Application of modified C5 in gasoline additives

A gasoline additive and modified carbon technology, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve problems such as air resistance, carbon deposition, and easy coking, and achieve mature technology, excellent cleanliness, and low emission performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

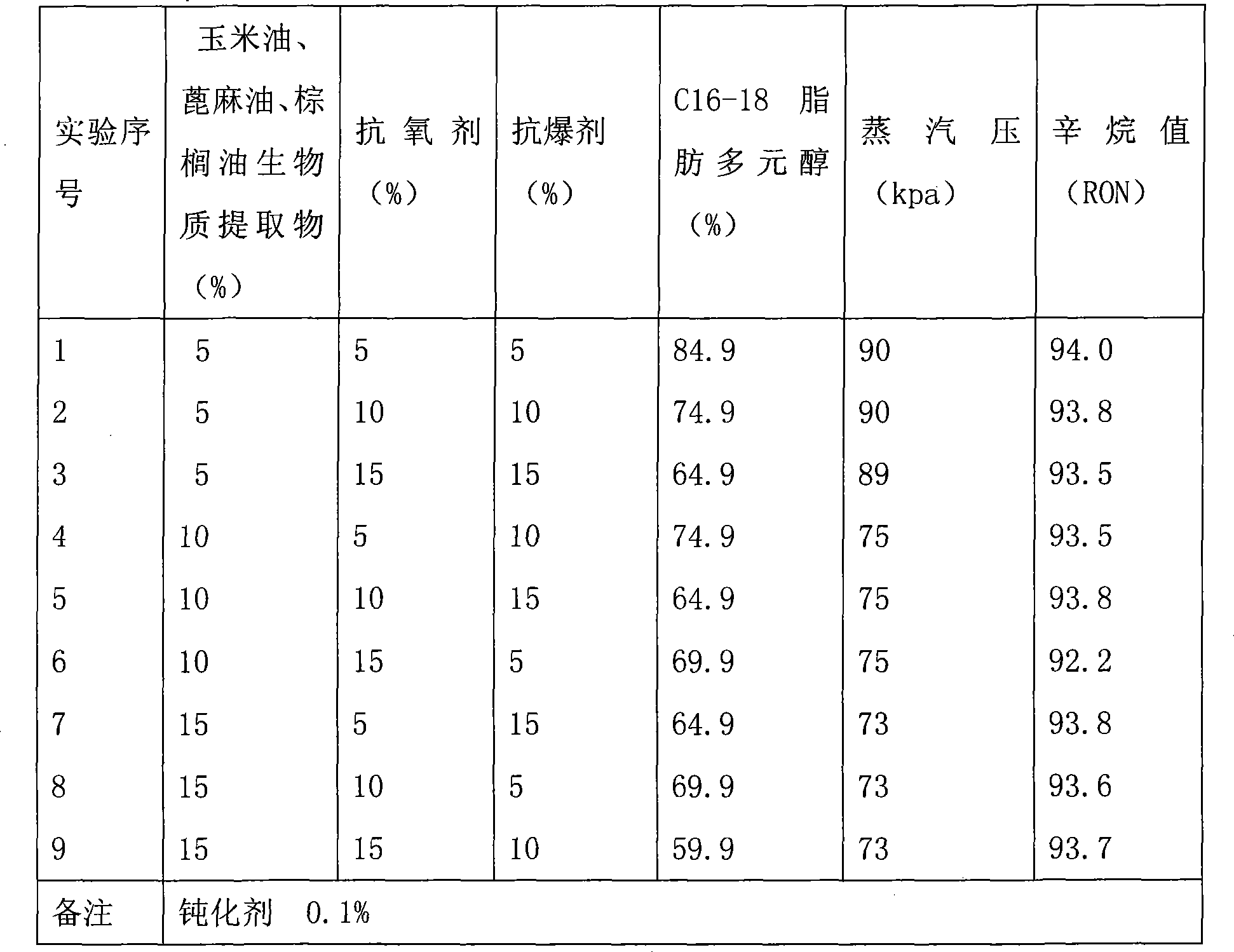

Examples

Embodiment Construction

[0021] In order to better illustrate the present invention, give an example as follows:

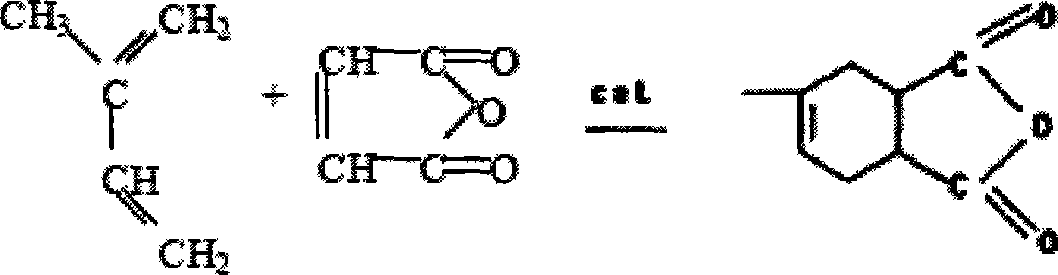

[0022] 1. Carbon five modification

[0023] Add 60kg of maleic anhydride in the reaction kettle, heat and melt, add mixed carbon five to it, after the reaction is exothermic, add 2g of catalyst zinc chloride, keep the reaction temperature at 80~90°C, and react for 2-3 hours, solid-liquid Separating and getting the liquid product is the modified carbon five used in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com