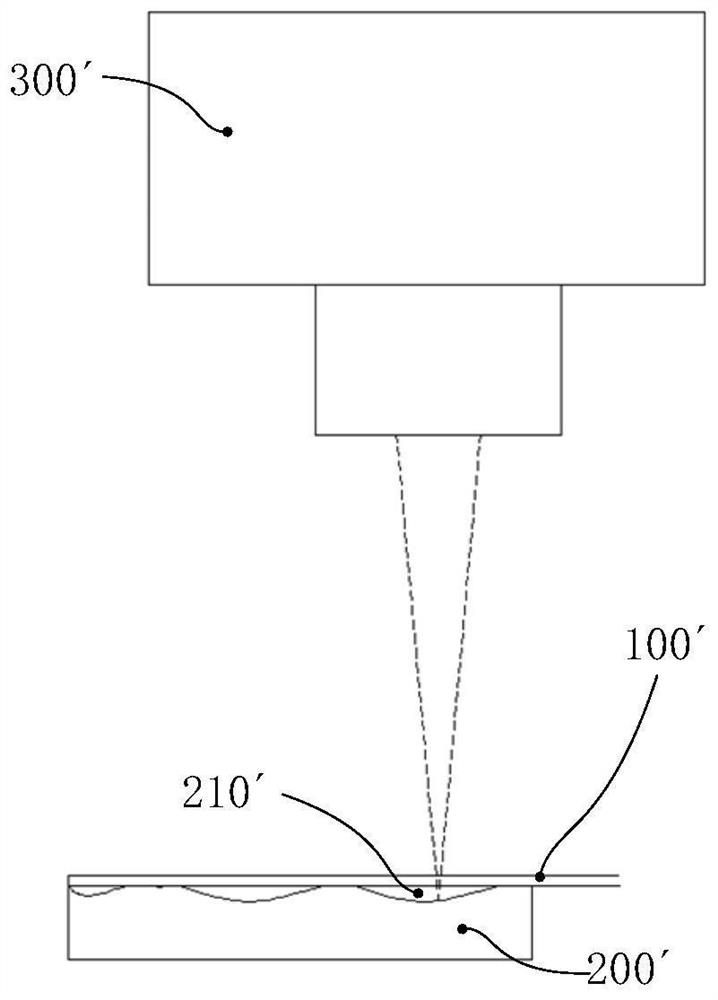

Welding temperature closed-loop control type laser soldering tin machine

InactiveCN108284274AReal-time temperature monitoringFix stability issuesLaser beam welding apparatusMachine partsLoop control

The invention relates to the field of laser soldering tin machines, in particular to a welding temperature closed-loop control type laser soldering tin machine. The welding temperature closed-loop control type laser soldering tin machine comprises a temperature control welding device, a sensitive resistor, a data acquisition card, an industrial PC, a laser control card and a laser device. The temperature control welding device generates 808 nano lasers through the laser device so as to weld PCB machined parts. The temperatures of soldering tin points on the PCB machined parts are measured in real time, measured temperature signals are converted into 4-20MA analog signals to be output to the sensitive resistor, and voltages are generated on the sensitive resistor. The data acquisition cardcollects voltage data generated on the sensitive resistor, and the voltage data are further transmitted to the industrial PC. The industrial PC calculates the real-time temperature according to the voltage data, and the laser control card can be controlled to output the analog quantity of 0-5V. The laser device changes the magnitude of laser currents according to the received analog quantity of 0-5V. Compared with the prior art, the welding temperature closed-loop control type laser soldering tin machine can achieve welding temperature closed-loop control, stability is improved and good production quality is guaranteed.

Owner:深圳市大鹏激光科技有限公司

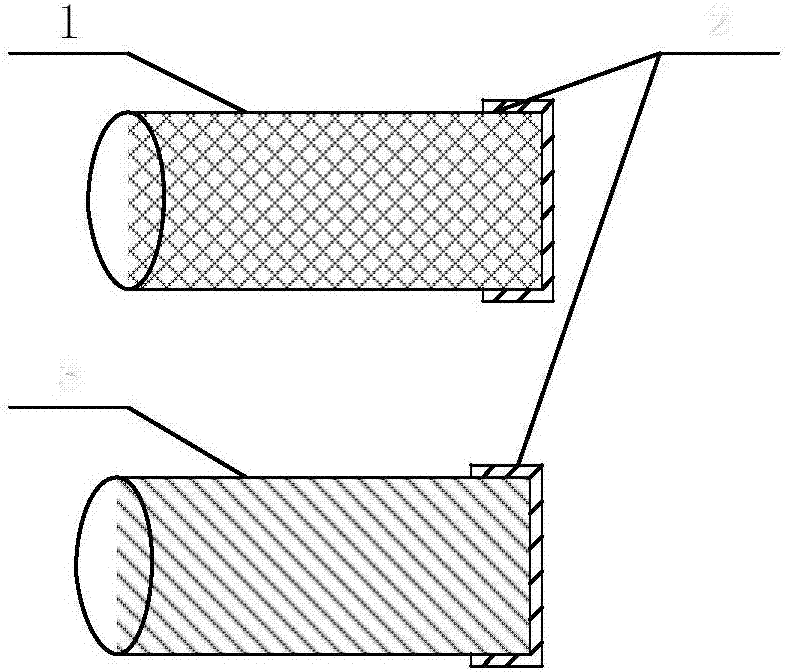

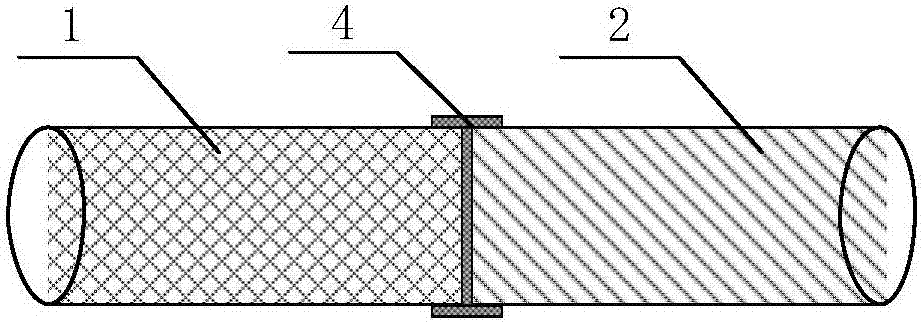

Copper and aluminum transition connection terminal soldering method

ActiveCN106862691ATightly boundEffective protectionSoldering apparatusEngineering industryFlash welding

The invention discloses a copper and aluminum transition connection terminal soldering method. It can be ensured that copper and aluminum connection terminal welding interfaces are tightly combined through the copper and aluminum transition connection terminal soldering method, the resistance of two metal welding faces is the resistance of tin, performance is quite stable, the rejection rate is smaller than 1%, and the defects that traditional methods such as flash welding, friction welding, braze welding and cold welding need special equipment or special processing materials, and the rejection rate is high are effectively overcome. According to the copper and aluminum transition connection terminal soldering method, no special material is adopted, a blocking layer and a weld assisting layer are formed through rosin, and the problems of the low binding face strength and insufficient soldering caused by surface oxidization in aluminum material welding can be effectively solved. The copper and aluminum transition connection terminal soldering method can be applicable to occasions in power industry, petroleum industry, chemical engineering industry and the like needing copper and aluminum terminals, and has the good market prospect.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Alloy resistor processed by composite material and preparation method thereof

PendingCN113871116AFix stability issuesSolve large weld seamResistor manufactureResistor detailsElectrical resistance and conductanceAlloy

The invention discloses a preparation method of an alloy resistor processed by adopting a composite material. The method comprises the following steps: using the composite material, gouging, stamping into strips, trimming the resistor, packaging, removing glue, printing, stamping and separating, and electroplating. The beneficial effects of the preparation method are that: compared with such structures in the market, adverse factors such as unstable material resistivity, large welding seam, pseudo welding, welding drop, welding deviation and the like are effectively solved through the composite material, the gouging process and the like. And meanwhile, the effect of high-efficiency output (52PCS or higher produced by one composite material) can be realized, the investment of equipment is reduced, the number of operators is reduced, and the effects of reducing the number of workers and improving the efficiency are achieved.

Owner:佛山好运电器配件有限公司

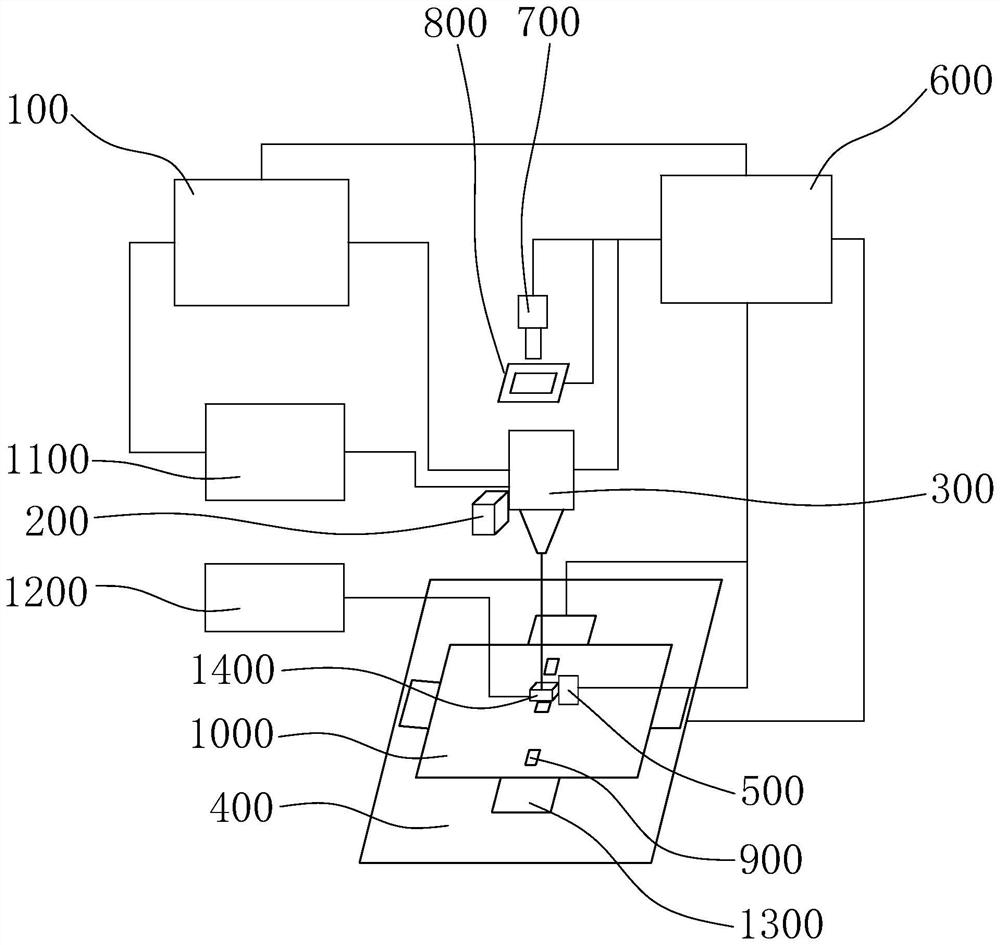

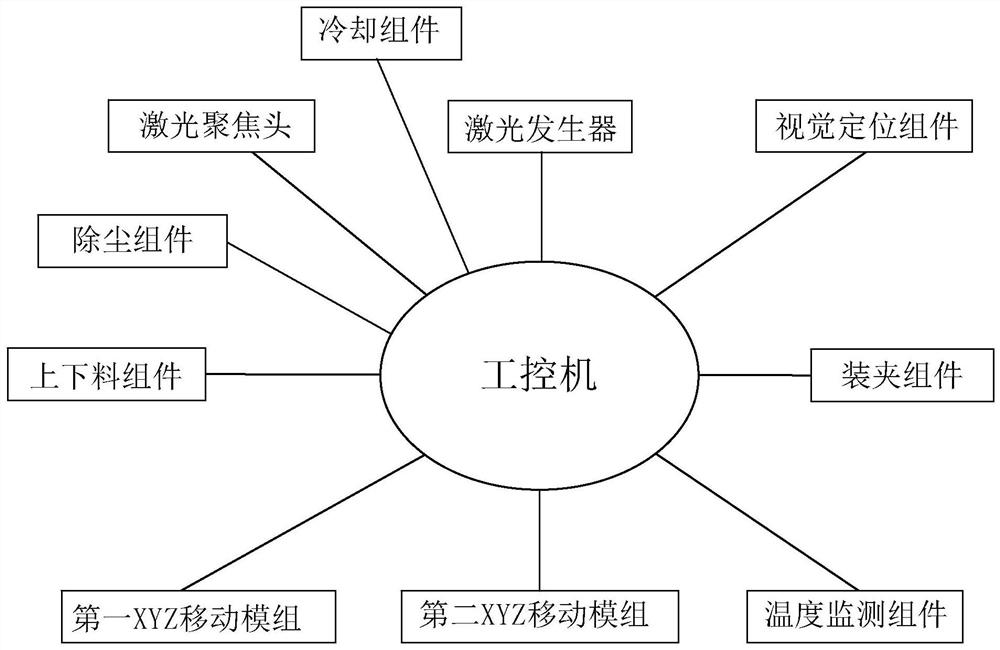

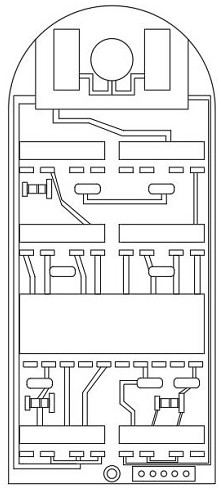

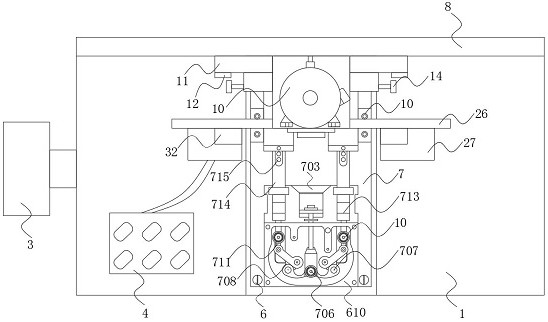

Laser welding system and method

PendingCN114147354AImprove the compaction effectImprove welding productivityLaser beam welding apparatusVisual positioningWorkbench

According to the laser welding system and method, in the laser welding system, a feeding and discharging assembly can transfer a photovoltaic assembly with a junction box to a workbench; the clamping assembly is arranged on the workbench so as to clamp and position the photovoltaic assembly. The welding pressure head assembly comprises a connecting plate, a mounting base, an elastic piece, a pressure head and a position detector, the connecting plate is connected with the first mechanical arm and the mounting base, the upper end of the elastic piece is connected with the mounting base, the lower end of the elastic piece is connected with the pressure head, the position detector is arranged on the mounting base, and the pressure head is provided with an induction piece located below the position detector; the laser generator is connected with the laser focusing assembly so that laser can be transmitted to the laser focusing assembly. The laser focusing assembly is connected with the second mechanical arm; the visual positioning assembly is located above the workbench, the visual positioning assembly and the position detector are electrically connected with the industrial personal computer, and the industrial personal computer is electrically connected with the laser generator, the first mechanical arm and the second mechanical arm. The welding reject ratio can be reduced, and the welding precision and quality of the junction box are improved.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

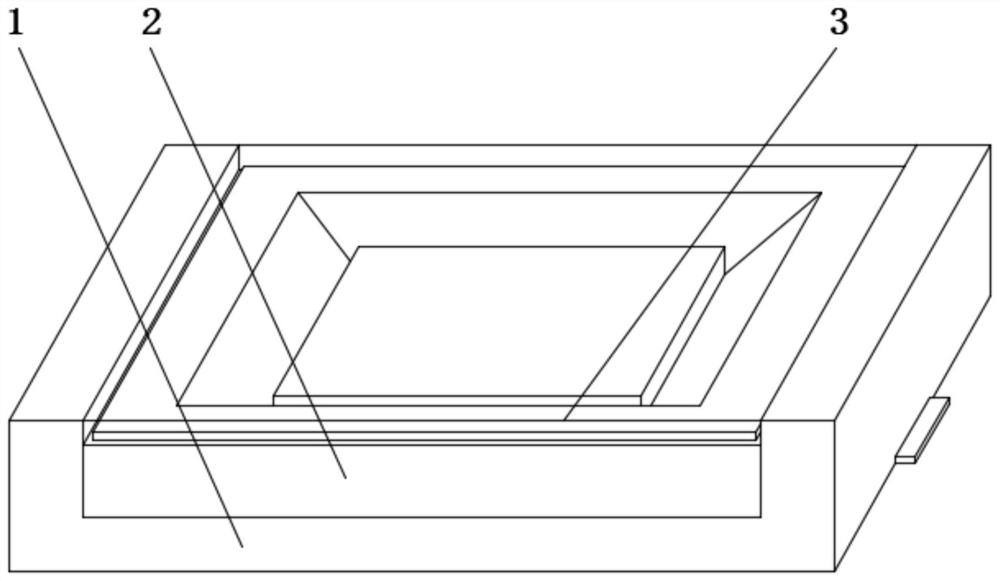

Pressing head and pressing device

ActiveCN112276437ASo as not to damageAvoid scrappingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMolten metal

The invention discloses a pressing head and a pressing device, and belongs to the technical field of welding. The pressing head comprises a mounting frame, wherein a through hole for a welding beam topenetrate through is formed in the mounting frame. Elastic pressing claws are arranged on two sides of the through hole, are connected with the mounting frame and are capable of making contact with ato-be-pressed piece and elastically pressing the to-be-pressed piece. The pressing device comprises the pressing head. By arranging the pressing head, stress change of the to-be-pressed part cannot be transmitted to a stretching device in the welding process, so that the phenomenon that a mask plate is scrapped due to movement of patterns on the surface of a mask is avoided, and the elastic pressing claws of the pressing head can enable the mask to be tightly attached to a frame with the uneven surface, so that a problem that the mask and the frame are not welded firmly or insufficient welding exists as a molten metal liquid flows in the frame with the uneven surface is solved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

PCB (printed circuit board) design method and PCB

ActiveCN108463053AEliminate weldsImprove yieldElectrical connection printed elementsPrinted circuit non-printed electric components associationEngineeringSurface-mount technology

The invention discloses a PCB design method and a PCB, and relates to the technical field of PCB design. The PCB design method comprises the steps that bonding pads corresponding to base pins are designed on a multi-layer PCB according to different base pins on a to-be-welded element, the bonding pads corresponding to the base pins in different sizes are arranged on different wiring copper layersof the PCB, the bonding pad corresponding to the base pin in the smallest size is arranged on the surface layer, and the bonding pad corresponding to the base pin in the largest size is farthest fromthe surface layer; and opening holes used for exposing the bonding pads are formed in the positions, corresponding to the bonding pads located on the internal layer, of the wiring copper layer and aninsulation layer located on the external layer. The PCB design method and PCB can effectively eliminate element cold solder joint caused by overmuch solder paste on the large bonding pad on the multi-layer PCB, improves the reliability of SMT (surface mount technology), and improves the product yield rate.

Owner:GOERTEK OPTICAL TECH CO LTD

Photovoltaic series welding machine with preheating device

PendingCN113305490AImprove welding qualityImprove welding efficiencyFinal product manufactureWelding/cutting auxillary devicesOxide ceramicAlumina ceramic

The invention discloses a photovoltaic series welding machine with a preheating device. The photovoltaic series welding machine comprises a welding machine frame, a belt for conveying multiple main grid batteries is arranged at the top of the welding machine frame, a welding lamp box is arranged above the welding machine frame, an infrared preheating device is arranged on the welding frame, the infrared preheating device is arranged below the belt and is attached to the belt, and the welding lamp box is located in the discharging direction of the infrared preheating device in the conveying direction of the belt. The photovoltaic series welding machine has the beneficial effects that an aluminum oxide ceramic plate is adopted as a heat conduction plate, a high-precision thermocouple and a controller are matched, the multiple main grid batteries can be preheated to the optimal welding temperature of a welding strip in a preheating area, so that the problems of over welding and pseudo welding in the welding process are solved, and the welding quality is improved; and the multiple main grid batteries are laid and integrally welded, thus, the problem that the production takt is not matched due to the fact that the welding time is long and the laying time is short is solved, and the welding efficiency can be improved.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

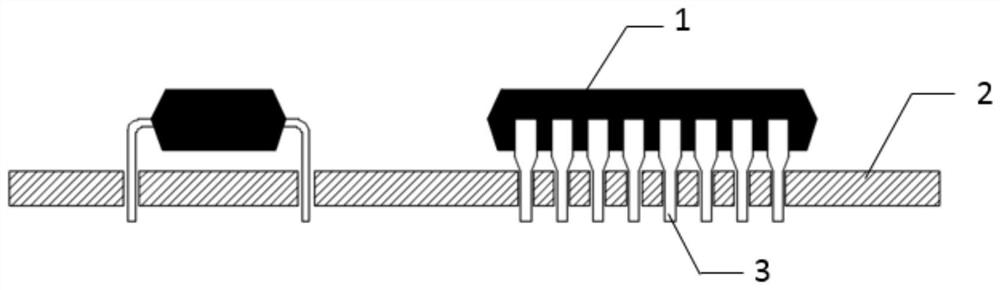

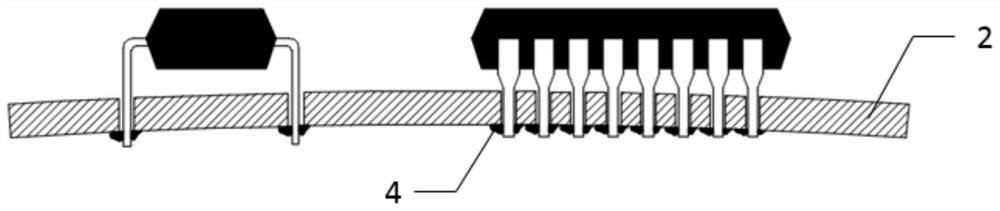

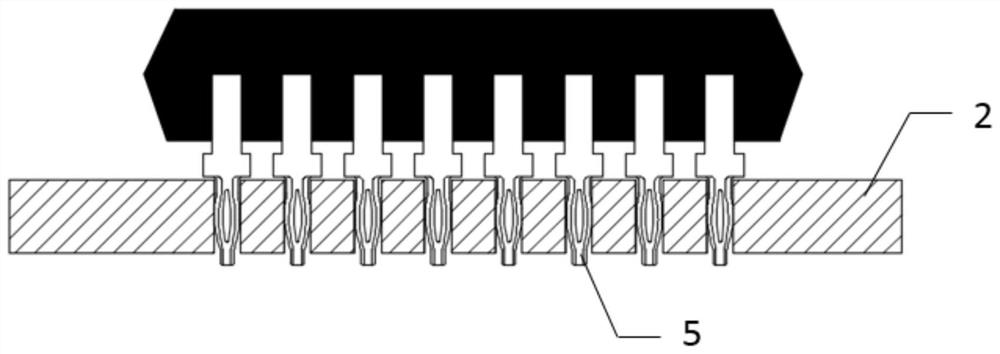

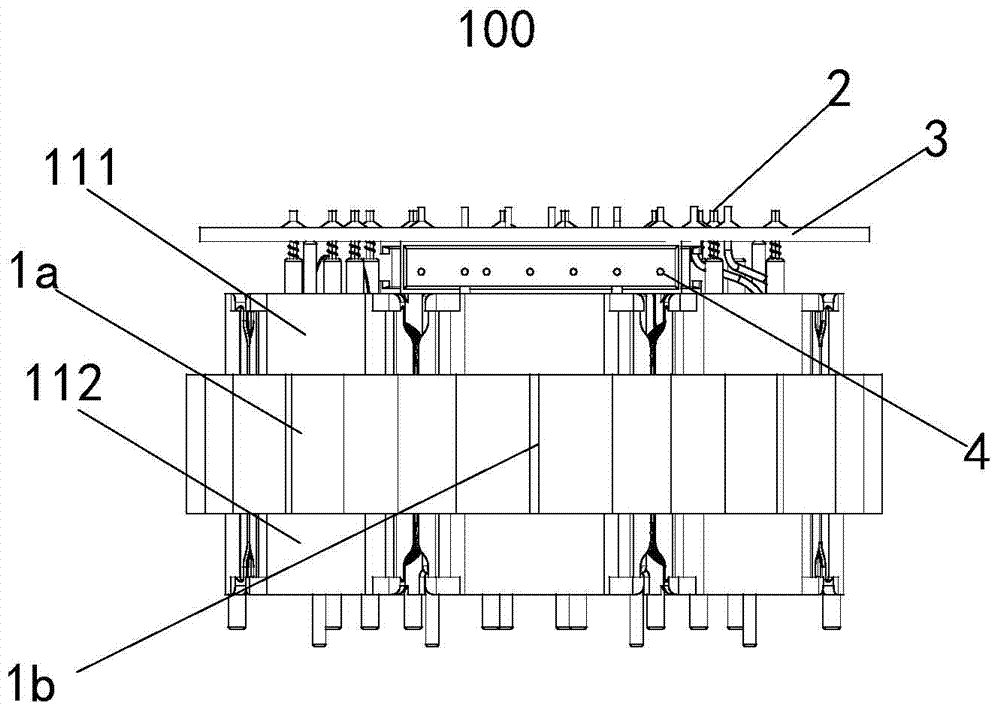

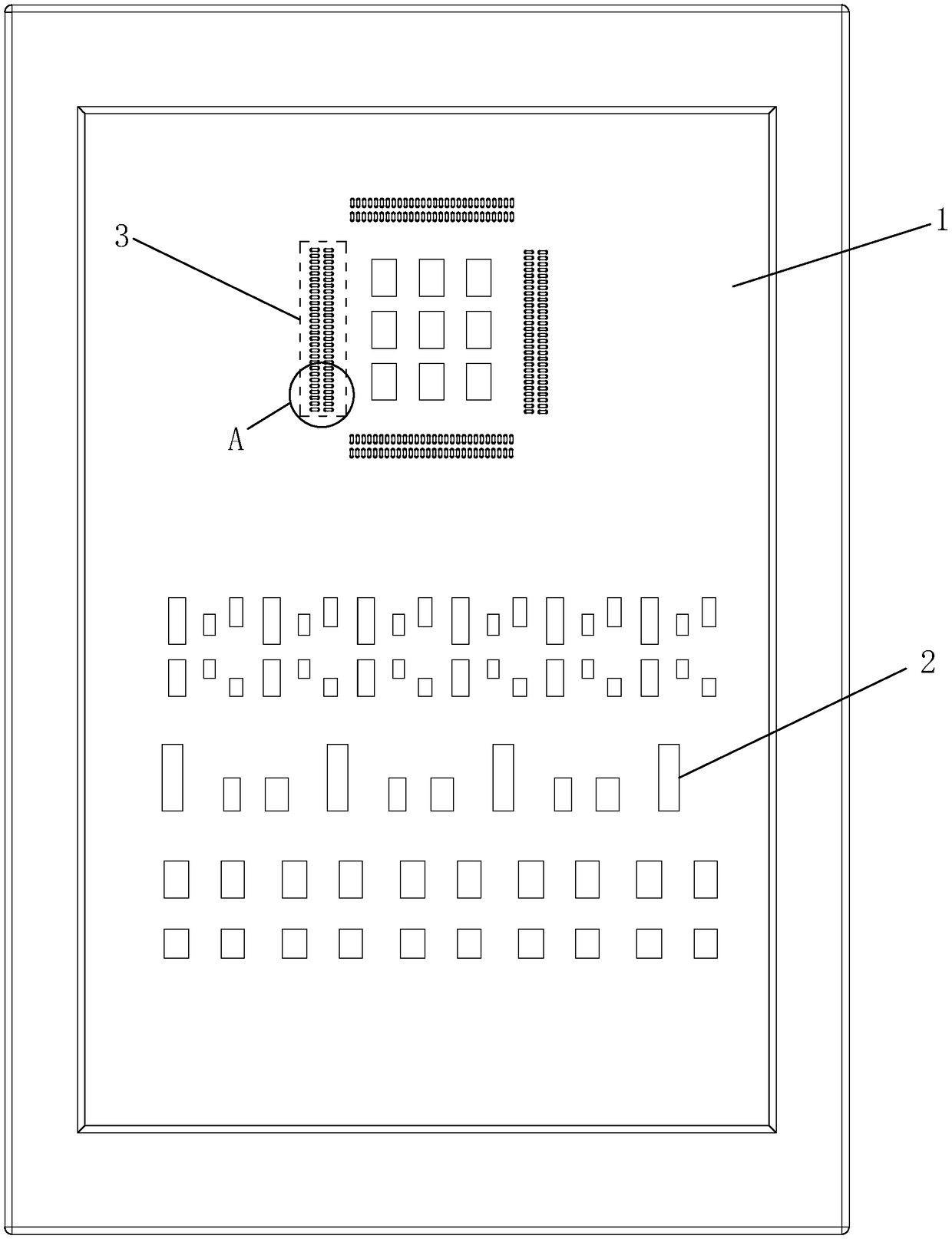

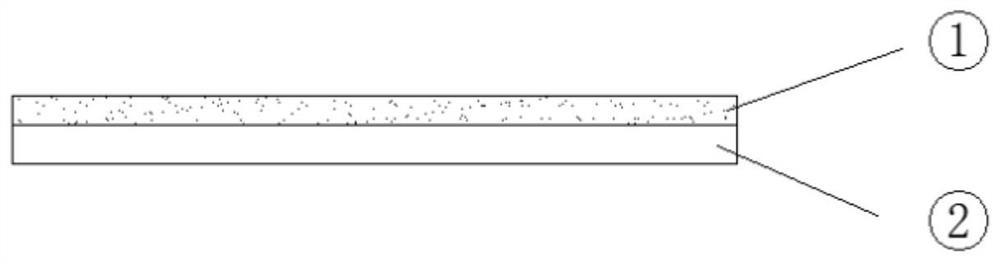

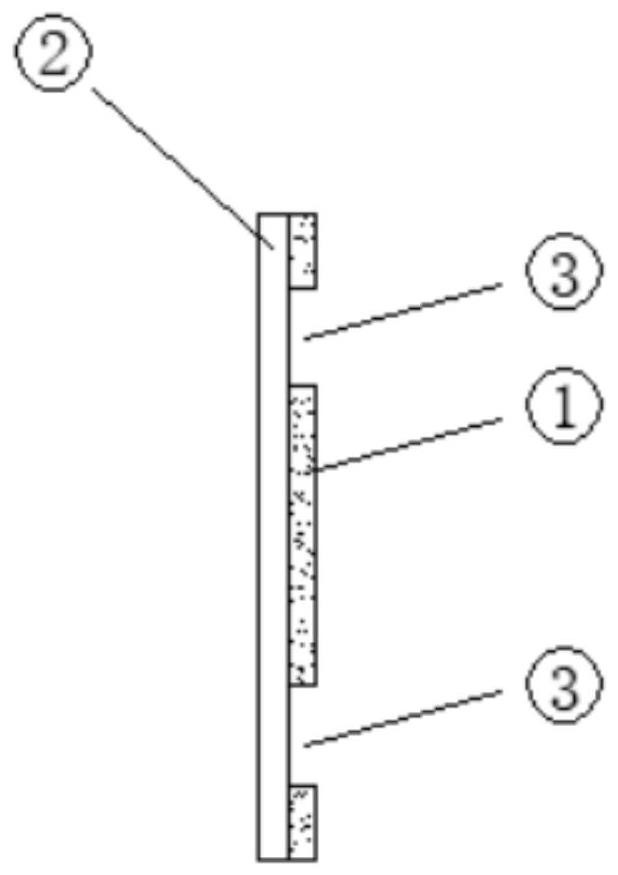

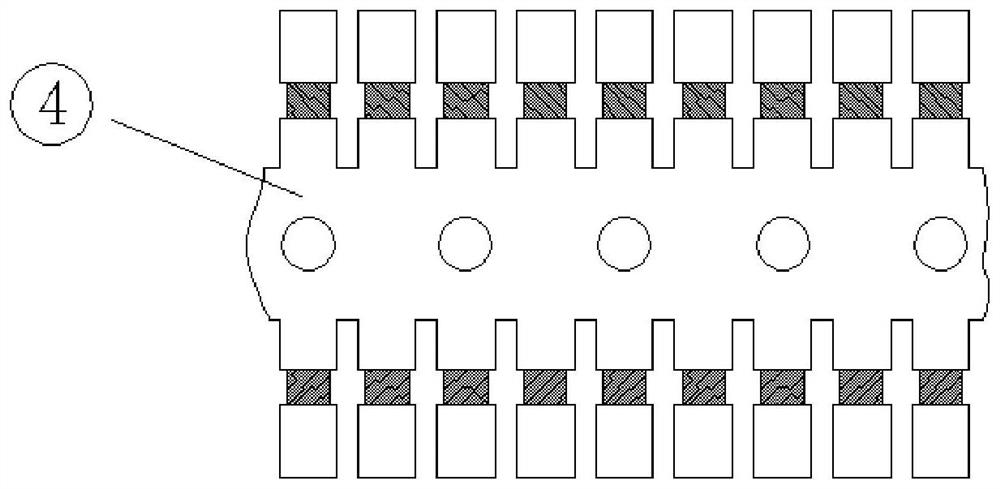

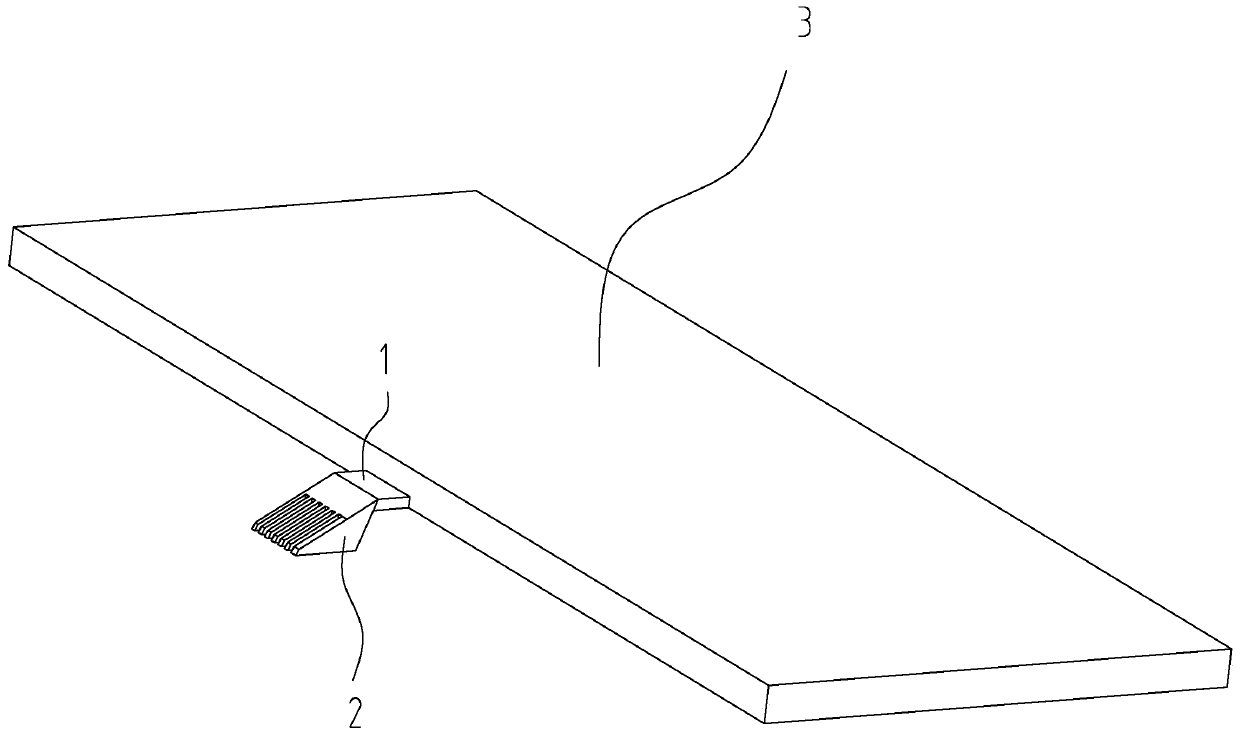

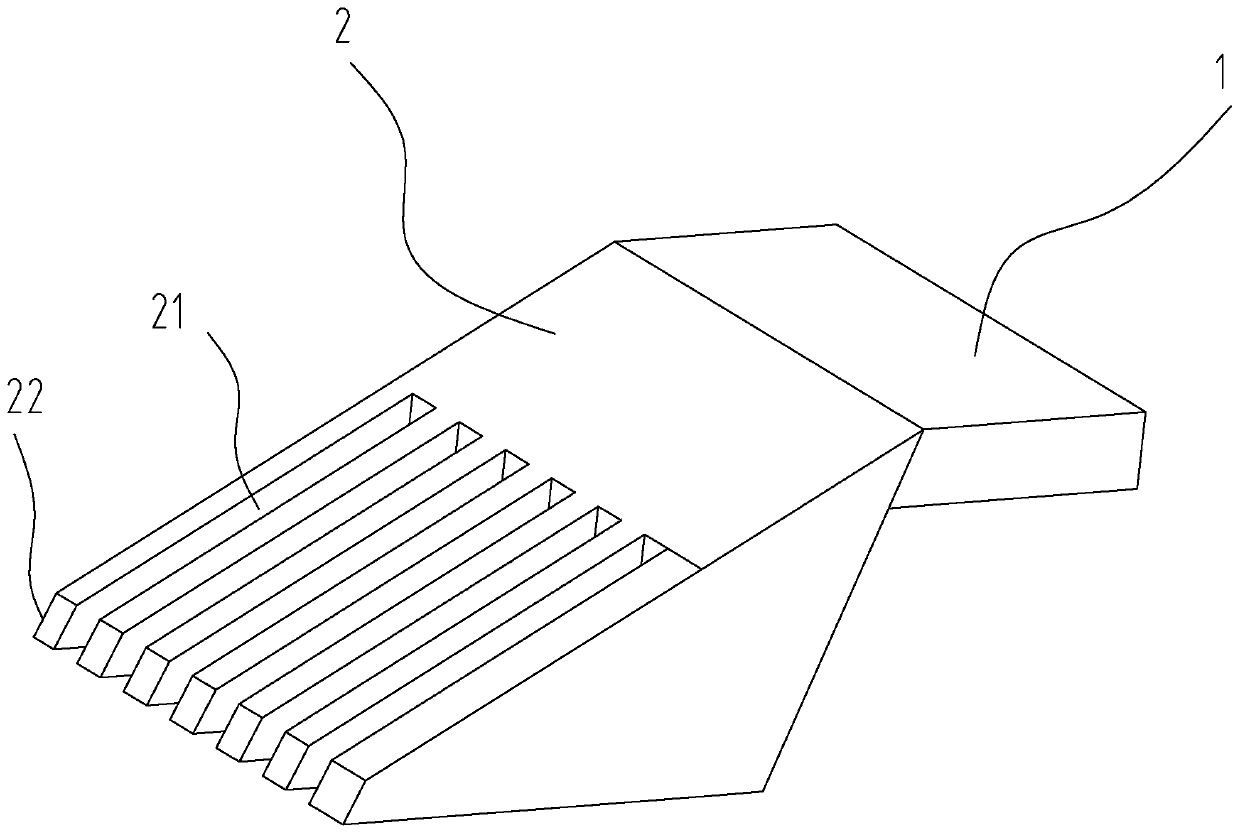

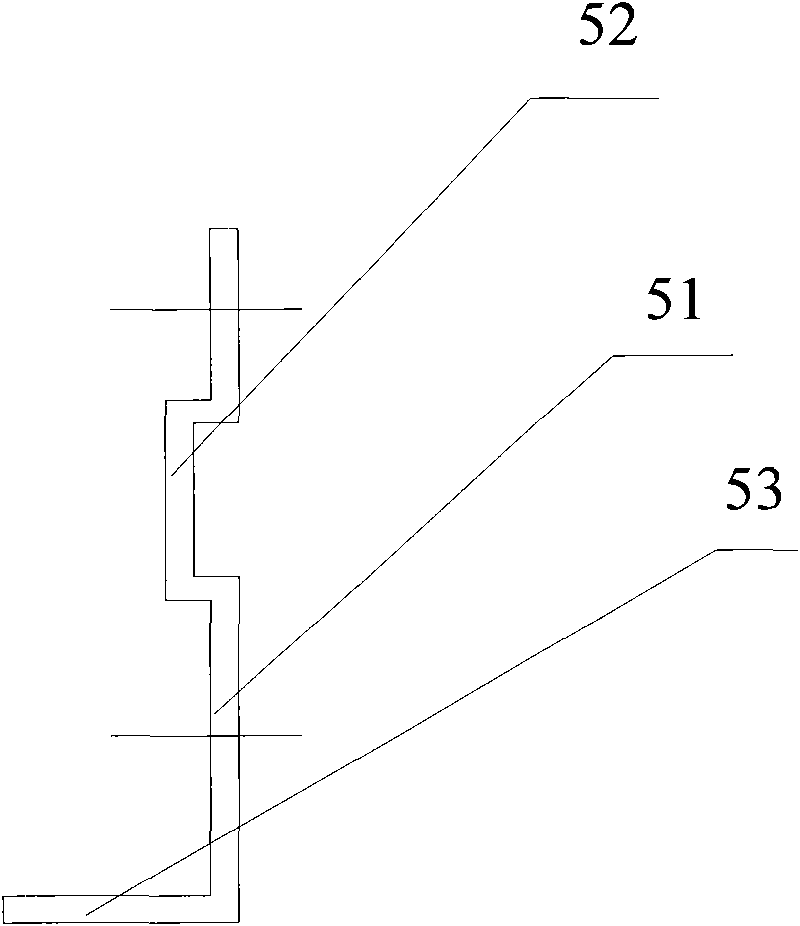

Pin used on component

PendingCN109962050AReduce thicknessSolve WeldingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSolder paste

The invention discloses a pin used on a component, and belongs to the technical field of component pins. The pin comprises a pin connecting plate and a pin bottom plate. The left end surface of the pin connecting plate is fixedly provided with the pin bottom plate, and the left end part of the pin bottom plate is a climbing inclined surface, wherein the climbing inclined surface is an inclined surface which is obliquely upwards arranged on the bottom surface of the pin bottom plate. The pin bottom plate is provided with a plurality of parallel solder paste storage grooves, and the solder pastestorage grooves are through grooves which penetrate through the pin bottom plate. The pin is used for solving the technical problems that floating and insufficient welding are liable to happen when atraditional pin is welded.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

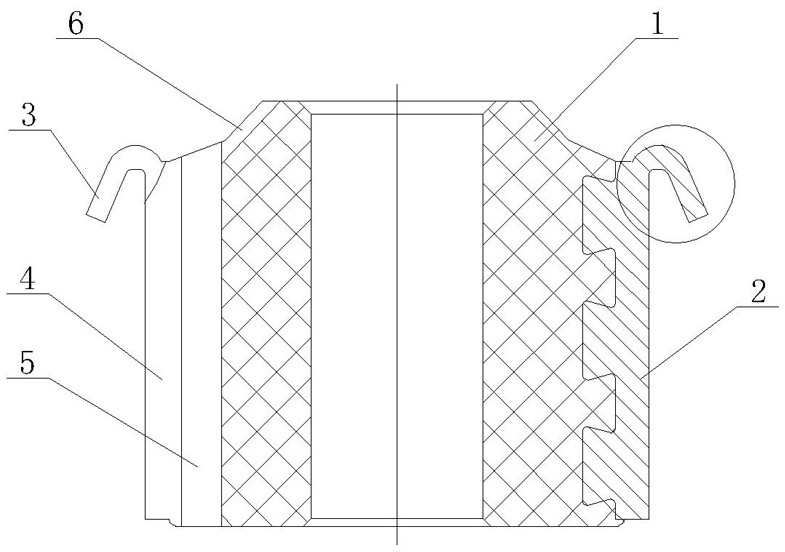

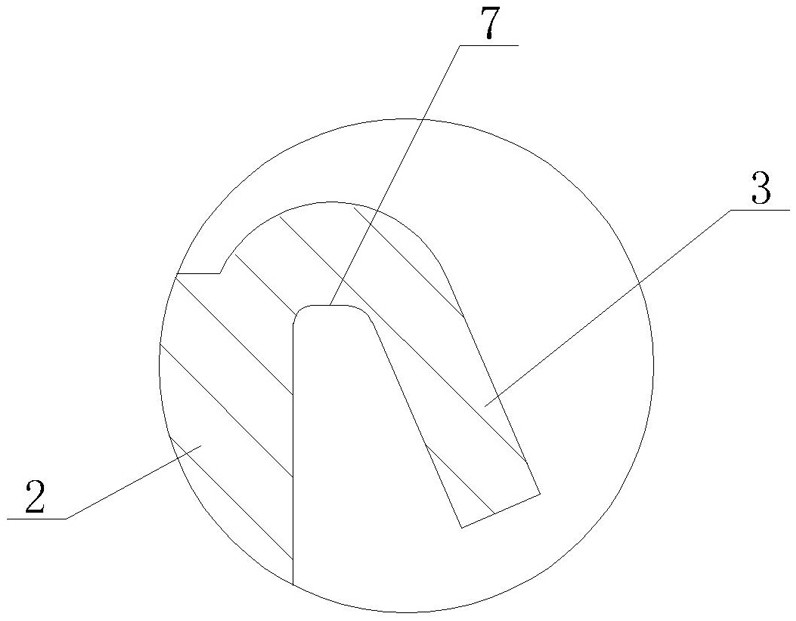

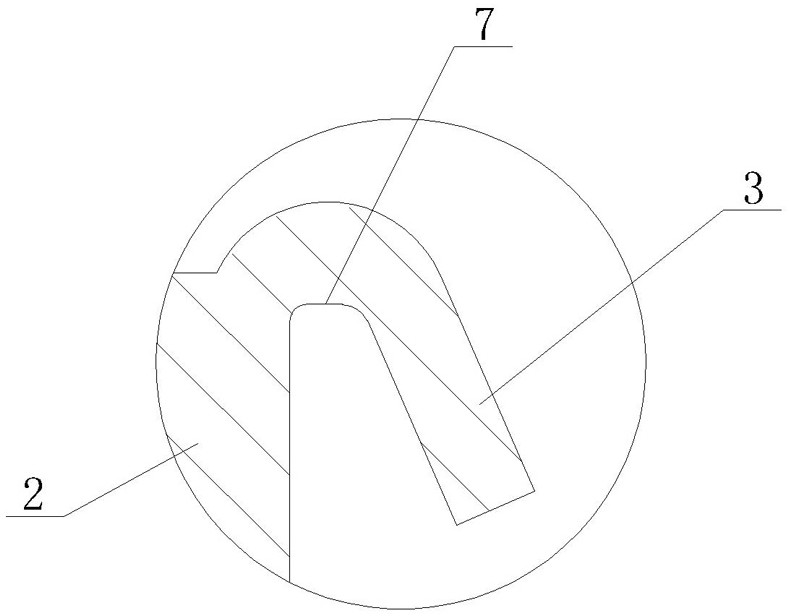

Hook type commutator

ActiveCN107968303AIncrease contact areaImprove bending strengthRotary current collectorDynamoelectric machine connectorsEngineeringElectrical and Electronics engineering

The invention discloses a hook type commutator. The hook type commutator comprises a substrate and commutator segments which are uniformly arranged on the outer circumference of the substrate, whereininsulation slots are formed among adjacent commutator segments for insulating. The hook type commutator is characterized in that the commutator segments have dual-hook designs; the top of each commutator segment is provided with two bonding wire hooks; the two bonding wire hooks are arranged side by side at a certain distance along the circumferential direction of each commutator segment; and molded surfaces of which two ends assume R angles and the middles are straight lines are molded on the tops of the hooks on inner sides of the bonding wire hooks. Through adoption of the hook type commutator, the problems of carbon deposition and pseudo soldering in the commutator can be solved completely, so that the two main factors of motor damage are eliminated; the service life of a motor is greatly prolonged and effectively ensured; and the production cost is low.

Owner:瑞安博宇科技股份有限公司

Automatic high-precision tin soldering device for printed circuit board processing

InactiveCN112087885ARealize clamping positioningEasy to assemble and locatePrinted circuit assemblingCircuit board tools positioningUniversal jointProcess engineering

The invention discloses an automatic high-precision tin soldering device for printed circuit board processing, and relates to the technical field of electronic part processing, in particular to a base, a spring pre-tightening clamping mechanism, a centering clamp, a throttle valve and a soldering bit, a support is fixed to the top end of the base, and the spring pre-tightening clamping mechanism is arranged on the surface of a workbench. The bottom end of the soldering mechanism is provided with universal joints, according to the automatic high-precision tin soldering device for printed circuit board processing, the spring pre-tightening clamping mechanism is arranged, the mechanism can rapidly and simply assembly and positioning based on a rapid change clamping mechanism of the workbench,the rotation handle can achieve positioning and clamping of the substrate, the substrate and a clamp body are rapidly changed, the installation time is short due to the detachable structure design ofthe rotation handle, so that a user can replace the knurls or the wrench plane conveniently according to the actual situation, the problems that in the traditional technology, replacement is troublesome, and repeated positioning precision is too poor are solved, and the device has the advantages of being convenient to use and rapid in replacement.

Owner:东莞市优伟机电科技有限公司

Bridge frame dedicated for nuclear power and length connecting component thereof

InactiveCN101881354AIncrease loading capacityImprove seismic strengthPipe supportsCarrying capacityNuclear power

The invention provides a bridge frame dedicated for nuclear power and a length connecting component thereof. The bridge frame dedicated for nuclear power comprises ladder sides and a ladder, wherein the ladder sides and the ladder are connected into the whole body by the connecting components; and the lateral surfaces of the ladder sides are provided with longitudinal grooves. Because the lateral surfaces of the ladder sides are provided with the longitudinal grooves, the shaped ladder sides have the characteristics of strong load-carrying capacity and high shock strength so as to improve the integral strength and bearing capability of the bridge frame and make the protection grade of the bridge frame reach IP66 to further greatly improve the safety performance of the bridge frame. Moreover, the invention only improves the shape of the ladder sides of the bridge frame, thus, the processing is convenient and the structure is simple.

Owner:JIANGSU HUAQIANG ELECTRIC EQUIP

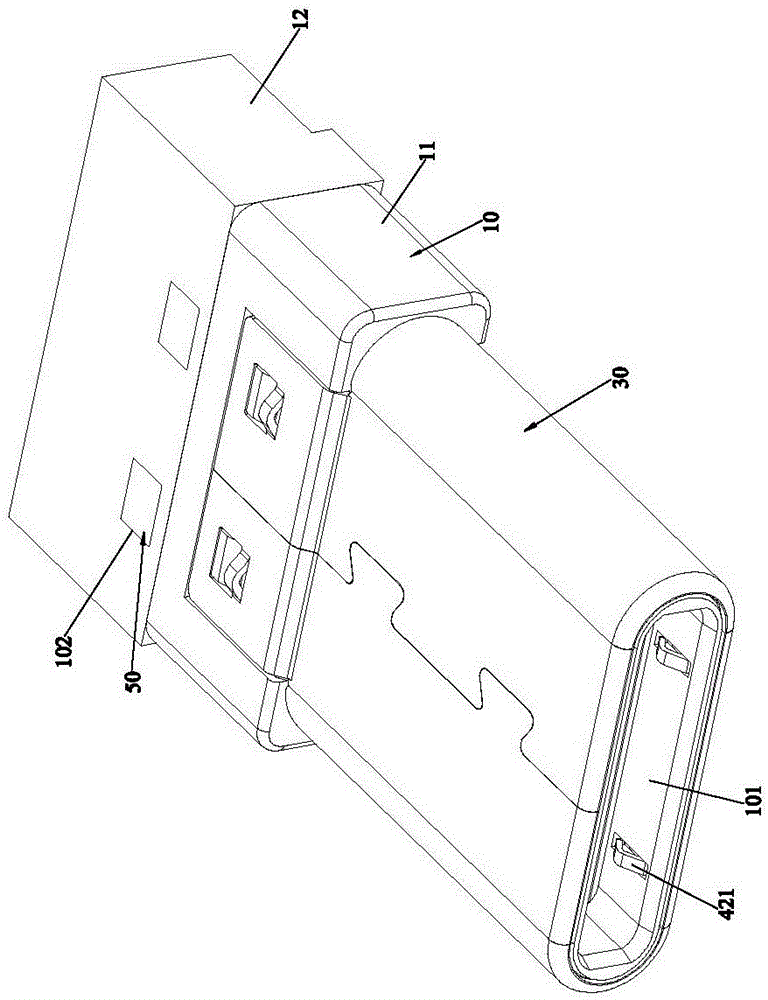

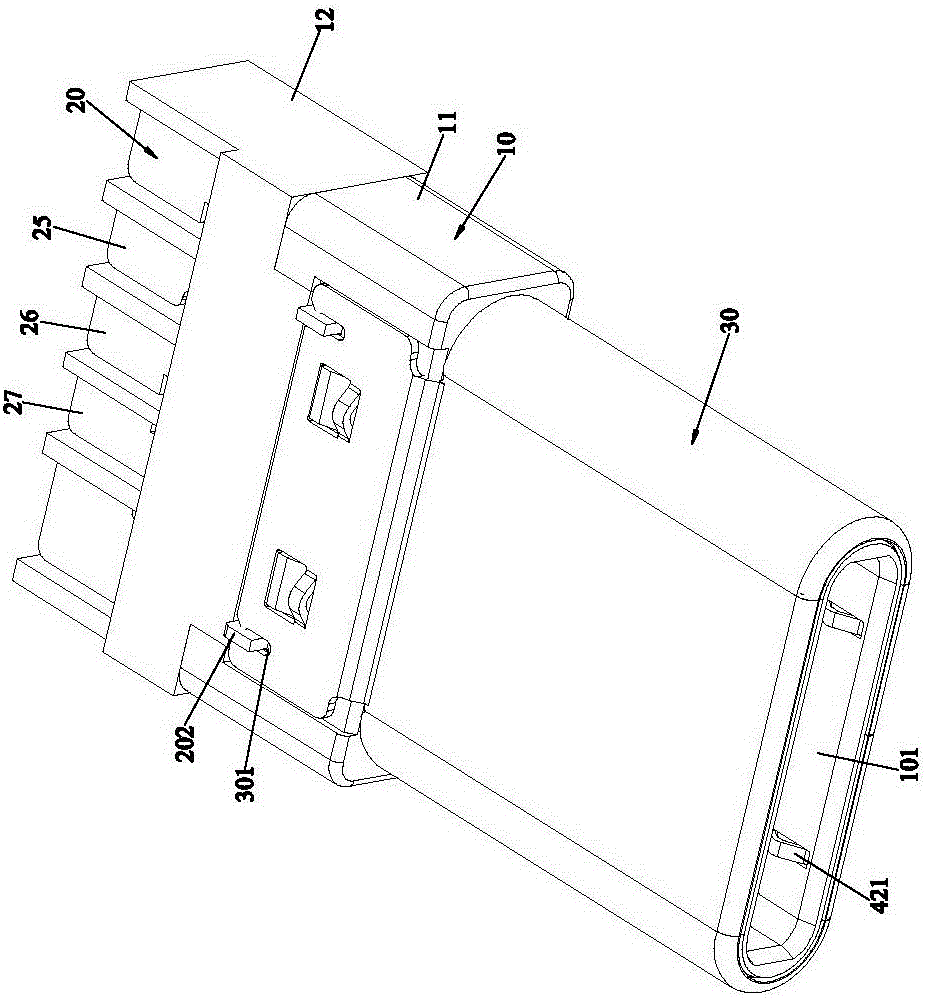

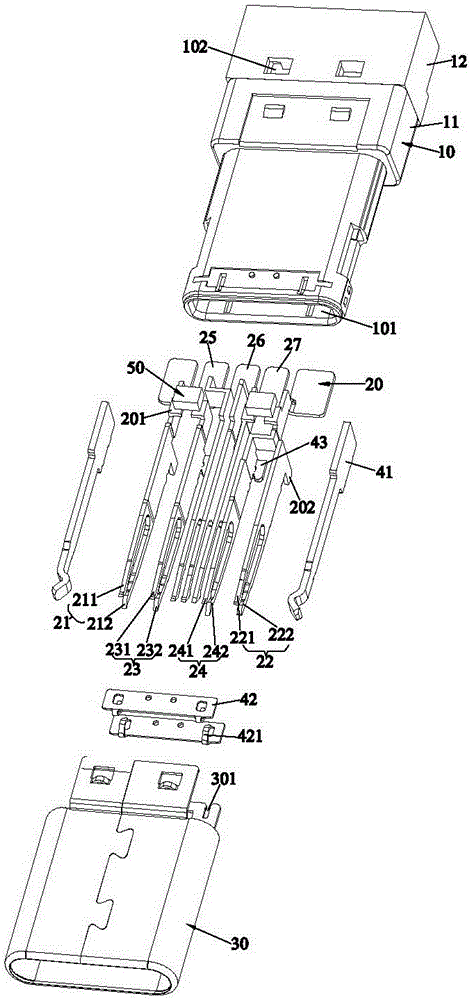

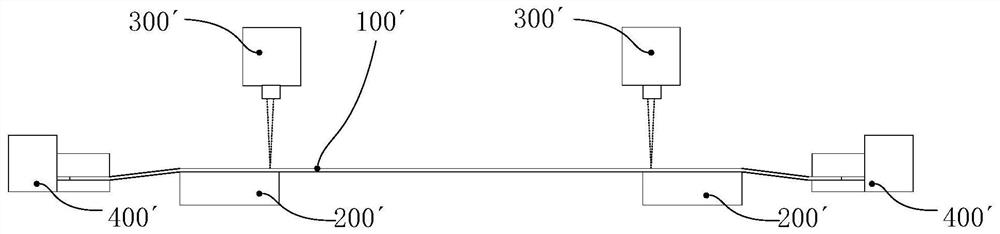

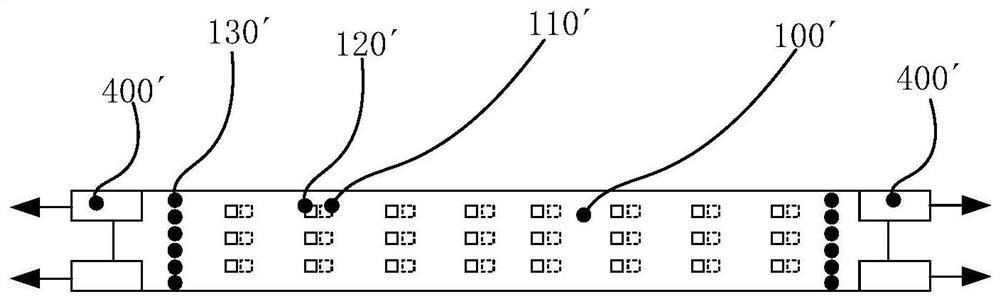

Novel USB Type-C connector

ActiveCN106848761ASimple processing technologyIncrease productivityCoupling device detailsElectrical resistance and conductanceCapacitance

The invention discloses a novel USB Type-C connector. The novel USB Type-C connector comprises an insulating body, a PIN needle and a shielding housing; the PIN needle has an A line and a B line, at least two adjacent PIN needles in the A line PIN needle are provided with a connecting sheets; the surface of the insulating body is provided with at least one accommodating groove, the accommodating groove is filled with a resistance material to form at least one resistor, the two ends of the resistor are connected to the connecting sheets on the two adjacent PIN needle; or the accommodating groove is filled with a capacitance material to form at least one capacitor, and the two ends of the capacitor are in communication connection with the connecting sheets on the two adjacent PIN needle. According to the novel USB Type-C connector, the accommodating groove is arranged on the rear end surface on the insulating body in a concave mode, is filled with the resistance material to form the resistor, or is filled with the capacitance material to form the capacitor, and the two ends of the resistor or the capacitor are in communication connection with the connecting sheets on the two adjacent PIN needles. The novel USB Type-C connector replaces a traditional manual welded resistor, simplifies the manufacturing technology, and improves the production efficiency.

Owner:SHENZHEN XINSHENGHUA ELECTRONICS DEVICES CO LTD

A compression head and a compression device

ActiveCN112276437BSo as not to damageAvoid scrappingWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceStructural engineering

The invention discloses a compression head and a compression device, belonging to the technical field of welding. The pressing head includes a mounting frame, and the mounting frame is provided with a through hole for the welding beam to pass through; both sides of the through hole are provided with elastic pressure claws, and the elastic pressure claws are connected with the mounting frame. The elastic pressing claws can be in contact with the parts to be pressed and pressed elastically. The pressing device includes the above-mentioned pressing head. In the present invention, by setting the compression head, the stress change of the parts to be compressed cannot be transmitted to the stretching device during the welding process, thereby avoiding the phenomenon that the mask surface pattern moves and the mask plate is scrapped, and the elastic claws of the compression head can be The mask is closely attached to the frame with uneven surface, which solves the problem that the molten metal liquid flows in the frame with uneven surface, resulting in weak or false welding between the mask and the frame.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Polyester wire enamel capable of realizing welding-slag-free direct welding and preparation method of polyester wire enamel

InactiveCN103725186ASolve WeldingSolve technical problems such as "virtual welding"Polyamide coatingsPolyester coatingsChemistryP-Cresol

The invention discloses polyester wire enamel capable of realizing welding-slag-free direct welding and a preparation method of the polyester wire enamel. The polyester wire enamel is characterized by comprising raw materials in parts by weight as follows: 20-24 parts of nylon 11, 12-15 parts of unsaturated polyester resin, 15-18 parts of polyester polyol, 14-18 parts of amino resin, 4-7 parts of triallyl isocyanurate, 3-4 parts of ferrocene, 1-2 parts of urotropine, 1-2 parts of 2-mercaptobenzimidazole, 12-14 parts of mica, 2-3 parts of titanium dioxide, 2-4 parts of isocyanate, 2-3 parts of zinc octoate, 1-2 parts of dibutyltin dilaurate, 7-9 parts of an additive, 120-140 parts of m,p-cresol and 140-160 parts of xylene. After enameled wires are coated with the obtained polyester wire enamel, welding slag is not produced during tin welding.

Owner:铜陵天河特种电磁线有限公司

Bonding-wire-free LED patch support and welding method thereof

ActiveCN113113525AEnhanced compressive capacity and structural strengthSolve WeldingSemiconductor devicesElectrically conductiveSolder paste

The invention provides a bonding-wire-free type LED patch support and a welding method thereof. The bonding-wire-free type LED patch support comprises a protection base, the protection base comprises a base body, a support mounting groove, solder paste, a metal electrode, hot melt adhesive and a conductive electrode slice, the support mounting groove is formed in the upper end face of the base body, the hot melt adhesive is fixedly connected to the bottom of the support mounting groove, the metal electrode is fixedly connected to the bottom of the support mounting groove, the solder paste is fixedly connected to the upper end face of the metal electrode, the conductive electrode plate is fixedly connected to the lower end face of the base body, the support is fixedly connected to the upper end face of the protection base, and the support comprises a support body, a limiting groove, a reflector, a chip, a chip mounting groove, an electrode groove and a cooling groove. The limiting groove is formed in the upper end face of the support body, the chip mounting groove is formed in the bottom of the limiting groove, the structural strength of the support is effectively improved, meanwhile, the refraction capacity of the support is improved, and the luminous efficiency of an LED chip is higher.

Owner:广东良友科技有限公司

Technology and device for welding periphery of plate layer of vacuum freeze dryer

ActiveCN102357743BSimple welding process stepsEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

Owner:山东浩器生物装备技术有限公司

A hook type commutator

ActiveCN107968303BIncrease contact areaImprove bending strengthRotary current collectorDynamoelectric machine connectorsElectric machineCarbon deposit

The invention discloses a hook-type commutator, which comprises a base body and commutation segments uniformly arranged on the outer circumference of the base body, insulating grooves are provided between adjacent commutation segments for insulation, and the feature is that the commutation segments have double hooks Design, there are two welding wire hooks on the top of each commutator piece, and the two welding wire hooks are arranged side by side along the circumferential direction of the commutator piece and separated from each other by a certain distance; the inner side of the welding wire hook is formed at the top of the hook. Forming surface with R angle at both ends and straight line in the middle. The invention can completely solve the problems of carbon deposition and virtual welding in the commutator, thereby eliminating the two most important factors of motor damage, greatly improving and effectively ensuring the service life of the motor, and low production cost.

Owner:瑞安博宇科技股份有限公司

socket

ActiveCN104934821BAchieve fixationAvoid short circuitSecuring/insulating coupling contact membersEngineeringShort circuit

The invention relates to the technical field of sockets, especially to a socket whose sleeves are arranged reasonably and safely. A pedestal is provided with an installation groove, one of an N-pole conducting strip and an L-pole conducting strip is arranged in the installation groove and integrated with corresponding sleeves of the same pole at the two sides of the installation groove, and the other of the N-pole conducting strip and the L-pole conducting strip is arranged at one side over the installation groove, crosses the installation groove, and is integrated with the corresponding sleeves of the same pole at the two sides of the installation groove. Compared with a socket in the prior art, the distance between the N-pole conducting strip and the L-pole conducting strip is longer, safe distance between zero and live wires is fully ensured, the socket is effectively prevented from short circuit, the using safety of the socket is improved, and all the conducting strips and the sleeves are reasonable and compact spatially and occupy small space.

Owner:GUANGDONG FUTINA ELECTRICAL

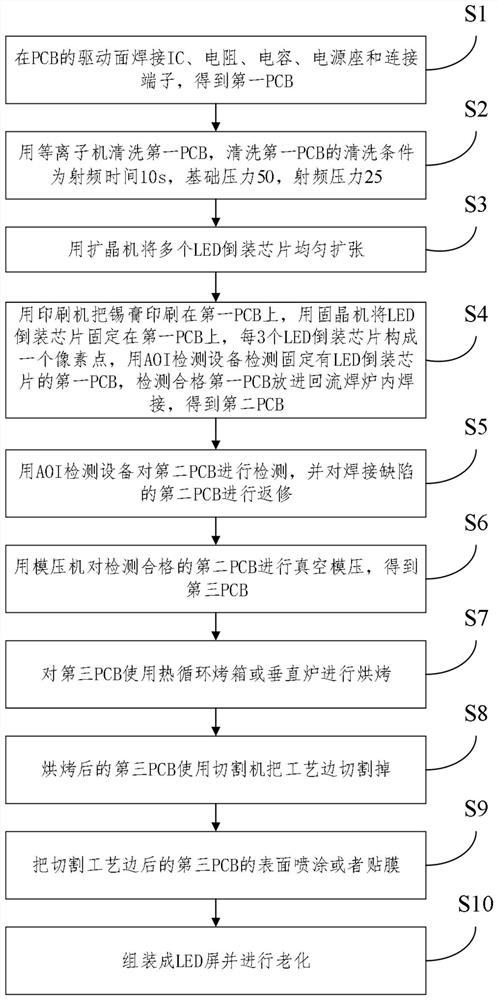

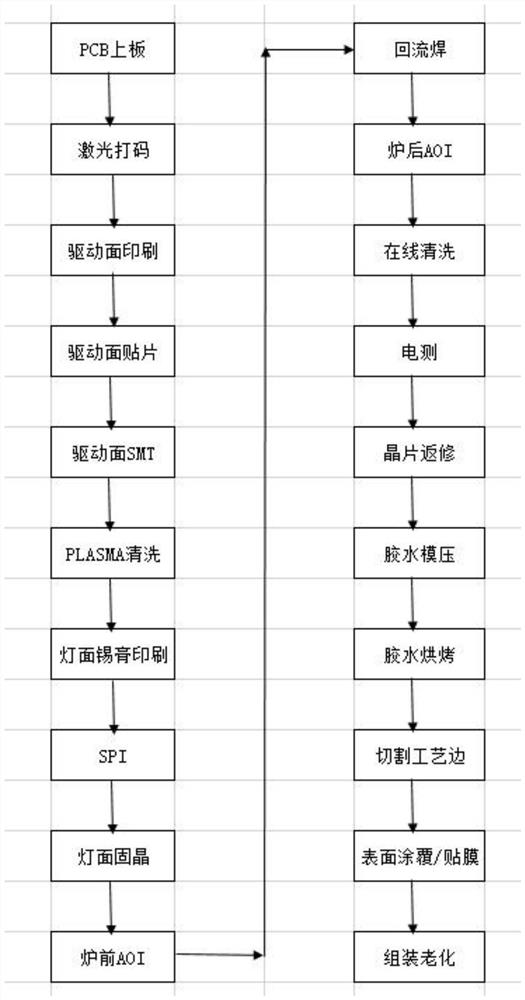

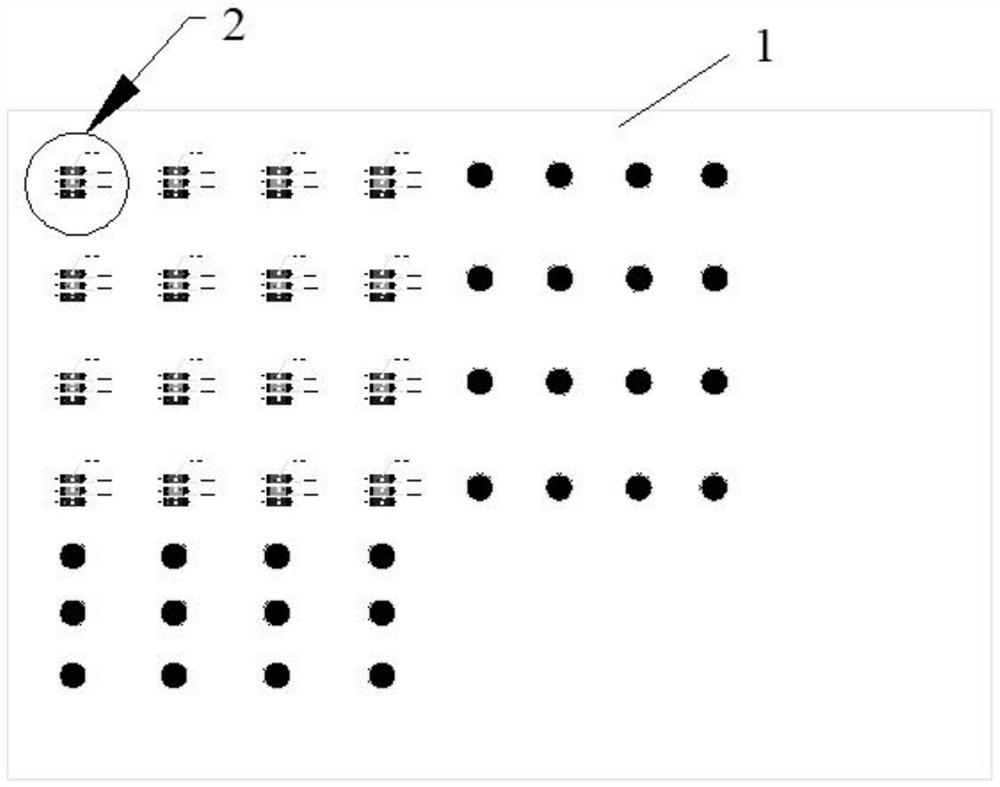

LED flip chip packaging technology-based LED screen packaging process and LED screen

PendingCN113782471APixel heightReduce spacingSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

The invention relates to an LED flip chip packaging technology-based LED screen packaging technology and an LED screen, and the packaging technology comprises the steps: welding an IC, a resistor, a capacitor, a power supply seat and a connection terminal on a PCB, and obtaining a first PCB; cleaning the first PCB, and uniformly expanding the plurality of LED flip chips by using a wafer expander; printing solder paste on the first PCB, fixing LED flip chips on the first PCB through a die bonder, enabling every three LED chips to form a pixel point, detecting the pixel point through AOI detection equipment, and putting qualified LED chips into a reflow soldering furnace to be welded into a second PCB; using the AOI detection equipment for detecting the second PCB, using a molding press to carry out out vacuum molding on the qualified second PCB to obtain a third PCB, after baking molding is carried out, according to the needed specification and size, cutting off unnecessary process edges, and carrying out coating or film pasting is carried out on the lamp face of the module. The surface is made to be black, the contrast ratio of the product is improved, and the color uniformity and consistency are improved, and the display effect is better; and each pixel point only needs six metal bonding points, so that a wire bonding link is omitted.

Owner:江西兆驰晶显有限公司

hook commutator

ActiveCN107994434BImprove ventilationSolve the problem of carbon accumulationRotary current collectorElectric machineEngineering

The invention discloses a hook-type commutator, which includes a base body and commutation segments uniformly arranged on the outer circumference of the base body, insulating grooves are provided between adjacent commutation segments for insulation, and welding wire hooks are arranged on the top of the commutation segments , characterized in that: the inner side of the insulating groove is provided with an axial through groove, the axial through groove is arranged in the same direction as the insulating groove and runs through the upper and lower end faces of the base body, the upper end face of the base body has a slope, and a guide groove is opened on the slope to guide The upper end of the flow groove is open, and the lower end of the flow guide groove communicates with the axial through groove. The invention can completely solve the problems of carbon deposition and virtual welding in the commutator, thereby eliminating the two most important factors of motor damage, greatly improving and effectively ensuring the service life of the motor, and low production cost.

Owner:瑞安博宇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com