Method for separating cyclopentadiene and methylcyclopentadiene from ethylene by-product C9

A technology of methylcyclopentadiene and cyclopentadiene, which is applied in the directions of distillation purification/separation, depolymerization to produce hydrocarbons, etc., can solve problems such as affecting normal production, pipeline blockage, increasing operating cost and labor intensity, etc. The effect of prolonging equipment production cycle, simplifying equipment, reducing production labor intensity and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

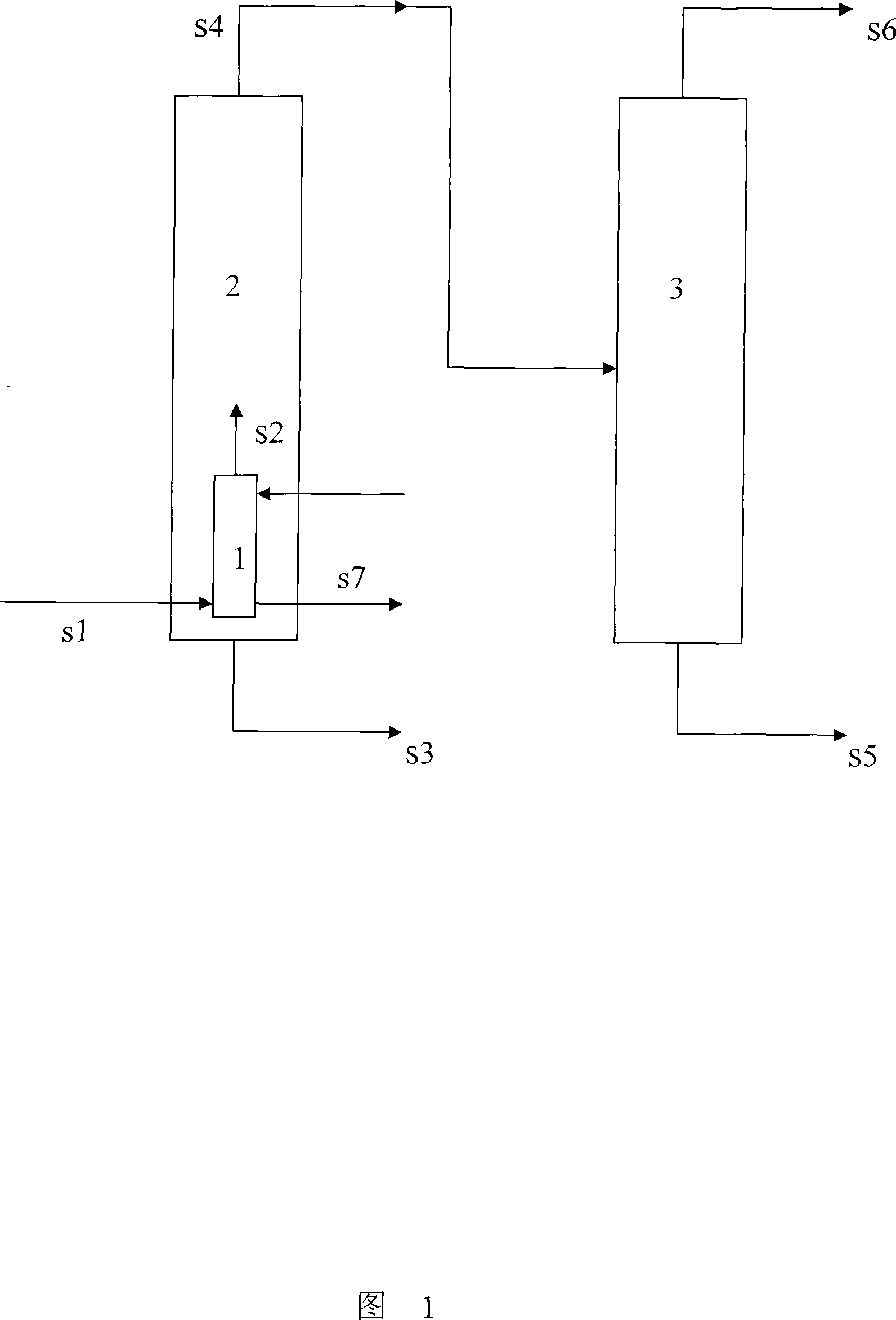

[0024]The ethylene by-product C9 containing 40% of dicyclopentadiene and dimethylcyclopentadiene is passed into the high-temperature cracking reactor in the 1st tank of the rectification tower. The cracking reaction temperature is 320°C. The mixed gas after the cracking reaction Pass into the rectification tower 1 filled with packing, the temperature at the bottom of the tower is 260°C, and the temperature at the top of the tower is 80°C. The fraction containing cyclopentadiene and methylcyclopentadiene is extracted at the top of the tower, containing cyclopentadiene, methylcyclopentadiene, and cyclopentadiene. The fraction of cyclopentadiene is passed into the rectifying tower 2 of packed packing, the temperature at the bottom of the tower is 90°C, the temperature at the top of the tower is 45°C, 97% of the cyclopentadiene product is extracted from the top of the tower, and 95% of the cyclopentadiene is extracted from the bottom of the tower. Methylcyclopentadiene products. B...

Embodiment 2

[0026] The ethylene by-product C9 containing 25% of dicyclopentadiene and dimethylcyclopentadiene is passed into the high-temperature cracking reactor in the first tank of the rectification tower. The cracking reaction temperature is 380 ° C. The mixed gas after the cracking reaction Pass into the rectifying tower 1 equipped with trays, the temperature at the bottom of the tower is 280°C, the temperature at the top of the tower is 90°C, and the fraction containing cyclopentadiene and methylcyclopentadiene is extracted at the top of the tower, containing cyclopentadiene, The fraction of methylcyclopentadiene is passed into the rectifying tower 2 equipped with trays, the temperature at the bottom of the tower is 100°C, the temperature at the top of the tower is 55°C, 95% of the cyclopentadiene product is extracted from the top of the tower, and 93% of the cyclopentadiene is extracted from the bottom of the tower. % of methylcyclopentadiene product. Both rectification column 1 an...

Embodiment 3

[0028] The crude cyclopentadiene containing 65% of dicyclopentadiene and dimethylcyclopentadiene is passed into the high-temperature cracking reactor in the 1st tank of the rectification tower, the cracking reaction temperature is 220°C, and the mixed steam after the cracking reaction The body is passed into the rectifying tower 1 equipped with trays, the temperature at the bottom of the tower is 160°C, and the temperature at the top of the tower is 35°C. The fraction containing cyclopentadiene and methylcyclopentadiene is extracted at the top of the tower, and the fraction containing cyclopentadiene 1. The cut of methylcyclopentadiene passes into the rectifying tower 2 that tray is equipped with, and tower bottom temperature is 70 ℃, tower top temperature 35 ℃, and the cyclopentadiene product of tower top mining 98%, tower bottom mining 91% Methylcyclopentadiene product. Both rectification column 1 and rectification column 2 are operated under normal pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com