A hook type commutator

A commutator, hook type technology, applied in the direction of current collectors, rotary current collectors, motor generator connectors, etc., can solve the problem of weak hook top strength of welding wire hooks, poor ventilation conditions of insulation grooves, affecting the stability of spot welding It can improve the stability of spot welding, increase the bending strength, and highlight the substantive characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

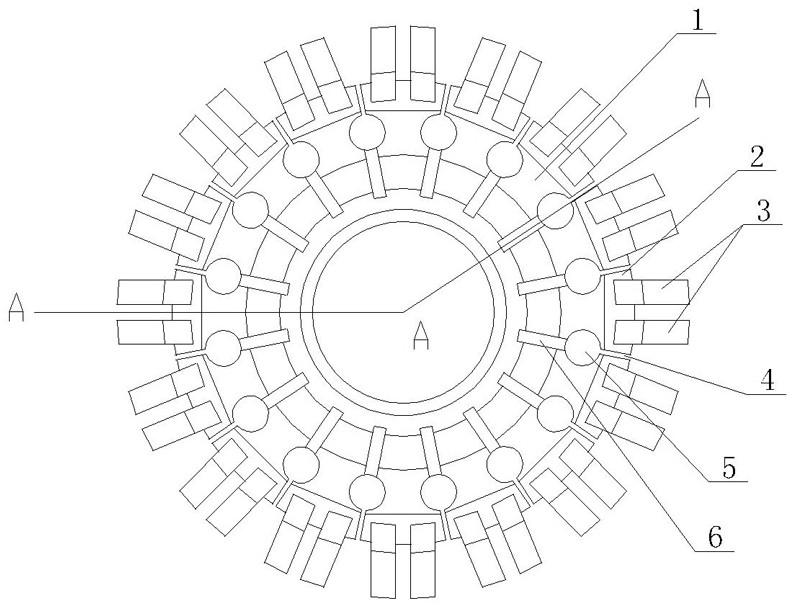

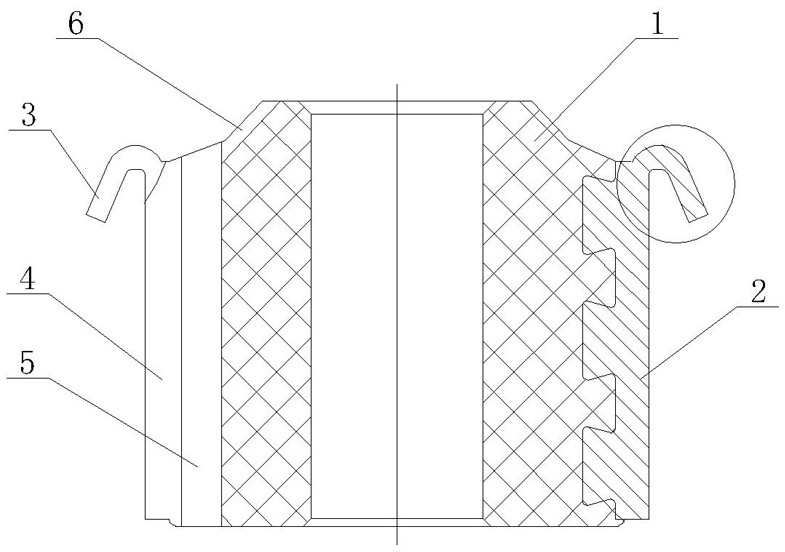

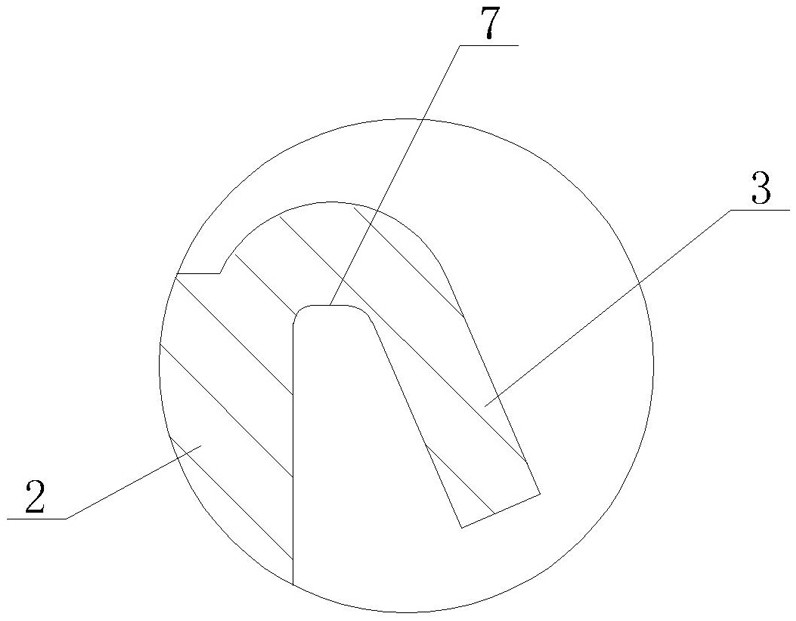

[0012] As shown in the figure, the hook-type commutator of the present invention includes a base body 1 and sixteen commutation segments 2 uniformly arranged on the outer circumference of the base body 1, and insulating grooves 4 are provided between adjacent commutation segments 2 for insulation. , the groove width of the insulating groove 4 is within 0.5 mm, the inner end of the insulating groove 4 is provided with an axial through groove 5, the axial through groove 5 is arranged in the same direction as the insulating groove 4 and penetrates the upper and lower end surfaces of the base body 1, and the upper end surface of the base body 1 The end face has an inclined surface, and a diversion groove 6 is opened on the inclined surface. The upper end of the diversion groove 6 is open, and the lower end of the diversion groove 6 communicates with the axial through groove 5. The axial through groove 5 is designed as a round hole. , the aperture of the axial through groove 5 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com