Seed treatment instrument of cold plasma

A cold plasma and seed treatment technology, applied in the fields of seed and rhizome treatment, application, agriculture, etc., can solve problems such as sharp increase in power consumption, eddy current in induction coil, and reduction in processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

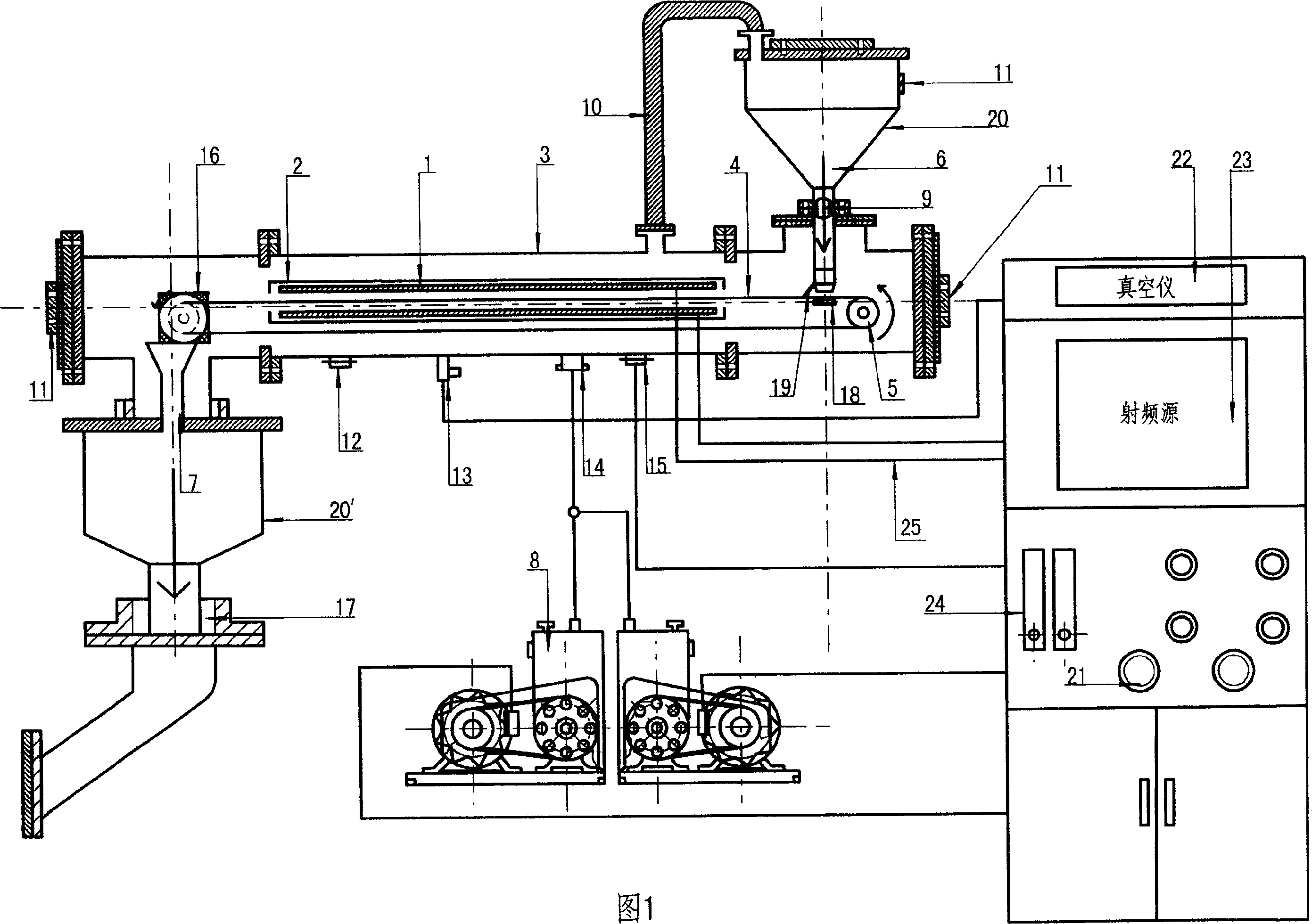

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

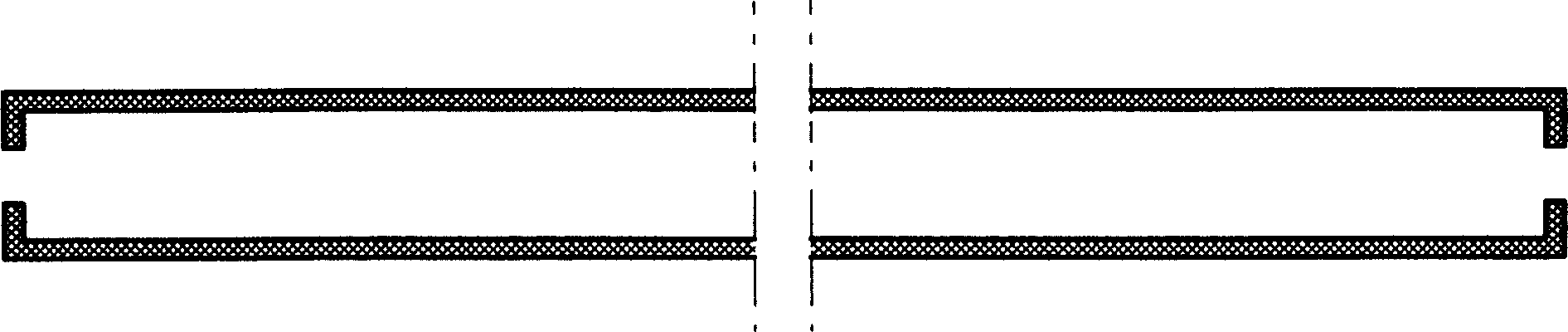

[0009] As shown in Figures 1 and 2, a cold plasma seed treatment instrument comprises a cylinder body 3 with a feed port 6, a discharge port 7, a vacuum port 14 and an air inlet 15, the vacuum port 14 and the vacuum pump 8 Connected by pipes, parallel upper and lower electrode plates 1 and a seed conveyor belt 4 driven by the power device are arranged in the cylinder body 3, and the seed conveyor belt 4 passes through the area between the upper and lower electrode plates 1, and the upper and lower electrode plates 1 The electrode plates 1 are respectively connected to the radio frequency source 23 through the radio frequency output lines 25 , and the outer periphery of the upper and lower electrode plates 1 is provided with a metal shield 2 . The power unit is made up of speed-regulating motor 16 and two guide wheels 5, wherein one guide wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com