Method for smelting schreyerite in coke oven gas-based shaft furnace-electric furnace melt separation deep reduction

A gas-based shaft furnace and coke oven gas technology, which is applied to shaft furnaces, furnaces, furnace types, etc., can solve the problems of lowering the grade of titanium slag, large investment in tubular heating furnaces, and increasing power consumption, and achieves uniform carbon distribution, Good restoration effect and lower power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

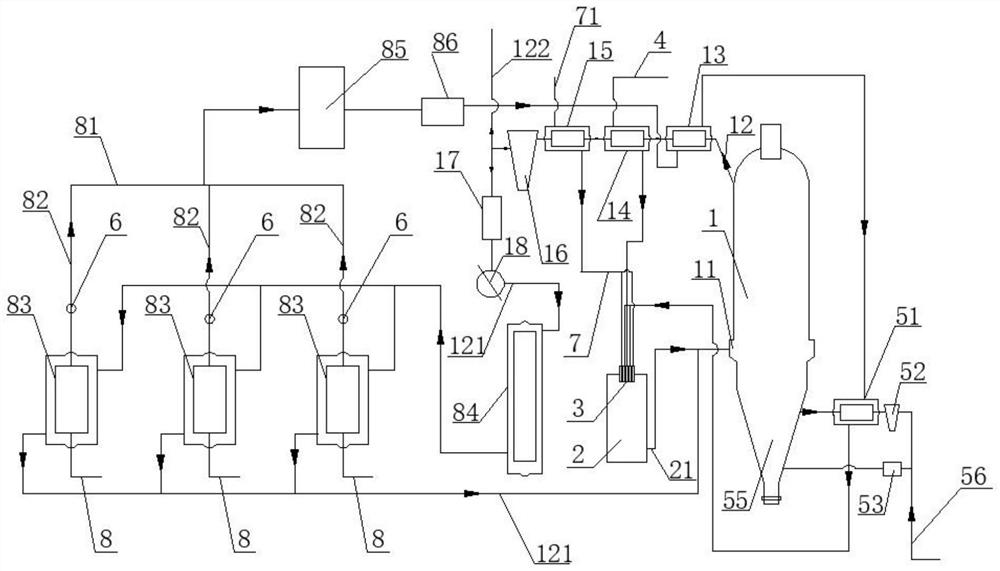

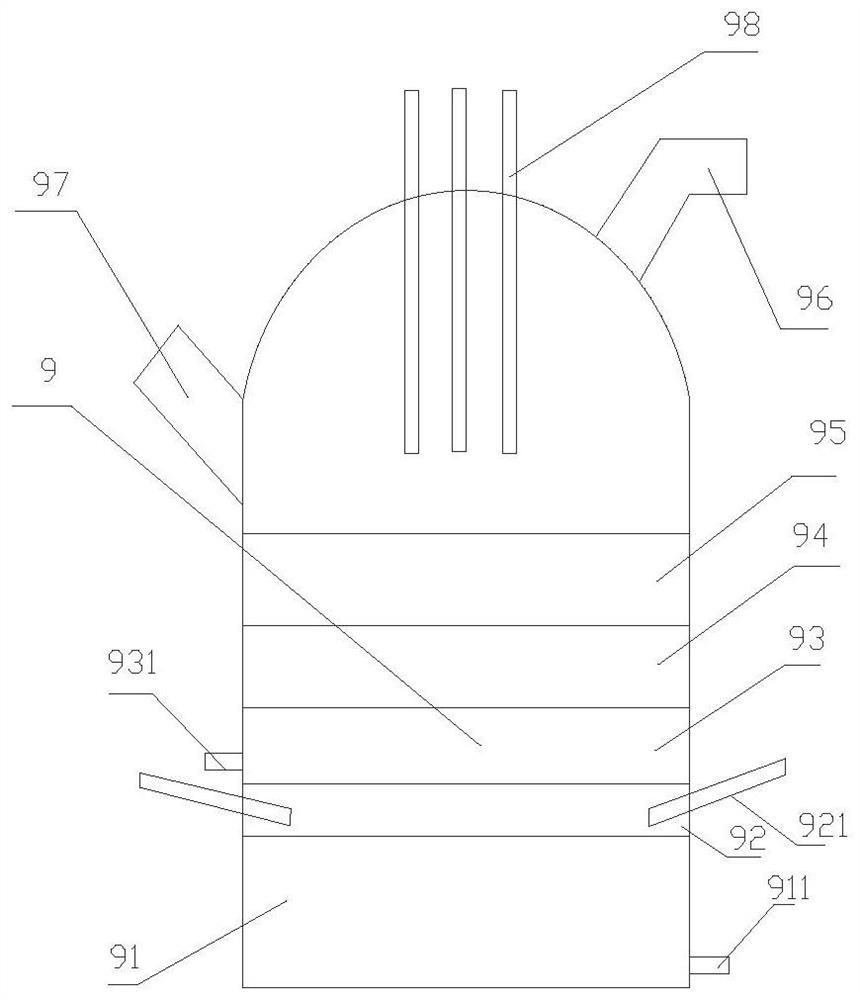

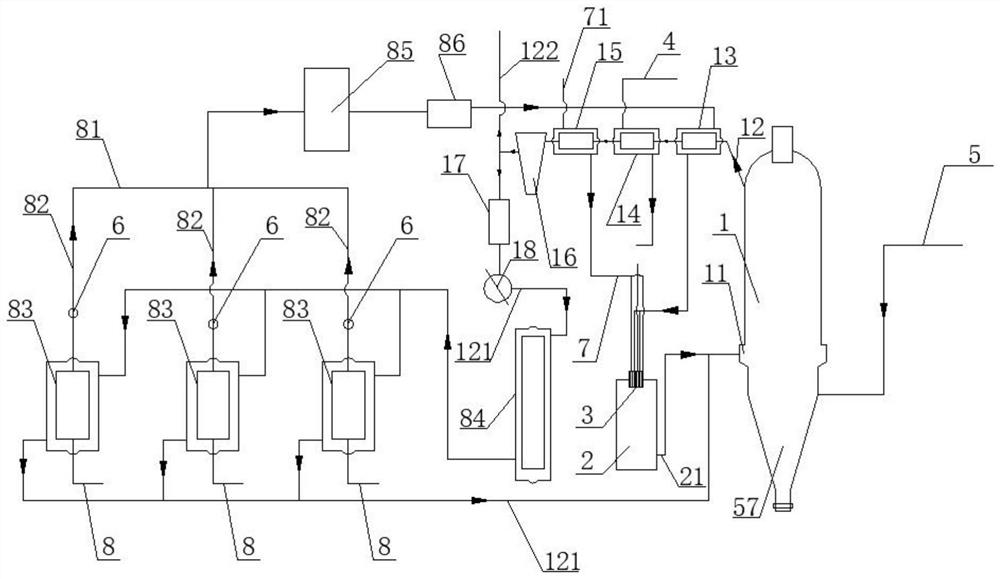

[0023] Specific embodiment 1: The method for smelting vanadium-titanium ore in a gas-based shaft furnace of coke oven gas-electric furnace for deep reduction by electric furnace in this embodiment is carried out according to the following steps: reducing the vanadium-titanium pellets in a gas-based shaft furnace to obtain vanadium Titanium direct-reduced iron; vanadium-titanium direct-reduced iron is smelted and reduced in an electric furnace to obtain vanadium-containing molten iron and titanium slag, characterized in that the gas-based shaft furnace uses at least one coke oven gas as the gas source, and the gas-based shaft furnace top is purified After the gas exchanges heat with the hot gas in the gas riser of the coke oven, it is mixed into the high-temperature reducing gas generated by the coke oven gas to form the reducing gas fed into the gas-based shaft furnace; the reducing gas is blown into the molten layer in the electric furnace , the reducing gas reacts with vanadi...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a part of the gas-based shaft furnace top hot gas is cooled, dehydrated, dedusted, and then CO is removed. 2After that, it becomes the gas-based shaft furnace top purification gas; the other part is not de-CO 2 The calorific value of the gas-based shaft furnace top gas replaces the coke oven gas and replaces the coke oven gas for other purposes. The coke oven gas formed by the replaced coke oven gas and the newly supplemented coke oven gas is preheated and enters the non-catalyzed The partial oxidation furnace is burned and heated to generate high-temperature reducing gas. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the gas-based shaft furnace top purification gas exchanges heat with the hot gas in the coke oven gas riser before exchanging heat with the hot flue gas of the coke oven flue. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com