Patents

Literature

86results about How to "Solve the problem of carbon accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

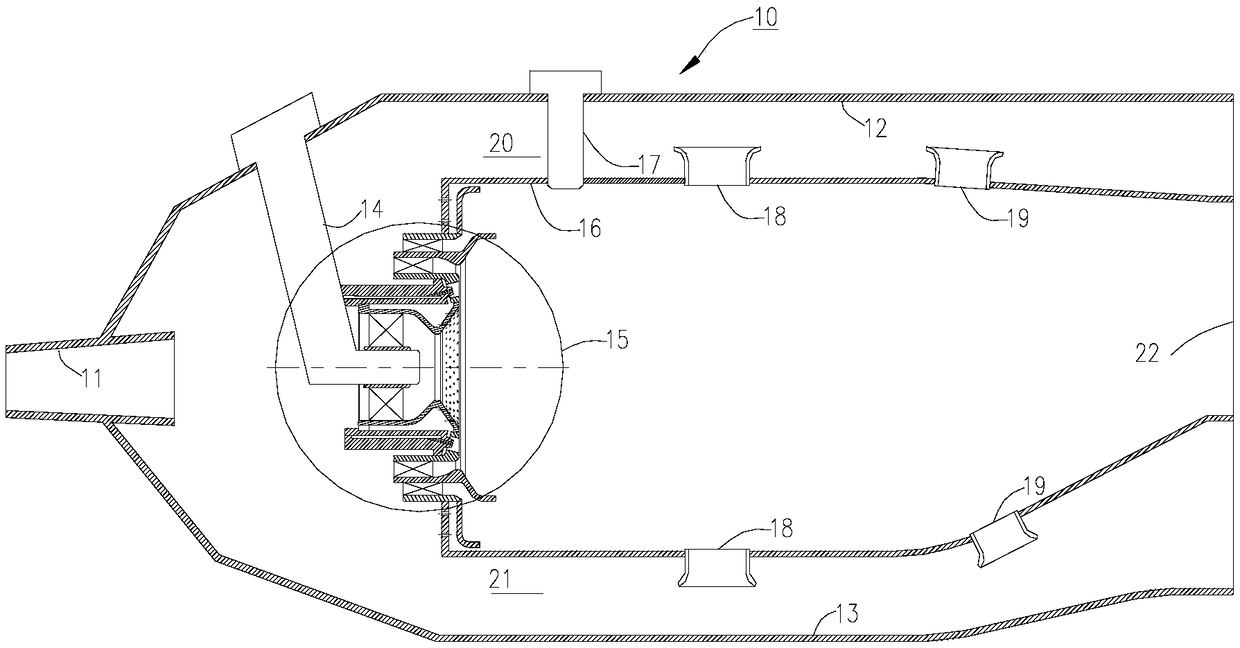

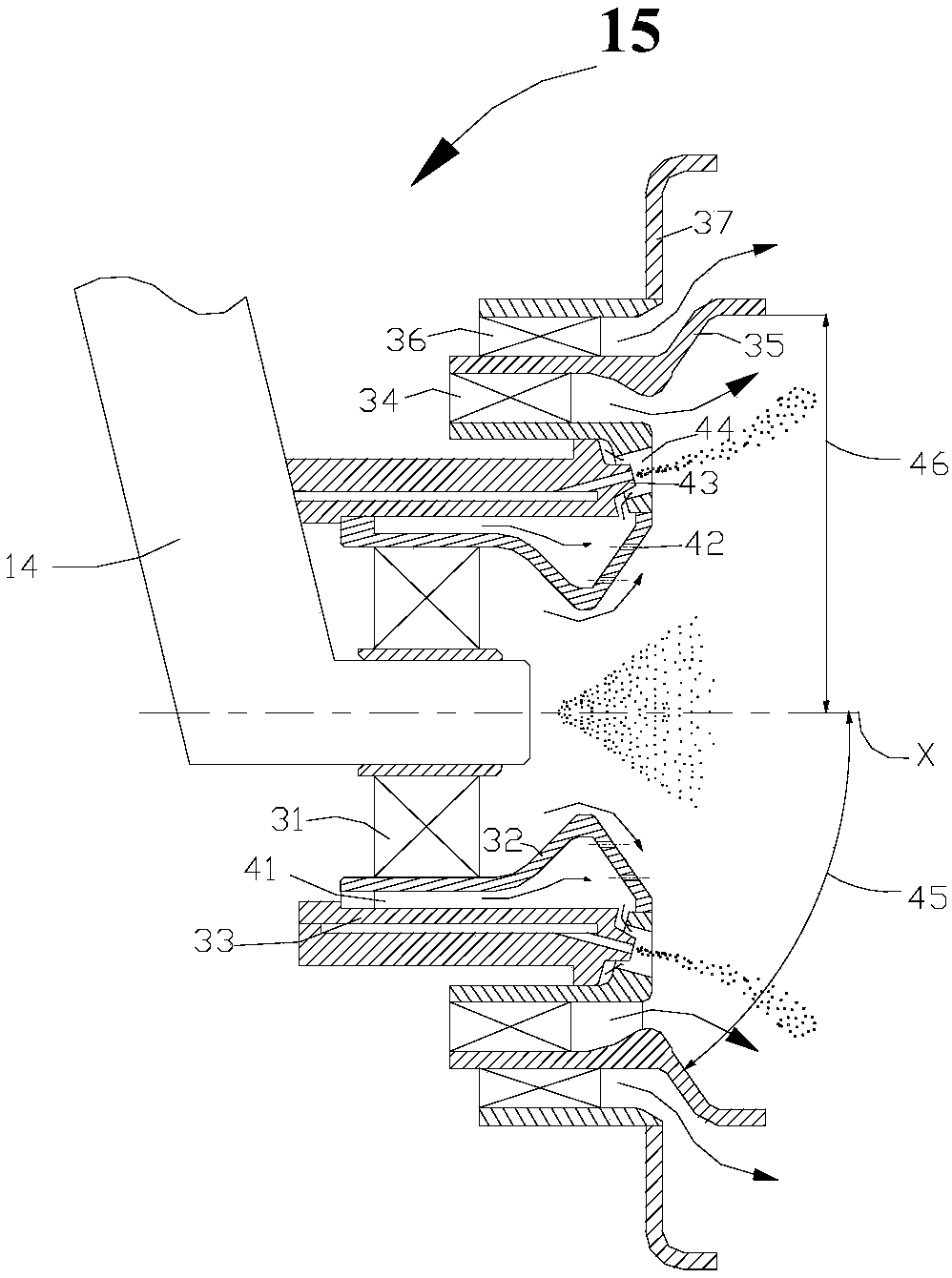

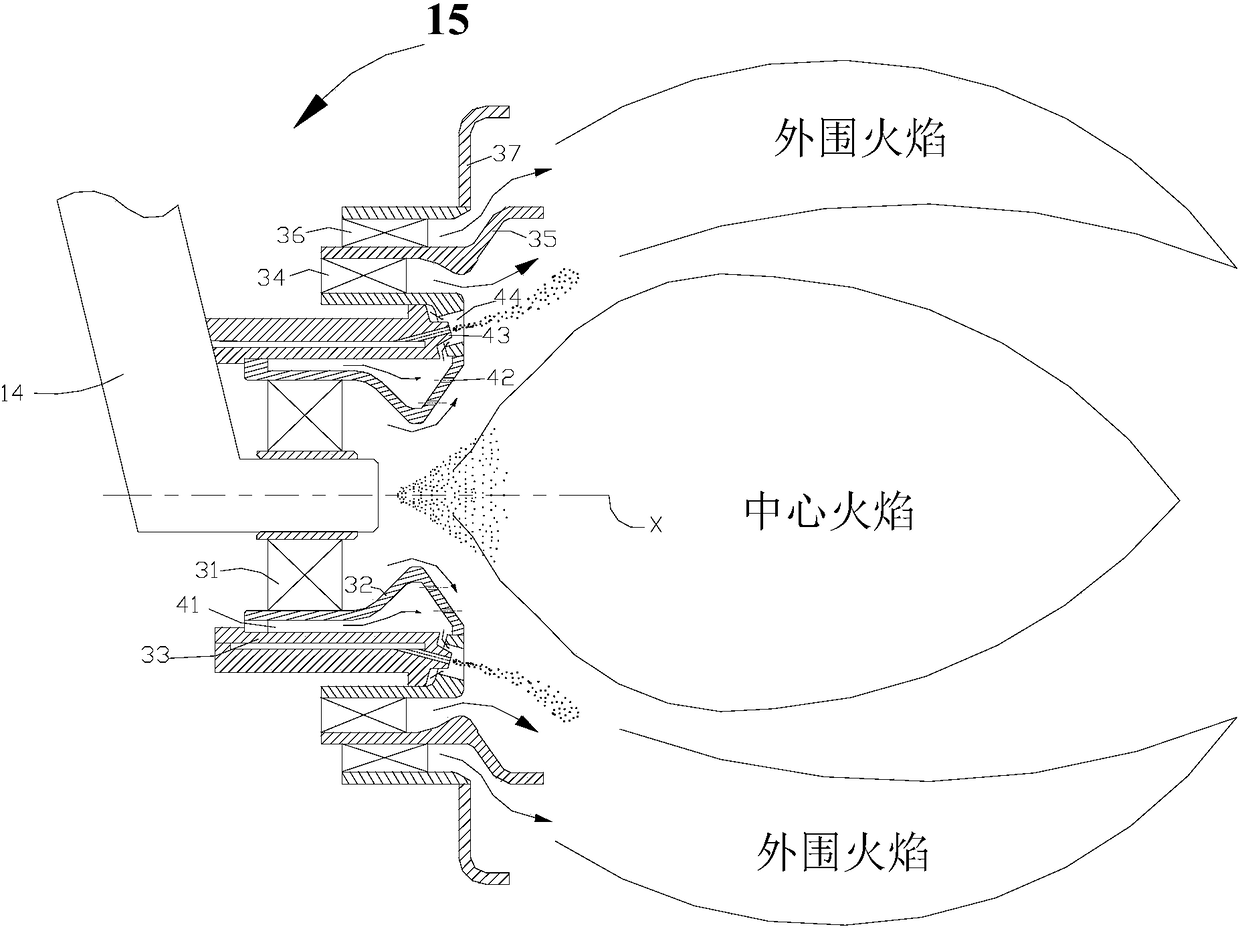

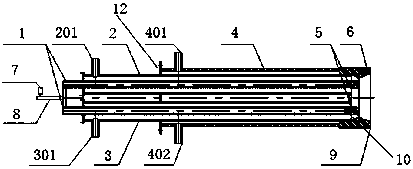

Coaxial partition high-temperature-rise combustor head

ActiveCN108561898AReliable ignitionStable jobContinuous combustion chamberCombustorCombustion chamber

The invention relates to a coaxial partition high-temperature-rise combustor head which comprises a first-stage axial hydrocyclone (31), a venturi (32), a main-stage fuel oil way (33), a second-stageaxial hydrocyclone (34), a baffling device (35), a three-stage axial hydrocyclone (36) and a splash pan (37). A middle cooling runner (41) is formed between the venturi (32) and the main-stage fuel oil way (33), an expansion section of the venturi (32) is provided with a plurality of rows of cooling small holes (42), part of air flowing into the middle cooling runner (41) flows out from the cooling small holes (42) in the expansion section of the venturi (32), the other part of air flows through the periphery of a main spraying opening (43) in the tail end of the main-stage fuel oil way (33) to flow out from a main-stage fuel oil atomization channel (44).

Owner:AECC SICHUAN GAS TURBINE RES INST

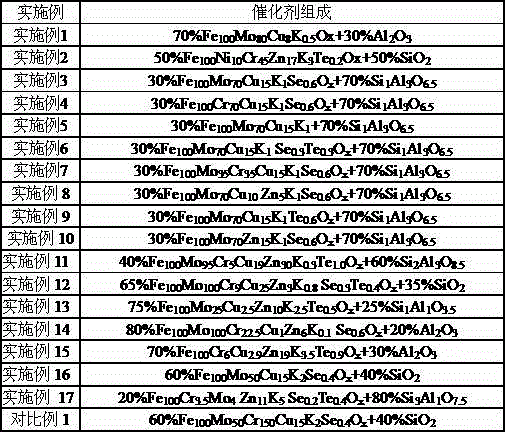

Catalyst for preparing low-carbon olefin from synthesis gas as well as preparation method and application of catalyst

ActiveCN104549343AGood choiceEnhanced adsorption and activationHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActive componentOrganic chemistry

The invention relates to a catalyst for preparing low-carbon olefin from synthesis gas as well as a preparation method and application of the catalyst, and aims at mainly solving the problems in a process of preparing the low-carbon olefin from the synthesis gas that the activity and the selectivity of the catalyst are low at a low temperature. The problems are solved very well by adopting the technical scheme that a Fischer-Tropsch synthesis catalyst is adopted and is prepared from the following components in percentage by weight: (1) 20%-80% of an active component; (2) 20%-80% of a carrier, wherein the carrier is selected from at least one of SiO2 and Al2O3; the active component is represented by the following formula according to an atomic ratio: Fe100AaBbKcOx, wherein A is at least one of Cu and Zn; B is at least one of Cr and Mo; the value range of a is 5-50; the value range of b is 5-150; and the value range of c is 0.1-5. The catalyst can be used for industrial production of preparing the low-carbon olefin from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alcohol-based liquid fuel and manufacturing method thereof

InactiveCN103710055ASolve the problem of carbon accumulationCarbon deposits do not appearLiquid carbonaceous fuelsSodium acetateGlycerol

The invention provides alcohol-based liquid fuel. The alcohol-based liquid fuel comprises methanol, an additive and a catalyst. The additive comprises, by mass, 31-35% of water, 5% of sodium hydroxide, 5% of sodium acetate, 35% of glycerol, 18% of hydrogen peroxide and 2-6% of ferric nitrate. The catalyst is ferrocene. The components in the additive and mass parts of the components are adjusted, content of hydrogen peroxide as an oxygenation agent is improved and water content is reduced. Through use of ferric nitrate, carbon formation of the existing alcohol-based liquid fuel is avoided and carbon deposit is not produced after continuous combustion for 12h. The invention also provides a manufacturing method of the alcohol-based liquid fuel. The manufacturing method comprises the following steps of additive mixing preparation, methanol addition and ferrocene addition. The manufacturing method has simple processes. All the components of the alcohol-based liquid fuel have good miscibility.

Owner:HUBEI LI RUI ENERGY TECH

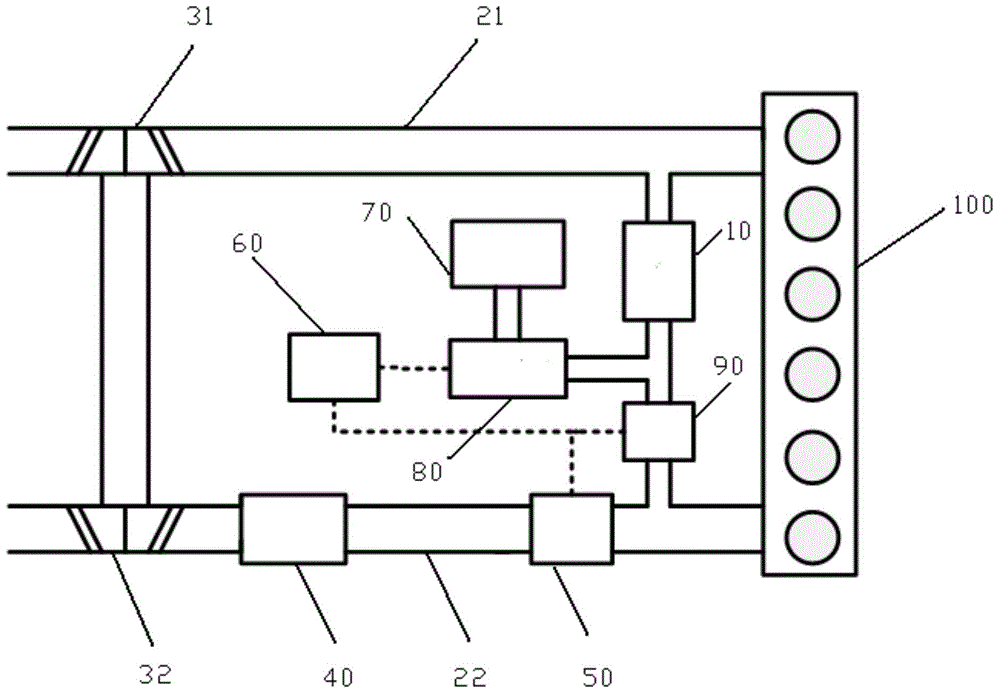

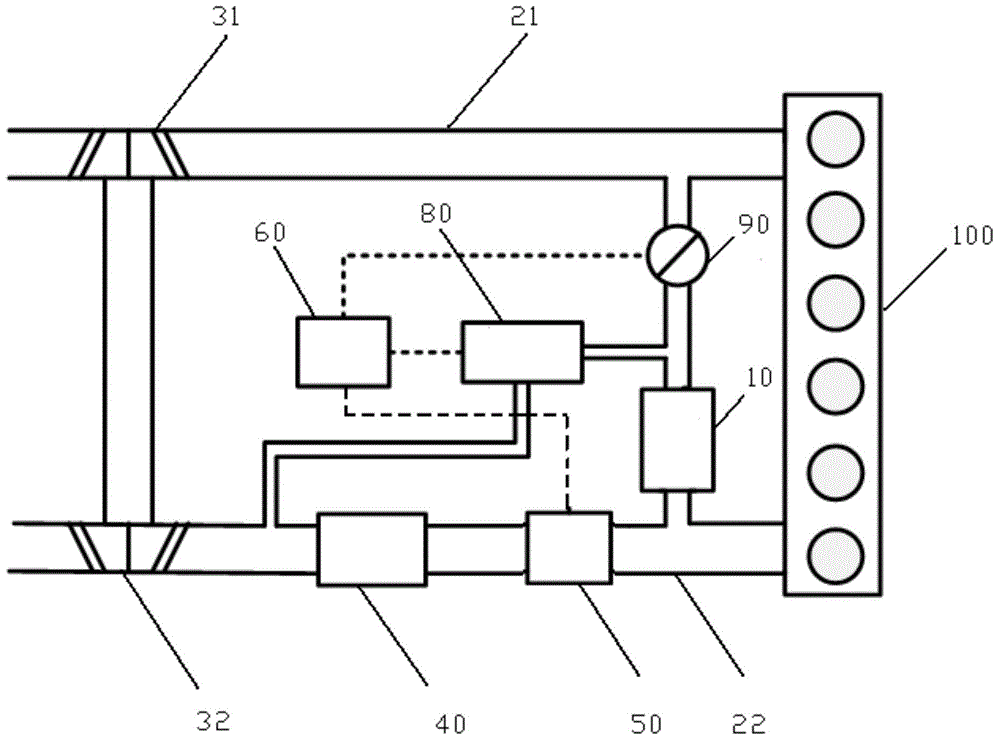

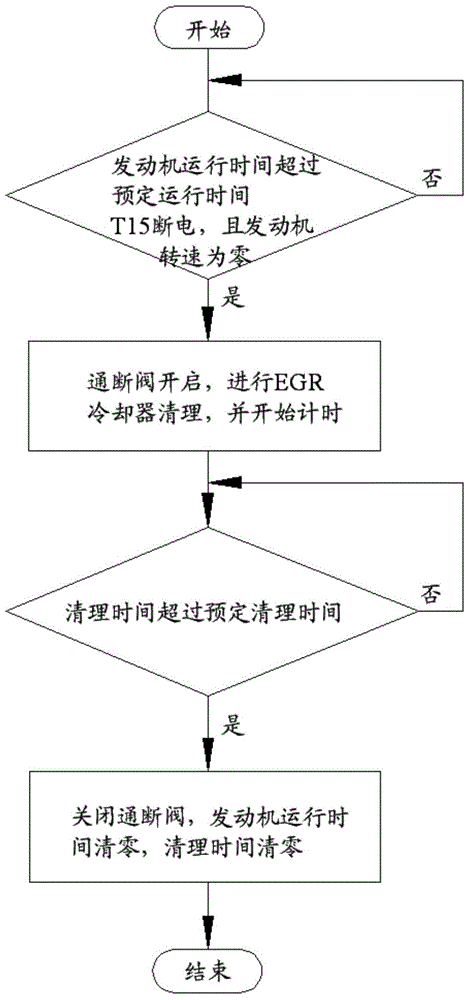

EGR cooler cleaning method and cleaning apparatus

InactiveCN104912664ASolve carbon deposits and corrosion problemsGuaranteed performanceNon-fuel substance addition to fuelInternal combustion piston enginesChillerCorrosion

The invention discloses an EGR cooler cleaning method and cleaning apparatus. The cleaning method comprises the following steps of building an activation condition for EGR cooler cleaning, injecting high pressure air into the EGR cooler upon activation condition establishment to clean the EGR cooler. Substance such as carbon deposit and acid liquor are blown away via the high pressure airflows, so carbon deposit and corrosion can be prevented and performance of the EGR cooler can be ensured; and compared with the prior art, with material improvements and DOC arrangement, cost can be remained the same or reduced.

Owner:WEICHAI POWER CO LTD

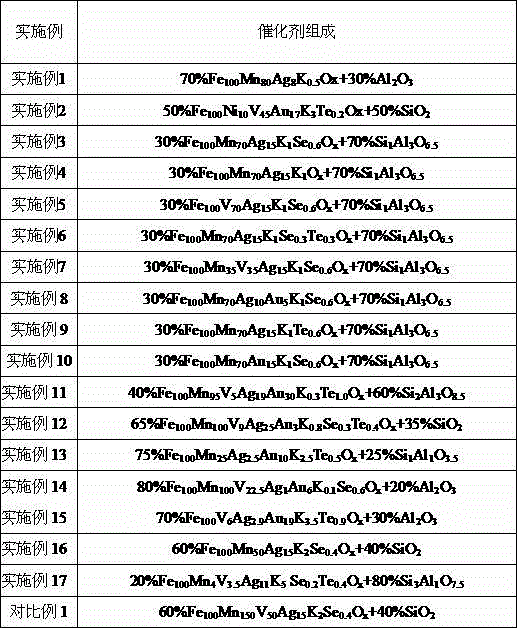

Catalyst for producing low-carbon olefin as well as preparation method and using method of catalyst

ActiveCN104549359AEnhanced adsorption and activationPromote reductionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsLow activityBULK ACTIVE INGREDIENT

The invention relates to a catalyst for producing low-carbon olefin and a preparation method of the catalyst, and mainly aims to solve the problems of low activity and low selectivity of the catalyst at low temperature in synthesis gas prepared olefin. The problems can be well solved by adopting the technical scheme that the catalyst is prepared from the following components in percentage by weight: 20-80 percent of an active ingredient (1) and 20-80 percent of carrier (2) which is at least one of SiO2 and Al2O3, wherein the active ingredient is as shown in the general formula Fe100AaBbKcOx in an atomic ratio, A is at least one of Ag and Au, and B is at least one of Mn and V; the value range of a is 5-50, the value range of b is 5-150, and the value range of c is 0.1-5. The catalyst can be applied to industrial production of low-carbon olefin from synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

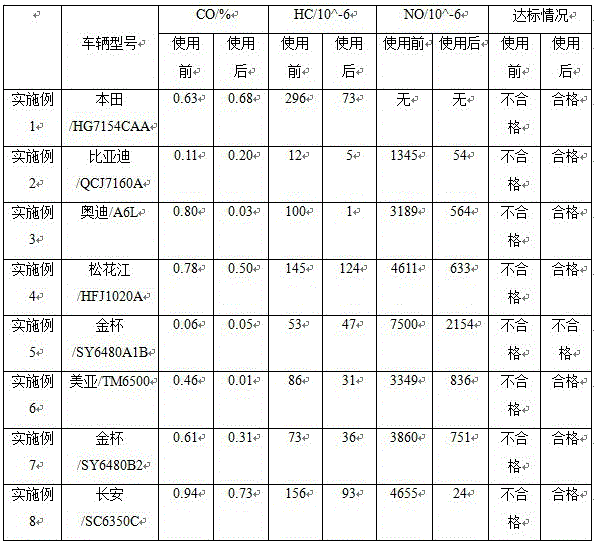

Function repair liquid for oxygen sensor and three-way catalyst and preparation method and use method

InactiveCN105861191AEasy to peelPyroelectricInorganic/elemental detergent compounding agentsCationic surface-active compoundsHeavy Metal PoisoningsCorrosion

The invention relates to the field of automobile component part repair liquids, in particular to a function repair liquid and a repair powder for an oxygen sensor and a three-way catalyst. The repair liquid comprises the following raw materials in parts by weight: 10 to 30 parts of weak acid or weak alkaline, 2 to 5 parts of inorganic bentonite, 2 to 5 parts of nanometer negative ion powder, and 60 to 86 parts of water. The function repair liquid has the advantages that the function repair liquid can enter the interior of deposited carbon, the deposited carbon structure can be loosened, and the oxide particles attached to the surface of the catalyst can be eroded; the problems of carbon deposition and heavy metal poisoning of the three-way catalyst and the oxygen sensor can be effectively solved, and the corrosion function on platinum, rhodium and palladium metals is little; the emission of tail gas can reach the national standard after the function repair liquid is used. The invention also provides a preparation method and a use method of the function repair liquid, and the function of the function repair liquid can be further improved.

Owner:江力

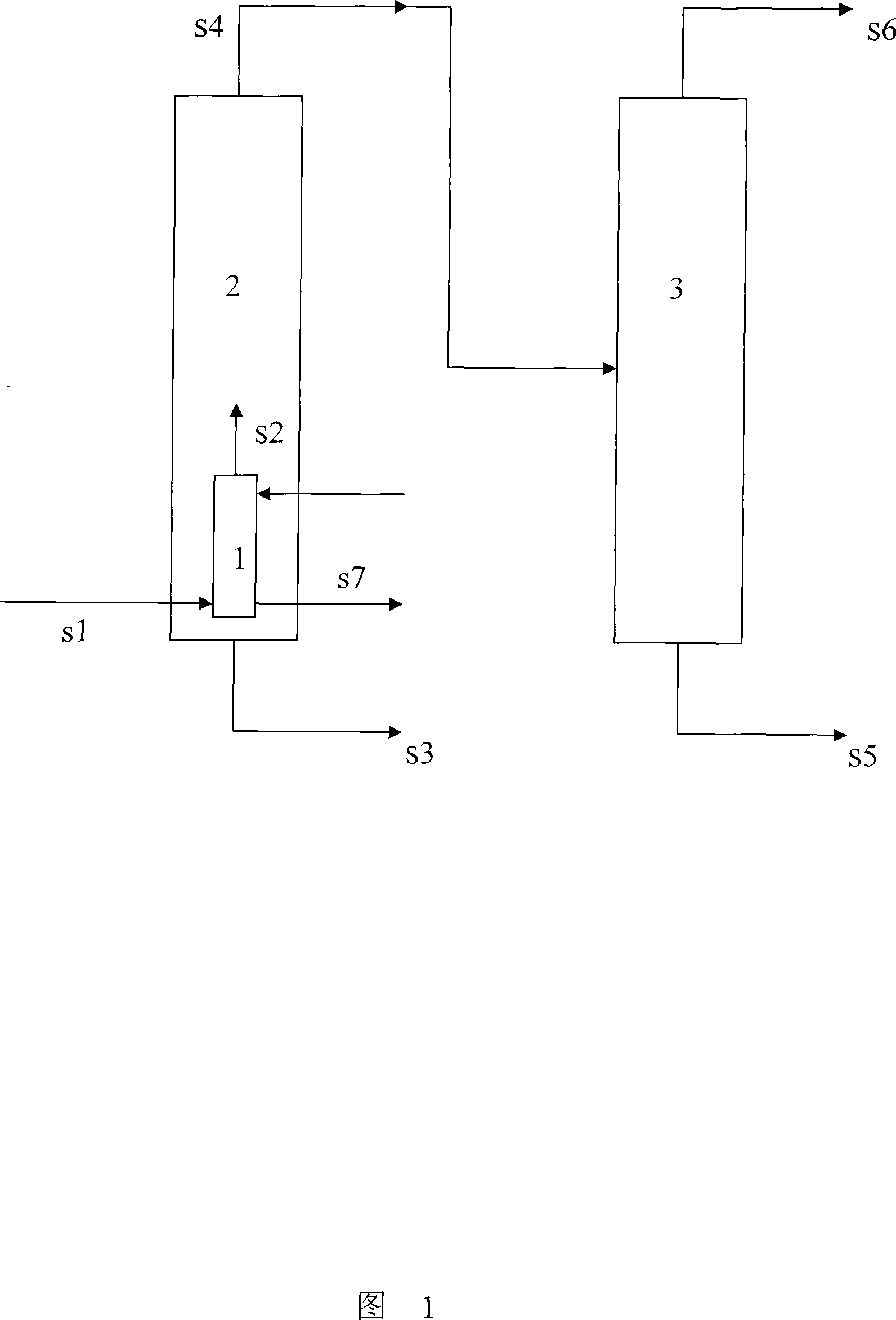

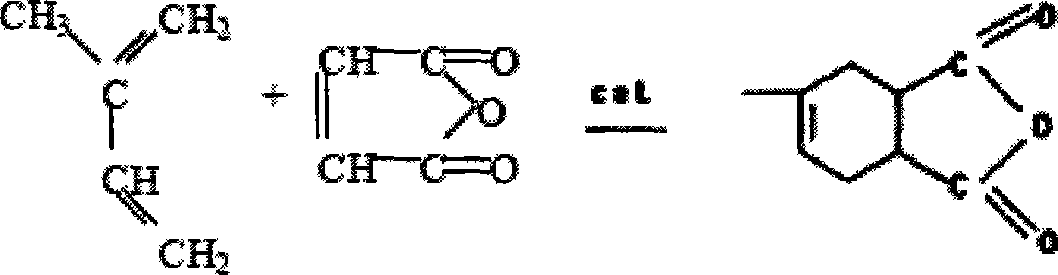

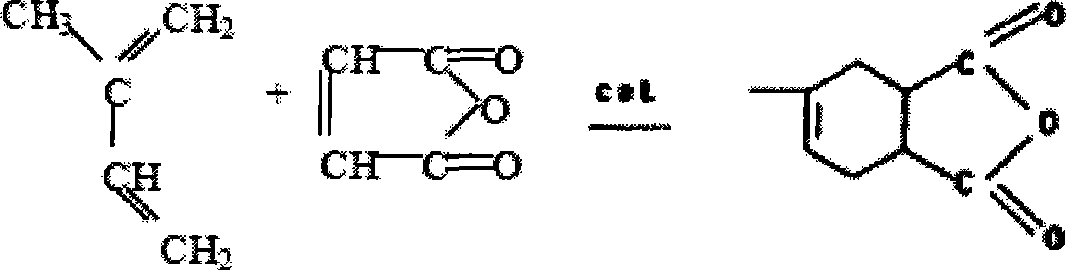

Method for separating cyclopentadiene and methylcyclopentadiene from ethylene by-product C9

InactiveCN101186553AExpand sourceSolve the problem of carbon accumulationDistillation purification/separationHydrocarbon by depolymerisationMethylcyclopentadieneEthylene

The invention relates to a method of separating cyclopentadiene and methyl cyclopentadiene from a mixture with ingredients of dicyclopentadiene and dimethyl cyclopentadiene. The method is particularly suitable for purifying and separating the cyclopentadiene and methyl cyclopentadiene from ethylene byproduct C9 or crude cyclopentadiene. Ethylene byproduct C9 or crude dicyclopentadiene that contains dicyclopentadiene and dimethyl cyclopentadiene is put into a high-temperature cracking reactor that is arranged in a tower boiler of a rectifying tower 1; pyrolyzed mixture gas under high temperature runs upwards through the rectifying tower to lead distillate that contains the cyclopentadiene and the methyl cyclopentadiene to be separated at the top of the tower; the mixture distillate of the cyclopentadiene and methyl cyclopentadiene that is extracted at the top of the rectifying tower 1 enters a rectifying tower 2, and the cyclopentadiene is extracted from the top of the tower and the methyl cyclopentadiene is extracted from the bottom of the tower.

Owner:天津天大天海化工新技术有限公司 +1

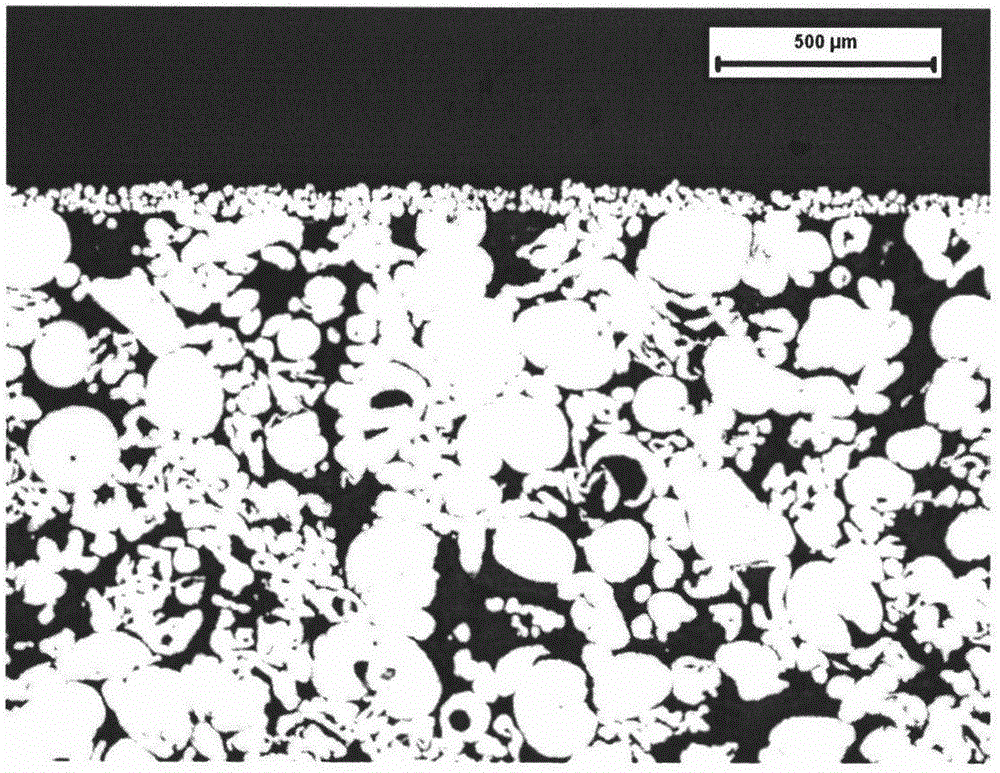

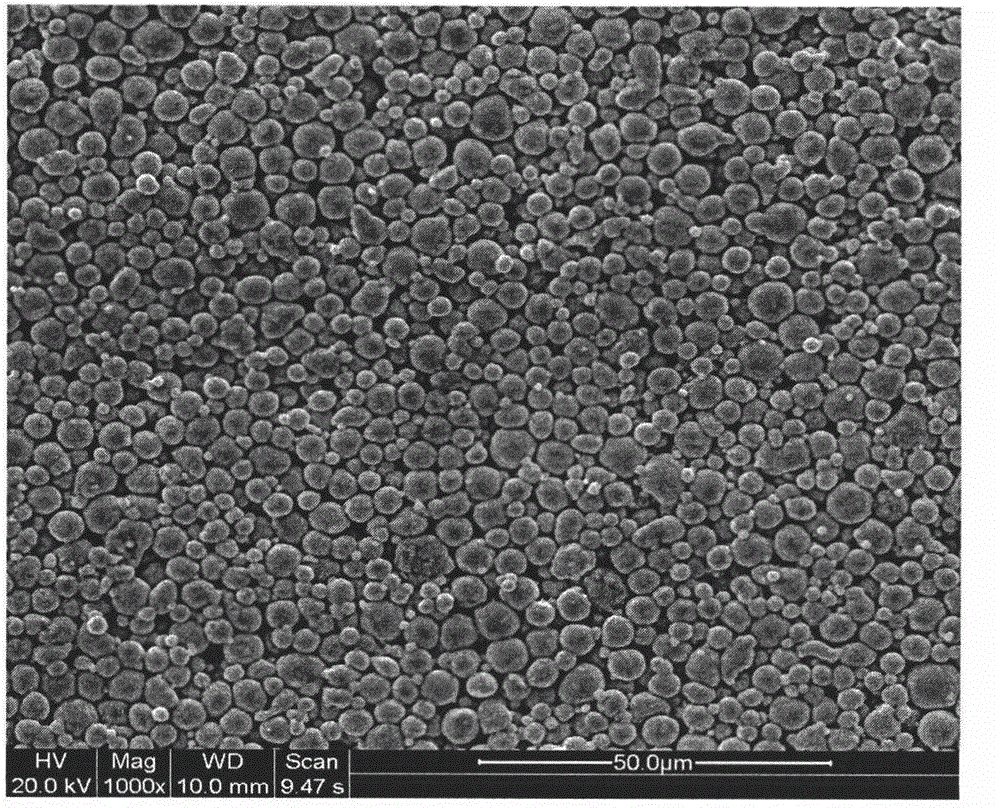

Method for preparing microporous metal layer on macroporous metal surface

The present invention relates to a method for preparing a microporous metal layer on the macroporous metal surface. The specific process comprises: brushing a hydroxide slurry on the surface of a macroporous metal substrate by using a brushing method to block pores, drying, and progressively carrying out burnishing, washing and drying on the obtained surface of the metal substrate by using sand paper; mixing metal powder for preparing the microporous metal layer and an organic additive to prepare a suspension, coating on the surface of the metal substrate to form a billet, and carrying out high temperature sintering in an inert or reducing atmosphere; and finally using a chemical reagent and ultrasonic washing to remove the residual inorganic material in the substrate to obtain the high gradient pore structure porous metal.

Owner:江苏七禾新材料科技有限公司

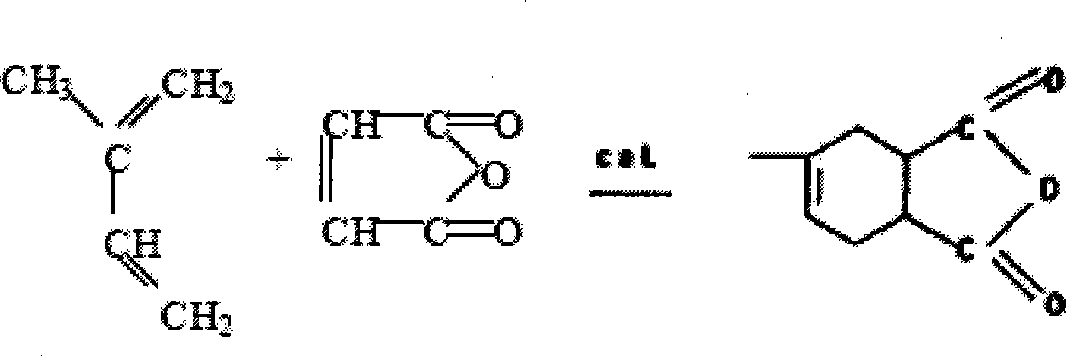

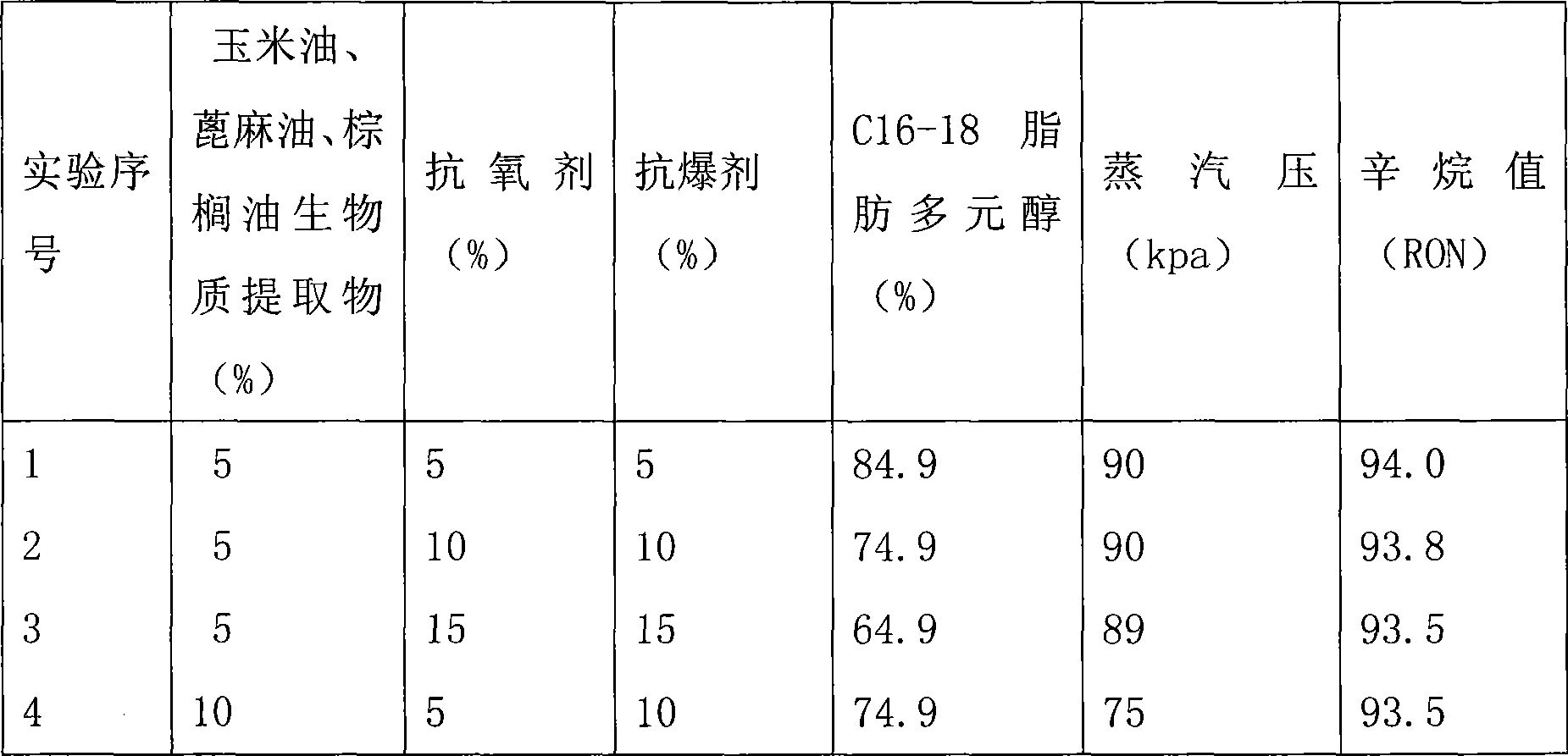

Automobile composite fuel

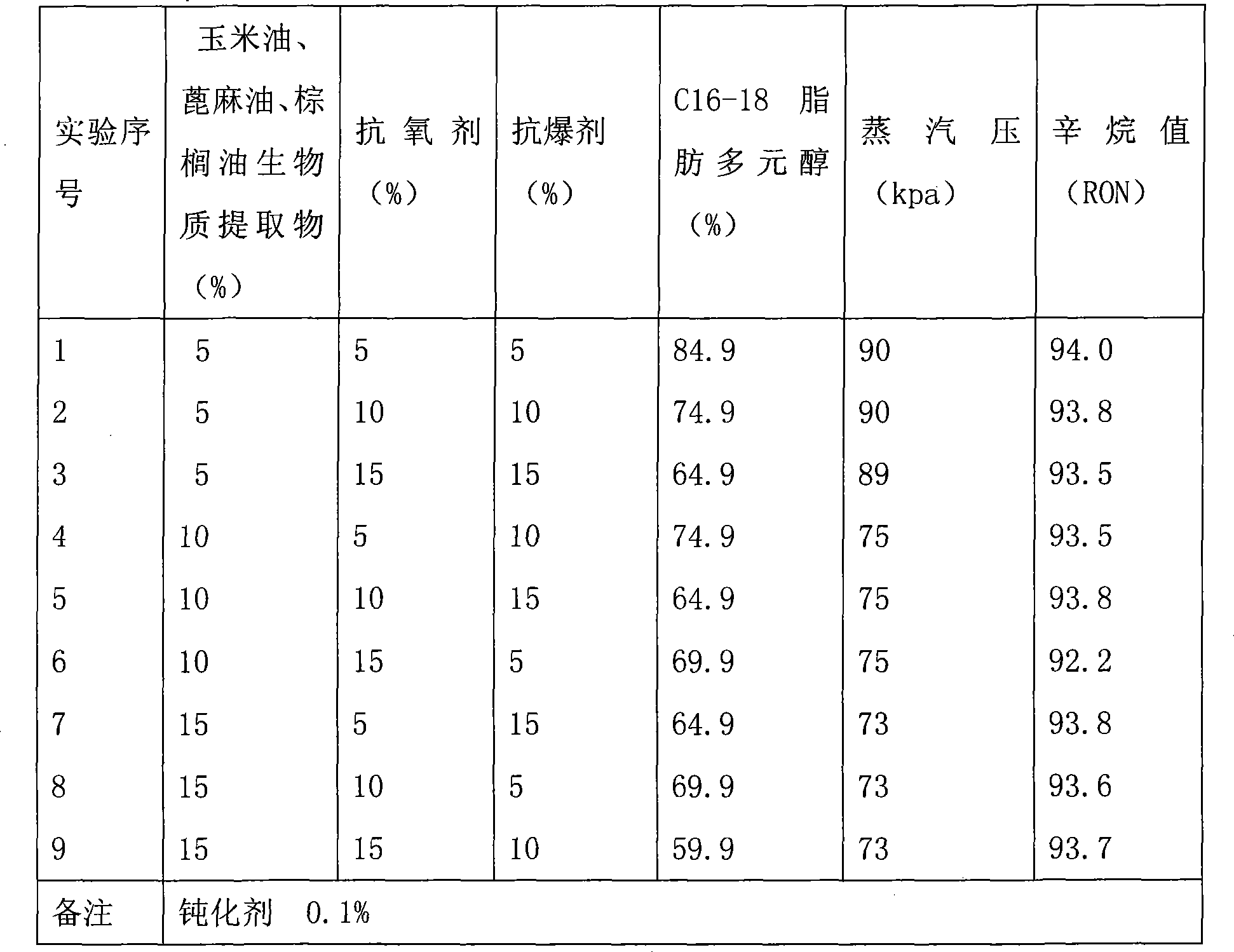

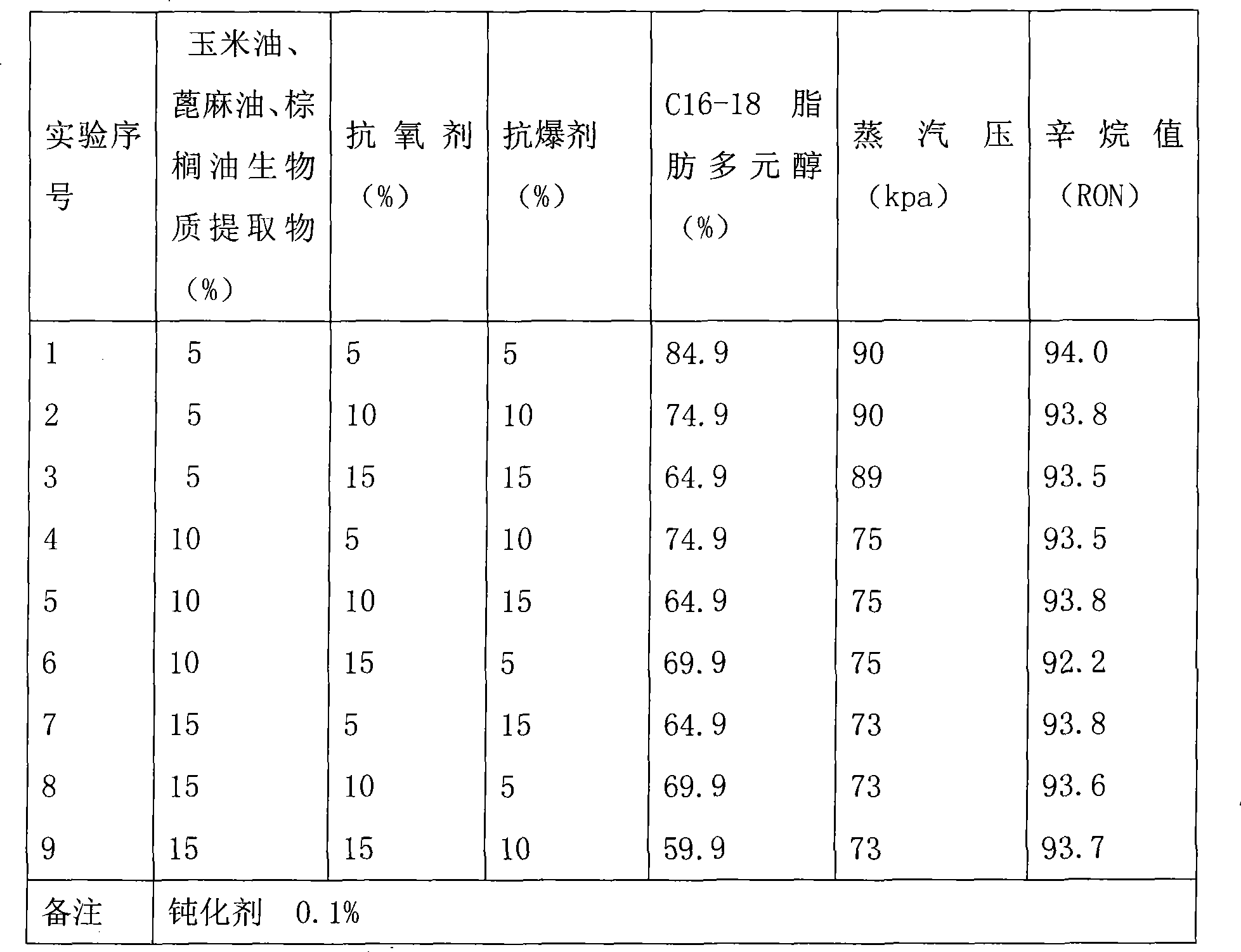

InactiveCN101386798ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsGasoline fuelAntioxidant

The invention discloses a composite fuel oil for automobiles, which belongs to the technical field of automobile fuel oil. The fuel oil product of the automobiles is compounded by a fuel oil additive and gasoline, wherein the fuel oil additive is prepared by mixing a mixture of extractives of biomass such as corn oils, castor oils and palm oils, fatty polyol, antioxidants, antiknock agents, passivation agents and modified C5 according to certain proportion. The composite fuel oil product can partly substitute gasoline as well as improve gasoline performance so as to combust gasoline more fully and reduce coking and carbon deposition in an engine and emission of harmful substances in automobile tail gas. Through inspection of Chinese Ethanol Gasoline Quality Supervision and Testing Center, the product reaches national standard.

Owner:HENAN ACAD OF SCI

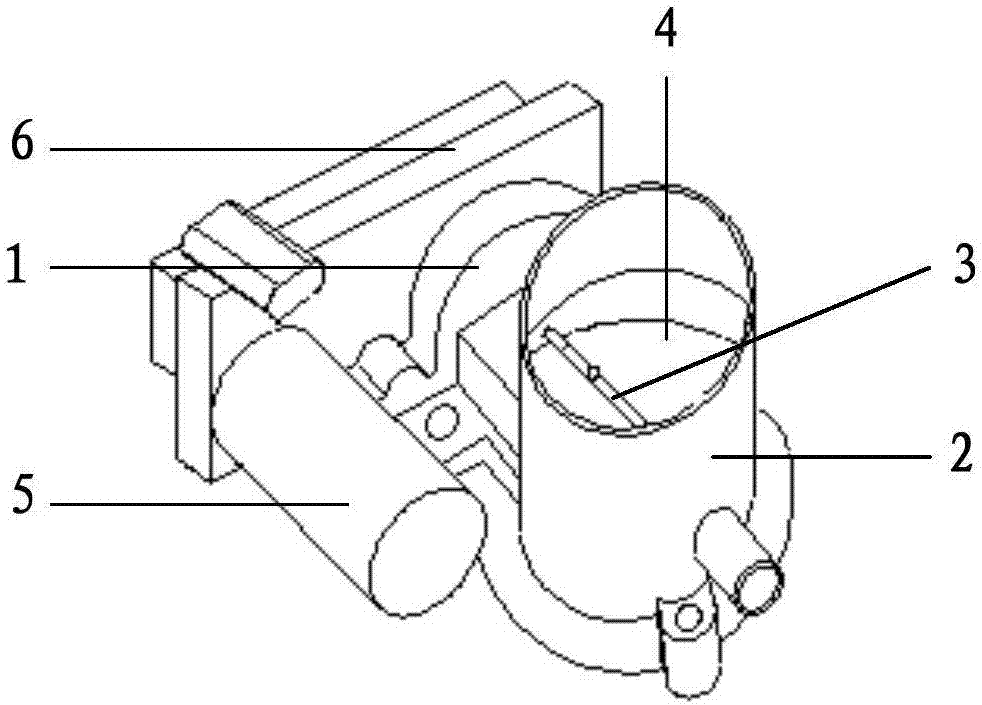

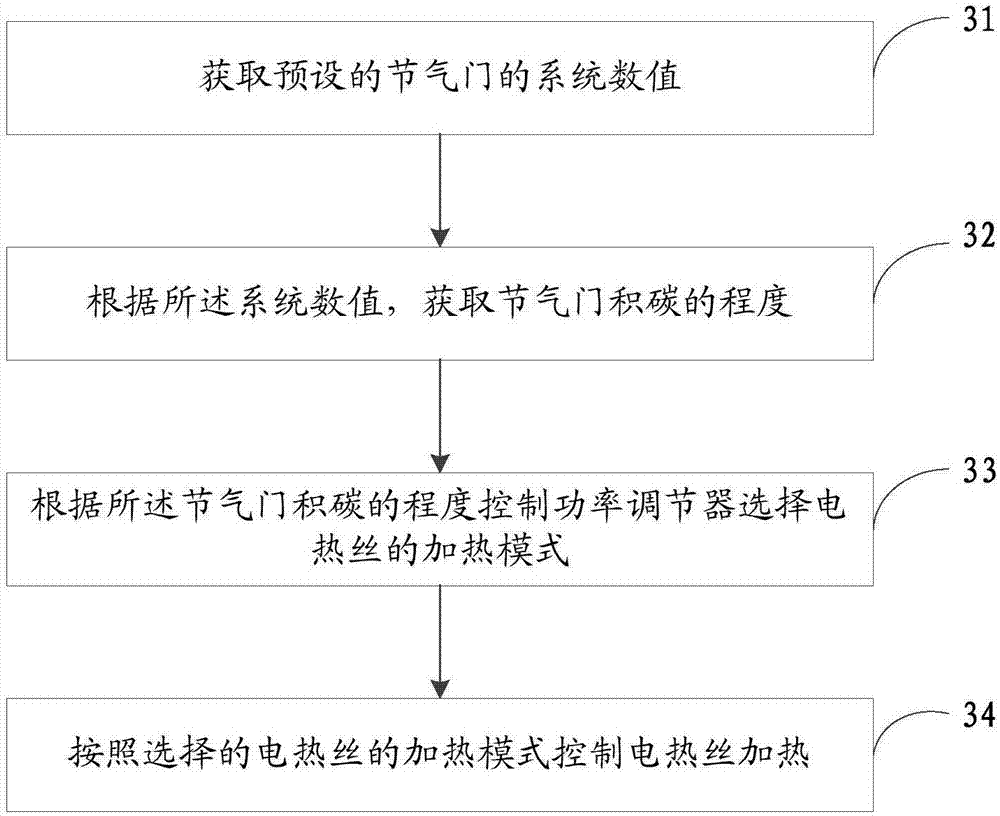

Throttle valve structure and self-cleaning method for throttle valve carbon deposit

PendingCN107288763ARealize self-cleaningSolve the problem of carbon accumulationEngine controllersMachines/enginesButterfly valveCarbon deposit

The invention discloses a throttle valve structure and a self-cleaning method for throttle valve carbon deposit. The throttle valve structure comprises a valve body, an air inlet pipe arranged on the valve body, a butterfly valve shaft vertically arranged in the air inlet pipe, a butterfly valve arranged on the butterfly valve shaft, an electric heating wire integrated in the butterfly valve, a power adjuster connected with the electric heating wire, and an ECU connected with the power adjuster and the butterfly valve shaft. When an engine shuts down, a system actively recognizes the carbon deposit situation, a proper self-cleaning mode is selected, the throttle valve body butterfly valve heating work manner is adopted, and two-level control is conducted on heating power; and through heating and evaporating of the carbon deposit on the butterfly valve, self-cleaning of a throttle valve body is achieved, and the problem of carbon deposit of a throttle valve can be effectively solved; and meanwhile a reference is provided for the ECU control strategy and throttle valve body design and development.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

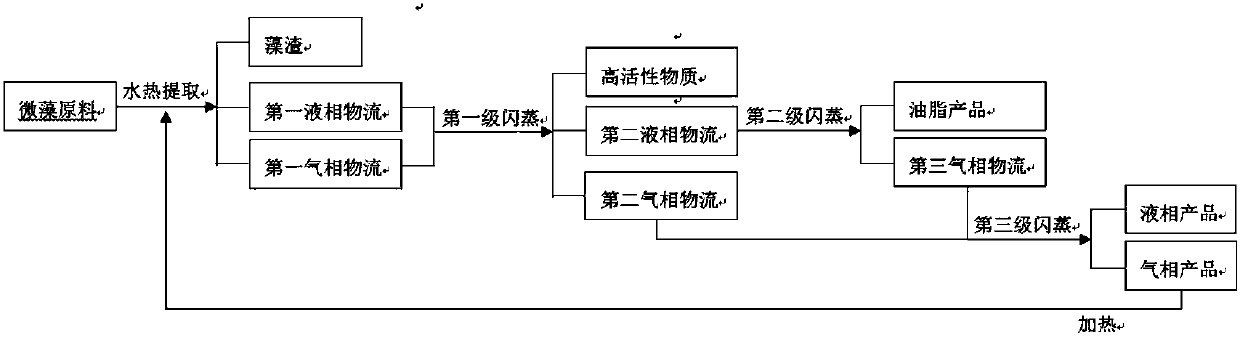

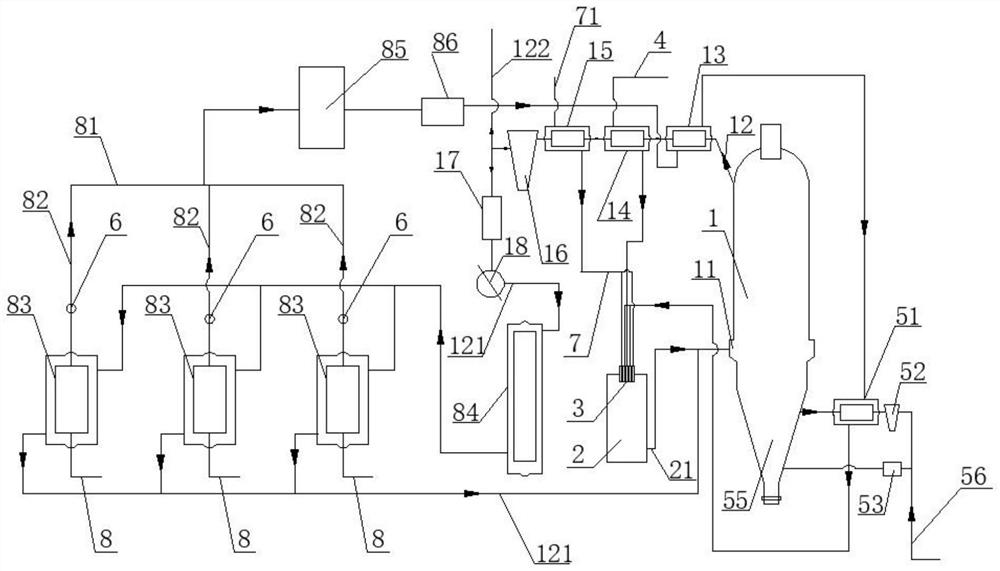

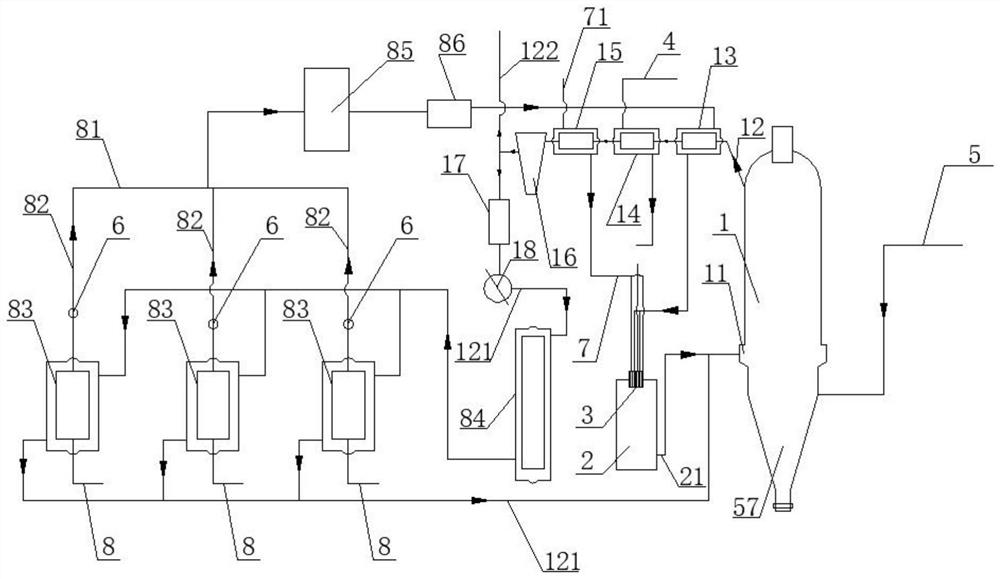

Microalgae grease extraction and separation method, equipment and application

InactiveCN107739655AObvious advantage of energy savingImprove extraction efficiencyFatty-oils/fats refiningFatty-oils/fats productionGas phaseHigh activity

The invention provides a microalgae grease extraction and separation method which comprises the following steps: S1, performing extraction treatment on a microalgae raw material with a hydrothermal method, so as to obtain a first liquid phase flow, a first gas phase flow and microalgae dregs; S2, performing first-stage flash evaporation treatment on the first liquid phase flow and the first gas phase flow, so as to obtain high-activity substances, a second liquid phase flow and a first gas phase flow; S3, performing second-stage flash evaporation treatment on the second gas phase flow, so as to obtain a grease product and a third gas phase flow; S4, performing third-stage flash evaporation treatment on the second gas phase flow and the third gas phase flow, so as to obtain a liquid phase product and a gas phase product. According to the method provided by the invention, high-quality components and grease are prepared by controlling steam wall breaking conditions, and separation of high-activity substances, grease and algae dregs is achieved by controlling the flash evaporation temperature and pressure. By adopting the method provided by the invention, not only is separation of high-activity substances from grease achieved, but also the grease of the obtained high-activity substances is high in purity.

Owner:BEIHANG UNIV

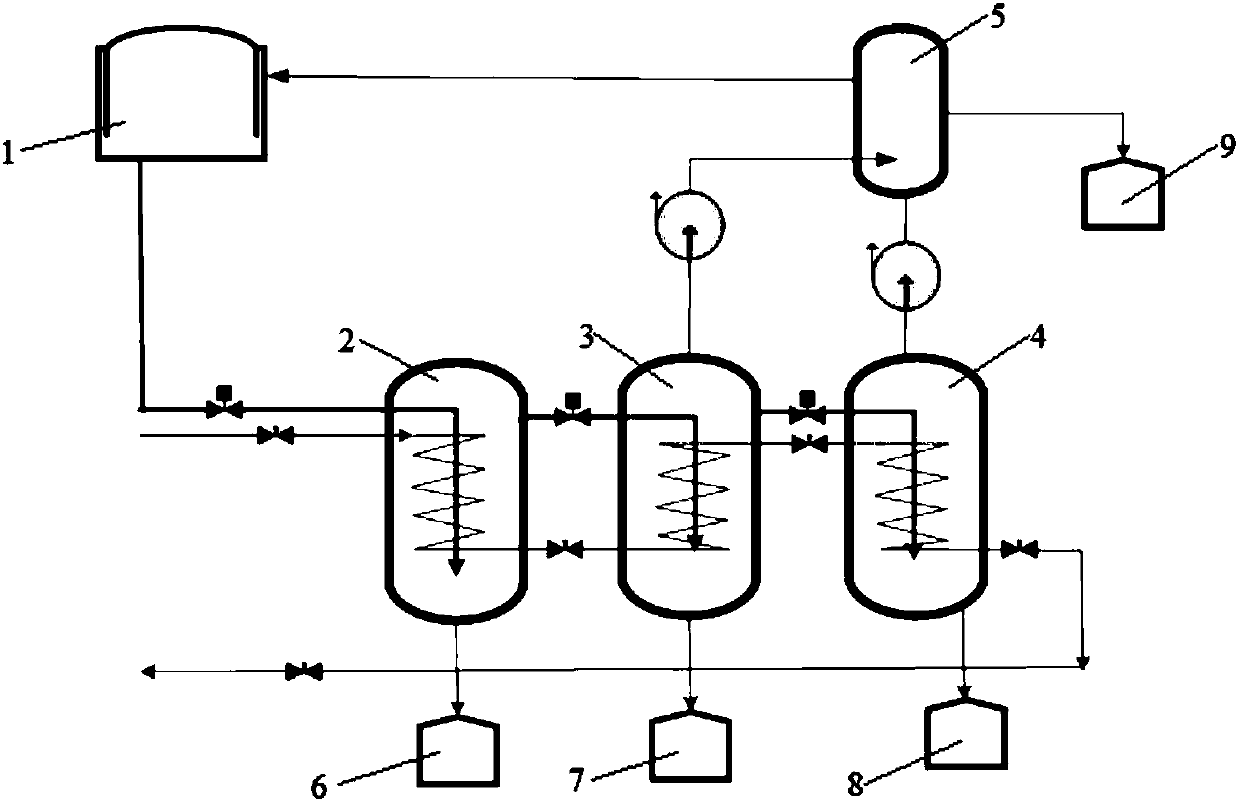

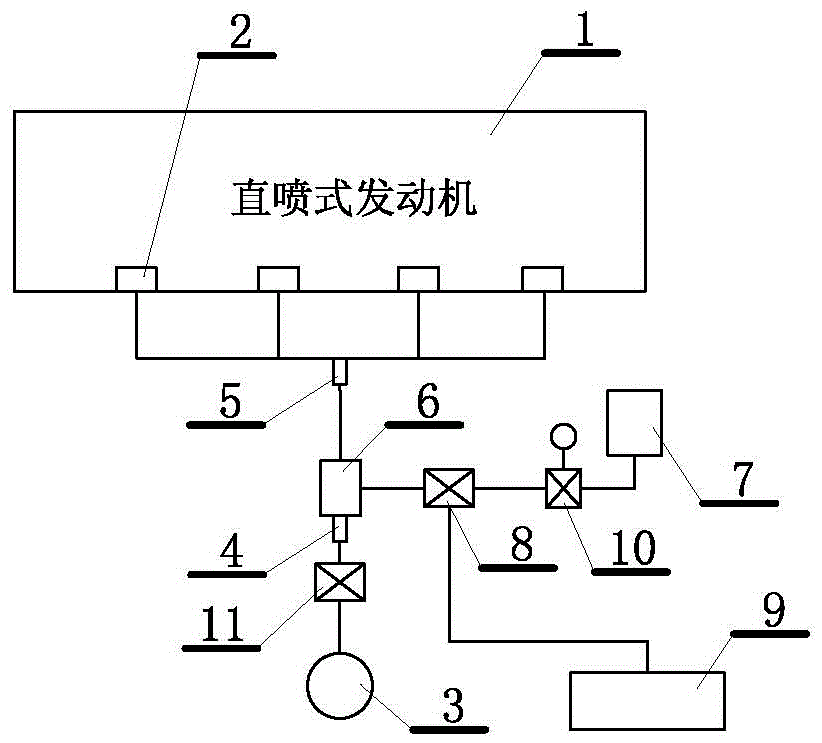

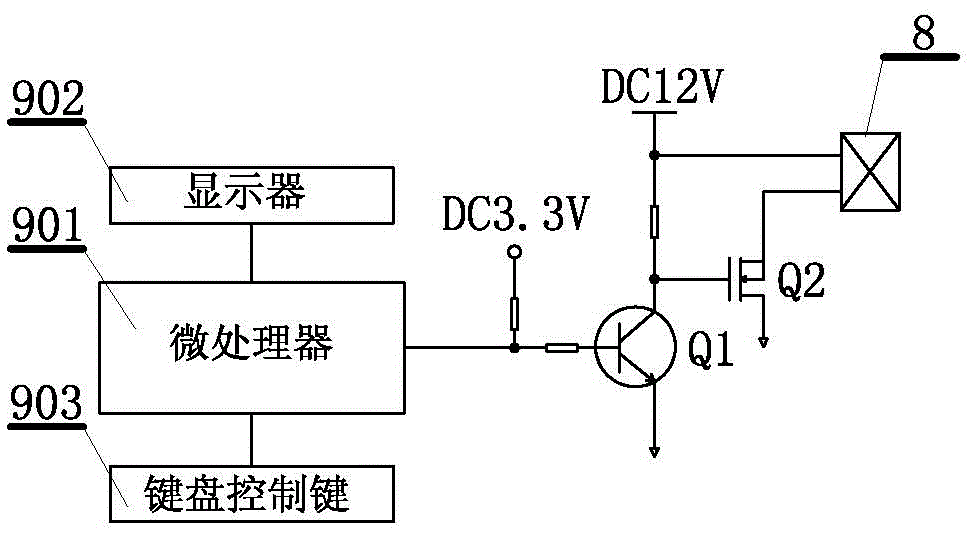

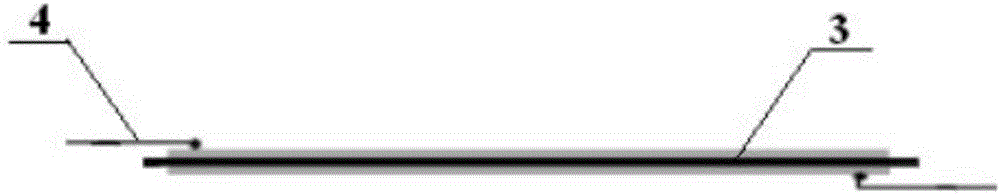

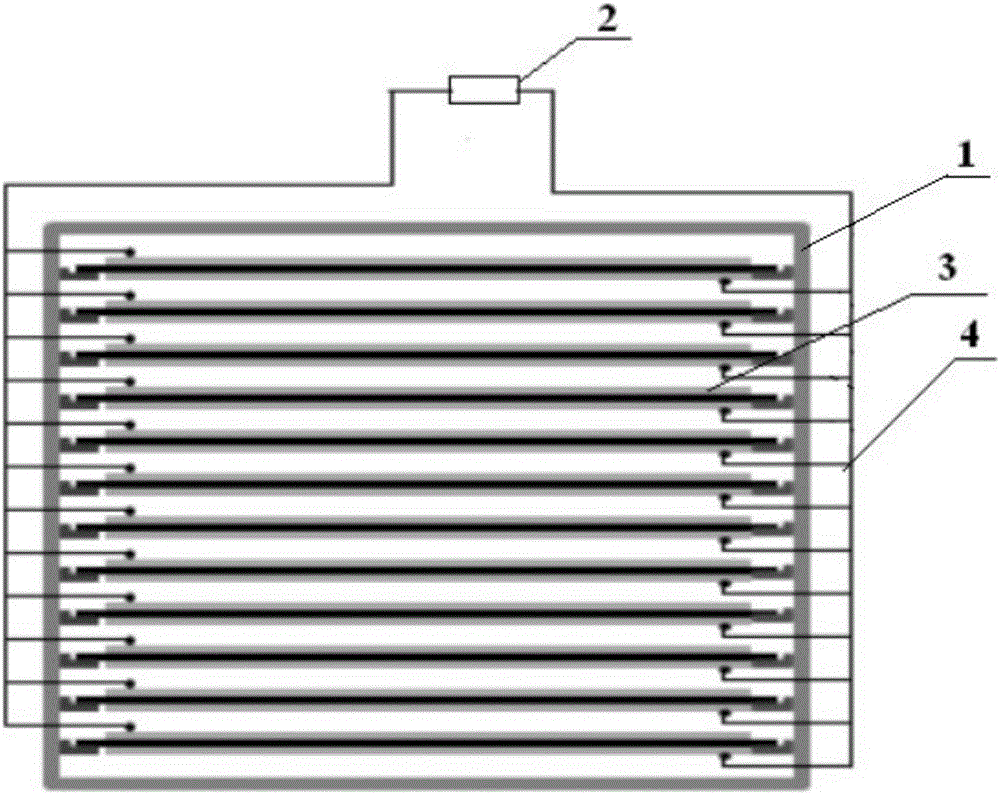

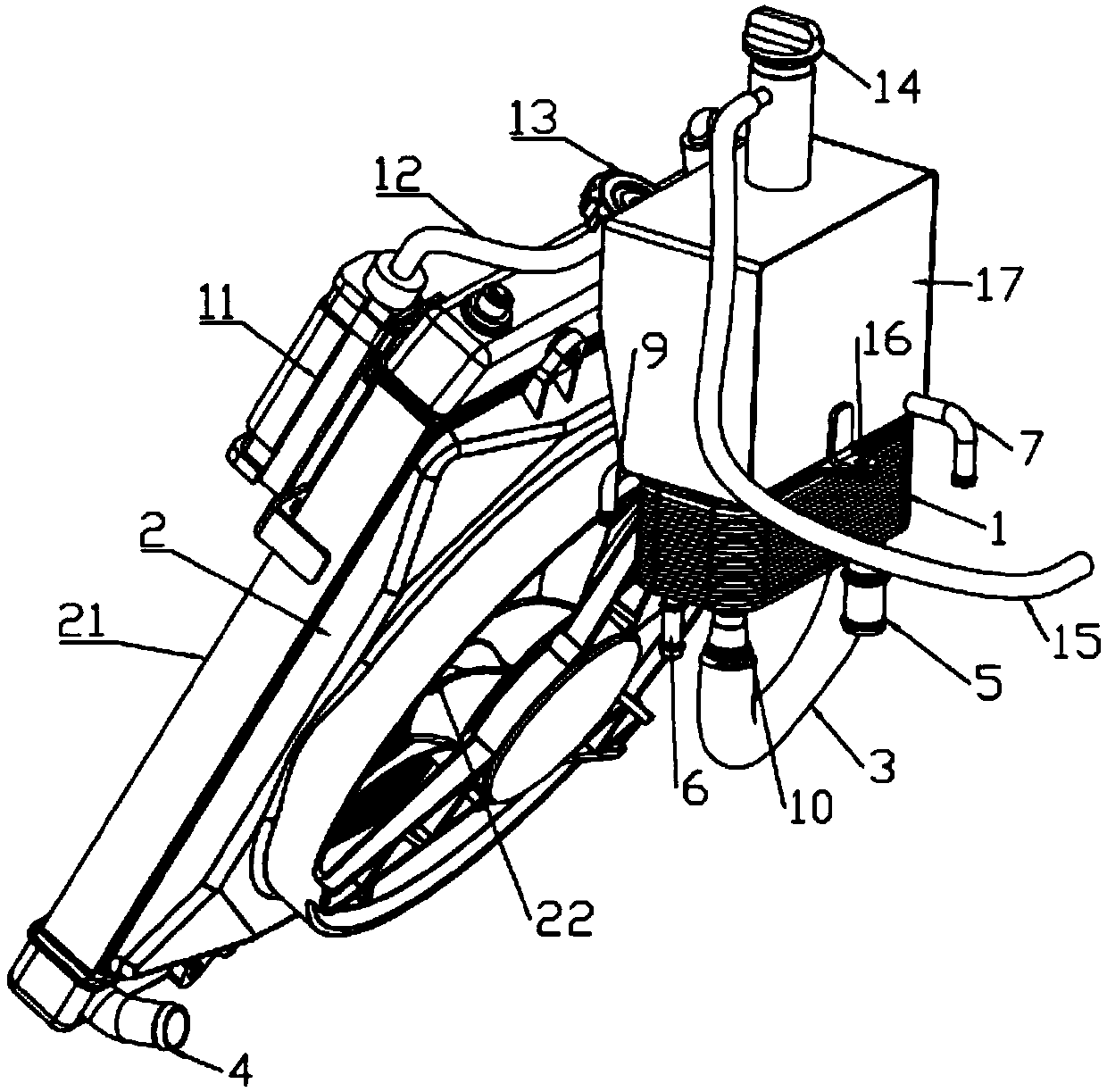

Vehicle engine fuel injection nozzle and combustion chamber carbon cleaning device

ActiveCN106536894ASatisfied with the cleaning effectSimple structureEngine testingFuel injection apparatusCombustion chamberSpray nozzle

A vehicle engine fuel injection nozzle and combustion chamber carbon cleaning device, comprising a fuel provision pipeline having a quick connector (4), and a fuel path port (5) before the engine fuel injection nozzle. Between the quick connector (4) and the fuel path port (5) is inserted a three-way connector (6). The quick connector (4) is connected to a first inlet of the three-way connector (6). An outlet of the three-way connector (6) is connected to the fuel path port (5). A second inlet of the three-way connector (6) is connected to a pressurized cleaning agent tank (7). Between the connection ports of the second inlet and the cleaning agent tank (7) is provided an electronically controlled cleaning agent nozzle (8). The pressure of the cleaning agent in the cleaning agent tank (7) is greater than the supply pressure of the fuel in the fuel supply pipeline. The invention further relates to a vehicle engine fuel injection nozzle and combustion chamber carbon cleaning control method. The cleaning device has a simple structure. The three-way connector in the fuel delivery pipeline can directly mix a cleaning agent with fuel, and the electronically controlled cleaning agent nozzle can dynamically control a mixing ratio, thereby inputting an appropriate amount of cleaning agent while stably maintaining idling of an engine, and within a reasonable cleaning time, realizing a satisfactory cleaning effect with respect to a fuel injection nozzle and a piston top portion.

Owner:刘新羽

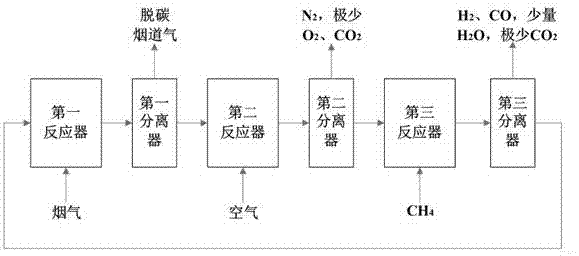

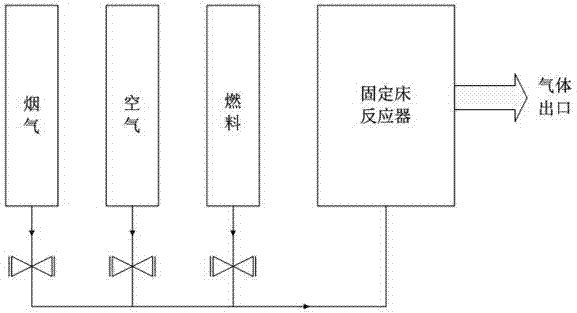

Electrochemical reforming system for dry reforming of methane and carbon dioxide and construction method and using method of electrochemical reforming system for dry reforming of methane and carbon dioxide

InactiveCN105862060AImprove conversion rateSolve the problem of carbon accumulationElectrolysis componentsChemistryCarbon dioxide

The invention relates to an electrochemical reforming system for dry reforming of methane and carbon dioxide and a construction method and a using method of the electrochemical reforming system for dry reforming of methane and carbon dioxide. The electrochemical reforming system for dry reforming of methane and carbon dioxide and the construction method and the using method of the electrochemical reforming system for dry reforming of methane and carbon dioxide aim at solving the problem that because of high-temperature condition limitation in an existing reforming reaction and carbon deposition, catalyst deactivation is caused. The system comprises a plurality of electrolytic tank thin pieces, a reactor and an external power source. The construction method includes the steps that firstly, an electrolyte thin film is prepared through a tape casting method; secondly, electrodes are prepared through a silk-screen printing method, and , and porous electrodes are obtained through a pore-forming agent and high-temperature calcination; thirdly, a confluence layer is prepared, and the electrolytic tank thin pieces are obtained after high-temperature sintering; and fourthly, the electrolytic tank thin pieces are placed in the reactor, and the power source is connected. The constructed system has the characteristics that the methane conversion efficiency is high, synthetic gas selectivity is high, and carbon deposition is avoided, and the preparation technology is simple, low in cost and easy and convenient to operate. The electrochemical reforming system for dry reforming of methane and carbon dioxide and the construction method and the using method of the electrochemical reforming system for dry reforming of methane and carbon dioxide belong to the electrochemical reforming field of dry reforming of methane and carbon dioxide.

Owner:NORTHEAST FORESTRY UNIVERSITY

Gold nano flower catalyst taking biomass activated carbon as carrier as well as preparation method and application thereof

ActiveCN111151245AHigh selectivityLow selectivityCarbon compoundsHydrogen productionPtru catalystHydrogen selectivity

The invention discloses a gold nano flower catalyst taking biomass activated carbon as a carrier as well as a preparation method and application thereof. According to the catalyst, waste shaddock peels are made into a porous activated carbon carrier, and gold nano flowers are taken as a catalytic active component. Based on the mass of the carrier, the mass percentage of the active component is 0.1-0.3%. The preparation method comprises the following steps: carrying out drying, pre-oxidation, carbonization, crushing, activation and other processes on waste shaddock peels to prepare a porous activated carbon carrier, reducing an active component precursor solution into a gold nano flower colloidal solution by using ascorbic acid, dipping the porous activated carbon carrier into the active component colloidal solution, and drying to obtain the reforming hydrogen production catalyst. Waste shaddock peels are converted into resources. The reforming hydrogen production catalyst has high H2 selectivity and a low noble metal content, the preparation technology is simple, the problem of carbon deposition of a reforming hydrogen production catalyst is solved, and the market application prospect is wide.

Owner:南京环福新材料科技有限公司

Method and device for preparing synthesis gas and capturing and utilizing carbon dioxide

The invention relates to a method and device for preparing a synthesis gas and capturing and utilizing carbon dioxide. The method for preparing the synthesis gas is mixing a carbonated carbon dioxide carrier and an oxidation-state oxygen carrier with methane to be subjected to a reforming reaction, and then obtaining a gas, namely the synthesis gas, after the reforming reaction. The method for capturing and utilizing carbon dioxide is using the carbon dioxide carrier for capturing carbon dioxide in the gas to obtain the carbonated carbon dioxide carrier, taking the carbonated carbon dioxide carrier as a raw material, and then preparing the synthesis gas by using the method for preparing the synthesis gas. The method not only can realize the low-energy consumption reforming reaction, but also can realize the utilization of a carbon dioxide waste gas.

Owner:HUNAN UNIV

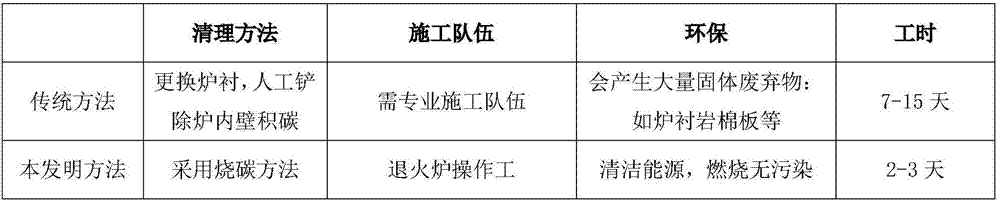

Method for eliminating carbon deposition in roller-bottom continuous nodulizing annealing furnace

InactiveCN107217132AEliminate depositsAvoid depositionFurnace typesHeat treatment furnacesMetallurgyInlet valve

The invention discloses a method for eliminating carbon deposition in a roller-bottom continuous nodulizing annealing furnace. The method comprises the following steps: closing an RX gas intake valve of the annealing furnace and furnace doors in the two sides in a no-load state of the annealing furnace; then heating the annealing furnace, controlling a temperature in a hearth to achieve 650+ / -10 DEG C and keeping constant temperature, and detecting tail gas of the annealing furnace; stopping heating when the content value of CO2 in the tail gas is not changed any more, and opening the furnace doors in the two sides; closing the furnace doors in the two sides again after air enters the annealing furnace and the hearth is fully filled with air, and repeating the heating treatment process; and stopping operation when the content value of CO2 in the tail gas is lowered to 0.3%-0.5%, and then completing elimination for the carbon deposition in the annealing furnace. The elimination method is capable of efficiently and thoroughly eliminating the carbon deposition in the roller-bottom continuous nodulizing annealing furnace, so that the annealing furnace recovers to an initial use effect; and moreover, the elimination method is short in elimination operation period, low in elimination and maintenance cost, and capable of effectively preventing recarburization in the case of ensuring no decarburization of an annealing material through regular implementation, thereby ensuring the annealing quality of refined wire products, reducing pollution to environment, and increasing the production efficiency.

Owner:邢台新翔金属材料科技股份有限公司

Single-anode-electrode double-medium gas source plasma burner

The invention belongs to the technical field of plasma burners that can be used in petrochemical, metallurgical, and electric power industries, and specifically relates to a single-anode dual-medium gas source plasma burner, including: two cathode channel tubes, air tubes, gas tubes, and burners Bushing, cathode, anode and other components, the present invention adopts discharge arc between two separate cathodes and the same anode to ionize two different medium gases, and generates At the same time, part of the fuel can be burned during the plasma, which indirectly replaces part of the electric energy and improves the use efficiency of secondary energy.

Owner:SHENWU TECH GRP CO LTD

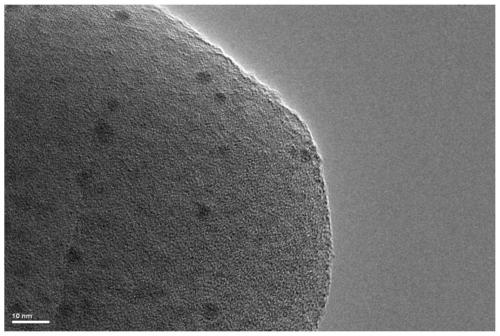

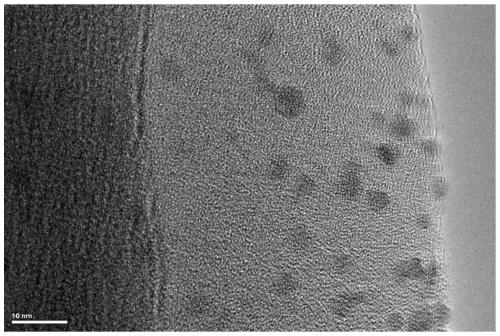

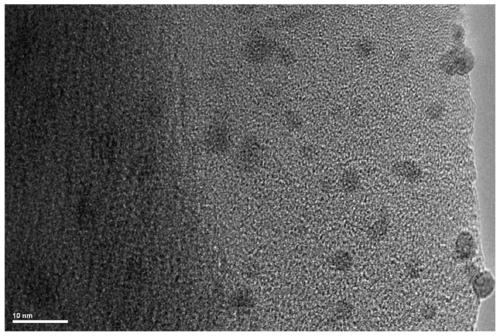

Catalyst for methane dry gas reforming reaction and preparation method thereof

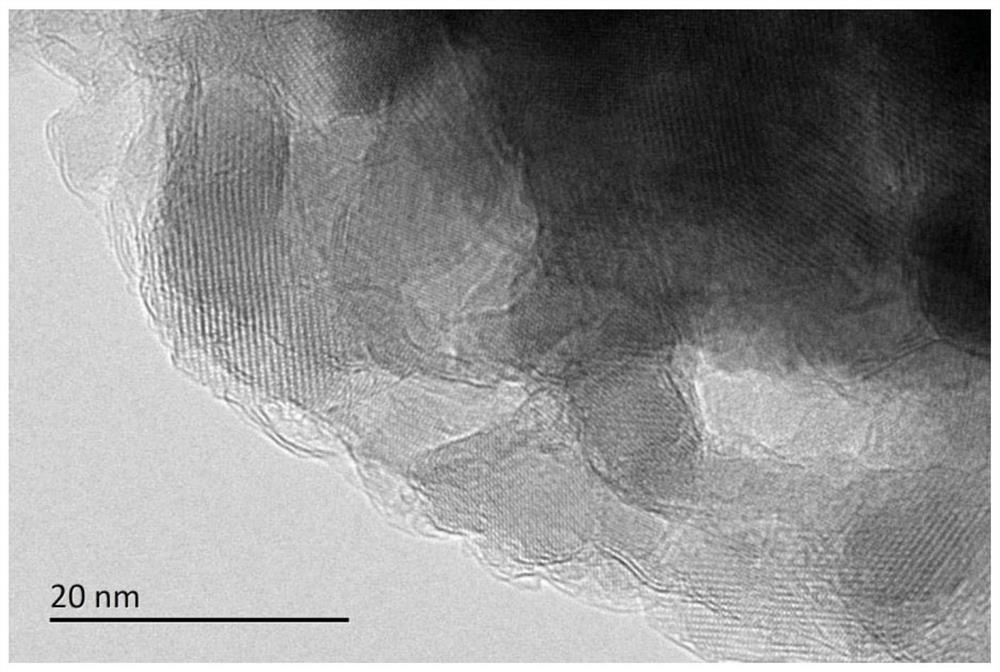

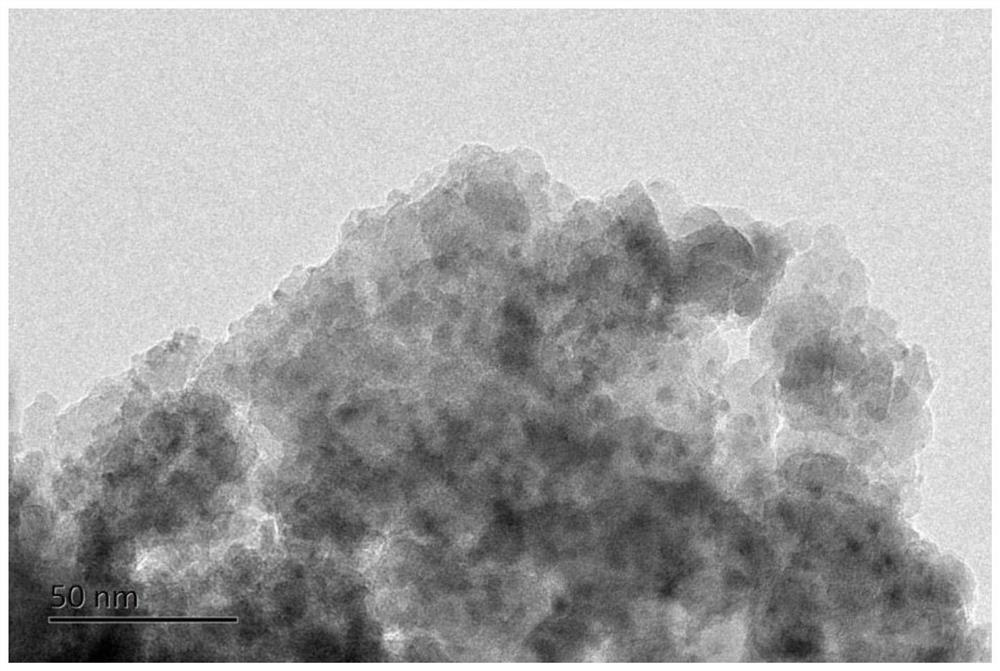

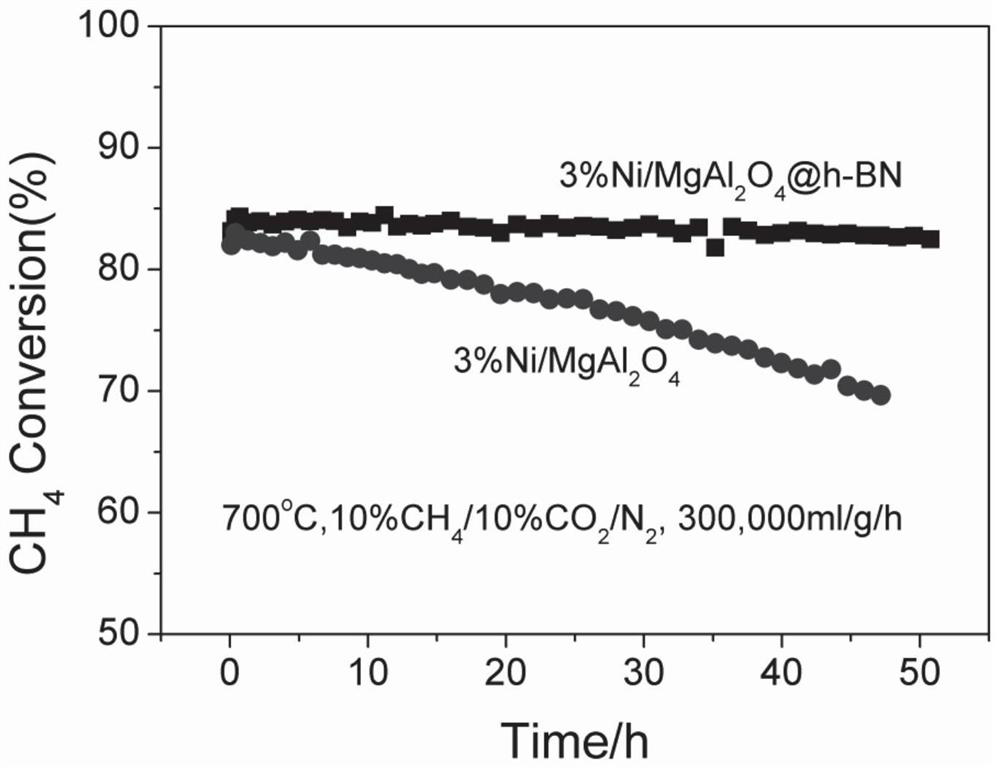

ActiveCN113209999AImprove thermal conductivityImprove transmission efficiencyHydrogenCatalyst activation/preparationPtru catalystBoron nitride

The invention discloses a catalyst for methane dry gas reforming reaction and a preparation method thereof. According to the catalyst, an oxide with the surface wrapped by ultra-thin boron nitride (h-BN, 1-2 layers) is adopted as a carrier, the size of an active component Ni nano particle supported on the oxide ranges from 2 nm to 5 nm, and the oxide is any one of SiO2, Al2O3, MgAl2O4, MgO and ZrO2. The prepared catalyst can be used for a reaction of reforming methane and carbon dioxide to prepare synthesis gas, the h-BN ultra-thin wrapping layer can greatly enhance the heat-conducting property of the oxide carrier, and the transfer efficiency of heat around Ni particles is improved; and in the reaction atmosphere, CO2 and CH4 can interact with the h-BN layer rich in defects, Ni particles can be partially wrapped and prevented from being sintered, the Ni particles can be modified by the element B in real time, and the carbon deposition resistance of the Ni particles is greatly improved. The catalyst simultaneously solves the problems of carbon deposition and sintering of metal nano particles in the reaction, the preparation method is simple, and the catalyst has a wide application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Environment-friendly fuel and preparation method thereof

InactiveCN109628172AWide variety of sourcesImprove solubilityLiquid carbonaceous fuelsFuel additivesSolubilityGlycerol

The invention discloses novel environment-friendly fuel. The fuel comprises, by weight, by weight, 60-90 parts of methanol, 0.1-0.3 part of ethanol, 0.3-0.5 part of ferrocene, 0.2-0.4 part of ethyl acetate, 0.5-1.5 parts of xylene, 0.5-1.5 parts of glycerol, 10-30 parts of water, 0.1-0.5 part of butanone, 0.3-1.0 part of paraffin oil, 0.3-0.5 part of dimethyl carbonate, 0.3-0.5 part of ferric nitrate, 0.5-1.5 parts of C12, 0.5-2.0 parts of octanol and 0.2-0.8 part of a stabilizer. According to the novel fuel, methanol serves as a main combustion component, no black smoke or carbon deposit is generated, the emission amount of combusted waste gas is over 80% lower than that of petroleum liquefied gas, and the environment is effectively protected; the heat value is obviously improved by adopting C12; the raw materials are relatively good in solubility, and methanol can be mutually dissolved with other components.

Owner:宁夏拓森环保能源有限公司

Continuous preparation method of foamed nickel chrome alloy

ActiveCN108070839AChromium plating is evenly distributedShort production timeVacuum evaporation coatingSputtering coatingWork in processBinding force

The invention discloses a continuous preparation method of a foamed nickel chrome alloy. The continuous preparation method of the foamed nickel chrome alloy comprises two steps of physical vapor deposition and heat treatment, wherein the heat treatment temperature is 550 to 950 DEG C, and the heat treatment time is 2 to 5h; and finally the homogeneous-phase foamed nickel chrome alloy is obtained.According to the continuous preparation method of the foamed nickel chrome alloy provided by the invention, a vacuum magnetron sputtering technology is utilized for preparing the foamed nickel chromealloy; the used device is provided with two chambers and can be used for continuously sputtering so as to obtain a continuous banded chroming semi-finished product, the coating distribution in a thickness direction is uniform, and after short-time heat treatment, the finally obtained alloy has high purity and the impurity content being less than 1 percent; and the foamed nickel chrome alloy adoptsfoamed nickel as a base material, a binding force of chrome deposited through the magnetron sputtering technology and the base material is good, and alloying can be realized through short-time heat treatment, so that the production efficiency is greatly improved.

Owner:CHANGDE LYRUN MATERIAL

Helicopter oil-water heat exchange device and helicopter

ActiveCN109611186AGood temperature controlAvoid obstructionLiquid coolingMachines/enginesCylinder headOil water

The invention discloses a helicopter oil-water heat exchange device and a helicopter. The helicopter oil-water heat exchange device comprises a heat exchanger connected with an engine coolant pipelineand an engine oil pipeline to be used for exchanging heat between coolant and engine oil; and the helicopter oil-water heat exchange device further comprises a coolant radiator for coolant radiating.The device fully utilizes the heat radiating capability of an existing cooling radiator, an engine oil radiator is omitted, obstruction of the engine oil radiator on a water tank radiating air passage is avoided, and the water tank radiating effect is high. Structural arrangement is optimized, the structure is compact, and the overall weight of a heat dissipation system is smaller compared with aconventional oil and water respective radiating manner. The oil-water heat exchange device has the better control ability on the engine oil temperature, and the problem about engine carbon depositioncaused by cylinder head temperature fluctuation is effectively avoided. An overflow pot is arranged on the coolant radiator so that the state of the coolant can be conveniently observed.

Owner:珠海隆华直升机科技有限公司

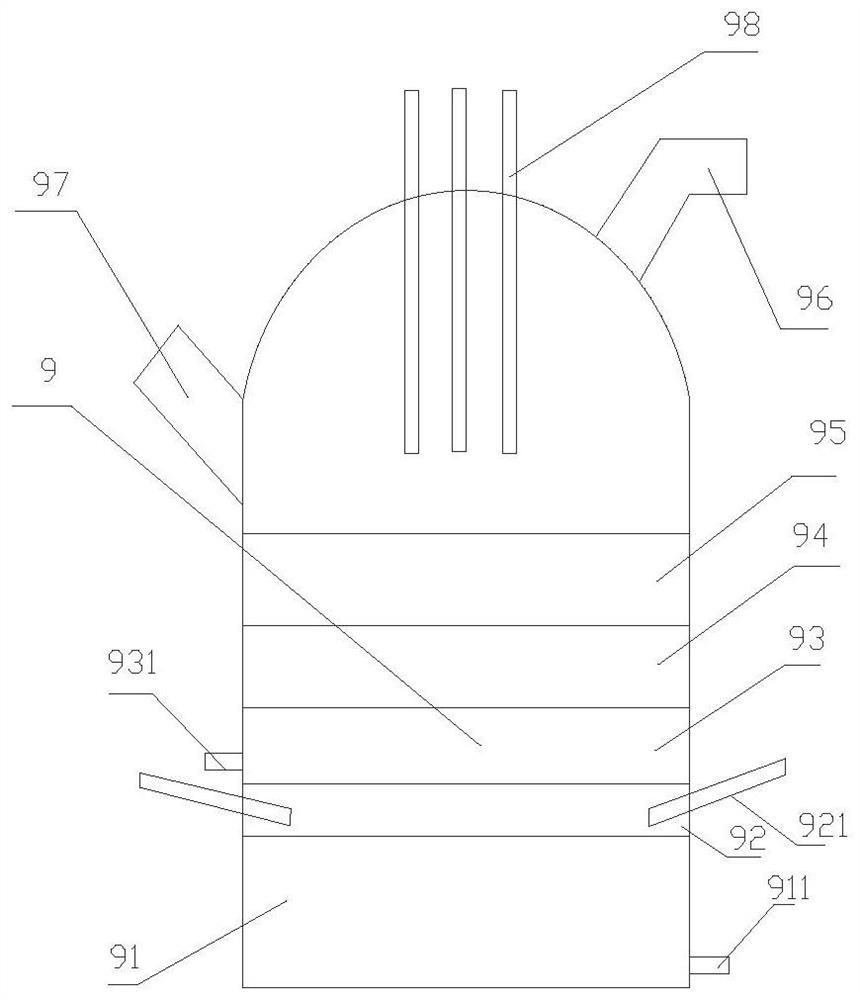

Method for smelting schreyerite in coke oven gas-based shaft furnace-electric furnace melt separation deep reduction

The invention belongs to the field of comprehensive utilization of schreyerite, and particularly relates to a method for smelting schreyerite in a coke oven gas-based shaft furnace and smelting deep reduction in an electric furnace, in particular to a method for smelting schreyerite in a coke oven gas-based shaft furnace and smelting deep reduction in an electric furnace. The vanadium-titanium pellets are reduced in the gas-based shaft furnace, and vanadium-titanium direct reduction iron is obtained; the vanadium-titanium direct reduction iron is subjected to melting reduction in an electric furnace to obtain vanadium-containing molten iron and titanium slag, the gas-based shaft furnace at least uses one coke oven gas as a gas source, and purified gas at the top of the gas-based shaft furnace exchanges heat with hot gas in a gas ascending pipe of the coke oven and then is mixed into high-temperature reducing gas generated by the coke oven gas to form furnace-entering reducing gas of the gas-based shaft furnace; and reducing gas is blown into the molten layer in the electric furnace, the reducing gas reacts with the vanadium and iron oxides to generate vanadium and iron metal liquid and titanium slag, and the vanadium and iron metal liquid enters the molten iron. Electric furnace smelting power consumption can be reduced, the influence of newly added materials of the electric furnace on the titanium slag grade is reduced, and efficient and reasonable utilization of different types of heat energy is achieved.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

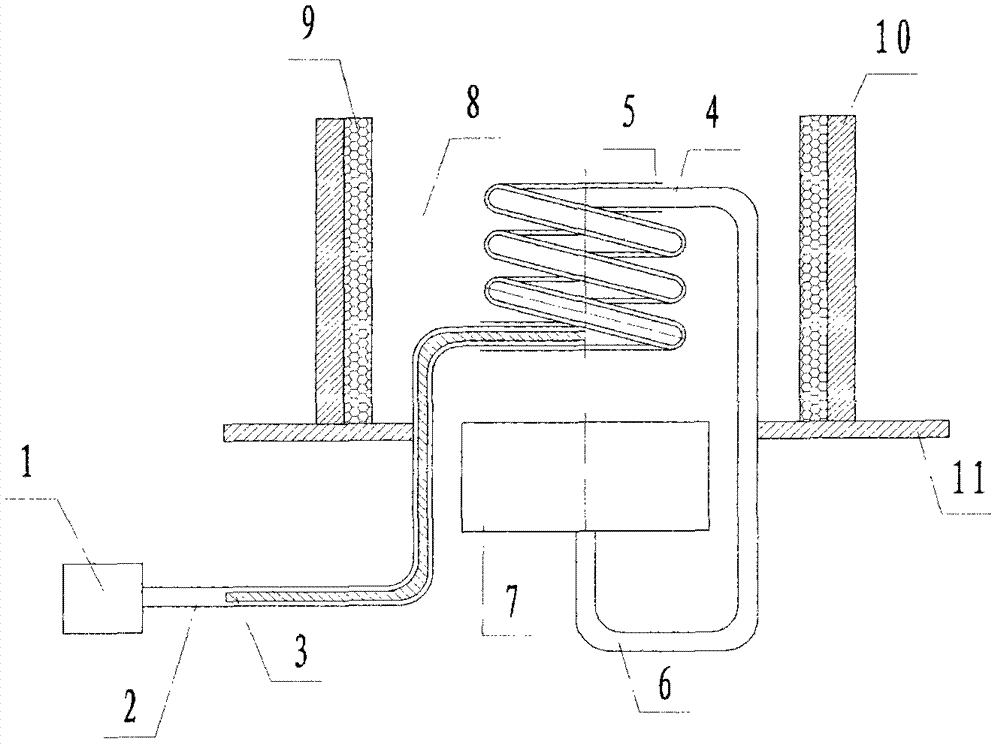

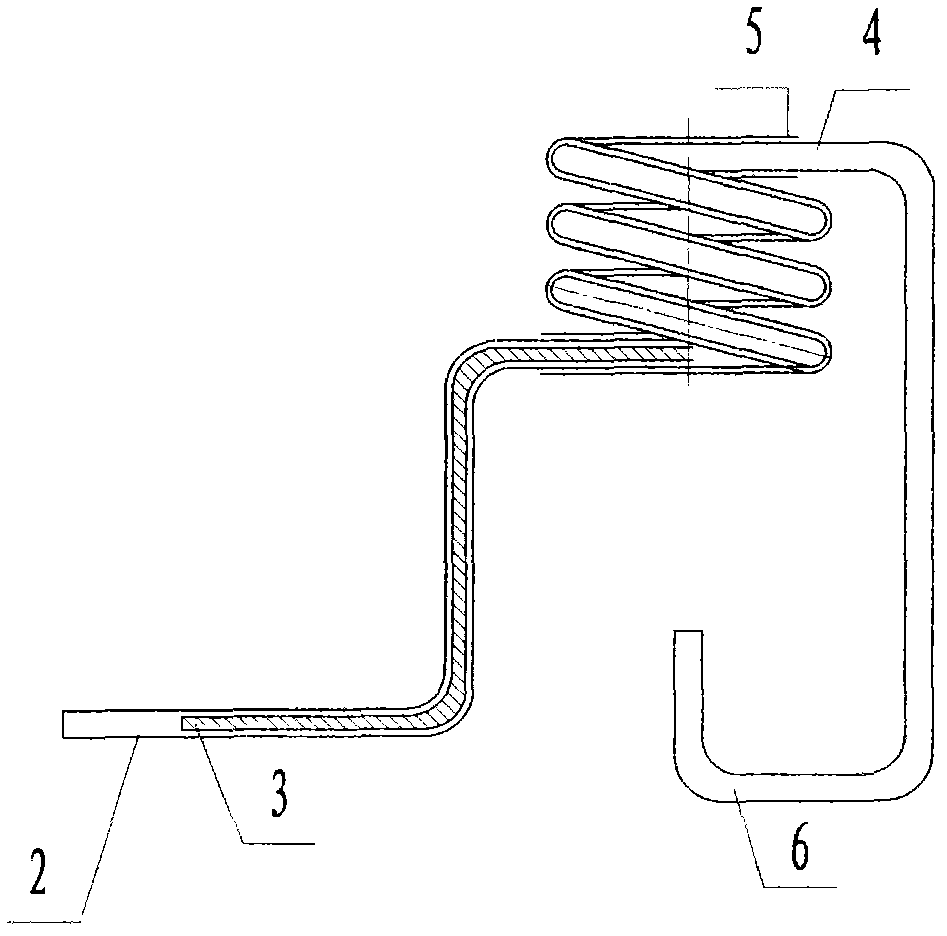

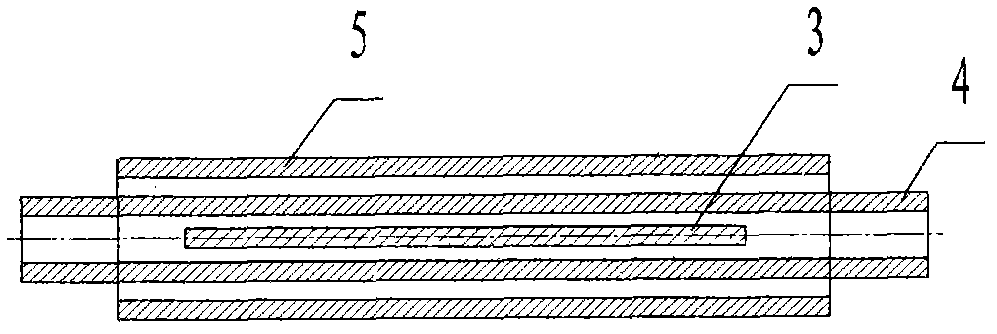

Liquid fuel gasifier

InactiveCN103090382AComplete gasificationReduce energy consumptionCombustion typesElectricityFixed frame

The invention provides a liquid fuel gasifier which is composed of a gasifying device, a burning device, a sound reducing device, a fire ring, a valve body assembly and a fixed frame. The gasifying device is placed above the burning device and is arranged in the sound reducing device. The burning device is partially or completely arranged in the sound reducing device. The gasifying device is composed of a gasifying pipe, a heat insulation pipe and a gas resistor. The gasifier is structurally characterized in that the gasifying pipe is arranged in the heat insulation pipe, the gas resistor is inserted in the gasifying pipe, the gasifying pipe and the gas resistor are combined and inserted to form a combination piece which is wound to form a spiral spring column body or a conical body, the gasifying pipe is a metal hollow pipe or a non-metal high temperature resistant hollow pipe, the heat insulation pipe is a metal hollow pipe, the length of the gas resistor and the heat insulation pipe is shorter than that of the gasifying pipe, the sound reduction device is of an annular columnar structure or a conical structure, and the sound reduction device is placed in the fire ring and surrounds the gasifying device and the burning device. The liquid fuel gasifier resolves the problem that the liquid fuel is completely gasified, enables burning to be complete, is low in energy consumption, saves energy by over 60% with flame temperature higher than 1200 DEG C, does not require a fan, is complete, convenient, electricity-saving, strong in fire and high in heating speed, simultaneously effectively controls gasifying temperature, resolves the problem of carbon accumulation and changes popularization of the liquid fuel especially alcohol group liquid fuel from ideal to reality.

Owner:李小辉

Application of modified C5 in gasoline additives

InactiveCN101381635ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsHazardous substanceGasoline fuel

The invention provides application of modified carbon-5 in a gasoline additive, which belongs to the technical field of recycling gasoline side products and particularly discloses a method for treating light hydrocarbons taking carbon-5 as a main composition and application of the treated carbon-5 in the gasoline additive. When the modified carbon-5 is used, 50 to 80 percent of the additive according to the weight percentage is added in gasoline to produce composite gasoline, thereby not only partially replacing the gasoline fuel with tension in supply, but also improving the performance of the gasoline, ensuring that the gasoline is fully burnt and reducing the coking and carbon deposition in an engine and the emission of harmful matters; moreover, according to the inspection by the National Ethanol Gasoline Quality Surveillance Inspection Center, the composite gasoline meets the national standard.

Owner:HENAN ACAD OF SCI

High-energy alcohol-based fuel additive for military use and preparation method thereof

InactiveCN107841357AAvoid corrosionImprove corrosion resistanceLiquid carbonaceous fuelsFuel additivesChemistryCorrosion

The invention belongs to the technical field of liquid fuel, and more specifically relates to a high-energy alcohol-based fuel additive for military use and a preparation method thereof. The additivecomprises the following raw materials in parts by weight: 5-10 parts of ethanol, 3-5 parts of triacetin, 4-7 parts of a cation fluorocarbon surfactant, 1-4 parts of ferric nitrate, 10-15 parts of a hydrocarbon compound, 10-15 parts of a combustion improver, 3-5 parts of a stabilizing agent, 3-5 parts of an anti-knock agent, and 1-4 parts of a deodorant. The composite additive can be added into thealcohol-based fuel, in order to substantially improve calorific value of the fuel, ensure fully and thoroughly combustion without generation of carbon deposition phenomenon, and improve corrosion resistance and stability of the fuel.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

Automobile fuel oil additive

InactiveCN101381642ASolve cokingSolve the problem of carbon accumulationLiquid carbonaceous fuelsHazardous substanceModified carbon

The invention provides an automobile fuel additive, which belongs to the technical field of fuel additive. The automobile fuel additive is formed by mixing the mixture of biomass extracts of corn oil, castor oil, palm oil and the like, fat polyhydric alcohol, an antioxidant, an antiknock agent, modified carbon-5 and the like according to certain ratio; when the automobile fuel additive is used, according to the weight percentage, 50 percent of additive is added in gasoline, thereby not only partially replacing the gasoline with tension in supply, but also improving the performance of the gasoline, ensuring that the gasoline is fully burnt and reducing the coking and carbon deposition in an engine and the emission of harmful matters; moreover, according to the inspection by the National Ethanol Gasoline Quality Surveillance Inspection Center, the automobile fuel additive meets the national standard.

Owner:HENAN ACAD OF SCI

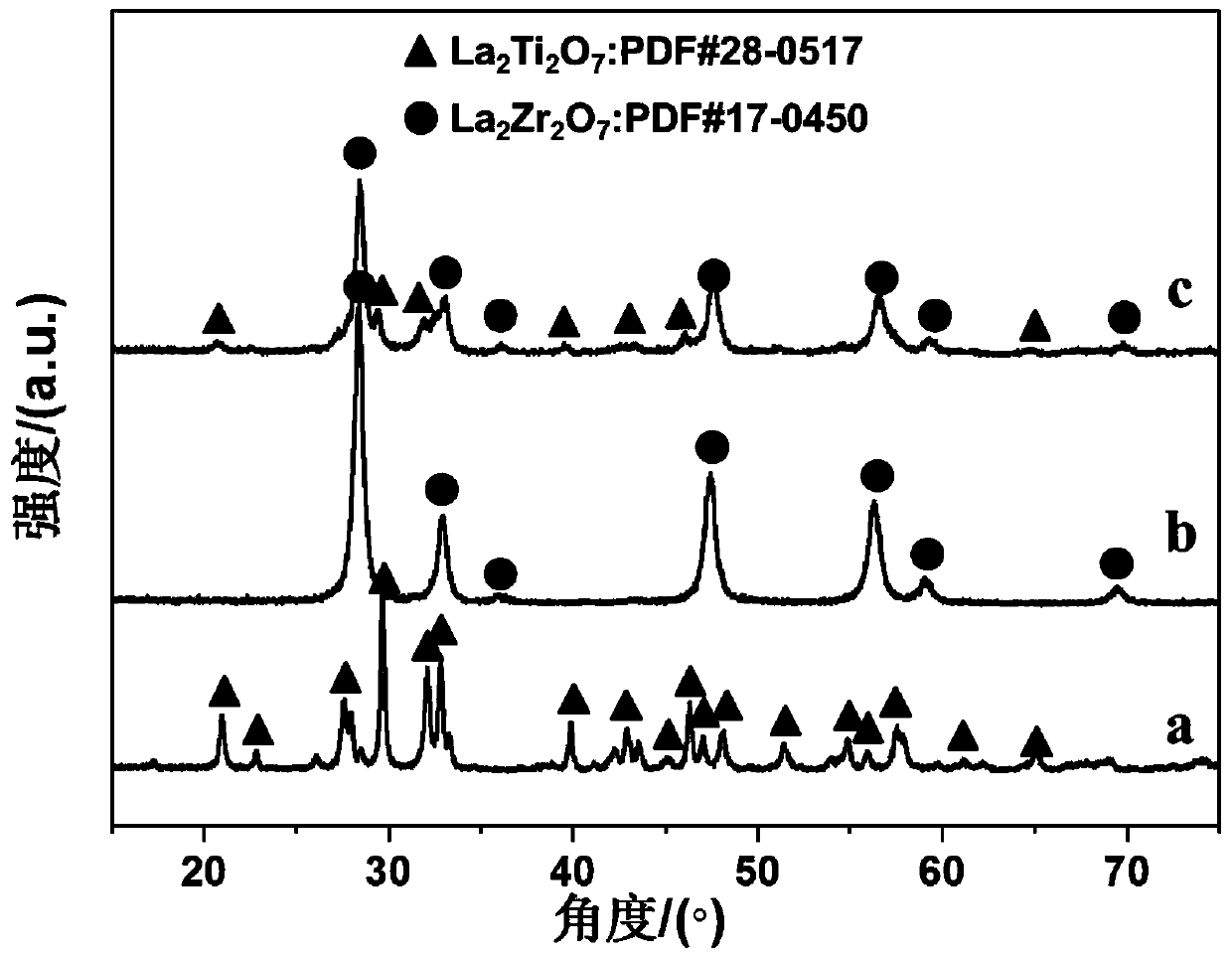

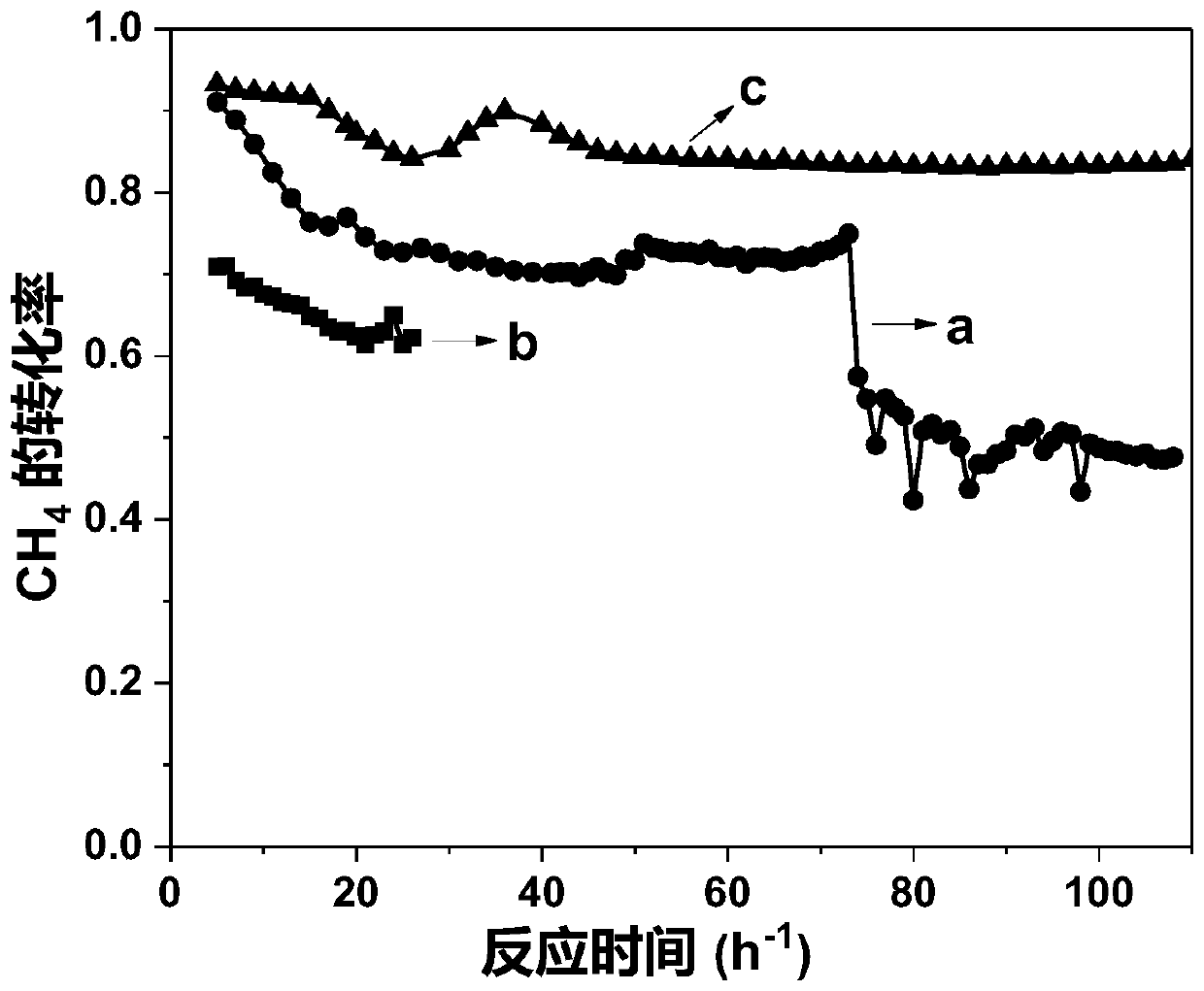

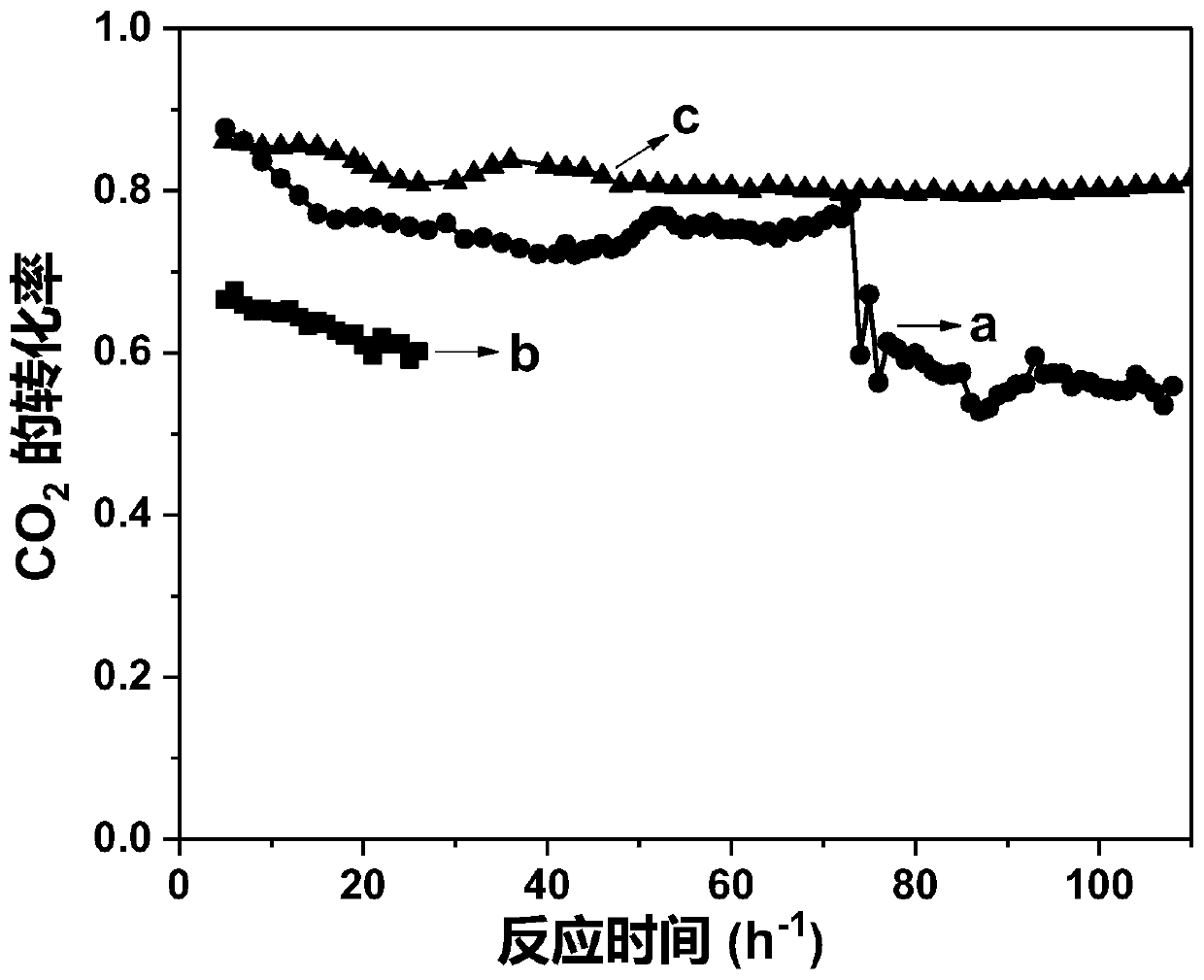

Special catalyst for reaction for preparing synthesis gas through dry reforming of methane, and preparation method thereof

InactiveCN110538653AImprove performanceSolve high temperature sinteringHydrogenHeterogenous catalyst chemical elementsActive componentReaction temperature

The invention provides a special catalyst for a reaction for preparing synthesis gas through dry reforming of methane, and a preparation method thereof, wherein the catalyst has a chemical formula Rh / xLa2Ti2O7-yLa2Zr2O7 (x is 0-1, y is 0-1, and x+y is 1), Rh is an active component and accounts for 1.0-2.0% by mass, and the catalyst has performances of high-temperature sintering resistance, carbondeposition resistance and high selectivity. According to the present invention, with the application of the catalyst in a reaction for preparing synthesis gas through dry reforming of methane, when the reaction temperature is 800 DEG C, the service life of the catalyst is as long as 110 h and has no inactivation trend, the conversion rate of methane is kept at about 90%, the conversion rate of carbon dioxide is kept at more than 85%, and the H2 / CO ratio of the product is stabilized at about 0.93 and has no reduction trend; and the catalyst can effectively solve the problems of high-temperaturesintering and carbon deposition of the catalyst in the reaction for preparing synthesis gas through dry reforming of methane.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

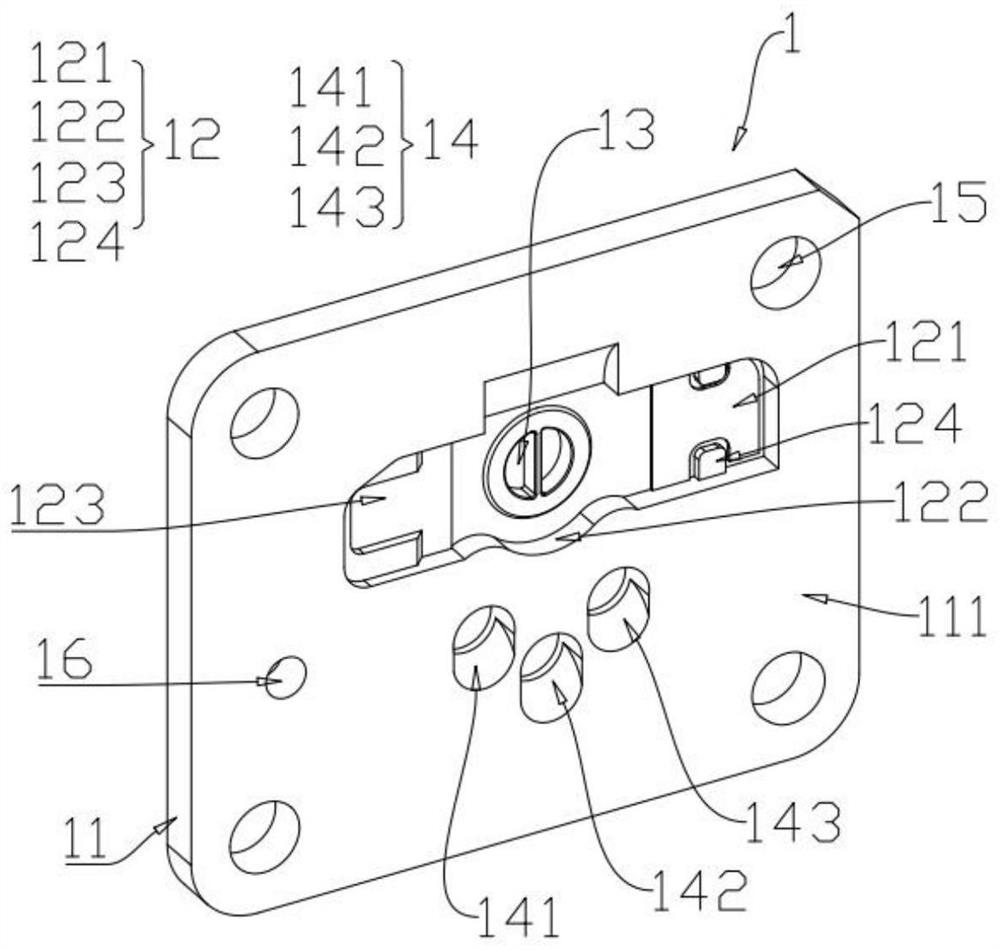

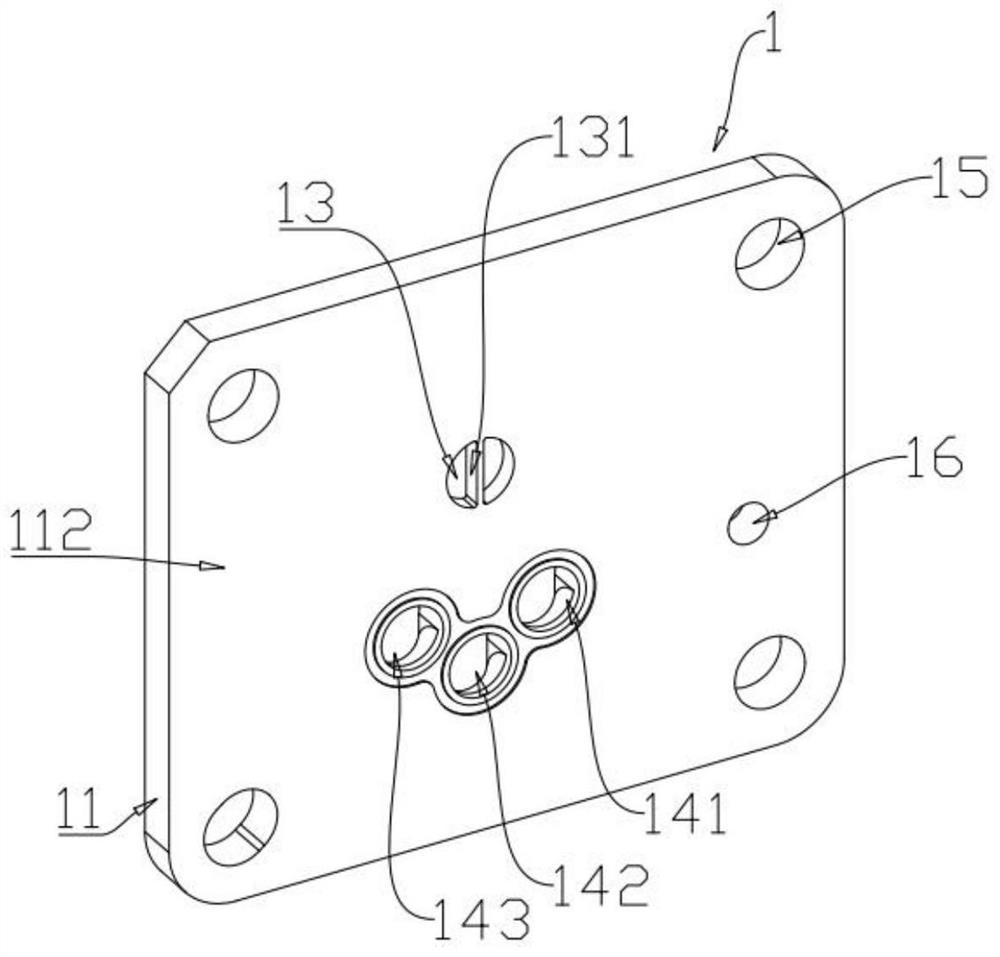

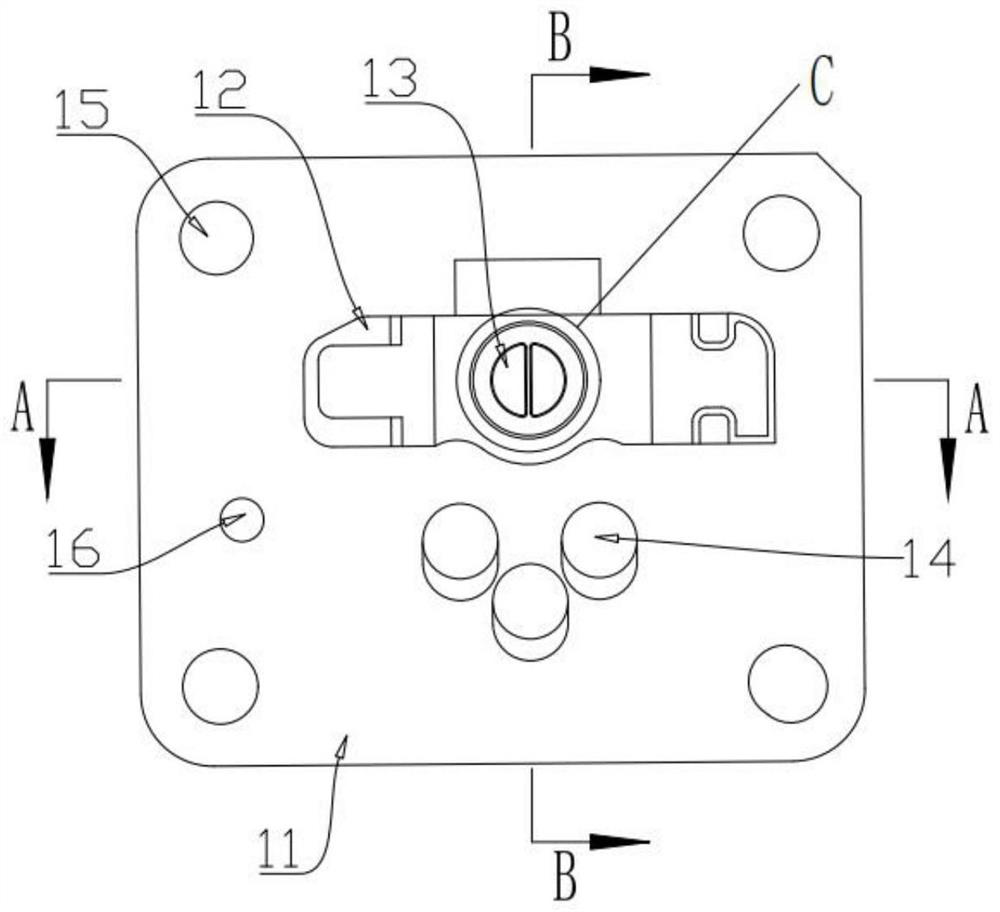

Valve bank assembly, compressor with valve bank assembly and refrigerator with valve bank assembly

PendingCN113464403AImprove reliabilitySave materialPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveIcebox

The invention provides a valve bank assembly, a compressor with the valve bank assembly and a refrigerator with the valve bank assembly. The valve bank assembly comprises a valve plate, an air suction valve plate, an air exhaust valve plate and a lift limiter. The valve plate comprises a steel valve plate main body, a groove and air suction ports, the groove is internally provided with an air exhaust port, and the air exhaust port is provided with a reinforcing rib. The exhaust valve plate is arranged in a first limiting structure in the groove and can close or open the exhaust port, and the lift limiter is arranged in a second limiting structure in the groove and can limit the lift height of the exhaust valve plate. The multiple air suction ports correspond to multiple air suction valves correspondingly, and the corresponding air suction ports can be closed or opened. The steel valve plate avoids the particle falling phenomenon possibly existing in the high-frequency operation of a powder metallurgy valve plate, and solves the problems of carbon deposition of the valve plate and failure of a valve bank. The reinforcing rib is designed at the exhaust port, so that the impact effect during high-frequency operation is effectively reduced, the contact area of the exhaust valve plate and the valve plate main body is increased, stress concentration is reduced, and the reliability of the exhaust valve plate and the energy efficiency of the compressor are improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Nitrogen-doped tungsten carbide catalyst, and preparation method and application thereof

ActiveCN111151293AHigh activityImprove conversion rateMolecular sieve catalystsMolecular sieve catalystPropanolPtru catalyst

The invention relates to the technical field of catalysis, and concretely relates to a nitrogen-doped tungsten carbide catalyst, and a preparation method and an application thereof. The nitrogen-dopedtungsten carbide catalyst comprises a nitrogen-doped tungsten carbide active center and a carrier containing a B acid site, the nitrogen-doped tungsten carbide active center is nitrogen-doped tungsten carbide nanoparticles, the particle size of the nitrogen-doped tungsten carbide nanoparticles is less than or equal to 10 nm, CO2 can be converted into ethanol and propanol products with high addedvalues, and the conversion rate and the selectivity of ethanol and propanol are remarkably improved. The co-impregnation preparation method is adopted, and the method is simple and convenient, the concentration of a metal salt solution does not need to be strictly controlled, and the content of C and N in the prepared catalyst active center is reasonably matched, so that the catalyst has high activity and stability; and a W2C electron structure is regulated, so that the C-C bond generation rate and the C-O bond breaking rate during the CO2 hydrogenation process are effectively regulated, theselectivity of the C1 product is substantially reduced, the selectivity of the ethanol and propanol products is improved, and the wide application prospect is provided.

Owner:ZHEJIANG NORMAL UNIVERSITY

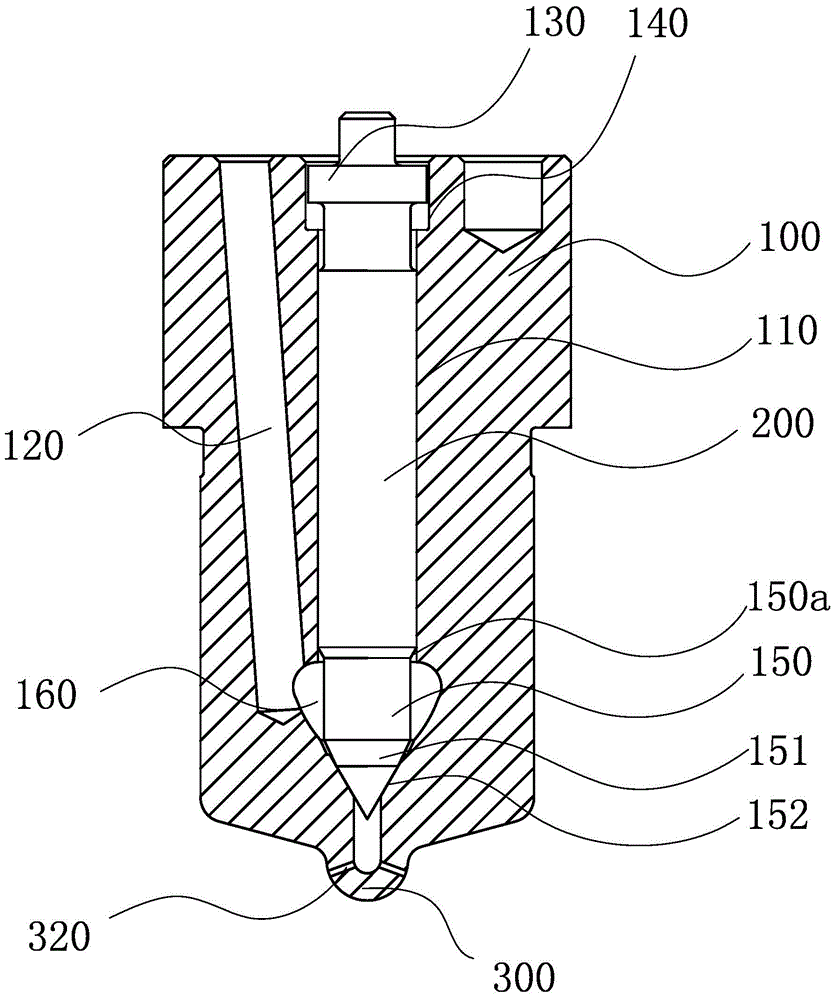

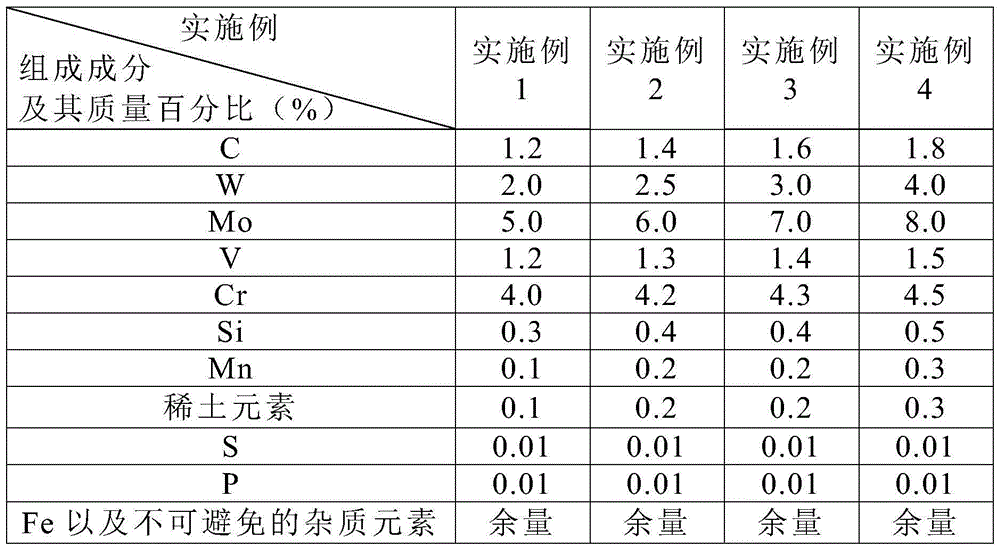

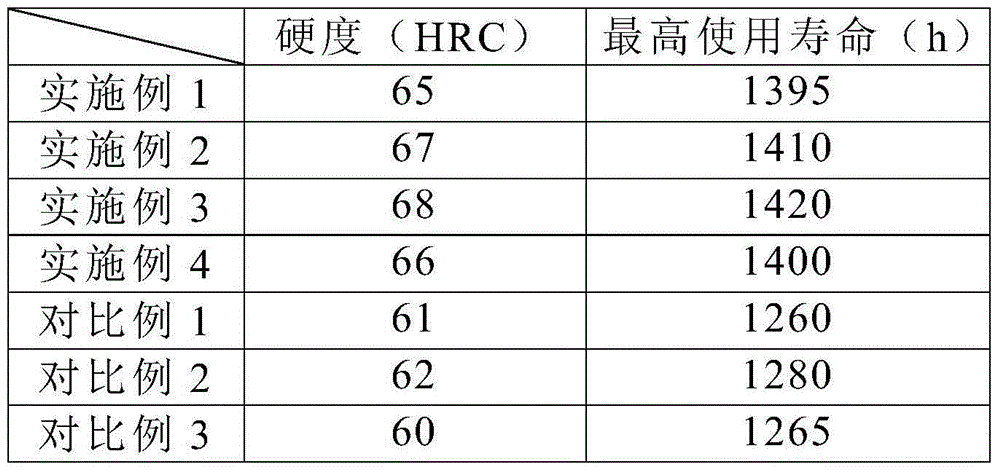

Needle valve mating part of diesel

InactiveCN104564469AImprove atomization effectIncrease profitFuel injection apparatusFurnace typesDiesel injectorBiomedical engineering

The invention provides a needle valve mating part of a diesel, and belongs to the technical field of marine diesel injectors; the problem that the atomization effect of the existing needle valve mating part is bad is solved by the needle valve mating part provided by the invention. The needle valve mating part of the diesel comprises a valve body; an axial passage of which one end is communicated with the outside and an oil inlet passage communicated with the axial passage are formed in the valve body; a needle valve is arranged in the axial passage; the other end of the valve body is provided with a sprayer; a plurality of spray orifices communicated with the axial passage are formed in the sprayer; the needle valve moves in the axial passage, and the oil inlet passage and the spray holes can be communicated or isolated. The needle valve mating part of the diesel has the advantages that the atomization effect is good, and the service life is long.

Owner:YUYAO SHUCHUN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com