Device and method for controlling suspension welding seam root gap and welding deformation in self-supporting mode

A welding seam root, welding deformation technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve problems such as reducing production efficiency, and achieve the effects of improving production efficiency, strong adaptability, and significant positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

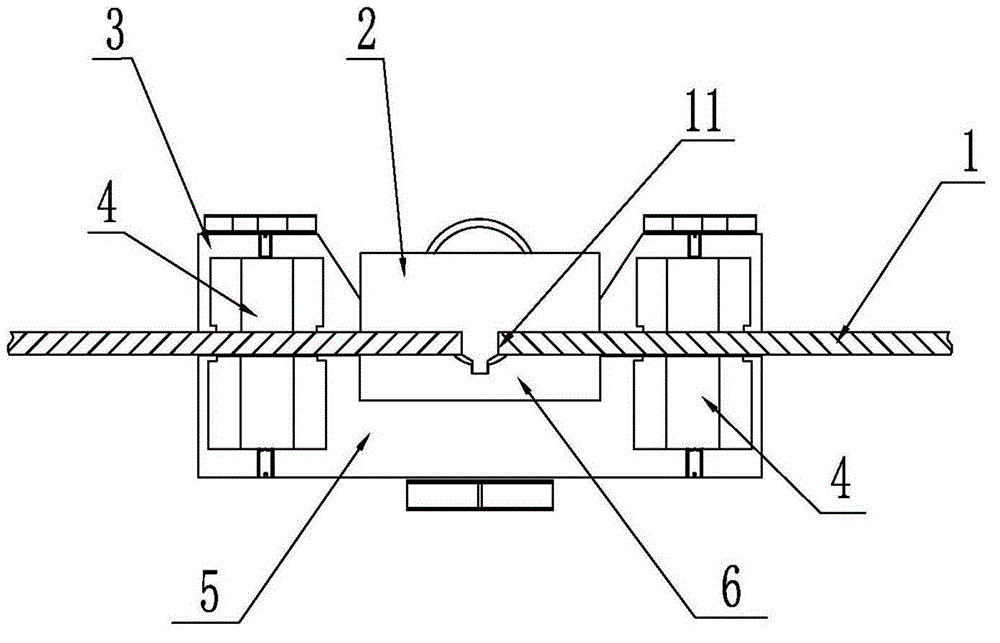

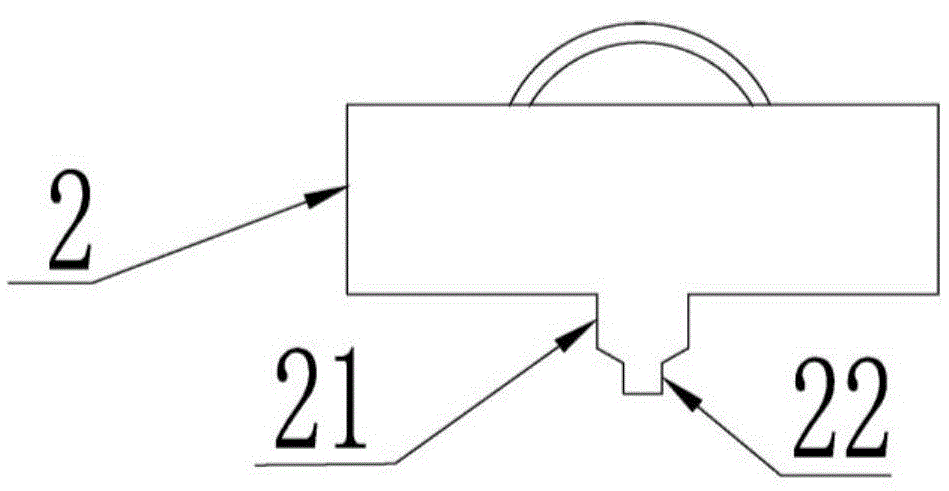

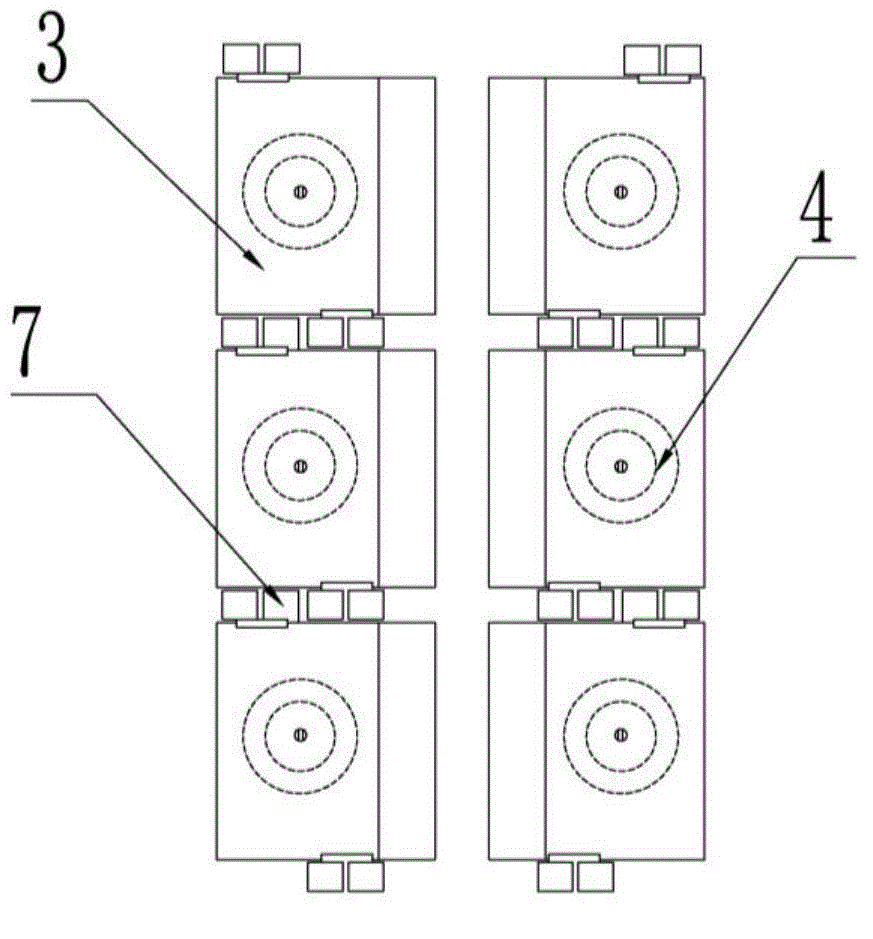

[0054] The self-supporting device for controlling the gap at the root of the suspended weld and welding deformation according to the present invention includes a positioning block 2, an upper rigid pressing block 3, a lower rigid pressing block 5 and a forming groove 6, and a groove is provided in the middle of the forming groove 6 61, the groove 61 is provided with a limit groove 62, the positioning block 2 includes a positioning block body and a positioning part, and the positioning part includes the first-level protrusion 21 on the positioning block body and the first-level The second-stage protruding part 22 on the protruding part 21, the shape of the first-stage protruding part 21 matches the weld root gap 11, and fits in the weld root gap 11, and the limiting groove The shape of 62 is matched with the second-stage protruding portion 22, and the second-stage protruding portion 22 is fitted in the limiting groove 62; the upper rigid pressure block 3 is symmetrically install...

Embodiment 2

[0063] In this embodiment, the device and welding method for self-supporting and controlling the gap at the root of the suspended weld seam and welding deformation are basically the same as in Embodiment 1, but the contact surfaces of the positioning block and the upper and lower rigid pressure blocks are all curved surfaces, so as to be used for welding of curved surface parts , the schematic diagram of the welding process is shown in figure 1 shown. In this embodiment, the thickness of the hull side plate is 4mm, and the butt welding part is a curved surface. Install the square positioning block whose contact surface is a curved surface, the upper and lower rigid pressing blocks, and the forming groove in sequence, and turn on the magnet. The magnets inside the upper and lower rigid pressing blocks will produce an anisotropic magnetic force. Strong pressure restraint, and then start TIG wire filler welding, because there is a forming groove below, the TIG welding single-sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com