Patents

Literature

273 results about "Methylcyclopentadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

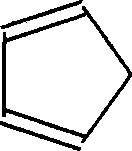

Methylcyclopentadiene is any of three isomeric cyclic dialkenes with the formula C₅MeH₅ (Me = CH₃). These isomers are the organic precursor to the methylcyclopentadienyl ligand (C₅H₄Me, often denoted as Cp′), commonly found in organometallic chemistry.

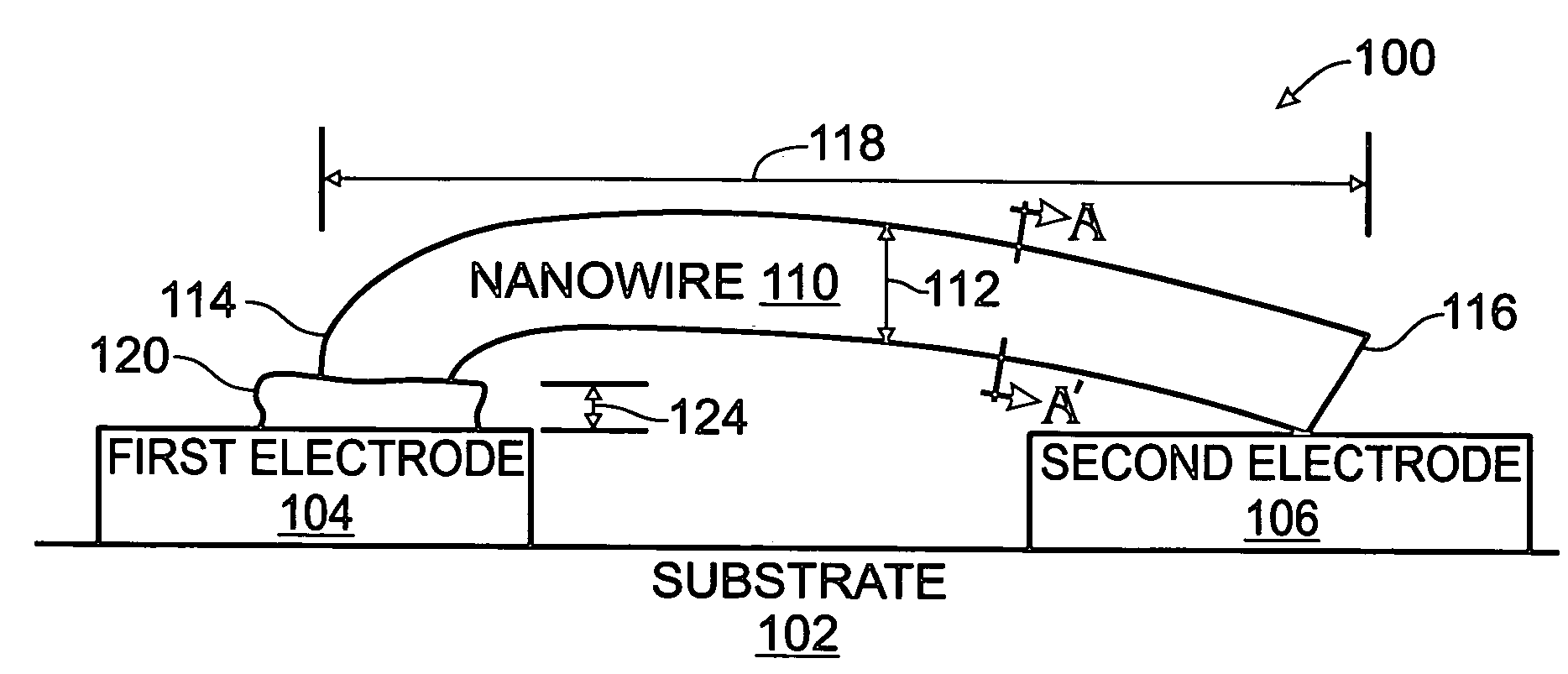

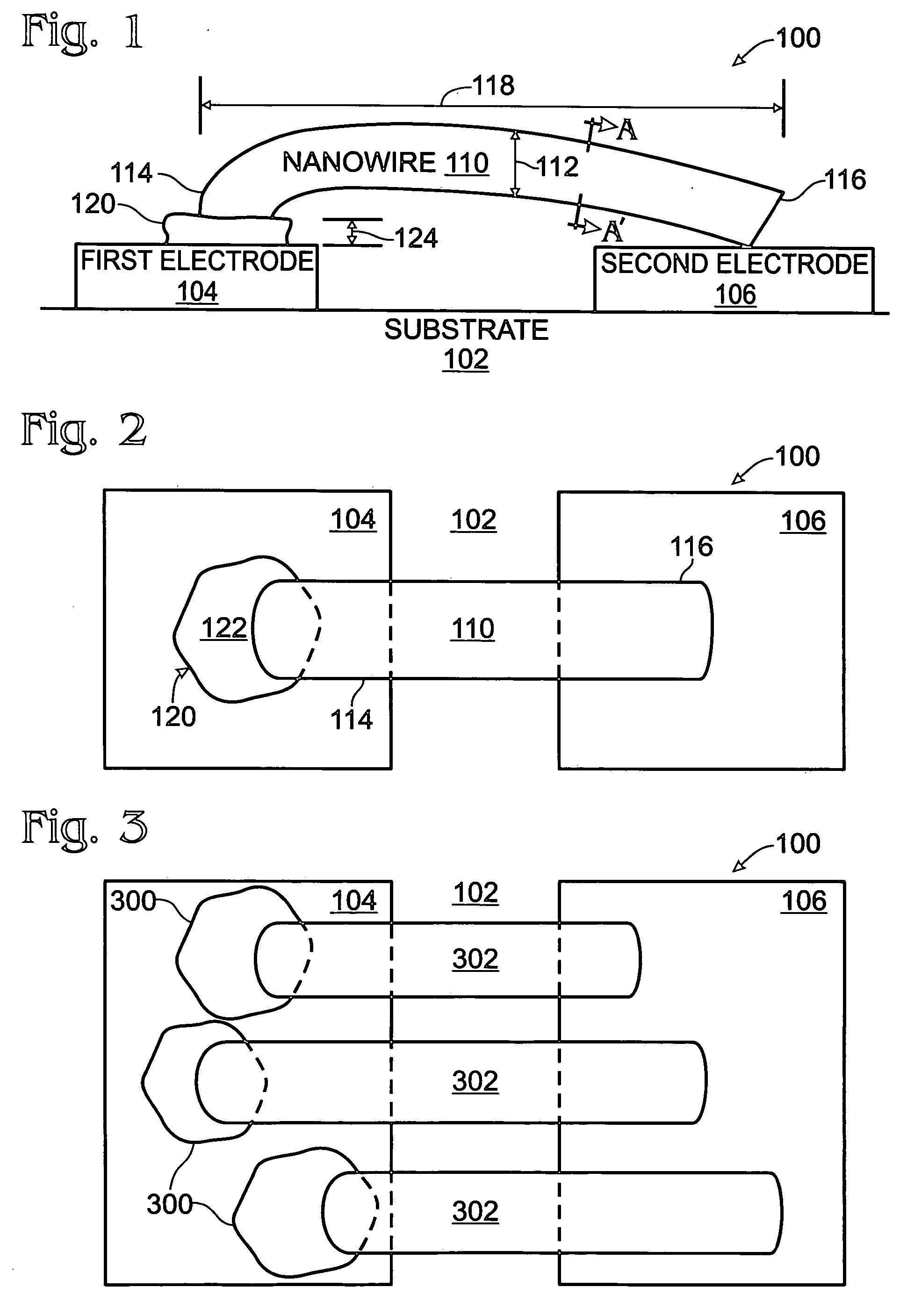

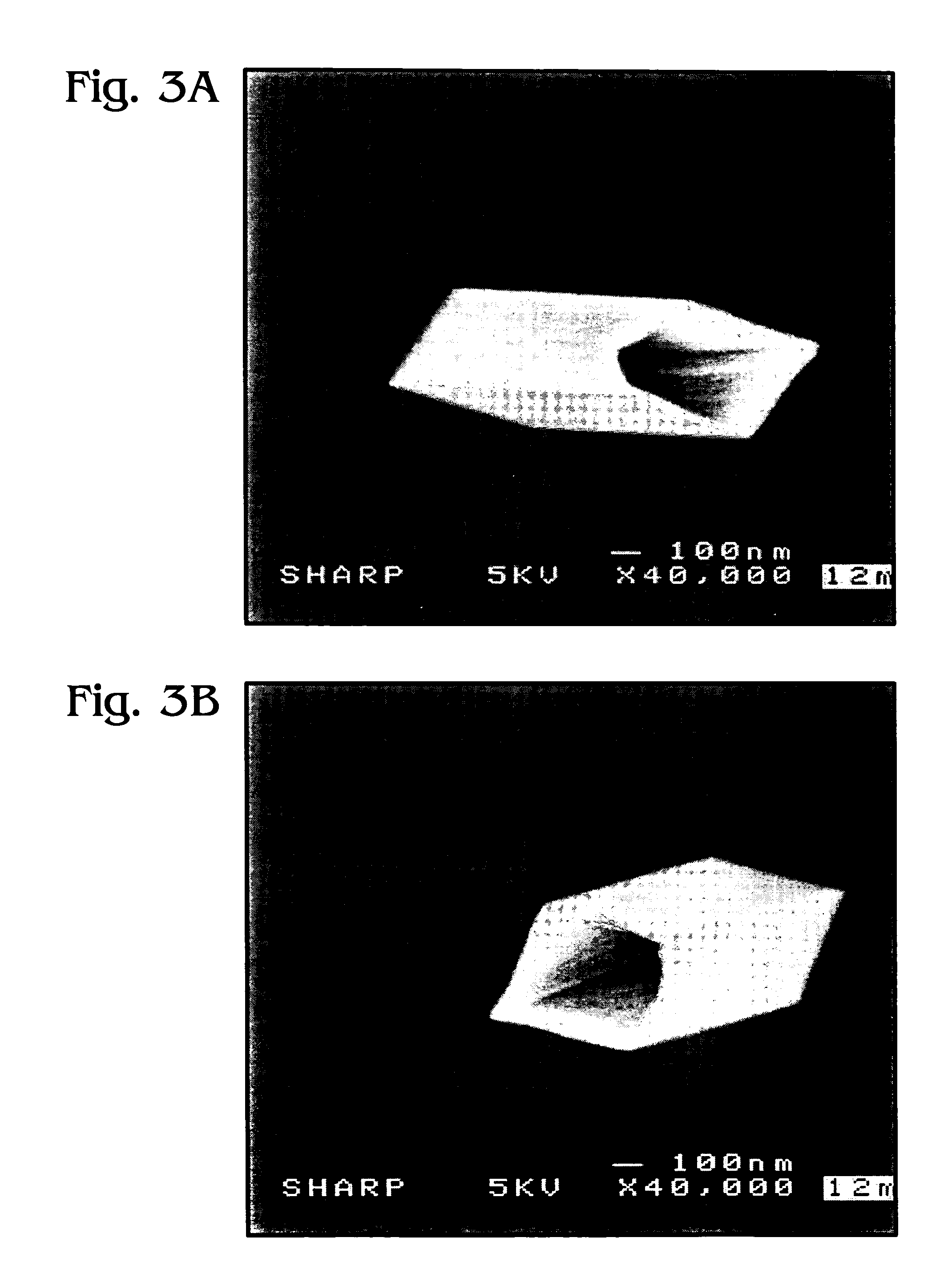

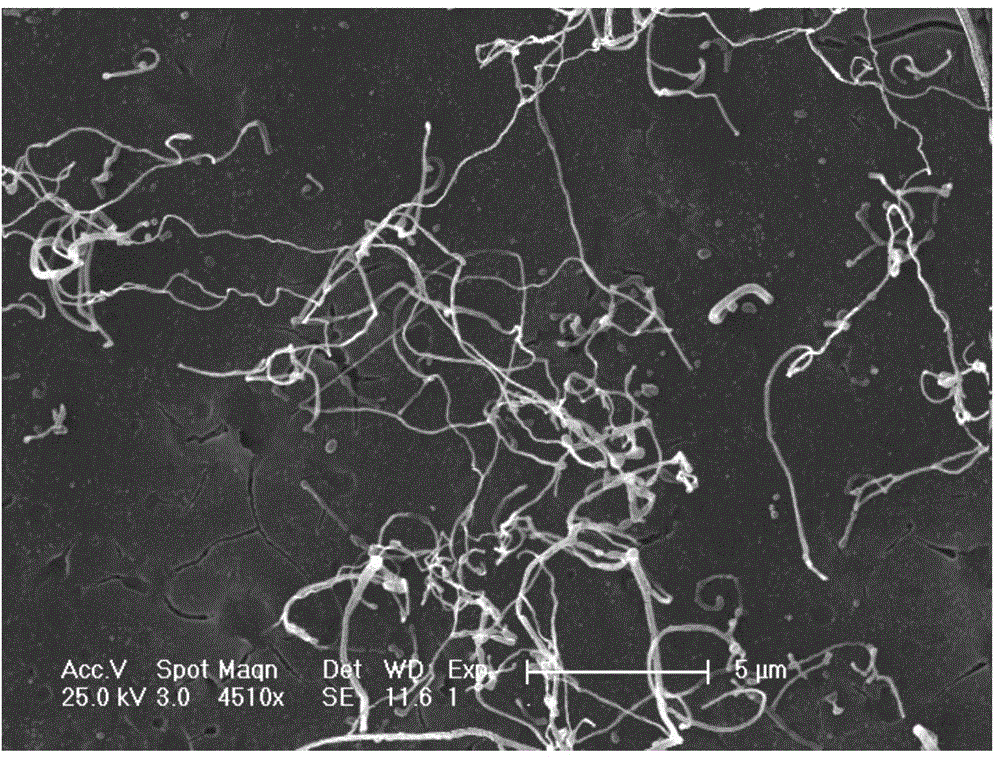

Iridium oxide nanowires and method for forming same

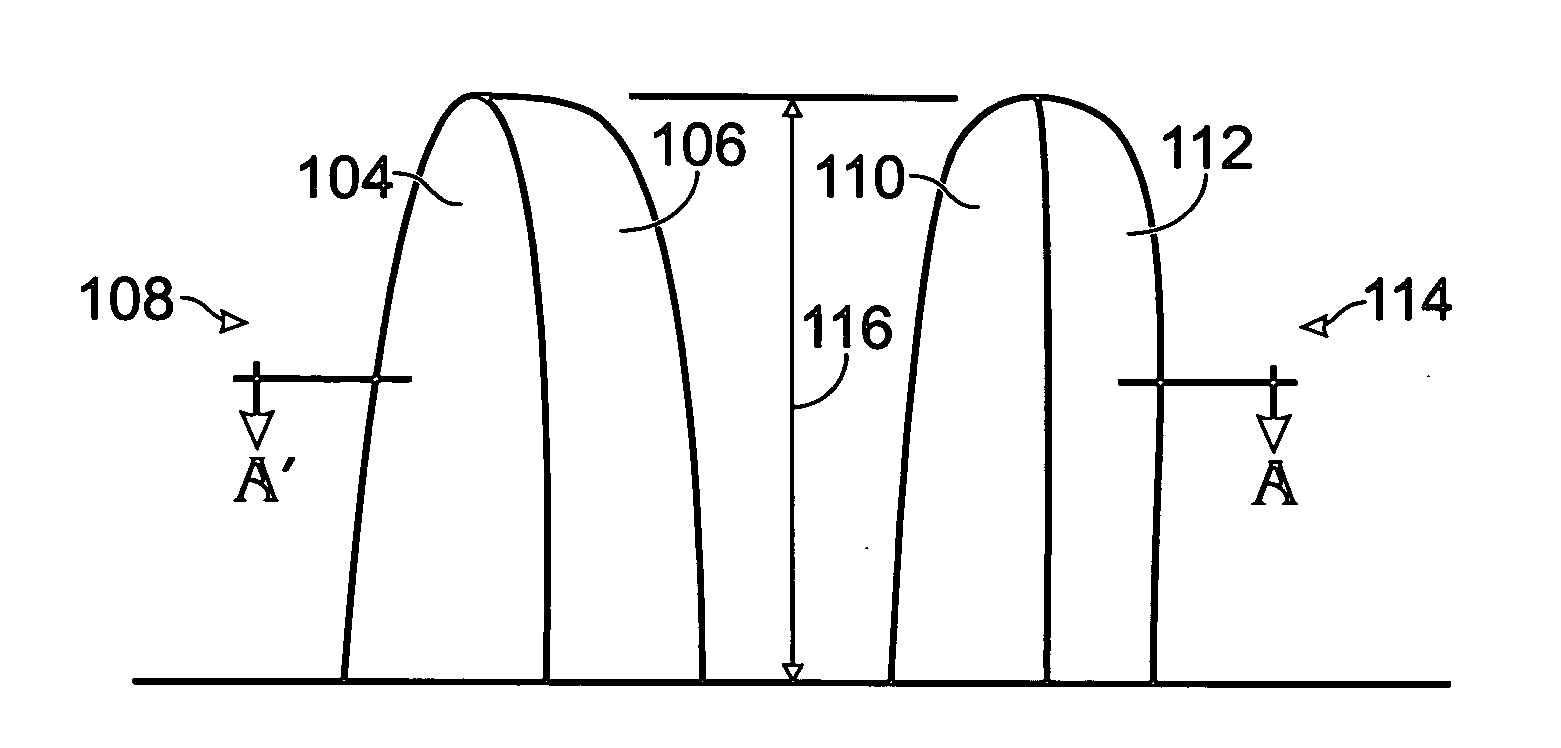

InactiveUS20060086314A1Good crystallinity and electrical propertyNanotechPolycrystalline material growthNanowireSingle crystal

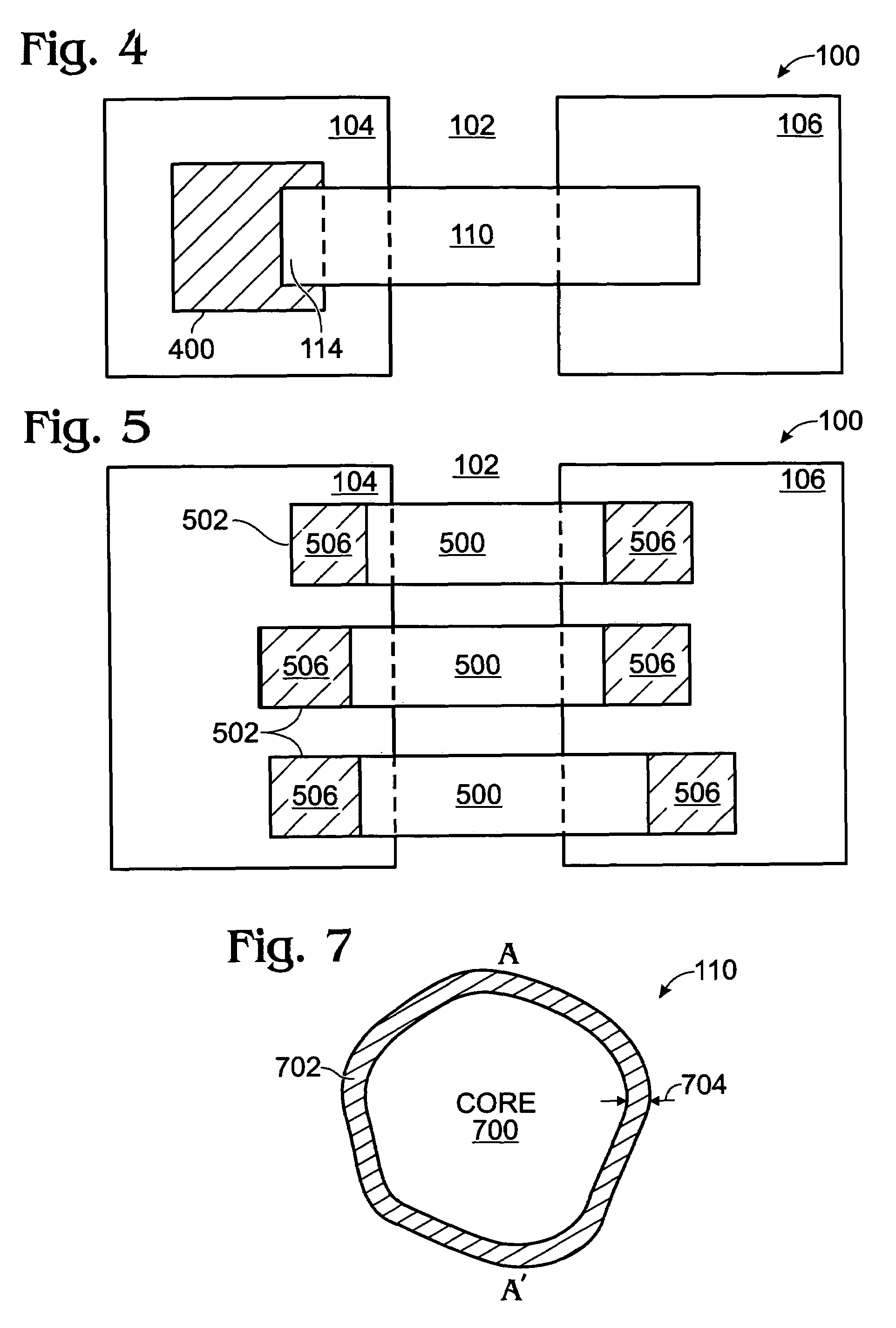

Iridium oxide (IrOx) nanowires and a method forming the nanowires are provided. The method comprises: providing a growth promotion film with non-continuous surfaces, having a thickness in the range of 0.5 to 5 nanometers (nm), and made from a material such as Ti, Co, Ni, Au, Ta, polycrystalline silicon (poly-Si), SiGe, Pt, Ir, TiN, or TaN; establishing a substrate temperature in the range of 200 to 600 degrees C.; introducing oxygen as a precursor reaction gas; introducing a (methylcyclopentadienyl)(1,5-cyclooctadiene)iridium(I) precursor; using a metalorganic chemical vapor deposition (MOCVD) process, growing IrOx nanowires from the growth promotion film surfaces. The IrOx nanowires have a diameter in the range of 100 to 1000 Å, a length in the range of 1000 Å to 2 microns, an aspect ratio (length to width) of greater than 50:1. Further, the nanowires include single-crystal nanowire cores covered with an amorphous layer having a thickness of less than 10 Å.

Owner:SHARP KK

Method for producing doped, alloyed, and mixed-phase magnesium boride films

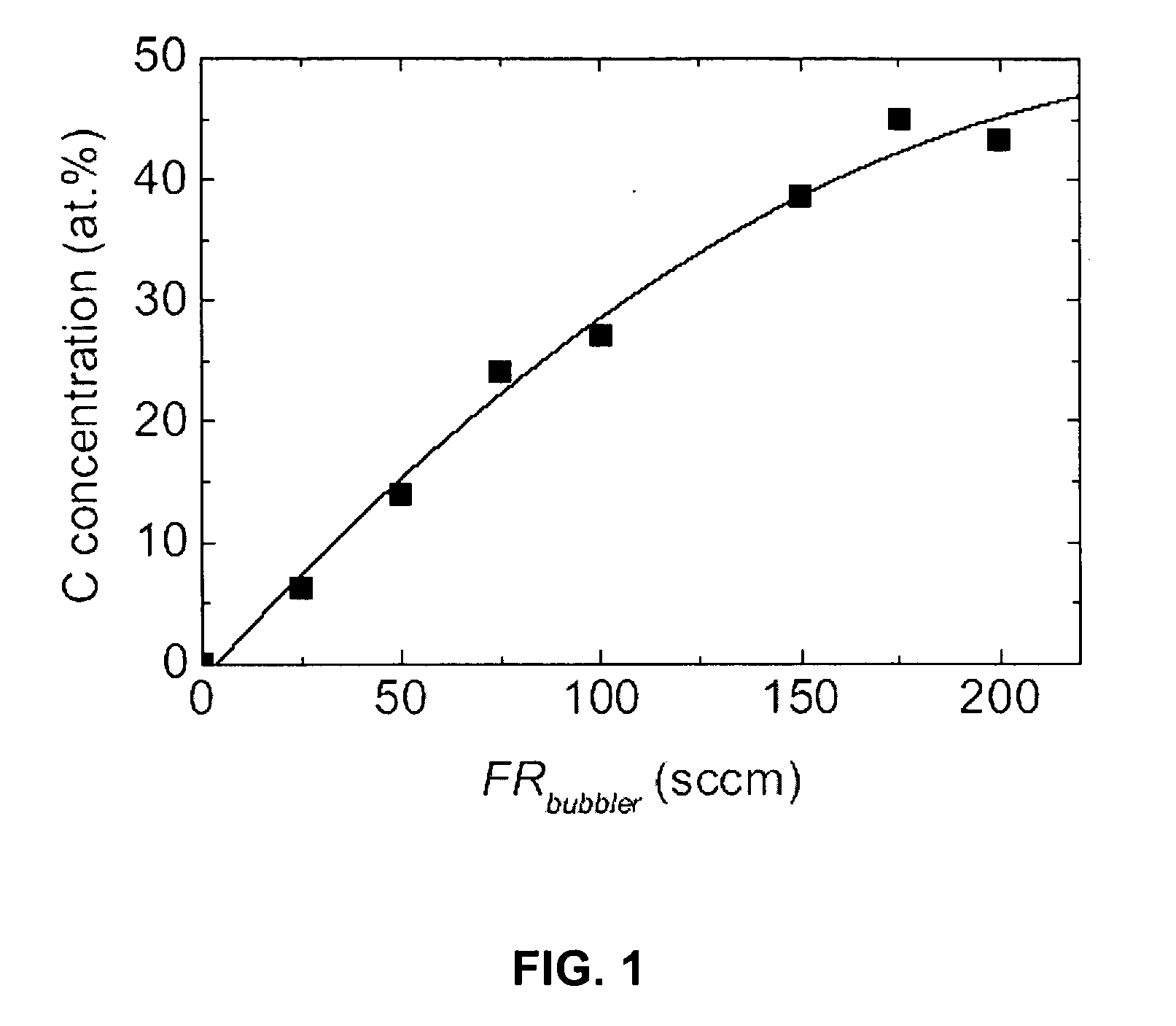

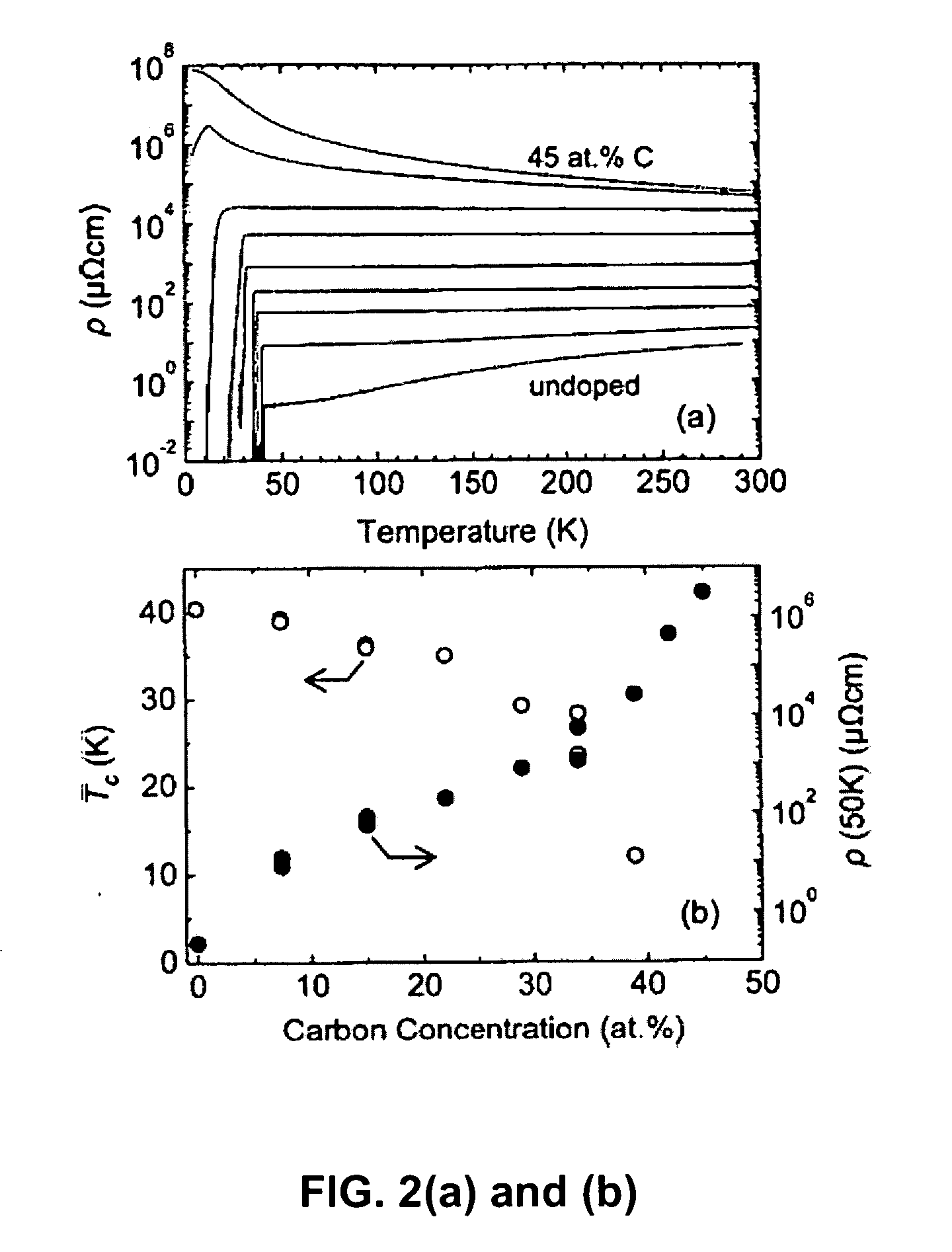

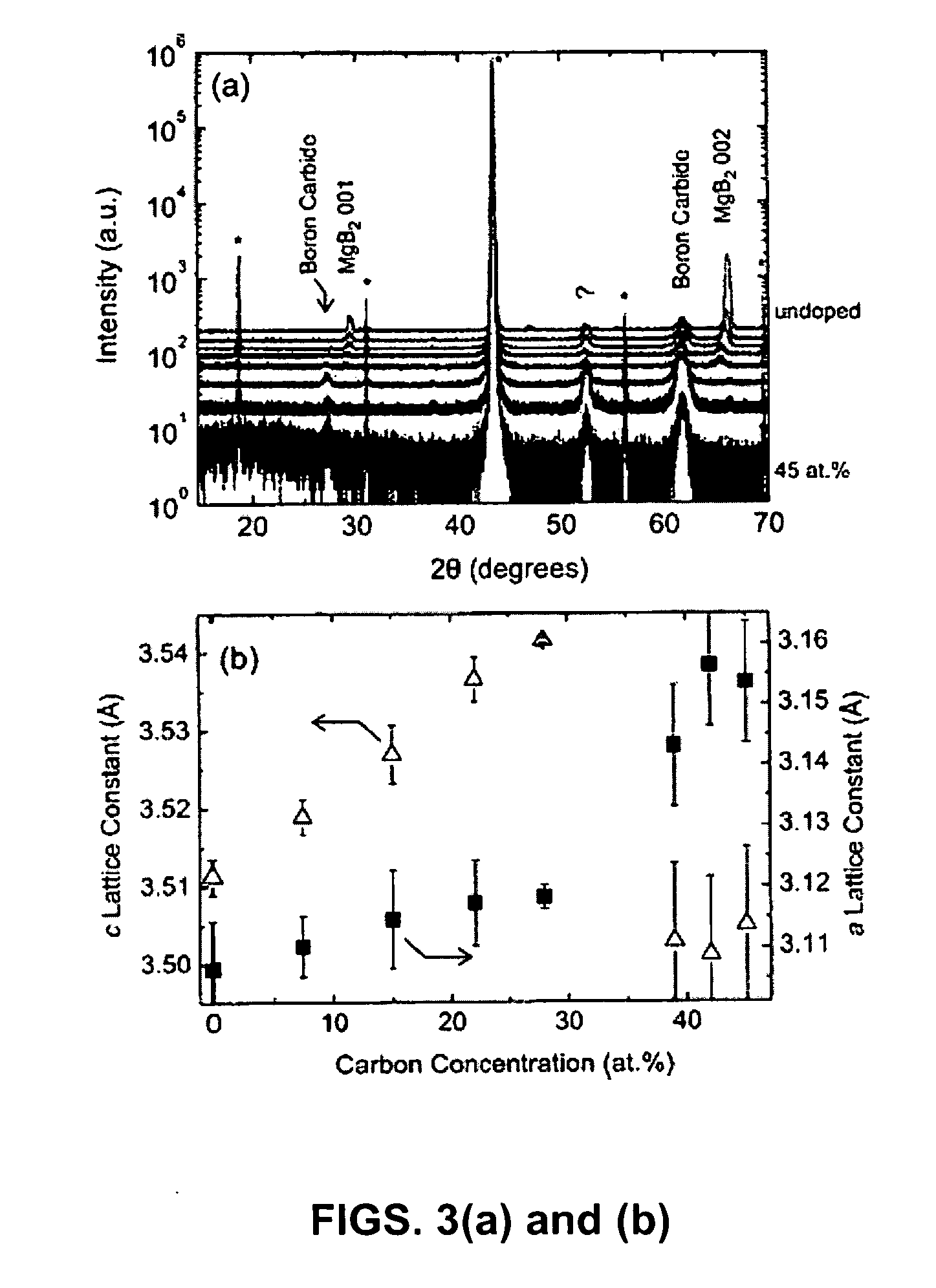

Conducting and superconducting doped, magnesium boride materials are formed by a process which combines physical vapor deposition with chemical vapor deposition by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor and a dopant into the chamber which combines with the magnesium vapor to form the material. Embodiments include forming carbon-doped magnesium diboride film and powder with hybrid physical-chemical vapor deposition (HPCVD) by adding a carbon-containing metalorganic magnesium precursor, bis(methylcyclopentadienyl)magnesium, with a hydrogen carrier gas together with a borane precursor in a chamber having a source of magnesium vapor.

Owner:PENN STATE RES FOUND

Process for preparing metal coatings from liquid solutions utilizing cold plasma

ActiveUS7258899B1Easy to handleMetallic state is rapidPretreated surfacesLiquid/solution decomposition chemical coatingAlloySolvent

A method for depositing metals, metal blends and alloys onto substrate surfaces, including microporous substrates utilizing a plasma operation undertaken at room temperature. In the process, a liquid solution of a monomer or comonomer precursor having a metallic component is utilized to wet the surface of the substrate, with the solvent portion thereafter being removed to leave the substrate surface coated with a dry deposit. The coated substrate is then introduced into a plasma reaction chamber with RF energy being applied across spaced electrodes to create a plasma glow along with the introduction of a plasma supporting gas. The substrate is exposed to the plasma glow for conversion of the precursor to dissociated form to create a deposit consisting essentially of the metallic component in elemental form as a cohesive film on the substrate surface. Preferred metals include such noble metals as platinum, gold and silver, as well as other metals. Preferred precursors include platinum hexafluoro-acetylacetonate, (trimethyl) methylcyclopentadienyl platinum, dimethyl(acetylacetonate) gold, and trimethyl phosphine (hexafluoroacetyl acetonate) silver.

Owner:AMT HLDG

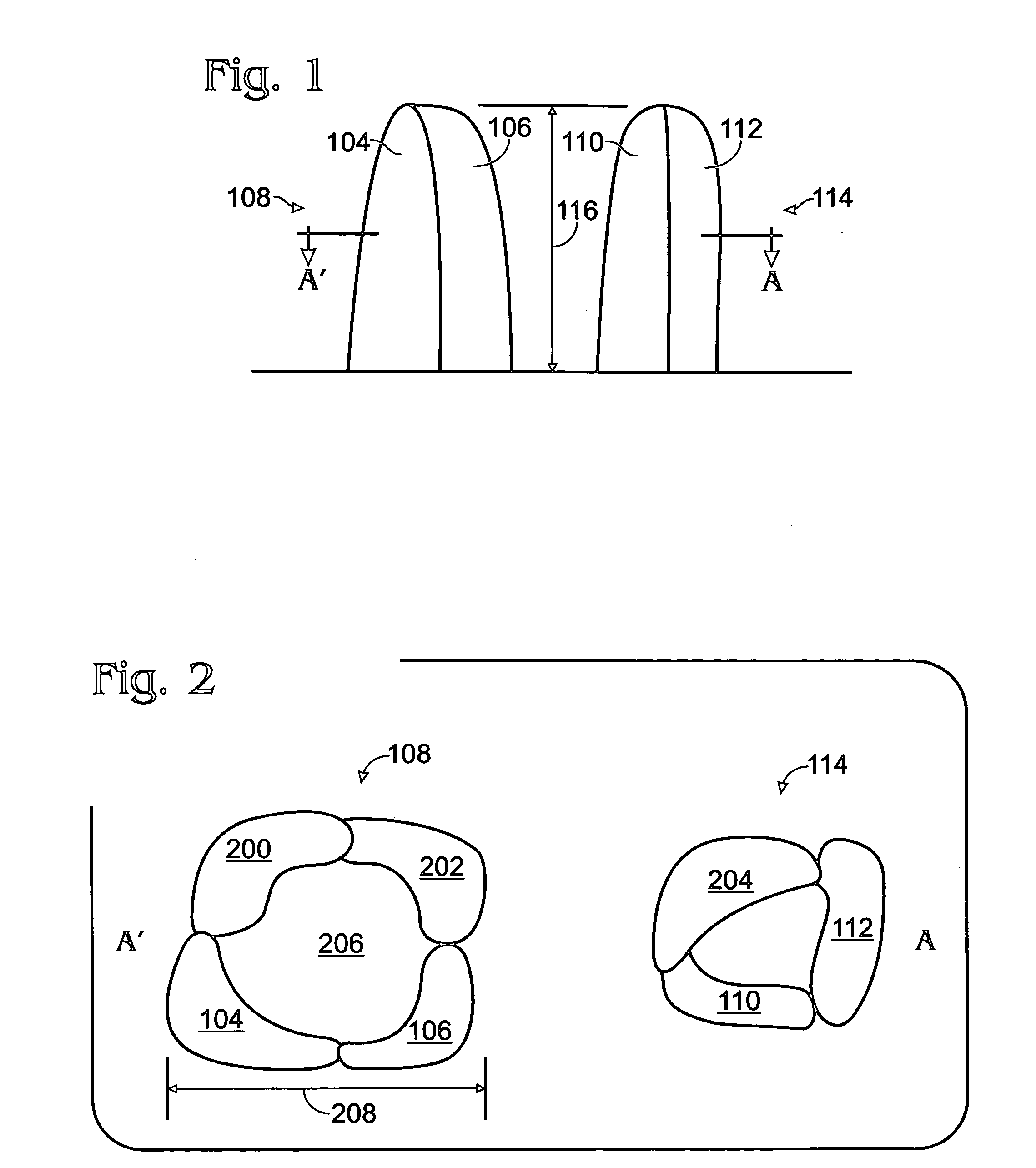

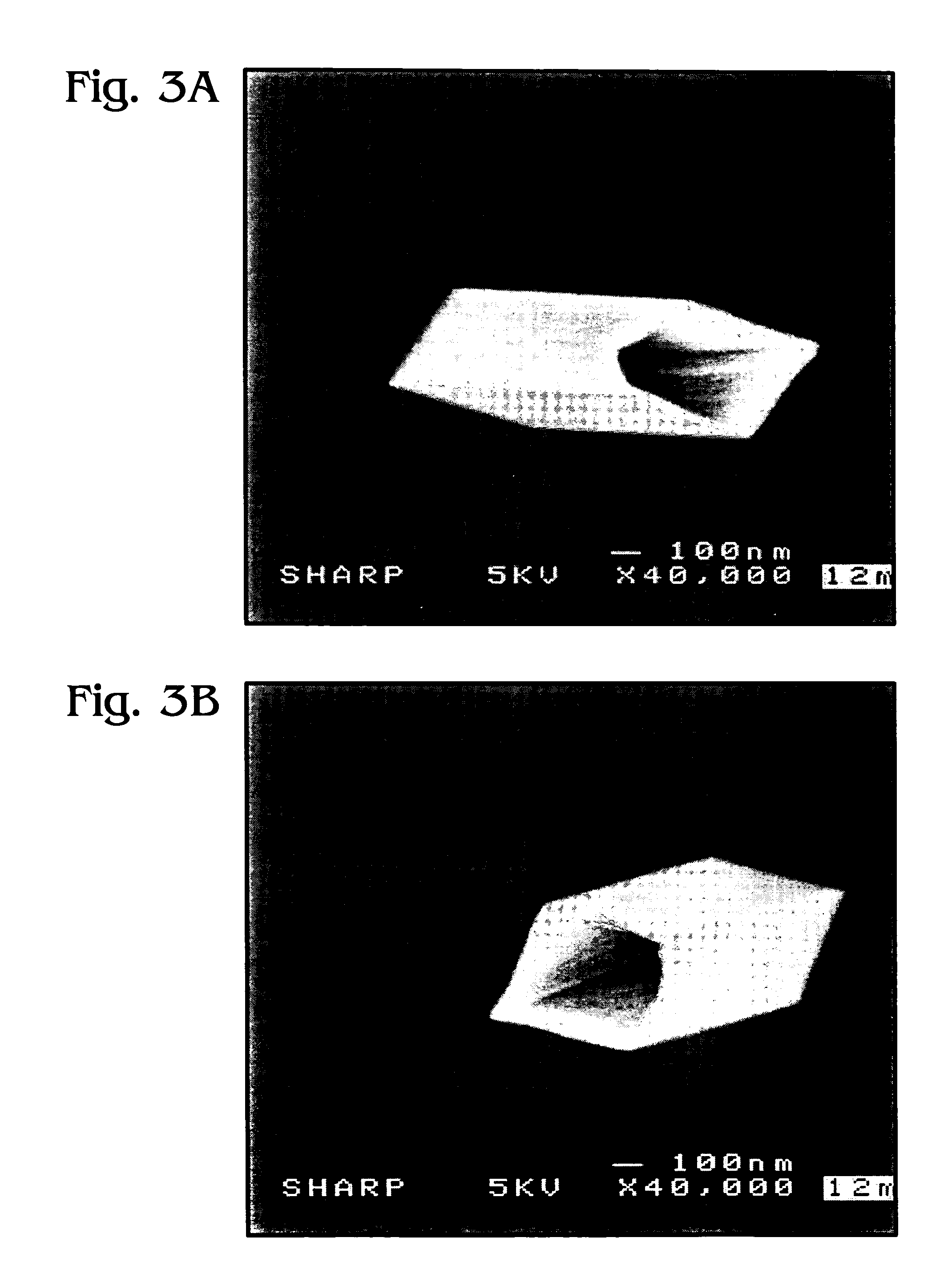

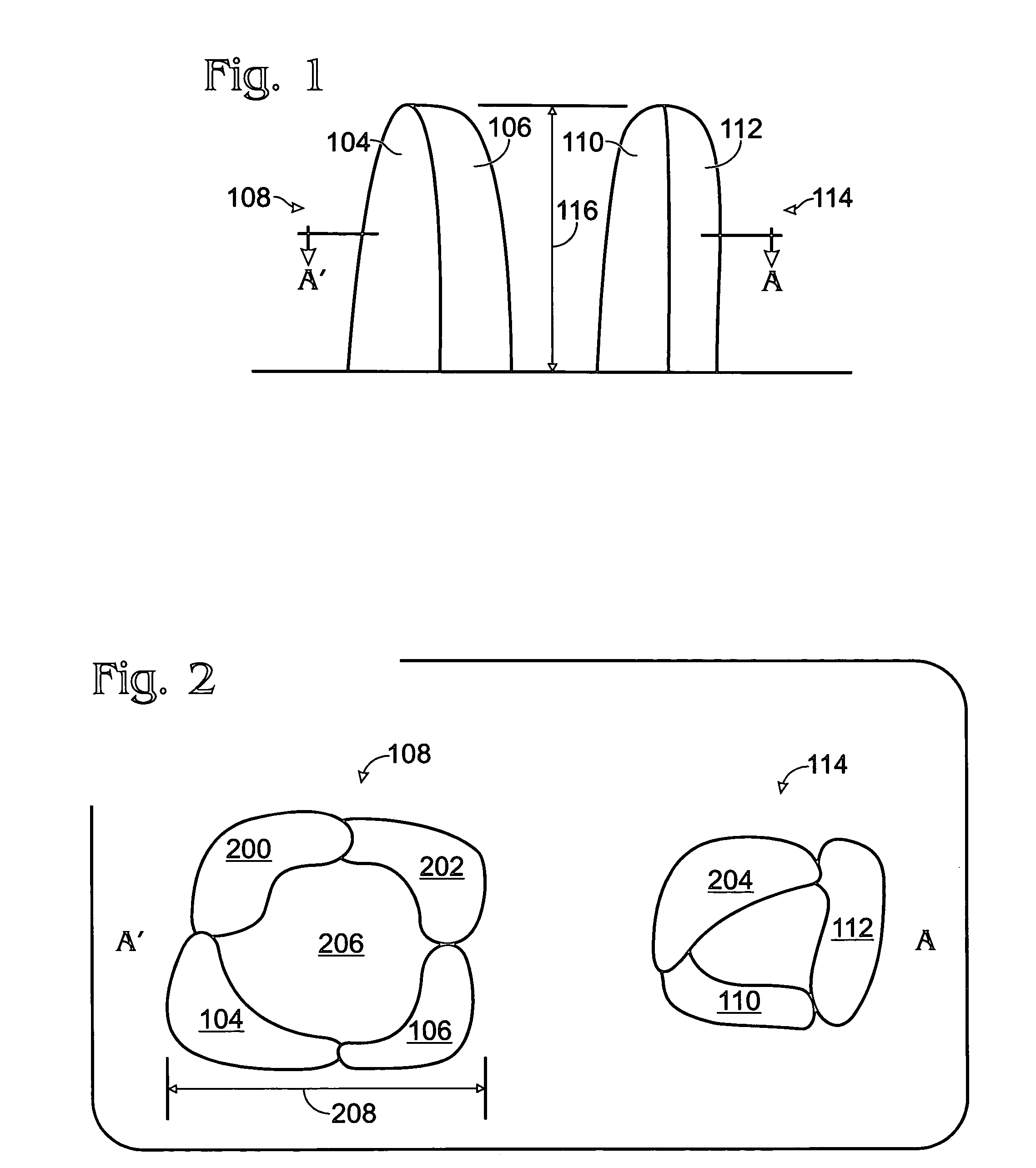

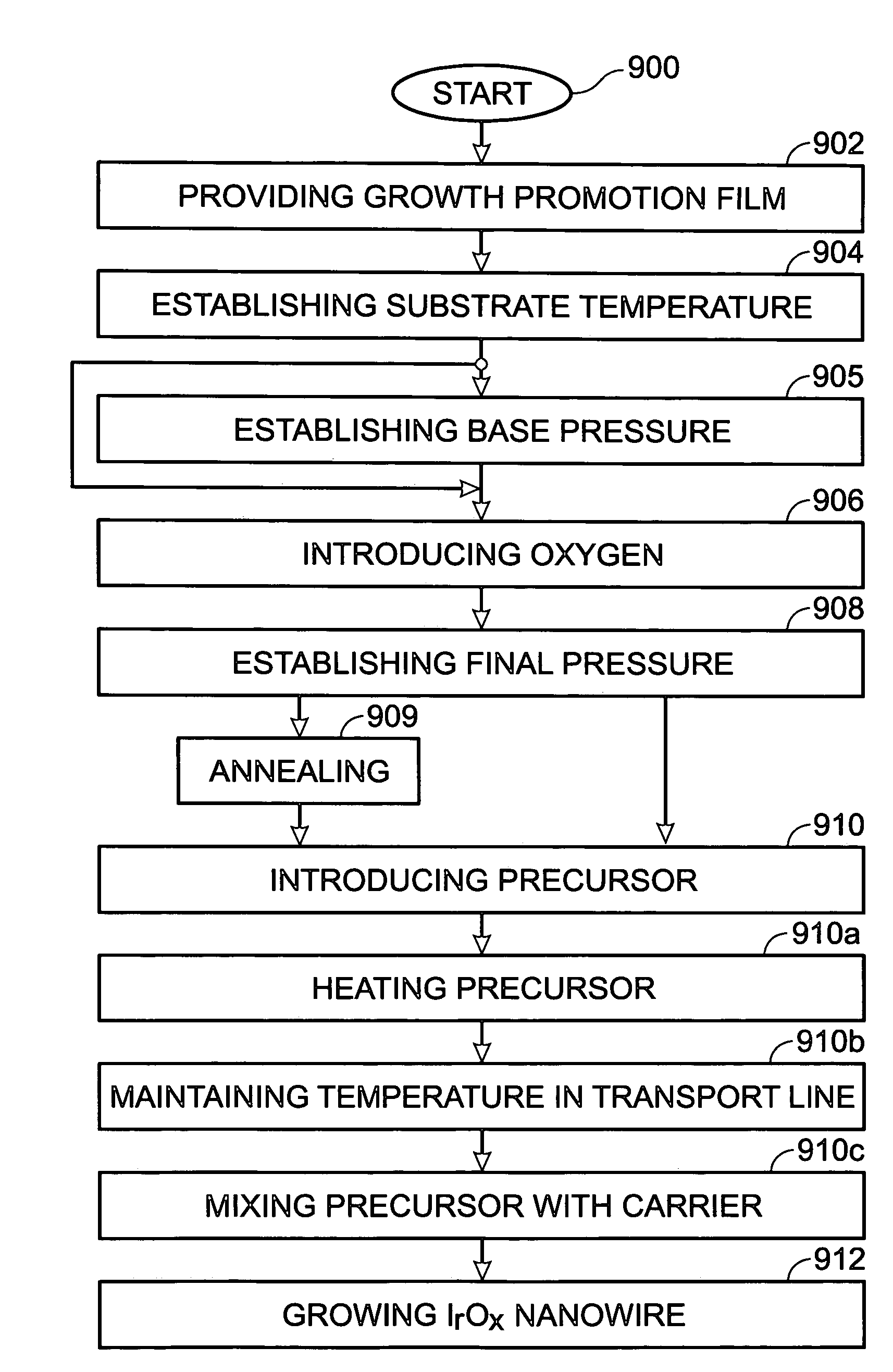

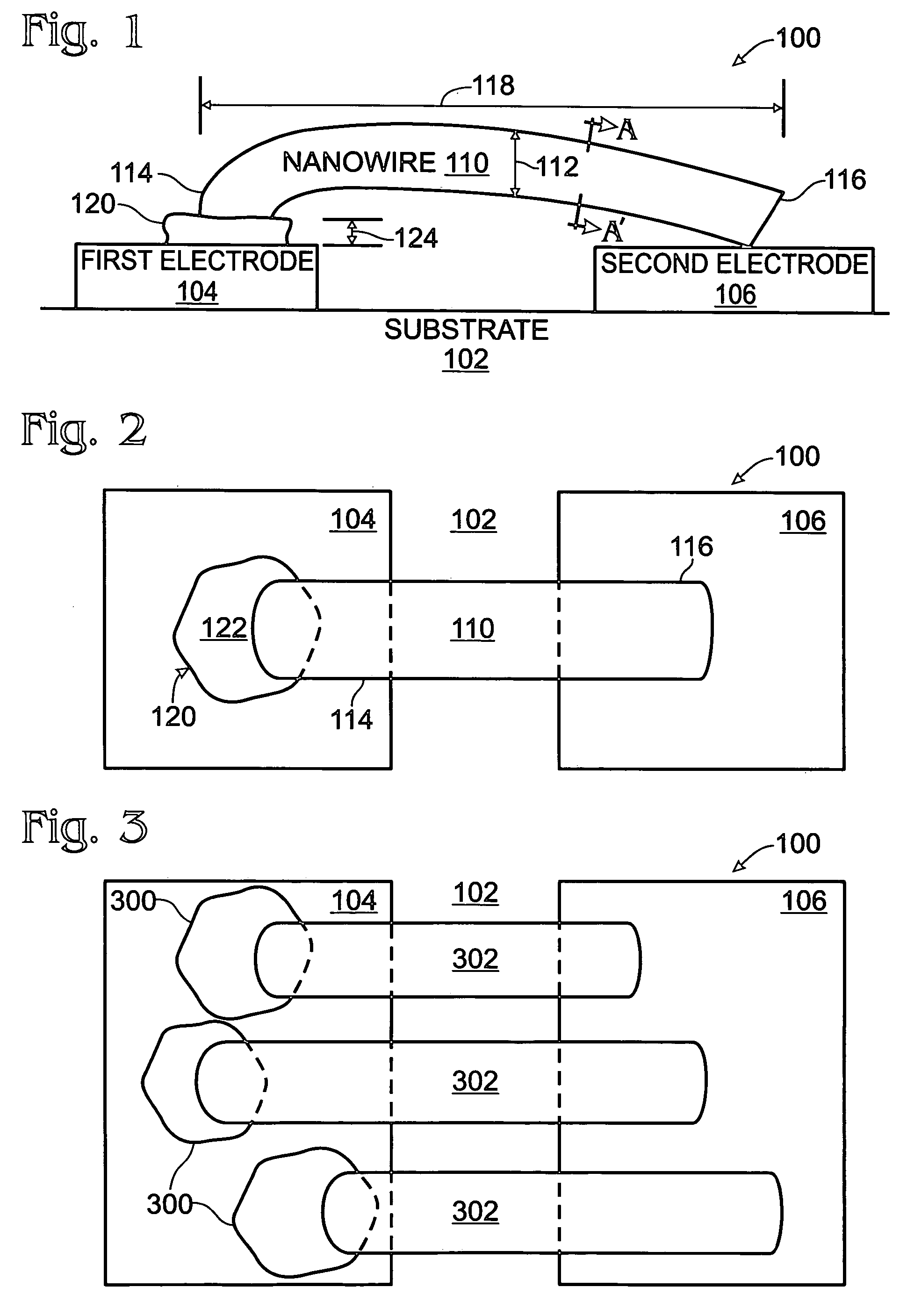

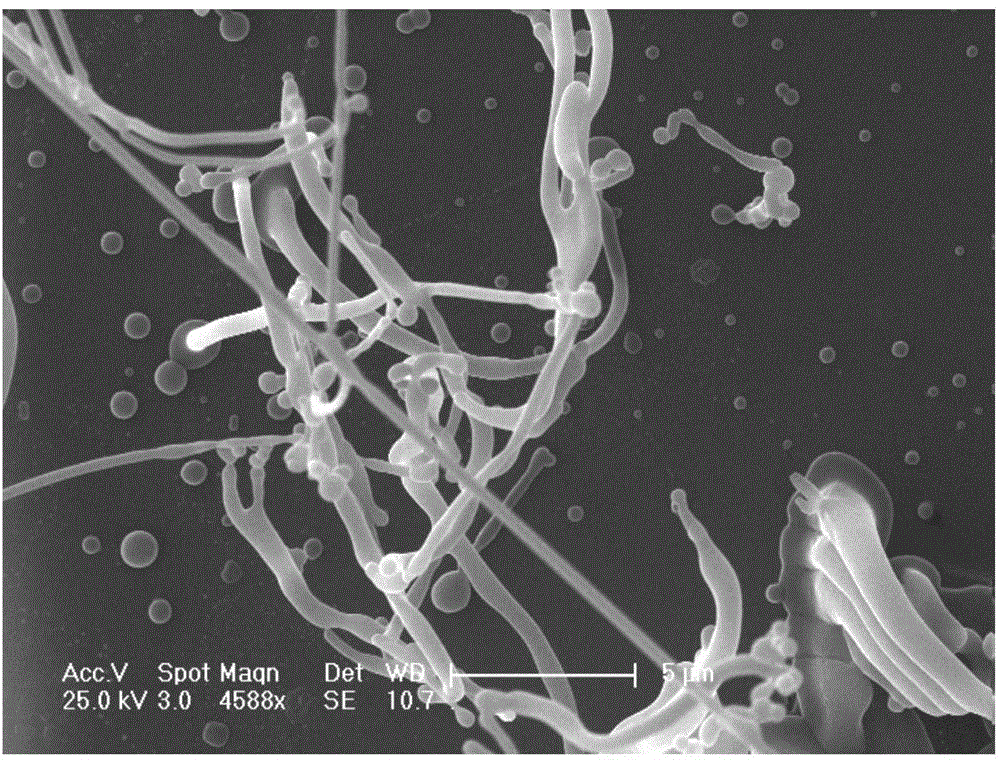

Iridium oxide nanotubes and method for forming same

ActiveUS7098144B2Material nanotechnologyPolycrystalline material growthOxygenChemical vapor deposition

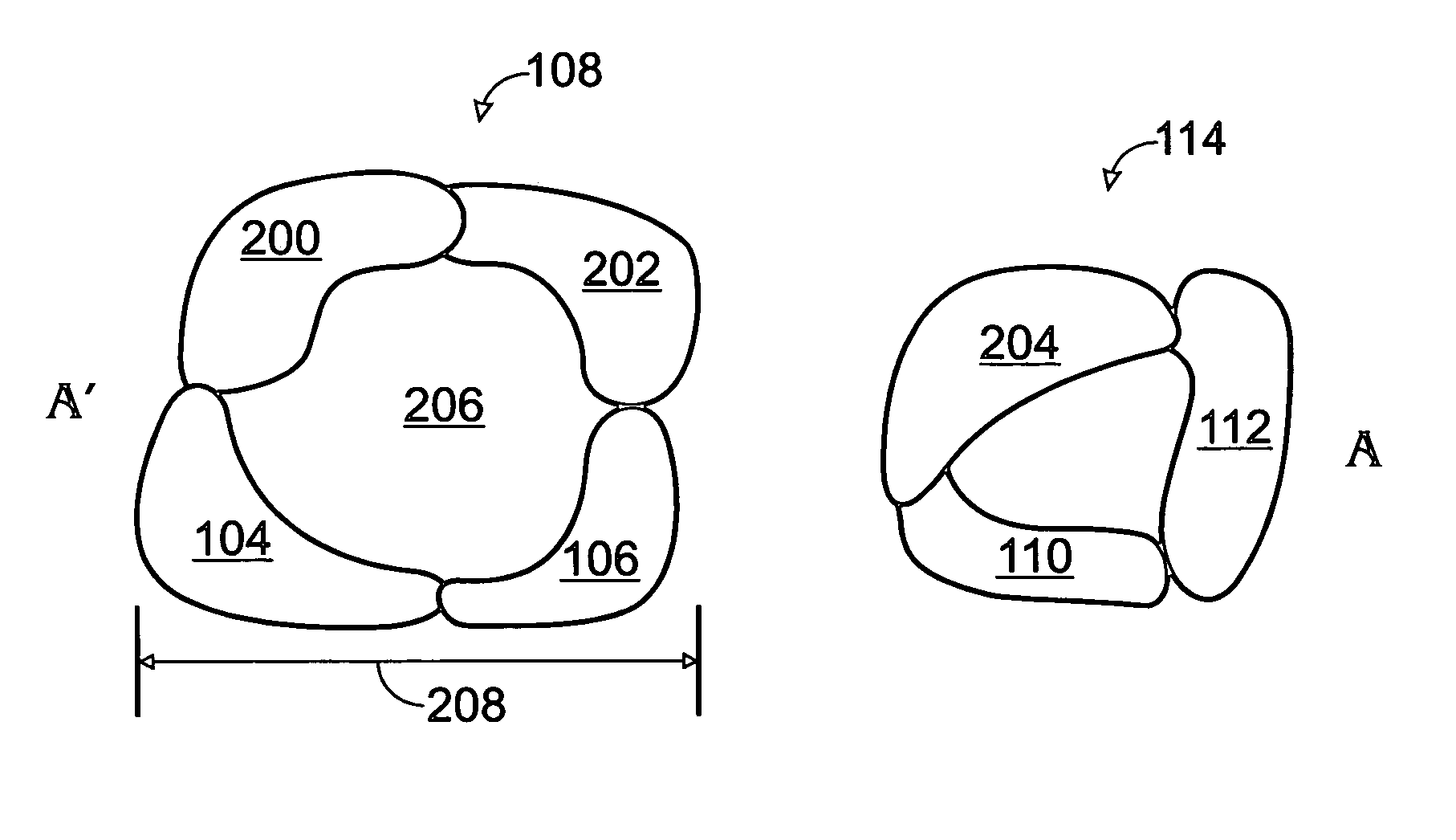

A method is provided for forming iridium oxide (IrOx) nanotubes. The method comprises: providing a substrate; introducing a (methylcyclopentadienyl)(1,5-cyclooctadiene)iridium(I) precursor; introducing oxygen as a precursor reaction gas; establishing a final pressure in the range of 1 to 50 Torr; establishing a substrate, or chamber temperature in the range of 200 to 500 degrees C.; and using a metalorganic chemical vapor deposition (MOCVD) process, growing IrOx hollow nanotubes from the substrate surface. Typically, the (methylcyclopentadienyl)(1,5-cyclooctadiene)iridium(I) precursor is initially heated in an ampule to a first temperature in the range of 60 to 90 degrees C., and the first temperature is maintained in the transport line introducing the precursor. The precursor may be mixed with an inert carrier gas such as Ar, or the oxygen precursor reaction gas may be used as the carrier.

Owner:SHARP KK

Iridium oxide nanowires and method for forming same

InactiveUS7255745B2Good crystallinity and electrical propertyNanotechPolycrystalline material growthIridiumNanowire

Iridium oxide (IrOx) nanowires and a method forming the nanowires are provided. The method comprises: providing a growth promotion film with non-continuous surfaces, having a thickness in the range of 0.5 to 5 nanometers (nm), and made from a material such as Ti, Co, Ni, Au, Ta, polycrystalline silicon (poly-Si), SiGe, Pt, Ir, TiN, or TaN; establishing a substrate temperature in the range of 200 to 600 degrees C.; introducing oxygen as a precursor reaction gas; introducing a (methylcyclopentadienyl)(1,5-cyclooctadiene)iridium(I) precursor; using a metalorganic chemical vapor deposition (MOCVD) process, growing IrOx nanowires from the growth promotion film surfaces. The IrOx nanowires have a diameter in the range of 100 to 1000 Å, a length in the range of 1000 Å to 2 microns, an aspect ratio (length to width) of greater than 50:1. Further, the nanowires include single-crystal nanowire cores covered with an amorphous layer having a thickness of less than 10 Å.

Owner:SHARP KK

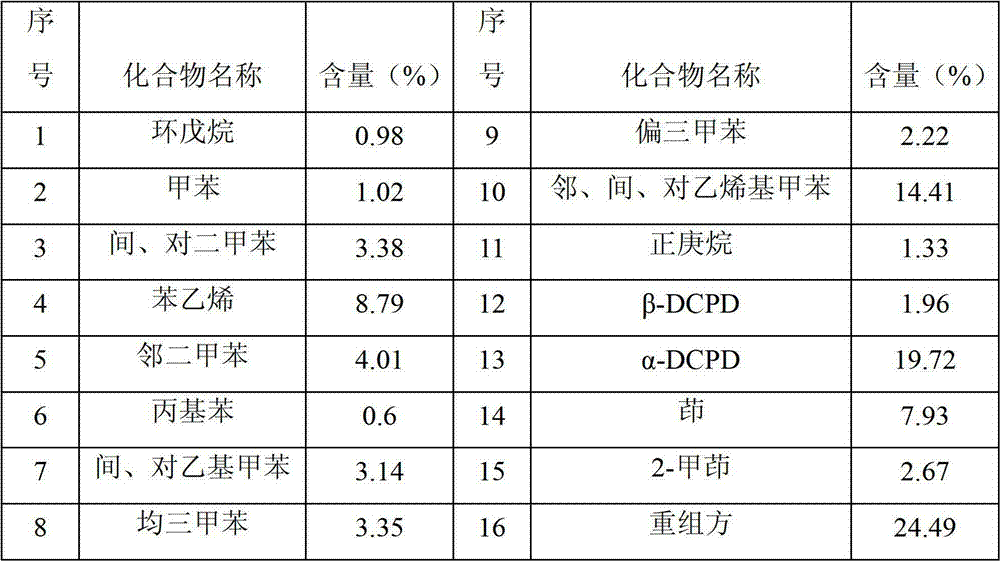

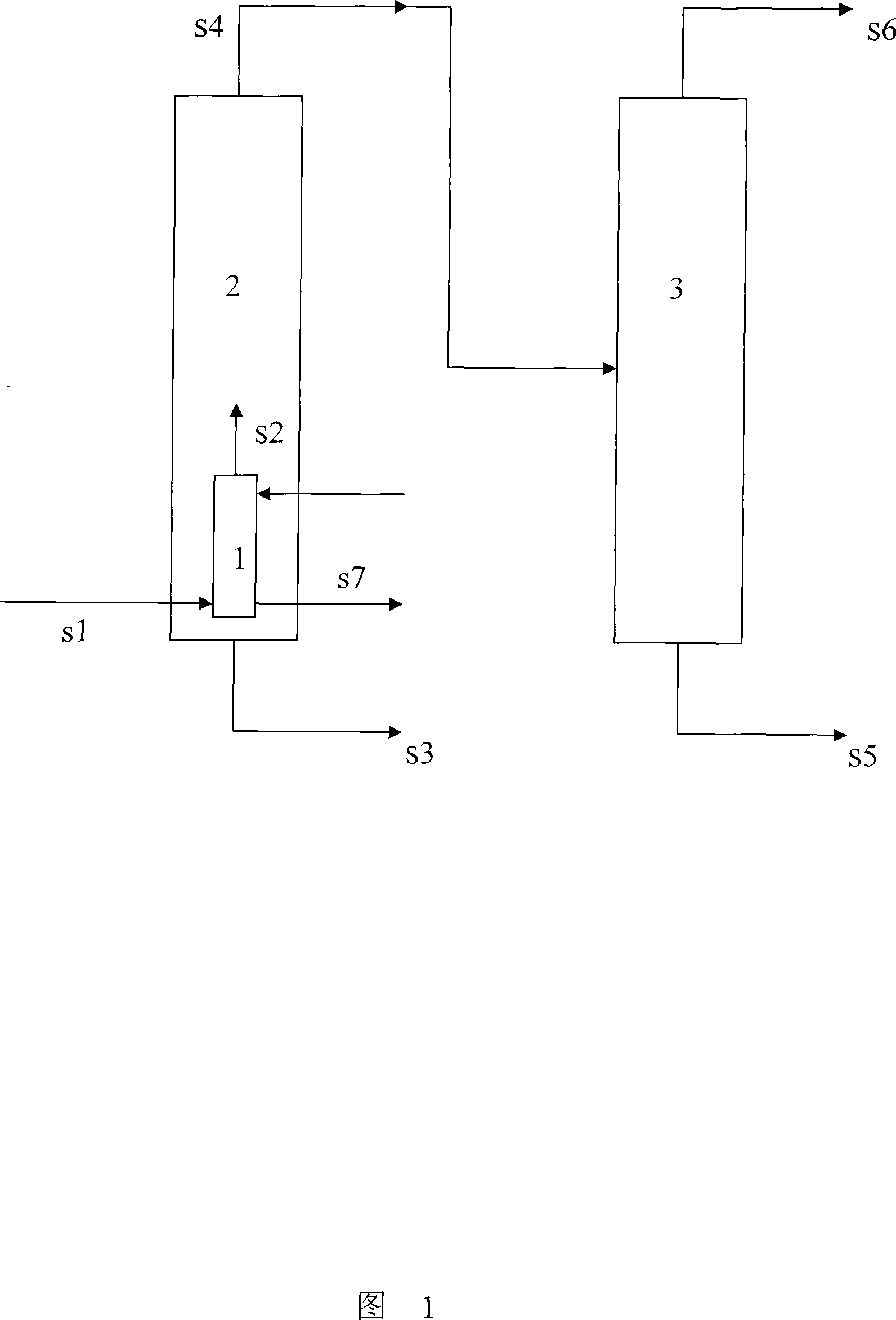

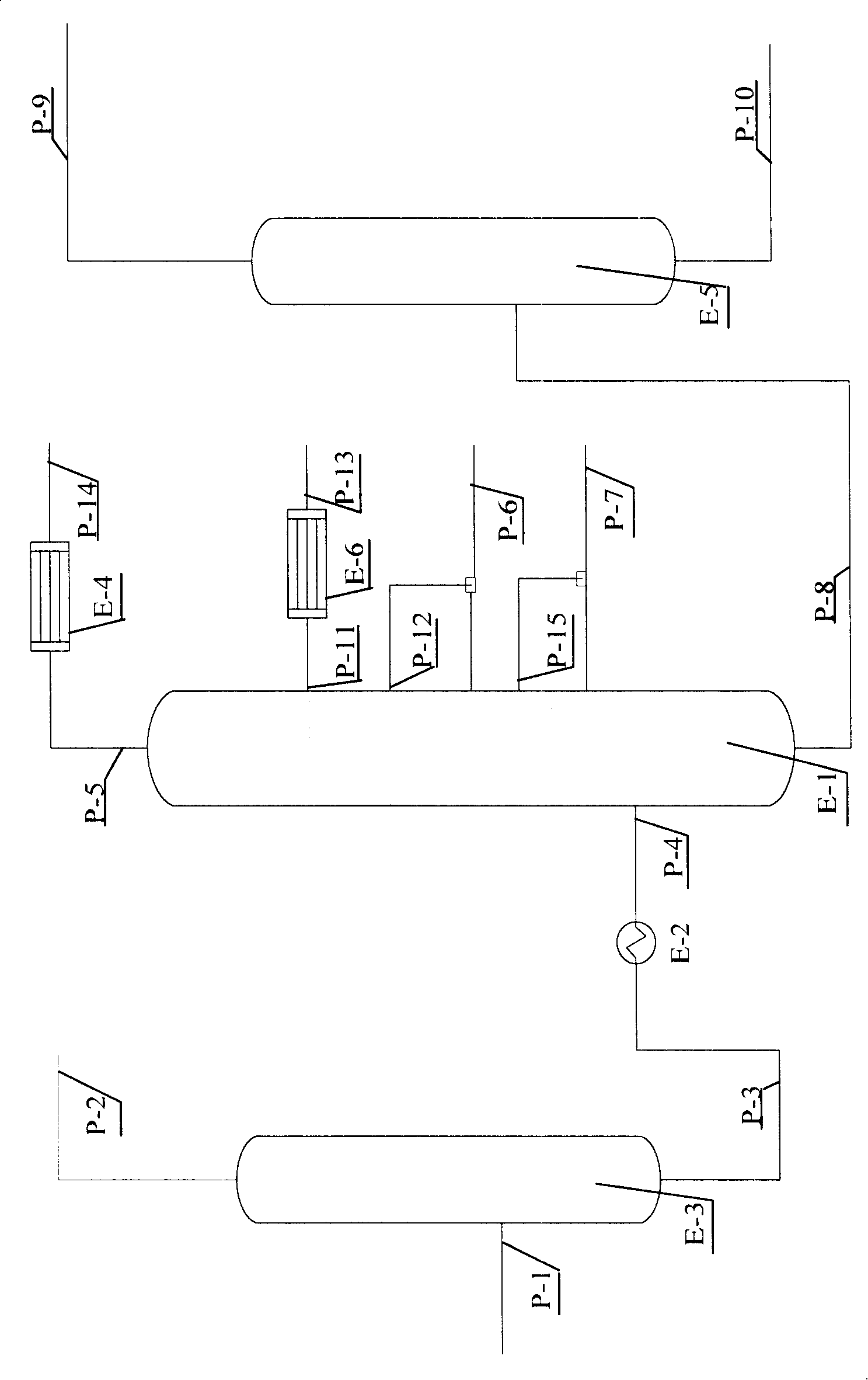

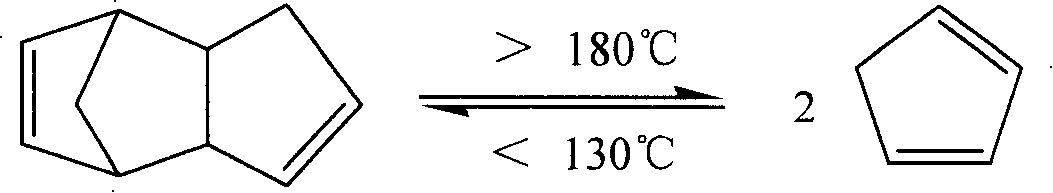

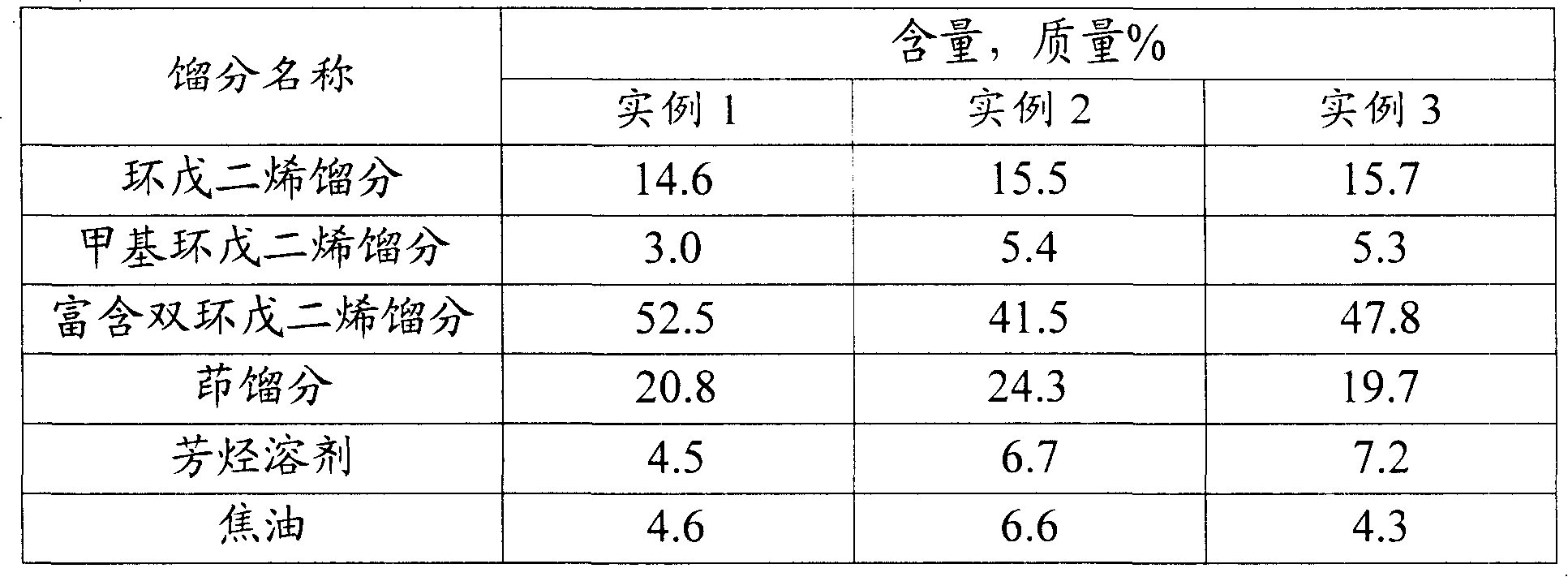

Separation utilization method for preparing ethene by-product C9+ fractioning by cracking

ActiveCN101190868AIncrease added valueFull use of valueDistillation purification/separationBenzenePetroleum resin

The invention relates to a method of separating and utilizing ethylene by product C9<+> distillate produced by cracking, and consists of the procedures: the C9<+> distillate is separated into ethylene distillate with rich benzene and distillate at the bottom of a rectifying tower by rectifying under reduced pressure; the distillate at the bottom of the rectifying tower is heated to 180 - 380DEG C and rectified under normal pressure; cyclopentadiene distillate, methyl cyclopentadiene distillate, distillate with rich dicyclopentadiene, distillate with high content of indene and heavy end distillate are separated from the top of the rectifying tower to the bottom of the rectifying tower in turn. With the method, not only high quality petroleum resin is available, but cyclopentadiene and methyl cyclopentadiene can also be obtained at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

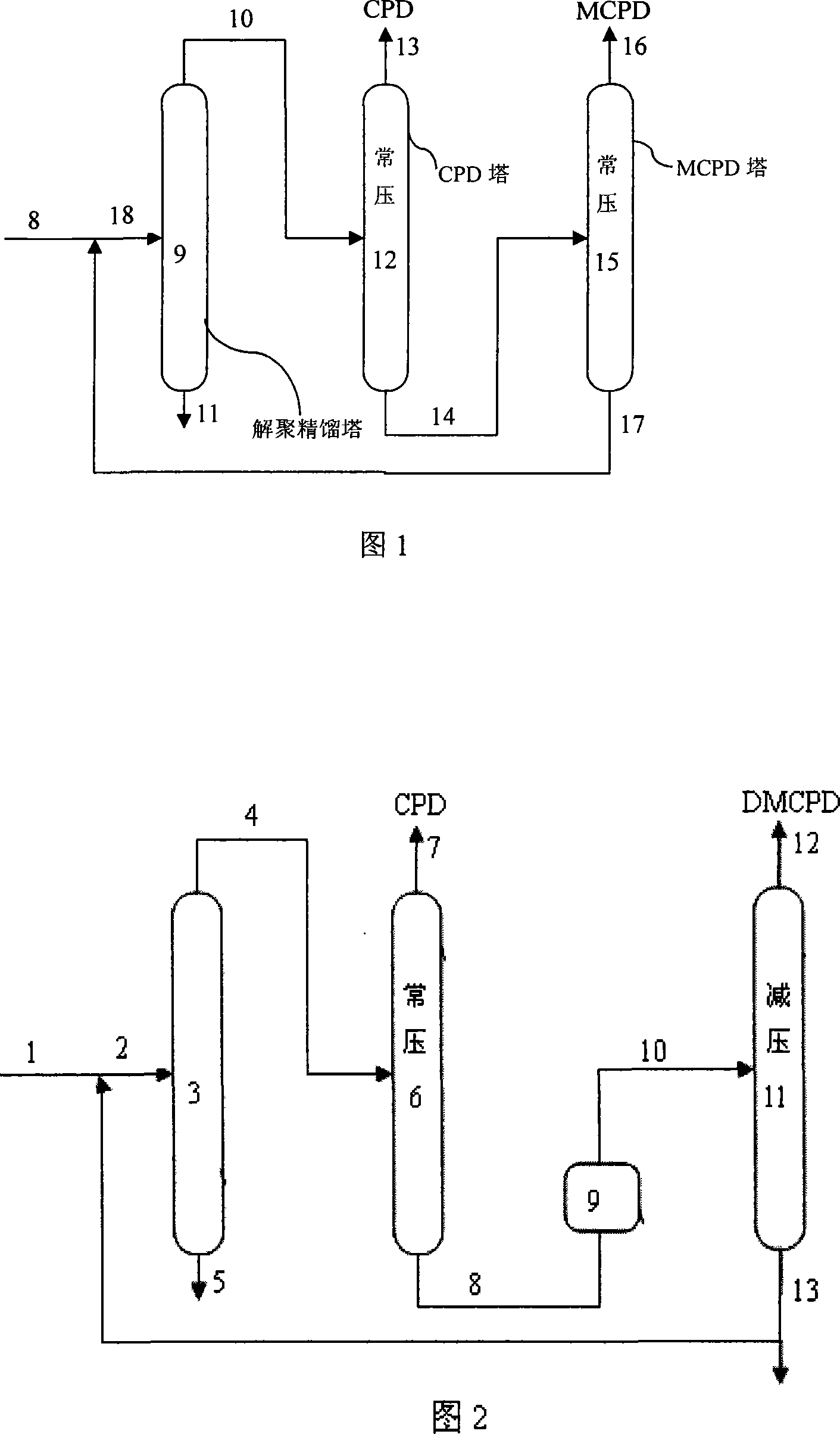

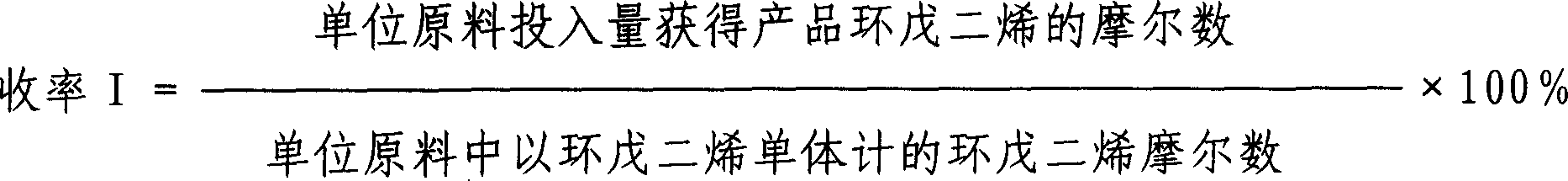

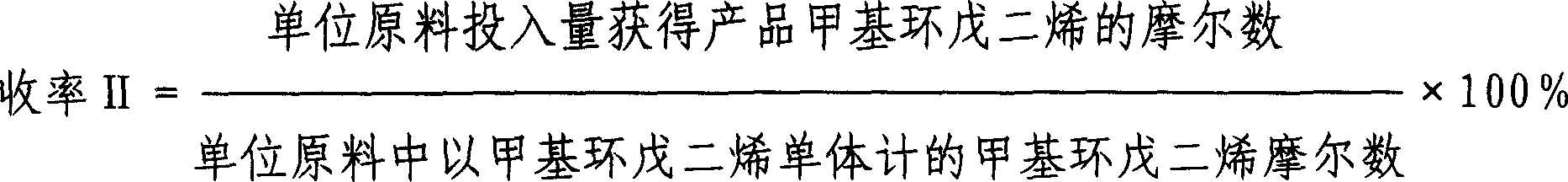

Technique for separating cyclopentadiene and methylcyclopentadiene

ActiveCN101186552AHigh purityReduce investmentDistillation purification/separationHydrocarbonsSeparation technologyMethylcyclopentadiene

The invention relates to a separation technology of a mixture with cyclopentadiene and methyl cyclopentadiene as main ingredients, which pertains to the fine chemicals manufacturing technical field. A mixture with main ingredients of CPD and MCPD is firstly extracted from the mixture with cyclopentadiene and methyl cyclopentadiene as main ingredients from the top of a de-polymerization rectifying tower; the mixture with the main ingredients of CPD and MCPD then enters a CPD tower, and CPD is extracted from the top of a normal pressure rectifying tower; materials at the bottom of the CPD tower enter a dimerization reactor, and a mixture material with DMCPD as a main ingredient is acquired; the mixture material enters a MCPD tower to be rectified under reduced pressure, and the methyl cyclopentadiene is extracted from the top of the MCPD tower in the form of DMCPD. The invention adopts a de-polymerization normal reduced pressure separation method, which requires little supportive equipment investment and simple operation technique and can effectively overcome defects of the prior art, reduce product waste during the mixture separation process, improve extraction rate by one operation and reduce energy consumption, so that the cyclopentadiene and methyl cyclopentadiene of relatively high purity can be obtained.

Owner:山东东昌精细化工科技有限公司

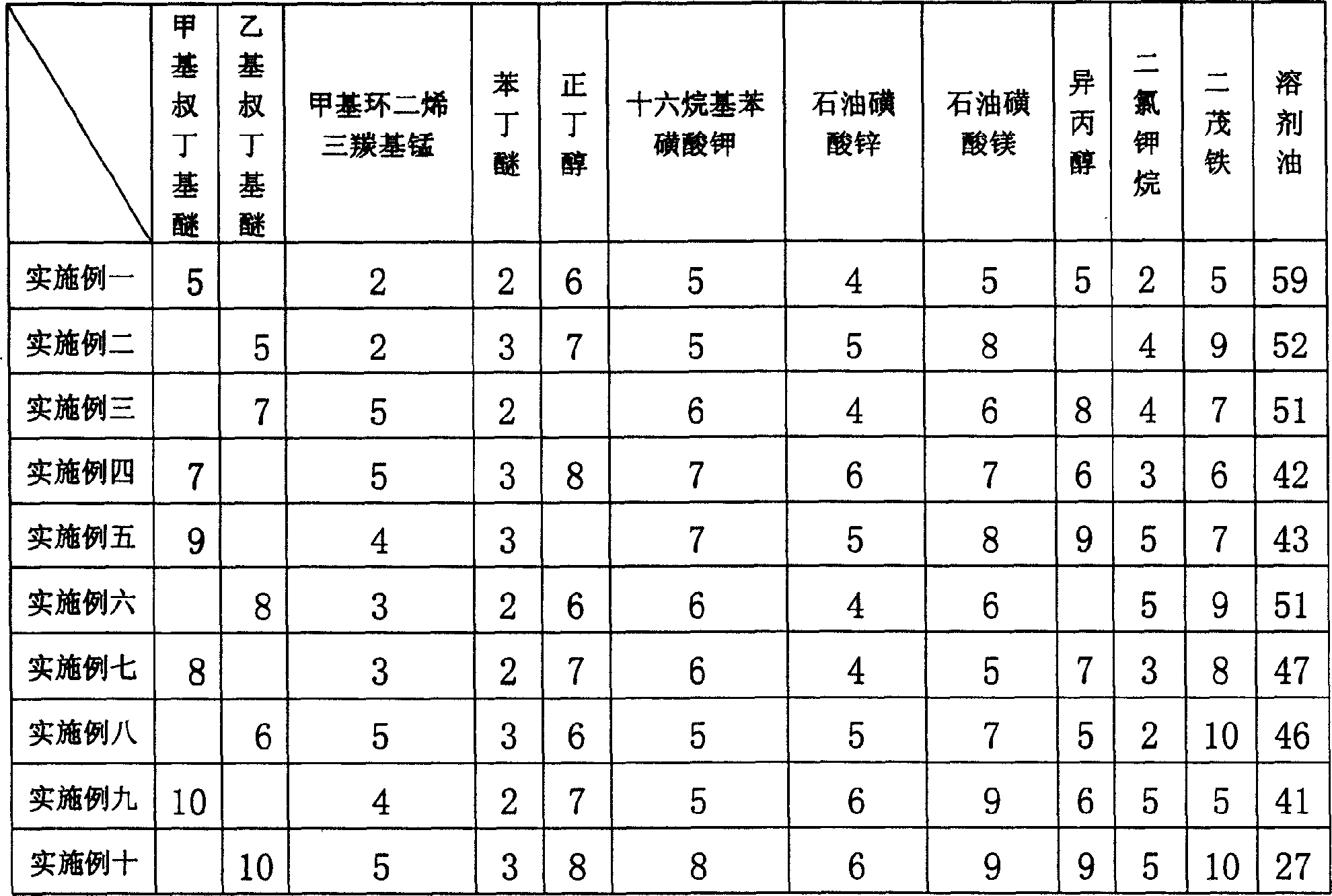

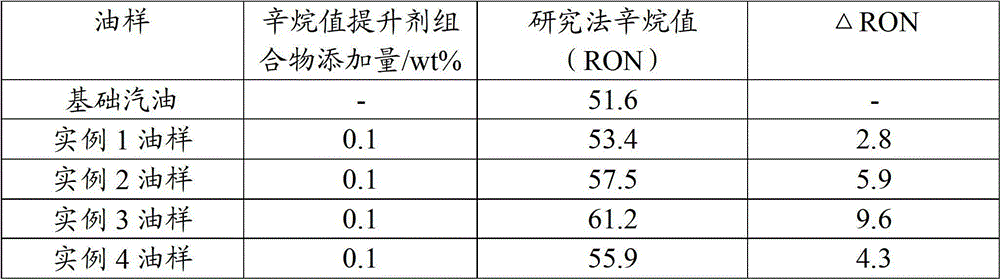

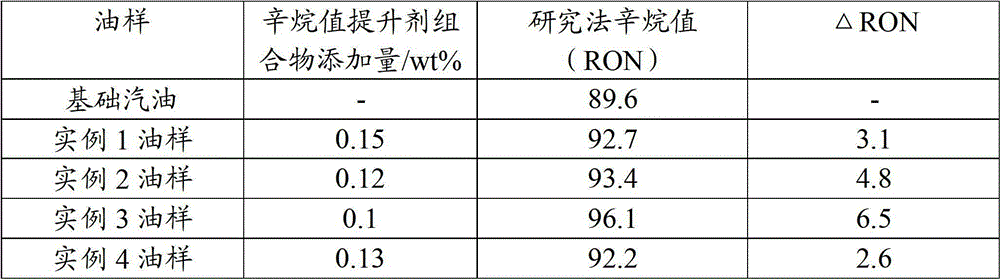

Gasoline octane number enhancer and preparation method thereof

The invention provides a gasoline octane number enhancer composition capable of greatly enhancing antiknock property of gasoline fuel. The additive comprises a gasoline antiknock agent methyl cyclopentadiene tricarbonyl manganese (MMT), an alcohol octane number accelerator, an amine accelerator, an amide accelerator, an alkyl phenol octane number enhancer, a metal extraction additive and a cosolvent. The gasoline octane number enhancer provided by the invention can enhance the gasoline octane number by 2.0-10.0 units, has the characteristic of preventing increase of engine deposits, and can not damage the automobile engine.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Gasoline anti-knock agent mixture for vehicle

InactiveCN101144041AReduce contentAvoid knockingLiquid carbonaceous fuelsFuel additivesAntioxidantCyclopentadienylmanganese tricarbonyl

The present invention relates to a vehicle gasoline antiknock additive mixture, which belongs to the gasoline antiknock additive technology field. The present invention uses cyclopentadiene manganese tricarbonyl (CMT) antiknock additive with more excellent antiknock performance to replace the prior methyl cyclopentadienyl manganese tricarbonyl (MMT) antiknock additive, to achieve the purposes of promoting the oil product octane number of gasoline components, in particular, promoting the oil product octane number of low grade gasoline components. The vehicle gasoline antiknock additive mixture of the present invention comprises antiknock additive, solvent, fluxing agent and antioxidating agent, wherein, the antiknock additive is methyl cyclopentadienyl manganese tricarbonyl. The technical effect of the present invention is outstanding, the octane number of the gasoline can be obviously promoted, in particular, the octane number of the low grade gasoline is promoted, and the octane number of a component gasoline is about 60 units, a high octane number gasoline is a high grade clean fuel after being concocted through adding the mixture of the present invention, and attains the national standards (GB17930-1999) of the vehicle gasoline, thereby pioneering the new way that the vehicle unleaded gasoline clean fuel is produced through the low grade oil products.

Owner:WUHAN DIBO PETROCHEM

Production method of unleaded gasoline for vehicle

InactiveCN101787310AEmission reductionReduce fuel consumptionLiquid carbonaceous fuelsIsobutyl alcoholManganese

The invention discloses a production method of unleaded gasoline for a vehicle, wherein the unleaded gasoline is prepared from the following raw materials in parts by weight: 35-65 parts of methanol, 60-30 parts of gasoline, 2-4 parts of isobutyl alcohol, 1-3 parts of acetone, 2-4 parts of methyl tertiary butyl ether, 2-5.5 parts of toluene or dimethyl benzene, 0.01-0.03 part of methyl cyclopentadienyl manganese tricarbonyl, 0.03-0.1 part of butyl octyl zinc thiophosphate and 0.1-3 parts of dicyclopentadienyl iron; the unleaded gasoline is prepared by the method comprising the following steps of: sequentially adding the acetone, the toluene or the dimethyl benzene, the isobutyl alcohol, the methyl tertiary butyl ether, the butyl octyl zinc thiophosphate, the dicyclopentadienyl iron and the methyl cyclopentadienyl manganese tricarbonyl as the raw materials into a container at normal temperature and under normal pressure, fully stirring to obtain a yellow transparent liquid, then adding the yellow transparent liquid into the methanol and fully stirring to obtain modified methanol; adding the modified methanol liquid into the gasoline and uniformly stirring to obtain a finished product. The invention has the advantages of low cost, low pollution, low oil consumption, low corrosion and high power, and each item index of the invention exceeds that of the traditional gasoline.

Owner:刘超

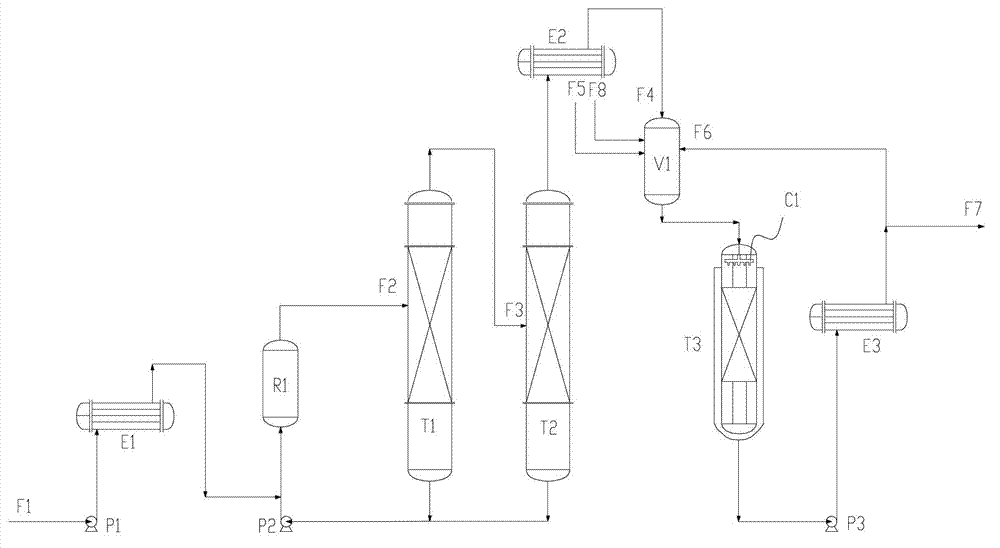

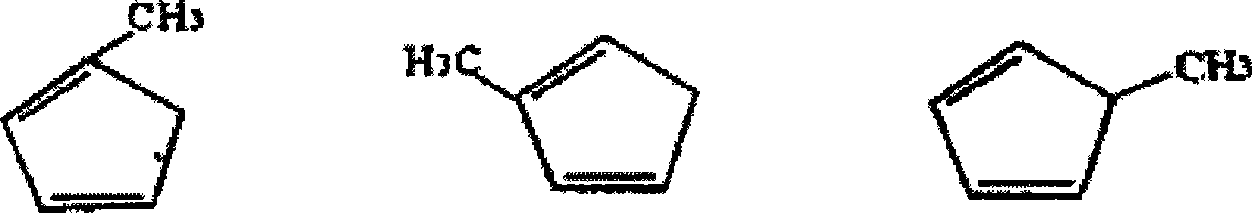

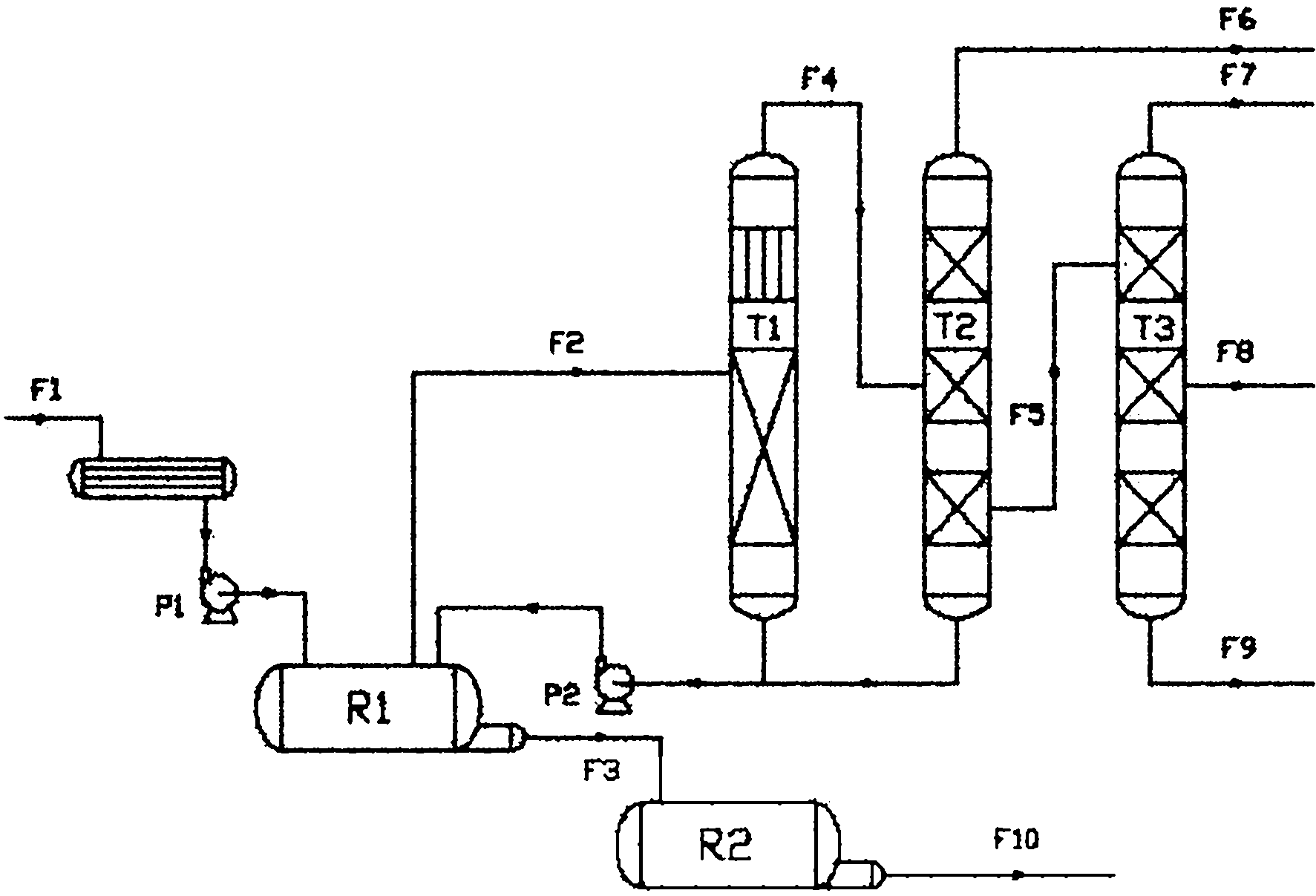

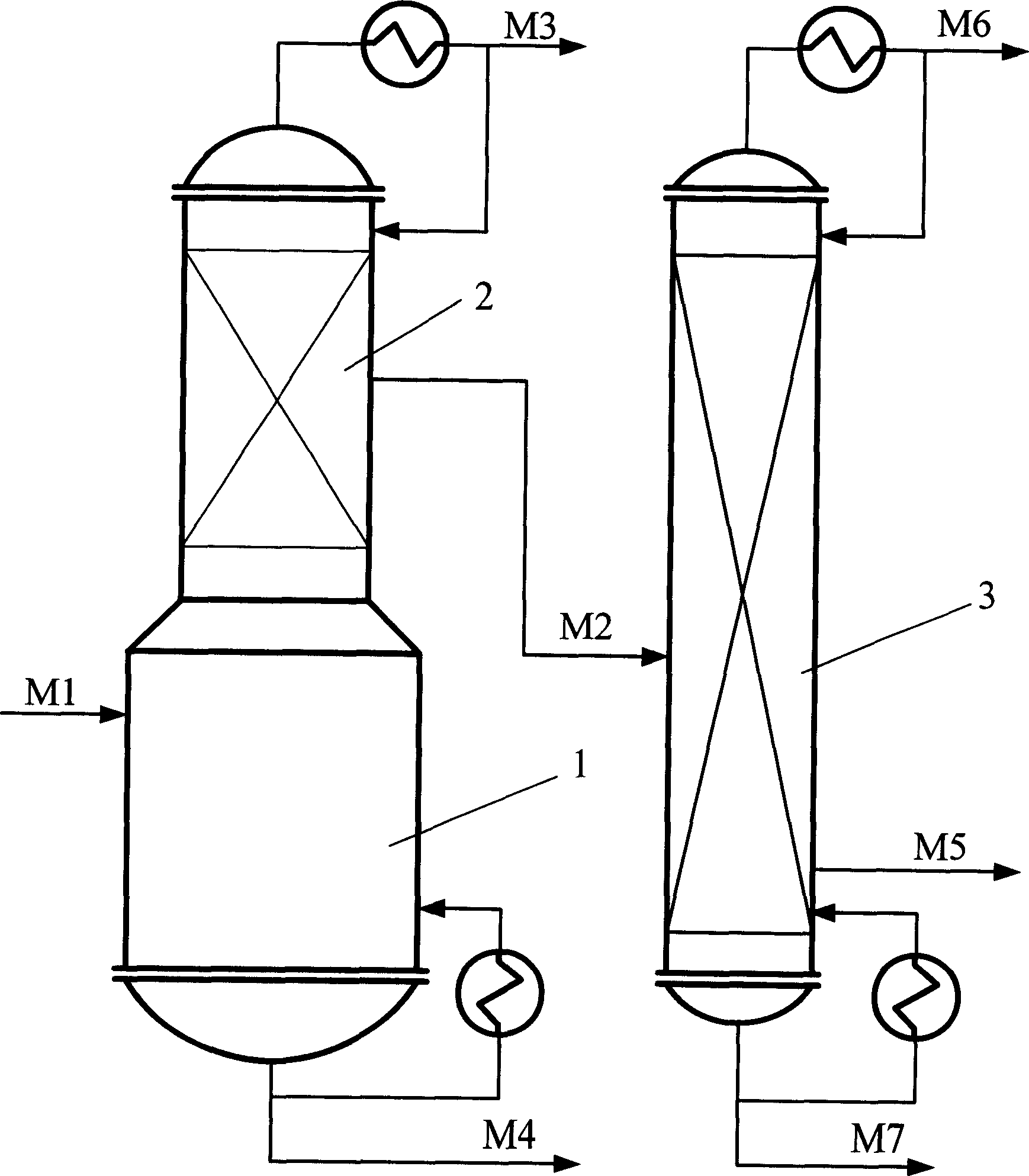

Method for extracting methyl cyclopentadiene from ethylene cracked C9 heavy fractions

ActiveCN102010285ANo preheating requiredIncrease profitDistillation purification/separationHydrocarbon by depolymerisationDepolymerizationGas phase

The invention relates to a method for extracting methyl cyclopentadiene from ethylene cracked C9 heavy fractions, which comprises the following steps of: (1) preheating C9 heavy fractions serving as a raw material and conveying to a depolymerizing reactor; (2) performing depolymerization reaction on the raw material; (3) adding a gas-phase material generated by depolymerization into a rectifying column T1; (4) adding a mixture of coarse cyclopentadiene and coarse methyl cyclopentadiene generated in the step (3) into a rectifying column T2 for further rectifying; (5) adding the residual material in the depolymerizing reactor into a coumarone resin reaction kettle to generate coumarone resin; (6) performing dimerization on the cyclopentadiene material to obtain dicyclopentadiene; (7) performing dimerization on the methyl cyclopentadiene material to obtain methyl cyclopentadiene dimer; and (8) adding the methyl cyclopentadiene dimer into a rectifying column T3, rectifying under reduced pressure, and removing light fractions on the tower top and heavy fractions at the tower bottom to obtain the methyl cyclopentadiene dimer on a side line. The method is simple and suitable for industrial application; and the purity of a product is not less than 98 percent.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

High-efficiency catalyst for catalyzing amine and carbodiimide to process addition reaction and application

InactiveCN101264456AHigh activityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLanthanideRare earth

The invention discloses a complex based on divalent rare earth as center ion, which is represented in a general formula as L 2 LnL', wherein Ln means center ion that is bivalent ion of the rare earth metal, which is selected from one of samarium, europium, and ytterbium in the lanthanides; L and L' mean two ligands, L is selected from one of 2,6-butylated hydroxytoluene, di-trimethyl silylamino, dimethylcyclo-pentadienyl, N,N'-dimethylamino bridged bisphenol; L' is a complex solvent, which is selected from one of tetrahydrofuran and glycol dimethyl ether. The complex has the advantages of being used as a reaction catalyst to additionally synthesize guanidine by the amine and carbodiimide, catalyzing the amine and carbodiimide in an extremely high activity to additionally react at a moderate temperature, having wide adaptability for the reaction substrate, showing the extremely high activity for the amine in aromatic series and the fat, and conducting reaction without the solvent.

Owner:SUZHOU UNIV

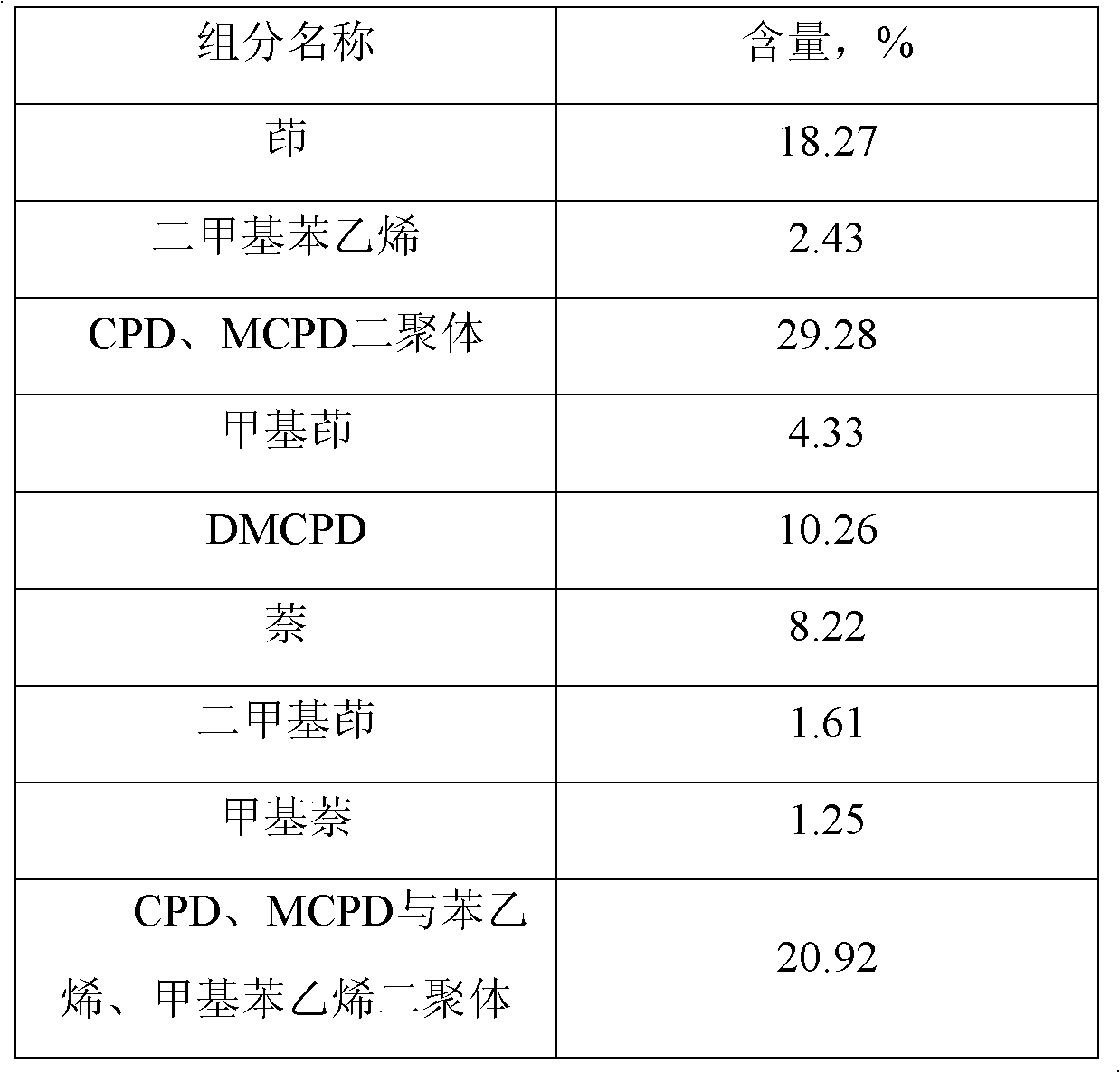

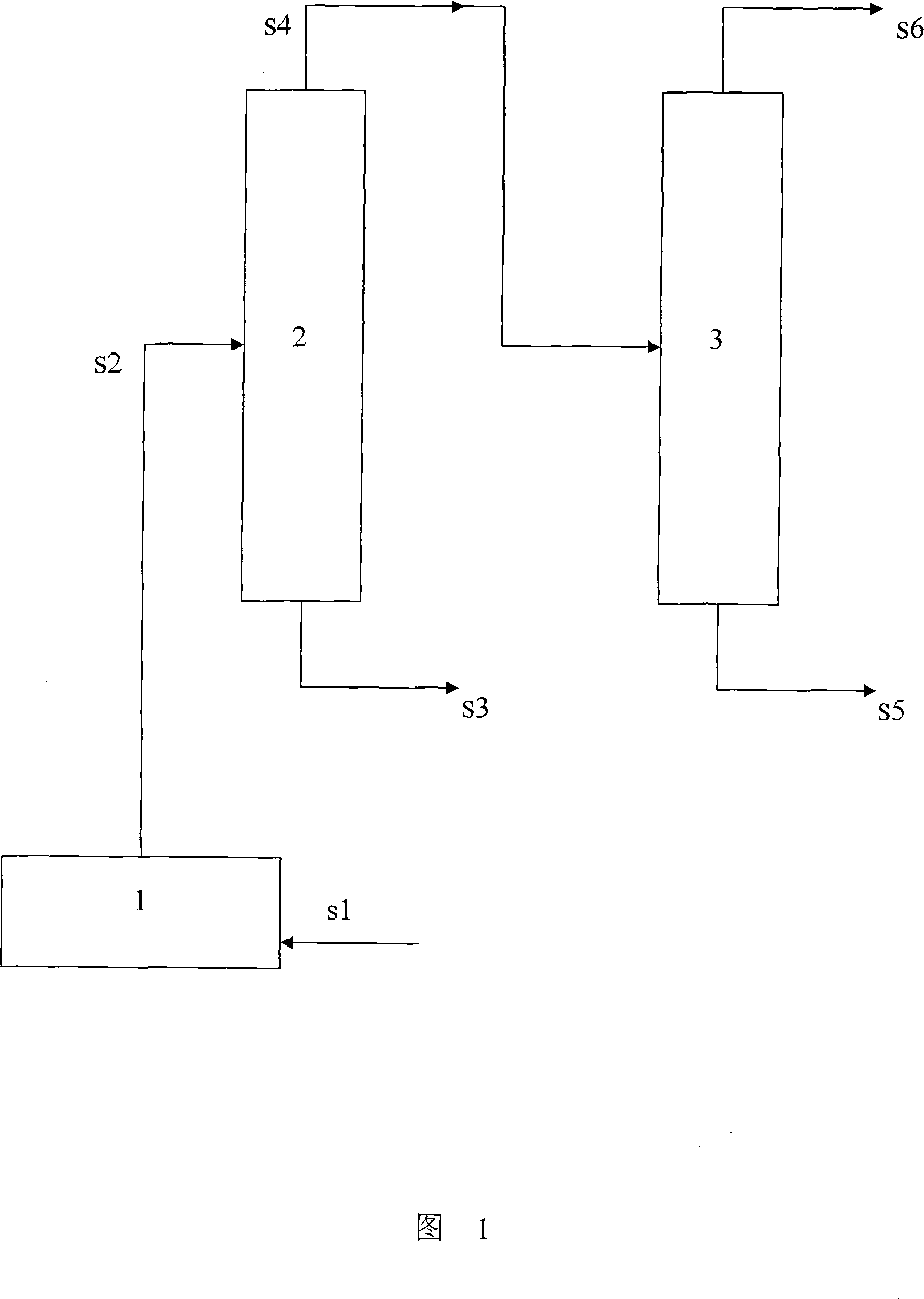

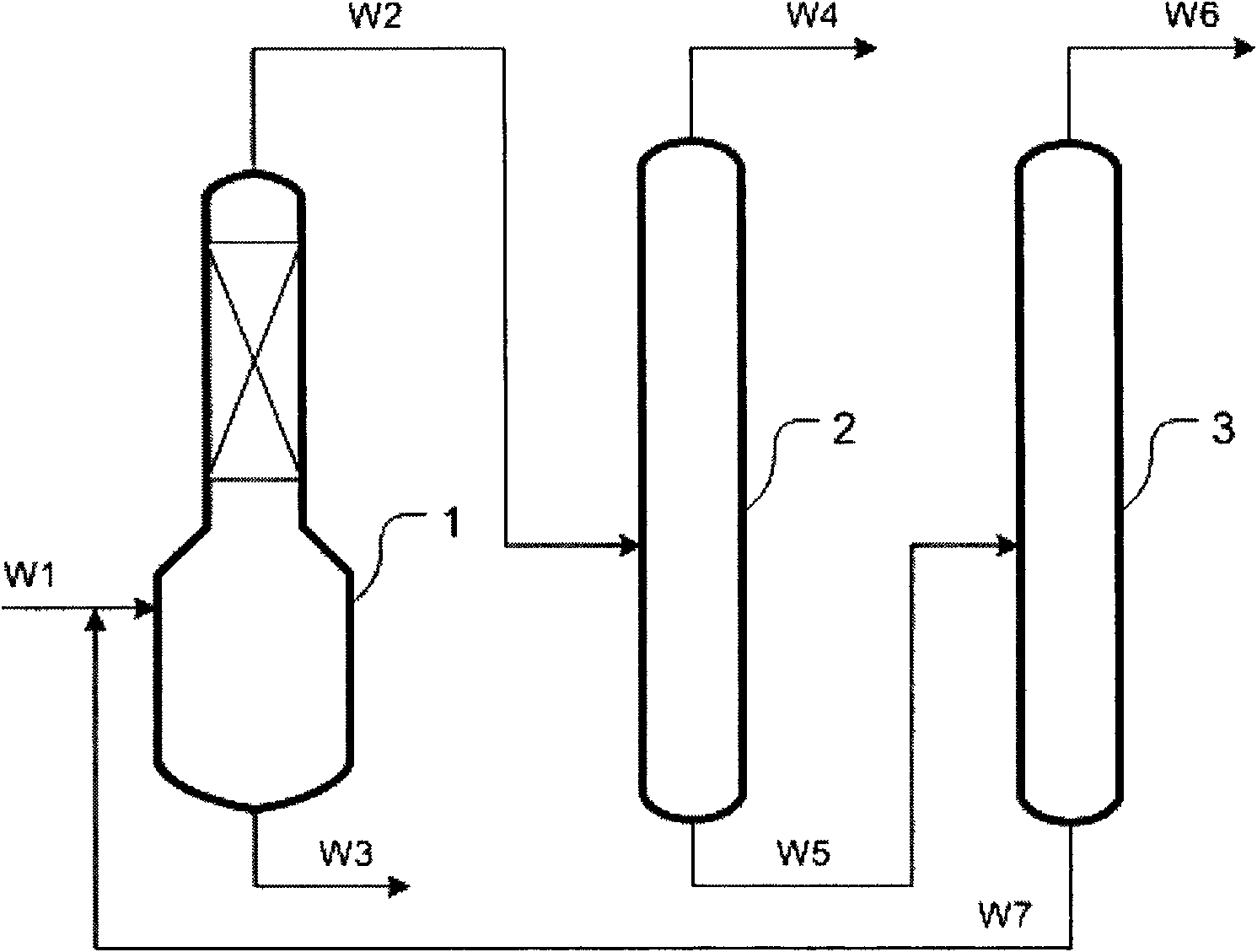

Process of separating cyclopentadiene and methyl cydopentadiene from ethylene side C9 product

ActiveCN101066902AExpand sourceEasy to separateFractional condensation purification/separationHydrocarbon by depolymerisationMethylcyclopentadieneEthylene

The present invention is process of separating cyclopentadiene and methyl cyclopentadiene from mixture containing dicyclopentadiene and dimethyl cyclopentadiene, and is especially suitable for separating and purifying cyclopentadiene and methyl cyclopentadiene from ethylene side C9 product or coarse cyclopentadiene product. The material, ethylene side C9 product or coarse cyclopentadiene product, is introduced into a high temperature cracking reactor, the high temperature cracked gas mixture is led to the first fractionating tower to separate out the fraction containing cyclopentadiene and methyl cyclopentadiene in the tower top, and the tower top fraction of the first fractionating tower is fed to the second fractionating tower to separate out cyclopentadiene in the tower top and methyl cyclopentadiene in the tower bottom.

Owner:天津天大天海化工新技术有限公司 +1

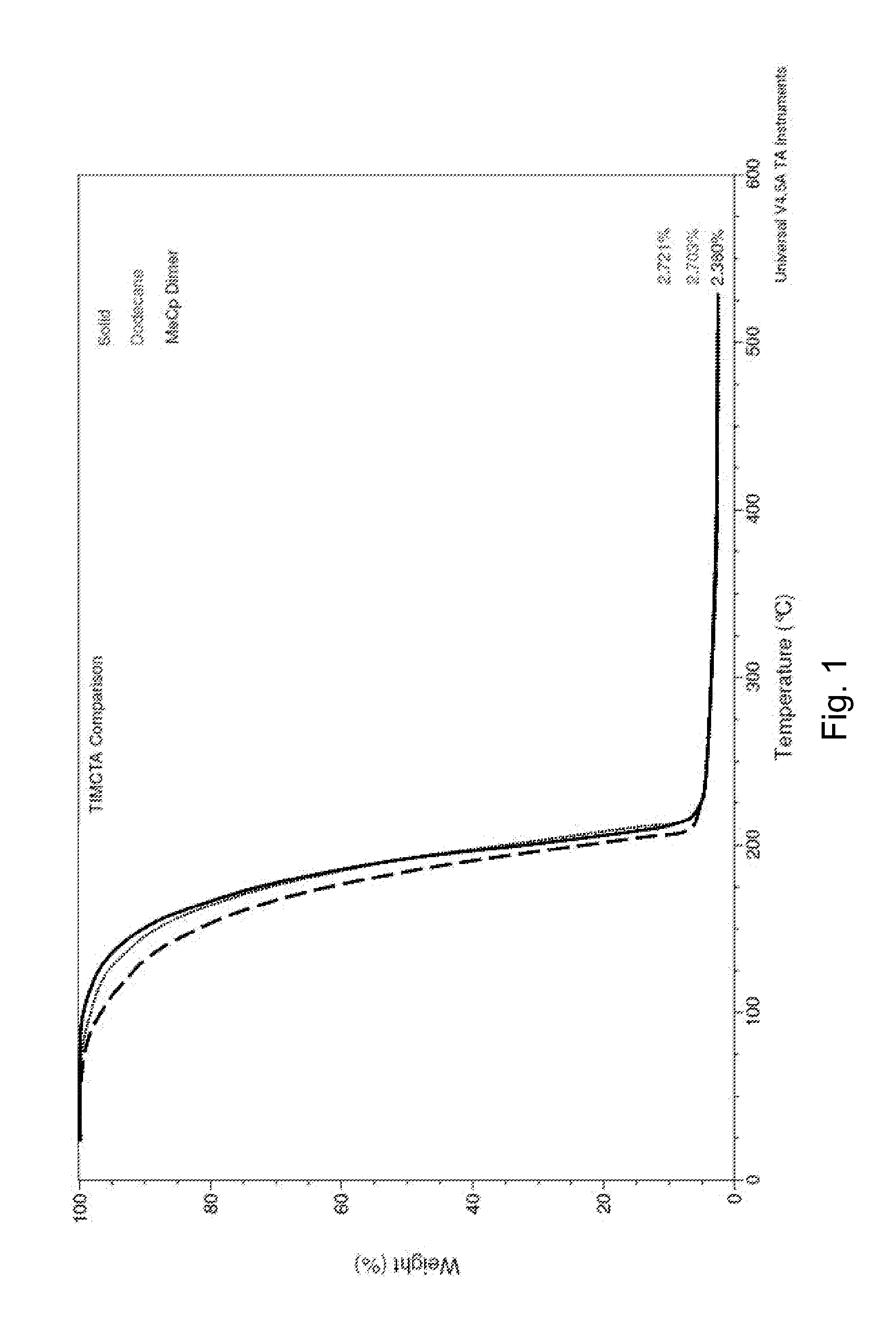

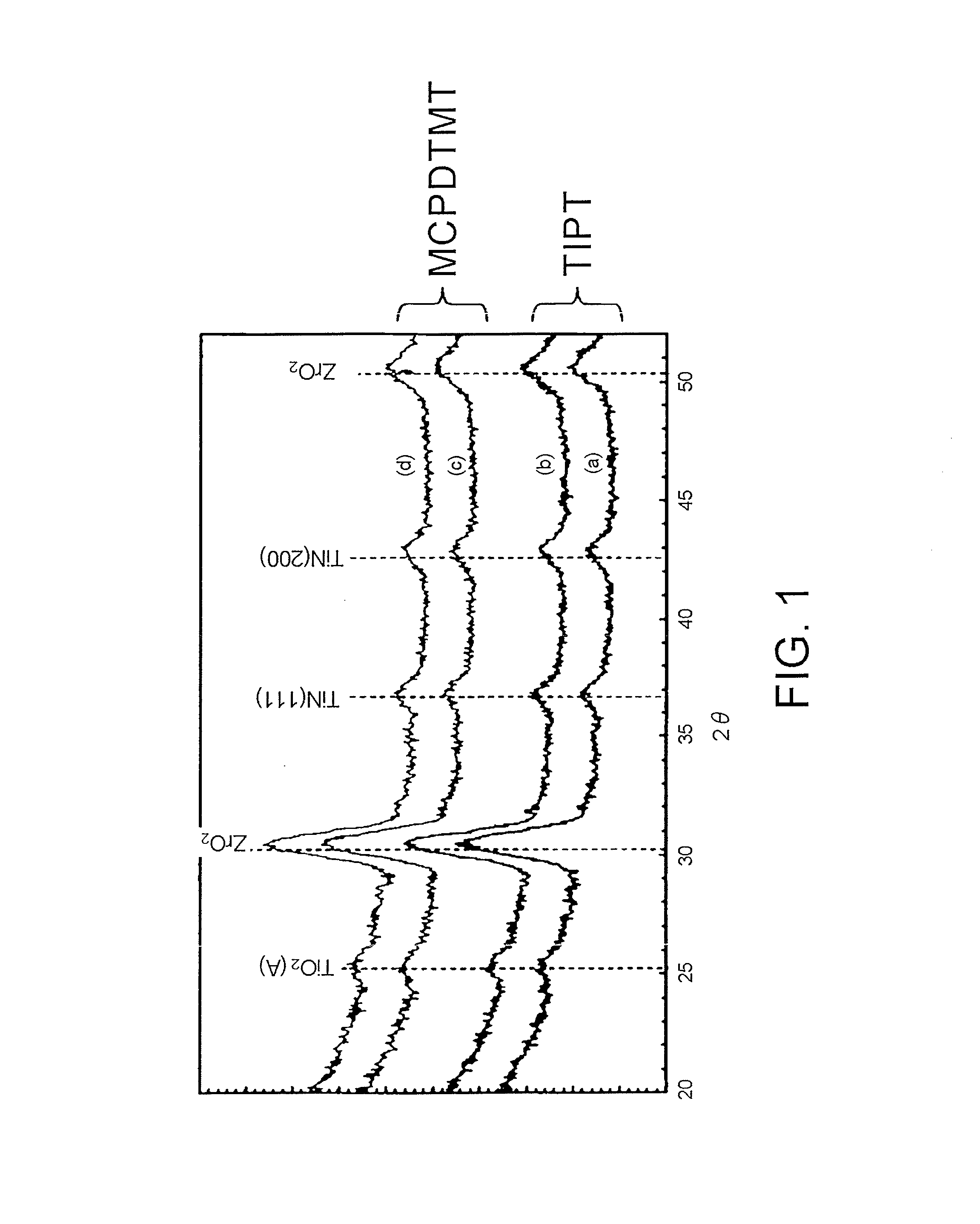

Compositions and methods of use for forming titanium-containing thin films

InactiveUS20120178266A1Organic compounds purification/separation/stabilisationSemiconductor/solid-state device manufacturingTitaniumMethylcyclopentadiene

Compositions and methods for forming titanium-containing thin films are provided. The compositions comprise at least one precursor selected from the group consisting of (methylcyclopentadienyl)Ti(NMe2)3, (ethylcyclopentadienyl)Ti(NMe2)3, (isopropylcyclopentadienyl)Ti(NMe2)3, (methylcyclopentadienyl)Ti(NEt2)3, (methylcyclopentadienyl)Ti(NMeEt)3, (ethylcyclopentadienyl)Ti(NMeEt)3 and (methylcyclopentadienyl)Ti(OMe)3; and at least one liquification co-factor other than the at least one precursor; wherein the at least one liquification co-factor is present in amount sufficient to co-act with the at least one precursor, and in combination with the at least one precursor, forms a liquid composition.

Owner:SIGMA ALDRICH CO LLC

Method for preparing cyclo pentadiene and methyl cyclopentadiene by carbon 9 and carbon 10 distillation

InactiveCN1850747AEffective way to useReduce manufacturing costHydrocarbon by hydrocarbon crackingDistillationGas phase

This invention relates to use carbon nine and carbon ten cut fraction making cyclopentadiene and methyl cyclopentadiene method. It includes 1) material cracking, cracking temperature is 160-230 degrees centigrade, system pressure is 0-0.3MPa, materials stay time is 1-5 hours. 2) Gas phase material generated in cracking process is directly refined, rectification tower roof temperature is 38-60 degrees centigrade, system pressure is 0-0.3MPa, reflux ratio is 0-4. Fine cyclopentadiene product is got at tower roof; crude methyl cyclopentadiene material is got at lateral line at temperature 60-80 degrees centigrade, tower tank material backs to cracking system. 3) The crude methyl cyclopentadiene material is refined, rectification tower roof temperature is 40-55 degrees centigrade, tower tank temperature is 90-120 degrees centigrade, system pressure is 0-0.2MPa, and reflux ratio is 4-10. Fine methyl cyclopentadiene product is got at tower bottom, and light component substance is discharged from tower roof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly transparent silicone mixtures that can be cross-linked by light

InactiveUS20130200554A1Monocomponent synthetic polymer artificial filamentOptical elementsFiberMethylcyclopentadiene

Silicone fibers suitable for use as optical fibers are prepared by crosslinking an extruded mixture of a silicone resin and an organopolysiloxane, both containing aliphatically unsaturated groups, an organopolysiloxane bearing Si—H groups, and a light activatable trimethyl(methylcyclopentadienyl) platinum catalyst.

Owner:WACKER CHEM GMBH

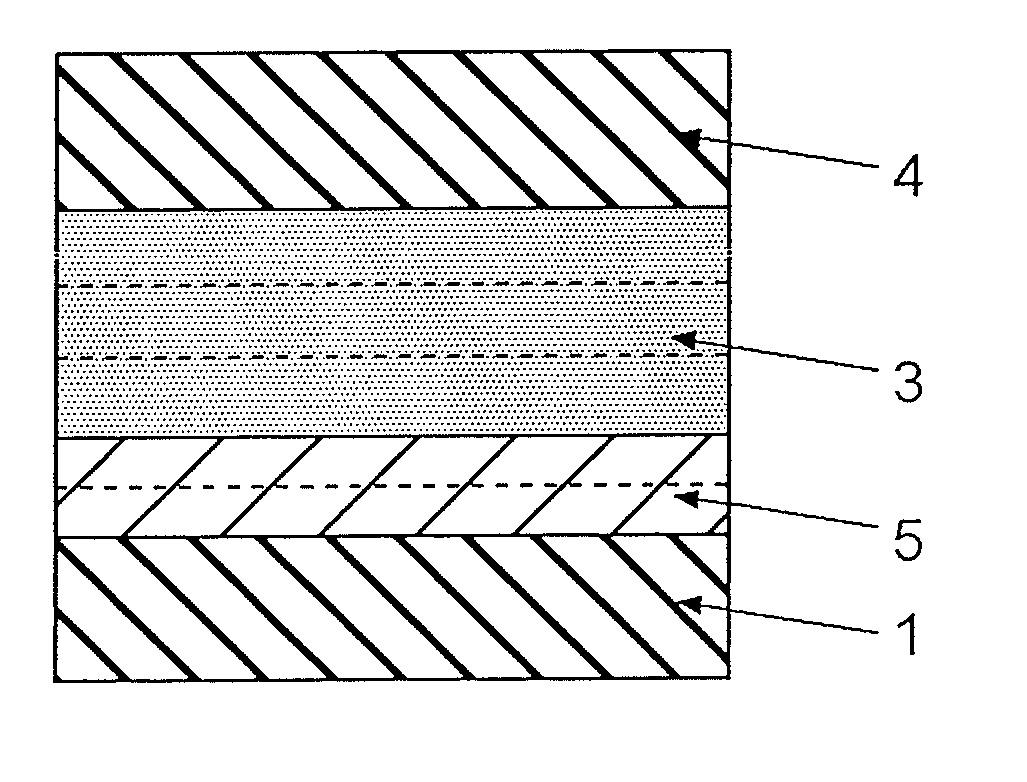

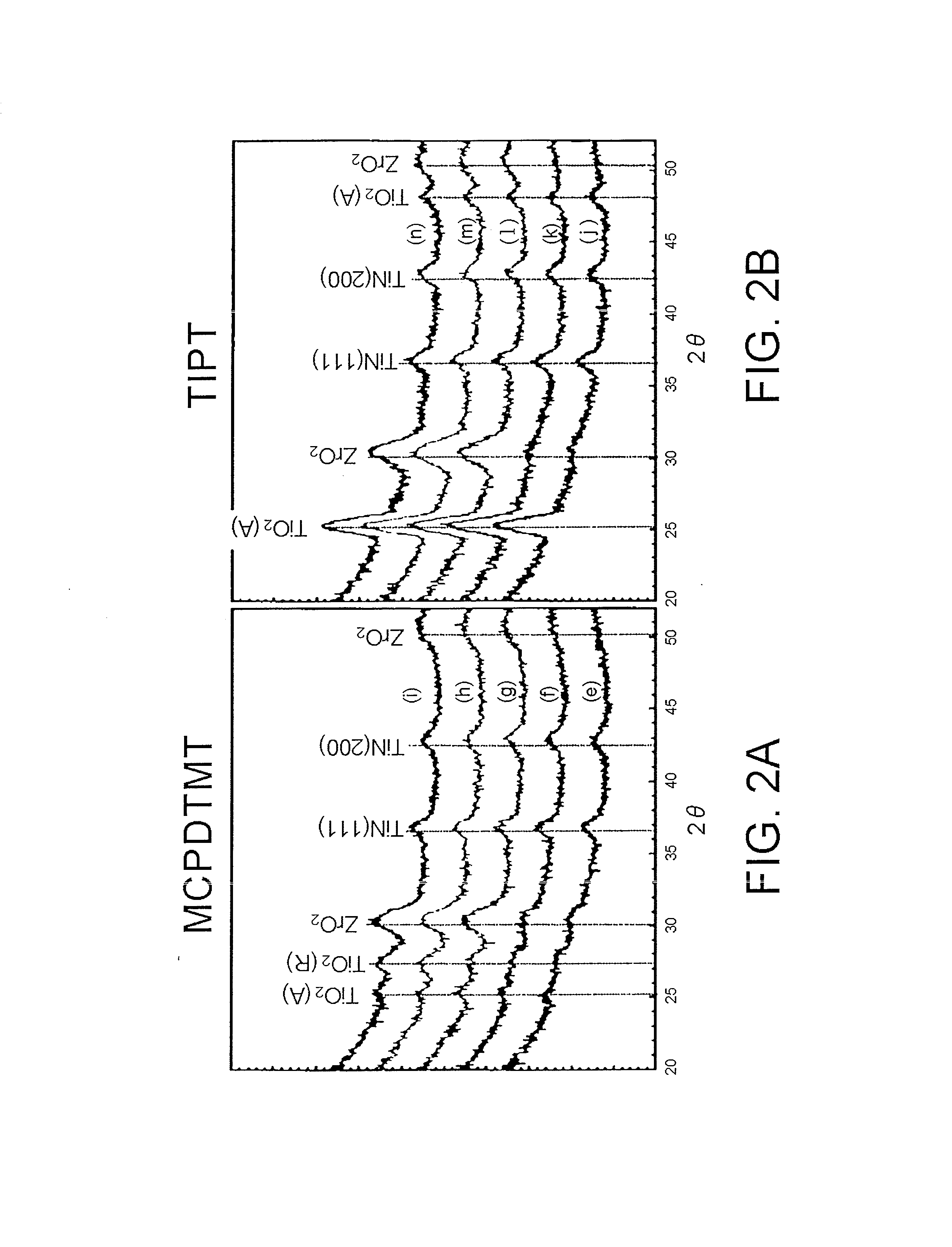

Method of forming titanium oxide film having rutile crystalline structure

InactiveUS20120309163A1Easy to produceLeakage currentSolid-state devicesSemiconductor/solid-state device manufacturingCrystal structureTitanium

The invention provides a method of forming a titanium oxide film having a rutile crystalline structure that has high permittivity. The titanium oxide film having a rutile crystalline structure is produced by forming an amorphous titanium oxide film on an amorphous zirconium oxide film using methyl cyclopentadienyl tris(dimethylamino)titanium as a titanium precursor by an ALD method, and crystallizing the amorphous titanium oxide film by annealing at a temperature of 300° C. or higher.

Owner:ELPIDA MEMORY INC +1

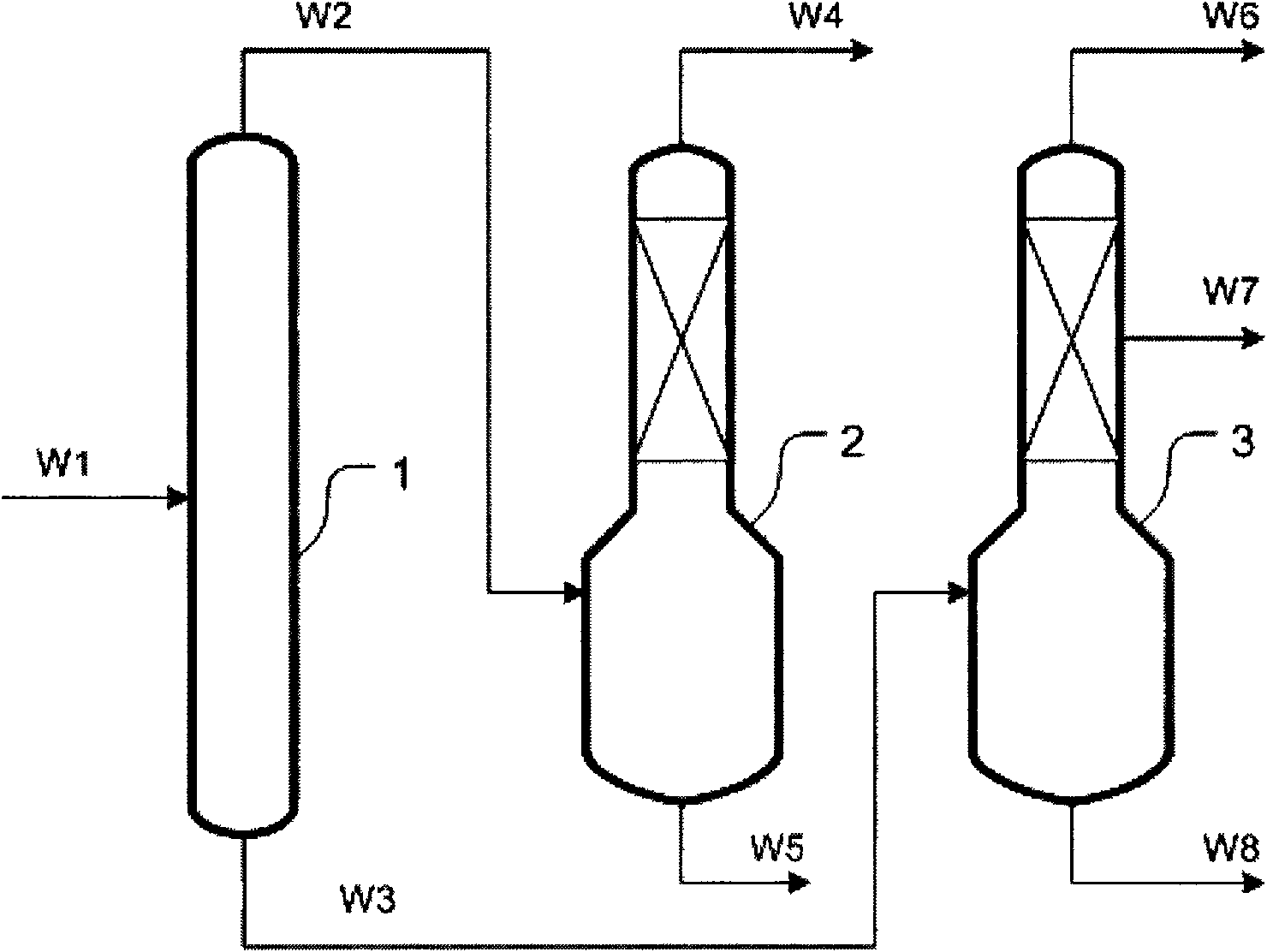

Method for preparing dicyclopentadiene and dimethylcyclopentadiene

InactiveCN102399123AAvoid generatingResolving Difficult Contradictions in SeparationDistillation purification/separationHydrocarbonsDepolymerizationPetroleum

The invention relates to a method for preparing dicyclopentadiene and dimethylcyclopentadiene. The method adopts C9-C19 fractions of byproducts of ethylene cracked from petroleum as raw materials. The method comprises the following processes: 1, the raw materials are subjected to reduced pressure rectification separation in a rectification tower, a concentrated dicyclopentadiene material is obtained from the tower top, and a concentrated dimethylcyclopentadiene material is obtained from the tower bottom; 2, the tower top material obtained in process 1 enters a depolymerization rectification tower for depolymerization rectification, and cyclopentadiene is obtained from the tower top; 3, the tower bottom material obtained in the process 1 enters the depolymerization rectification tower for depolymerization rectification, cyclopentadiene is obtained from the tower top, and methylcyclopentadiene is obtained from the lateral line; 4, cyclopentadiene obtained in process 2 and cyclopentadiene obtained in process 3 undergo a thermal dimerization reaction to obtain dicyclopentadiene; and 5, methylcyclopentadiene obtained in the process 3 undergoes the thermal dimerization reaction to obtain dimethylcyclopentadiene. The method of the invention has the following advantages: dimerization reactions in the depolymerization product rectification separation process are substantially reduced; and high purity methylcyclopentadiene can be directly obtained after the depolymerization product separation, so the refinement and the purification of above depolymerized products are avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid coal combustion improver

The invention discloses a liquid coal combustion improver which is prepared from the following raw materials in proportion: carboxymethyl ferrocene, methylcyclopentadienyl manganese tricarbonyl, acerdol, cerous nitrate, aluminum nitrate, magnesium nitrate, tween and absolute ethyl alcohol. In the liquid combustion improver, the carboxymethyl ferrocene and the methylcyclopentadienyl manganese tricarbonyl are taken as combustion-supporting synergist, the acerdol, the cerous nitrate and the magnesium nitrate are taken as oxidant, the aluminum nitrate is taken as adsorbent, the tween is taken as penetration dispersant, and the absolute ethyl alcohol is taken as complex solubilizer. When the combustion improver is added into coal, chemical substances with macromolecular structures in raw coal can be destroyed; when the liquid coal combustion improver is reacted with coal powder under the action of a high temperature, bonds among connecting structure units of the coal powder can be ruptured, so that the reaction activity of the coal powder can be enhanced, the thermolysis process of the coal powder can be promoted, active oxygen and oxygen gas can be released, the function of catalysis and combustion support can be achieved, pyrolysis products can increase, and the combustion performance can be better; and by virtue of catalytic cracking on the coal, the coal powder can be quickly and completely combusted, so that the aims of increasing coal powder quantity and decreasing coke ratio can be achieved.

Owner:郑州丰元冶金材料有限公司

Metallocene catalyst and preparation method thereof, and preparation method of polyethylene nanofiber

ActiveCN104017117AHigh melting pointEasy to getMonocomponent polyolefin artificial filamentAluminoxaneMicrosphere

The invention provides a metallocene catalyst and a preparation method thereof, and a preparation method of polyethylene nanofiber. The metallocene catalyst is formed by loading metallocene on porous polymeric microsphere through an aluminoxane compound, wherein the aluminoxane compound is methyl aluminoxane and / or modified methyl aluminoxane; the metallocene is represented as a formula (I) in the specification, wherein x is 1 or 2, y is 2 or 3, Cp is a cyclopentadiene group or a cyclopentadiene group derivative, and the cyclopentadiene group derivative is a methyl cyclopentadiene group or an ethyl cyclopentadiene group. Compared with the prior art, the metallocene catalyst has the advantages that the porous polymeric microsphere are used as carrier by the metallocene catalyst, and the porous polymeric microsphere is of a hierarchical pore structure, so that the molecular chain in the polymer product can only grow along the pore canal direction, and the growth in other directions is inhibited so as to obtain a fibrous product, the entanglement of the molecular chains is caused in the existence of hierarchical pores, the movement of the molecular chains is obstructed, and thus the melting point of the obtained polymer is increased.

Owner:芜湖万隆新材料有限公司

Environment-friendly energy-saving super-gasoline accelerator

ActiveCN105907432AEmission reductionBoost octaneLiquid carbonaceous fuelsFuel additivesCombustionPhosphate

The invention relates to an environment-friendly energy-saving super-gasoline accelerator which is characterized by comprising 10-30% of motor-process promoter, 20-30% of alkyl phenol octane promoter, 5-10% of octadecyl phosphate, 4-8% of dimethylbenzene, 10-15% of cycloalkane and 10-15% of combustion improver. The environment-friendly energy-saving super-gasoline accelerator enhances the gasoline octane number by adding the methyl tert-butyl ether or methyl cyclopentadiene tricarbonyl manganese, solves the problem of that the automobile exhaust generates PM2.5 and pollutes the environment, and is suitable to be added into various types of gasoline.

Owner:QINGDAO YONGQUAN PETROLEUM CO LTD

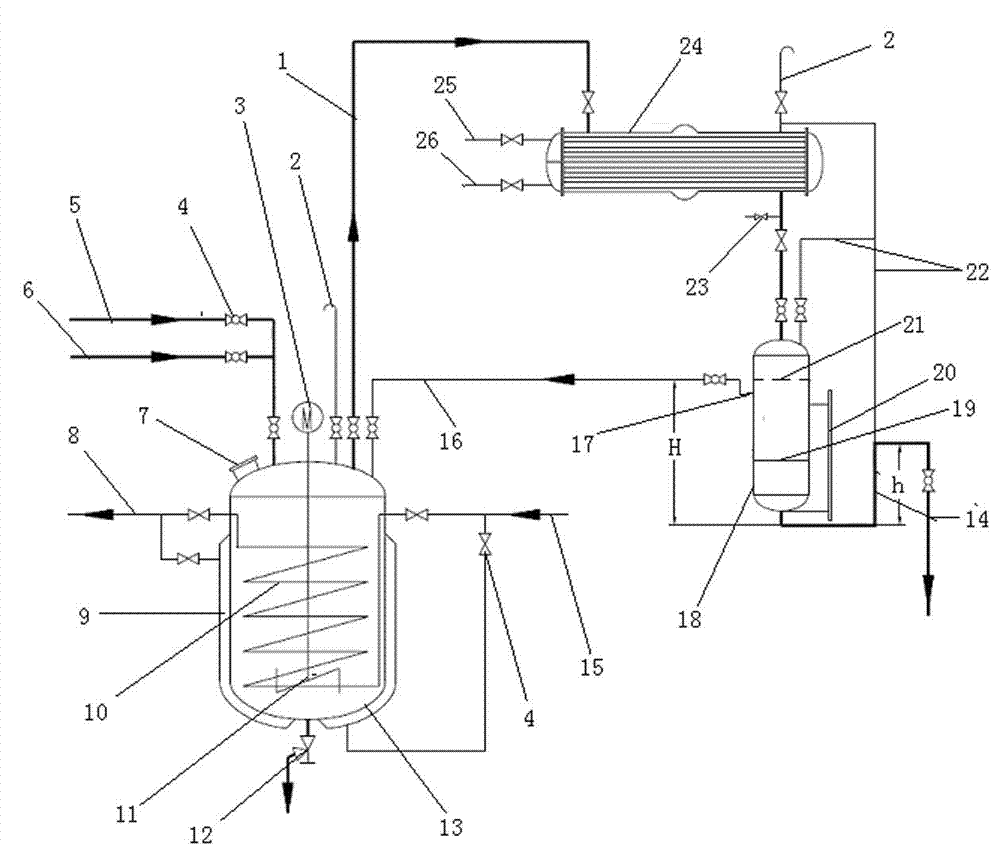

Circulating steam distillation apparatus and process for extracting methylcyclopentadienyl manganese tricarbonyl by aid of apparatus

ActiveCN102784490AAchieve recyclingEmission reductionSteam distillationMetallocenesWater vaporFilling materials

Owner:山东东昌精细化工科技有限公司

Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound

ActiveCN111471047AEasy to synthesizeAtom economy is highOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsArylAcyl group

The invention discloses a method for selectively synthesizing a pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound, and belongs to the technical field of organic chemistry. Starting from a 1-aryl pyrazolidone compound 1 and an alkynyl cyclobutanol compound 2, the pyrazolo[1,2-a] pyrazolone compound 3 or 2-acyl indole compound 4 is synthesized with high selectivity by changing the reaction temperature, solvent and additive types under the catalysis of a dichloro (pentamethylcyclopentadienyl) rhodium (III) dimer. The method has the advantages of simple and easily available raw materials, simplicity and convenience in operation, mild conditions, good selectivity, wide substrate application range and the like.

Owner:HENAN NORMAL UNIV

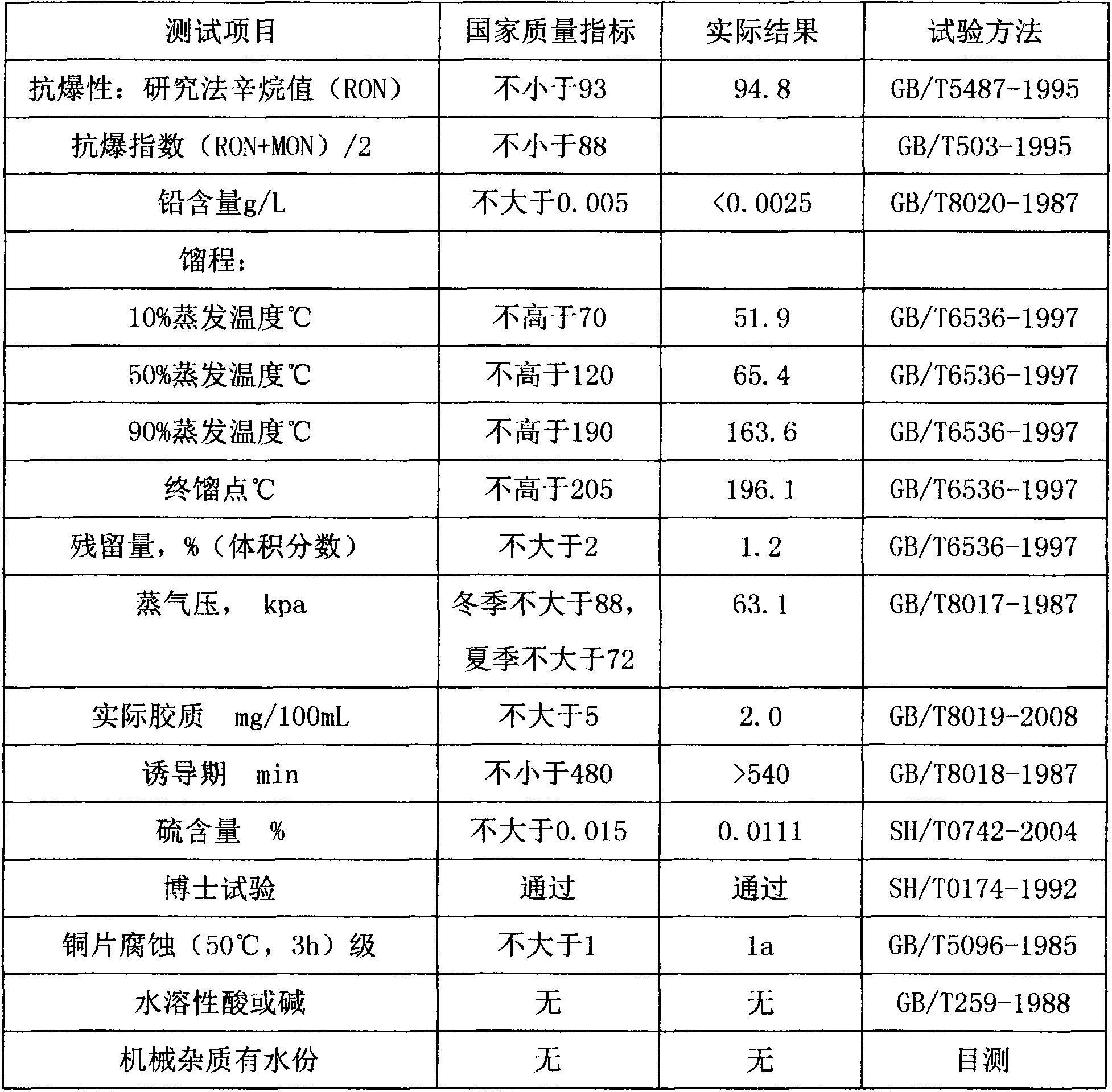

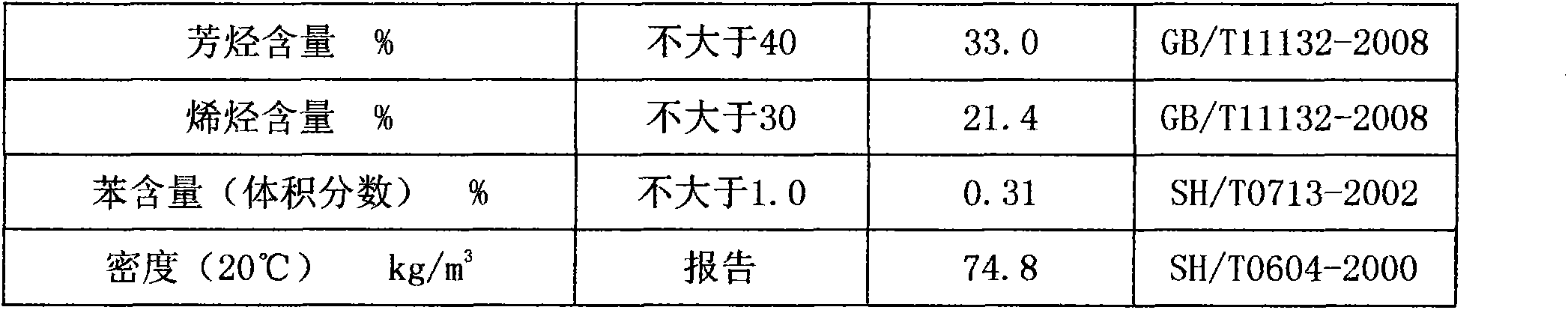

Highly efficient fuel accelerant and method for preparing the same

The invention discloses a highly performance fuel combustion adjuvant and process for preparation, wherein the combustion adjuvant comprises low grade alkyl teriarybutyl ether, methyl cyclopentadiene manganese tricarbonyl, butoxy benzene, C3-5 lower alcohol, hexadecyl benzene sulfonic acid potassium, petroleum zinc sulphonate, petroleum magnesium sulphonate, dichlor potassium alkyl, ferrocene and 200# solvent oil for the rest. The combustion adjuvant is prepared through stirring and mixing at a finite temperature in sequences.

Owner:张金芝

Methanol gasoline for vehicle and preparation method thereof

InactiveCN104004551AImprove combustion characteristicsIncrease profitLiquid carbonaceous fuelsAlternative fuelsTert butyl

The invention discloses methanol gasoline for a vehicle and a preparation method thereof. The methanol gasoline is prepared from the following raw materials in parts by weight: 60-70 parts of methanol, 15-25 parts of 90# gasoline, 10-15 parts of dipropylene glycol methyl ether acetate, 5-10 parts of tert amyl methyl ether, 5-10 parts of dimethyl carbonate, 4-8 parts of diethylene glycol dimethyl ether, 3-6 parts of 2,2-dimethoxypropane, 1-2 parts of ferrocene, 0.5-1.5 parts of methyl cyclopentadiene tricarbonyl manganese, 0.8-1.4 parts of 2,5-di-tert-butyl hydroquinone, 0.4-0.8 part of glycerol monolaurate, 0.5-1 part of sodium petroleum sulfonate, 0.3-0.6 part of N-Polyoxyethylated-N-tallow-alkylamine, 5-10 parts of wood tar, 3-6 parts of isopropanol, 2.5-4.5 parts of fish meal, 2-3 parts of bone meal, 1-2 parts of stearic acid and 0.5-1 part of urotropine. The methanol gasoline disclosed by the invention is favorable in combustion characteristic, high in utilization ratio, favorable in anti-detonating quality, low in corrosivity, high in safety and reliability, energy-saving and environment-friendly, can be used instead of any of 90#, 93#, 97# and 98# gasoline for a vehicle, is novel environment-friendly alternative fuel, and can reduce pollutant emission and carbon emission; and the combustion emission of the methanol gasoline meets the standards in Europe and America. The methanol gasoline has excellent economic benefits and far-reaching social benefits.

Owner:BEIJING DAMING QIAOHUA ENERGY SCI & TECH

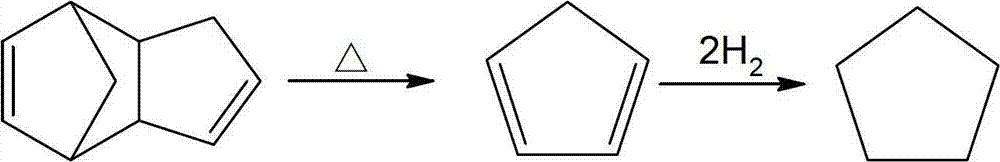

Method for preparing cyclopentane from ethylene cracking C9 heavy fraction

InactiveCN102850173AHigh yieldAvoid lostHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsDepolymerizationHydrogen

The invention relates to a method for preparing cyclopentane from an ethylene cracking C9 heavy fraction. The method comprises the following steps: 1, preheating the ethylene cracking C9 heavy fraction, and depolymerizing to obtain a gas phase material; 2, depolymerizing the gas phase material to obtain crude methylcyclopentadiene and crude cyclopentadiene at the tower top; 3, carrying out monomer separation refining of the crude cyclopentadiene and the crude methylcyclopentadiene to obtain high-purity cyclopentadiene at the tower top; and 4, mixing the high-purity cyclopentadiene with a solvent and hydrogen, allowing the obtained mixture to enter a fixed bed catalyst bed layer, and carrying out a catalytic hydrogenation reaction. The preparation method provided by the invention, which adopts the cracking C9 heavy fraction as a depolymerization raw material, has the advantages of low cost, low equipment requirement, and suitableness for large-scale production; and in the invention, the cyclopentadiene yield is greater than 95%, the cyclopentadiene conversion rate is about 100%, the cyclopentane selectivity is greater than 99%, the cyclopentane yield is greater than 95%, and the purity of the obtained cyclopentane is greater than 99%.

Owner:NINGBO POLYTECHNIC +1

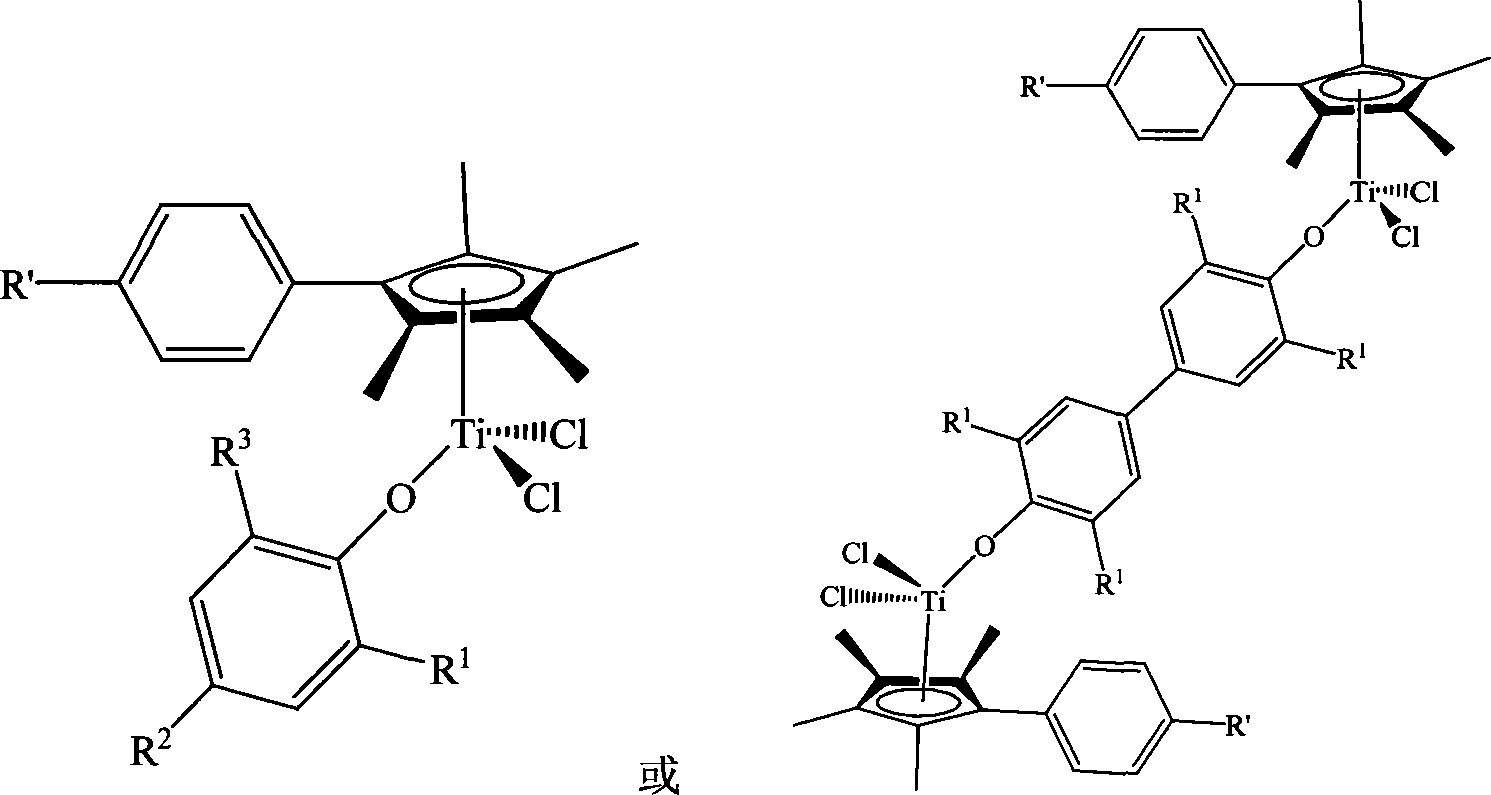

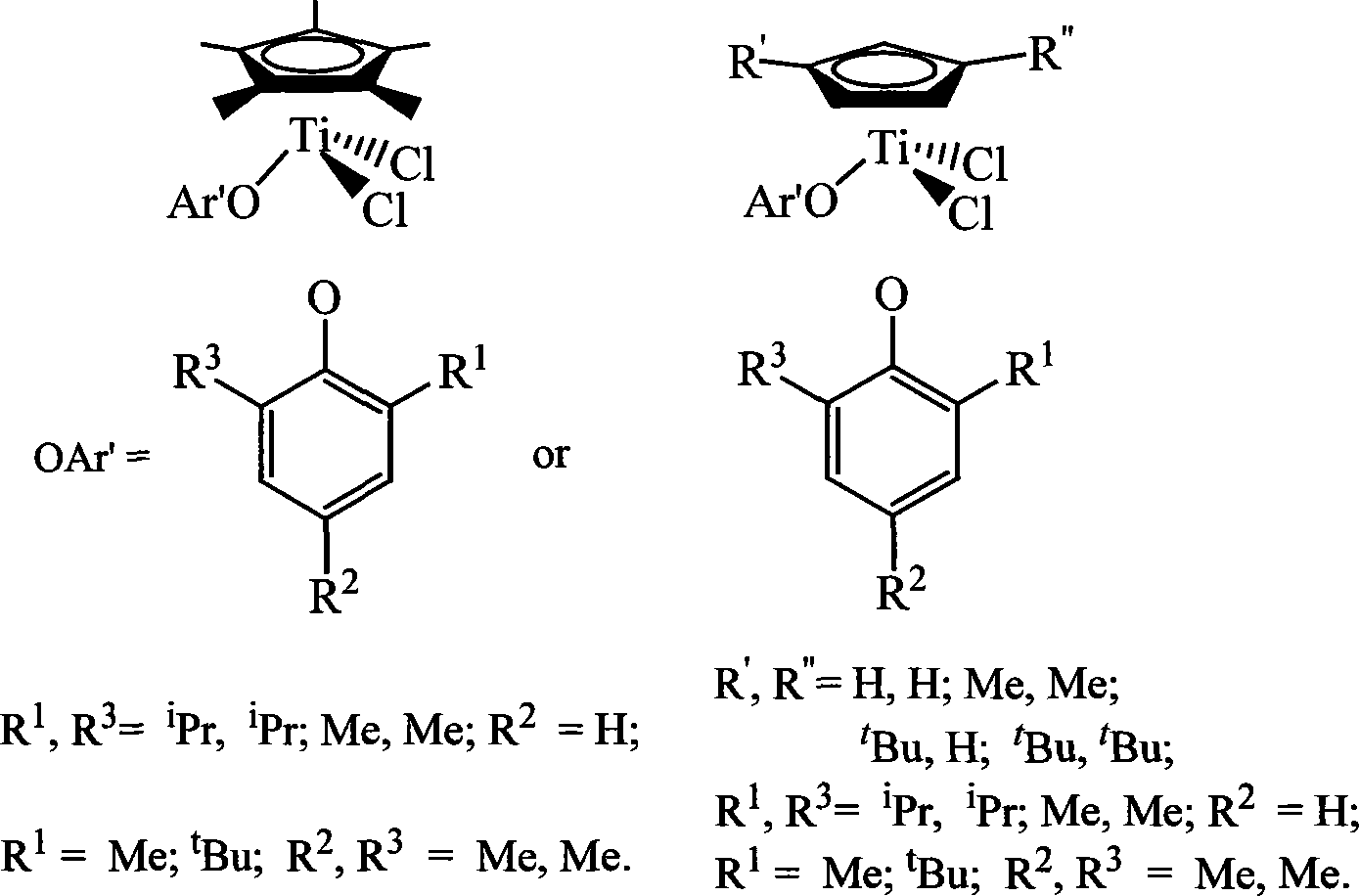

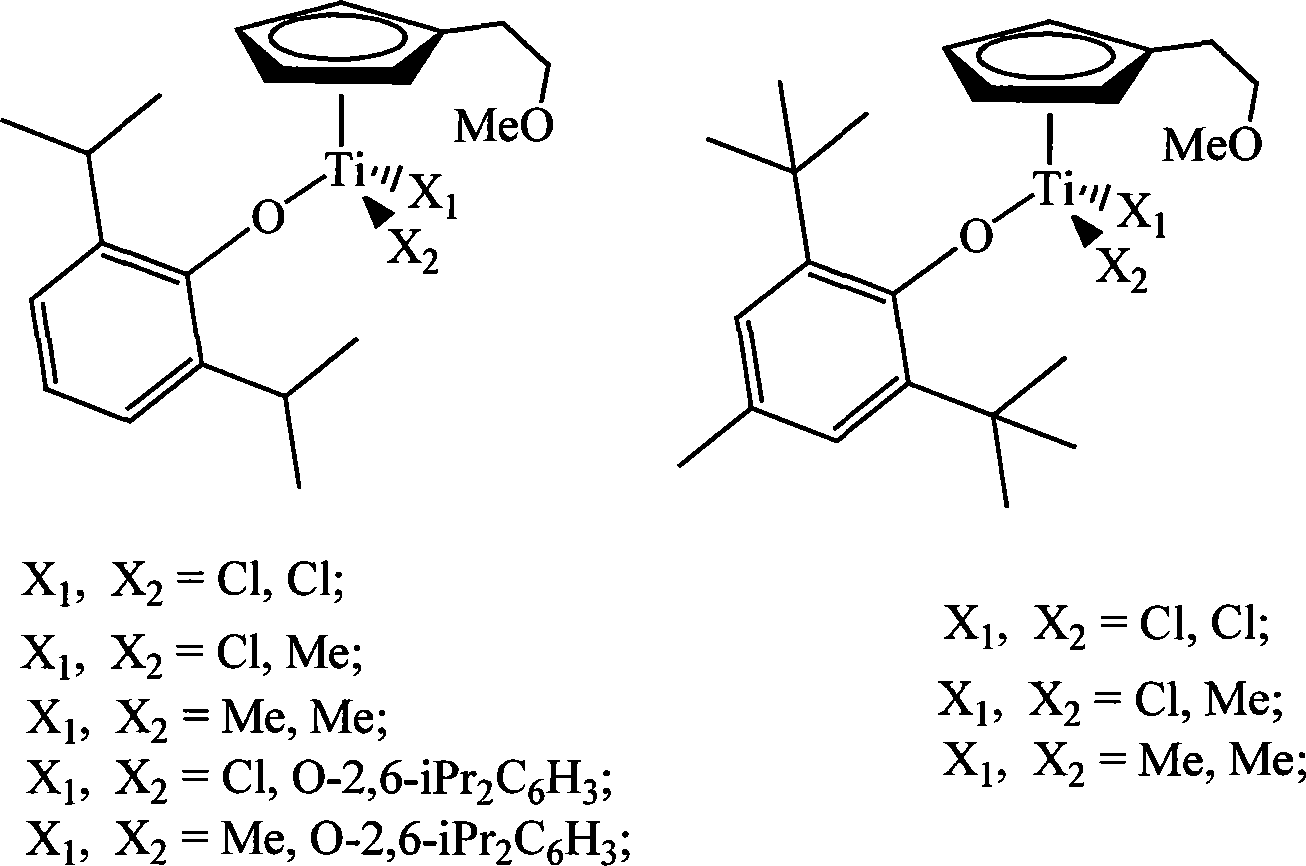

Non-bridged single/double-nucleus metallocene compound and uses thereof

InactiveCN101195644AHigh comonomer contentModerate molecular weight distributionMetallocenesTitanium chlorideOxygen

The invention relates to a non-bridge mono / bi-nuclear metallocene compound and a relative application olefin polymerization catalyst technical field. The compound contains 1-(4-methyl)-phenyl-2, 3, 4, 5-tetramethyl cyclopentadienyl-(2, 4, 6-tertiary butyl phenoxy)-titanium chloride, and (3, 3', 5, 5'-quattuor isopropyl-4, 4'-biphenyl oxygen)-bi-[1-(4-methyl)-phenyl-2, 3, 4, 5-tetramethyl cyclopentadienyl-titanium dichloride] or the like. The metallocene compound can be used as main catalyst, while alkyl aluminum is used as promoter, or organic boron compound and alkyl aluminum are assembled into a promoter system, to catalyze and synthesize high-molecular-weight atactic polypropylene with improved catalysis activity and polymer molecular weight, which can catalyze the polymerization of vinyl and alpha-olefin, to obtain the polymer with suitable molecular weight in narrow distribution and high co-monomer content.

Owner:JILIN UNIV

Iridium oxide nanotubes and method for forming same

A method is provided for forming iridium oxide (IrOx) nanotubes. The method comprises: providing a substrate; introducing a (methylcyclopentadienyl)(1,5-cyclooctadiene)iridium(I) precursor; introducing oxygen as a precursor reaction gas; establishing a final pressure in the range of 1 to 50 Torr; establishing a substrate, or chamber temperature in the range of 200 to 500 degrees C.; and using a metalorganic chemical vapor deposition (MOCVD) process, growing IrOx hollow nanotubes from the substrate surface. Typically, the (methylcyclopentadienyl)(1,5-cyclooctadiene)iridium(I) precursor is initially heated in an ampule to a first temperature in the range of 60 to 90 degrees C., and the first temperature is maintained in the transport line introducing the precursor. The precursor may be mixed with an inert carrier gas such as Ar, or the oxygen precursor reaction gas may be used as the carrier.

Owner:SHARP KK

Cleaning gasoline with advantages of fog and haze treatment, environmental protection and energy saving

InactiveCN106947553ANo pollutionReduce consumptionLiquid carbonaceous fuelsFuel additivesCombustionDistillation

The invention relates to a cleaning gasoline with advantages of fog and haze treatment, environmental protection and energy saving, wherein the components comprises 30-40% of alkylated gasoline, 15-20% of direct distillation gasoline, 20-25% of aromatic hydrocarbon, 20-25% of carbon olefin, 2-5% of a metal purification agent, and 0.05% of a MG2000 gasoline accelerator. In the prior art, a large amount of PM2.5 can be produced after the gasoline produced by using methyl tert-butyl ether (MTBE) and methylcyclopentadienyl manganese tricarbonyl (MMT) as the additive is burned so as to pollute the environment. According to the present invention, the problem in the prior art is solved, and the obtained cleaning gasoline is particularly suitable for the gasoline engine combustion.

Owner:QINGDAO YONGQUAN PETROLEUM CO LTD

Method for separating cyclopentadiene and methylcyclopentadiene from ethylene by-product C9

InactiveCN101186553AExpand sourceSolve the problem of carbon accumulationDistillation purification/separationHydrocarbon by depolymerisationMethylcyclopentadieneEthylene

The invention relates to a method of separating cyclopentadiene and methyl cyclopentadiene from a mixture with ingredients of dicyclopentadiene and dimethyl cyclopentadiene. The method is particularly suitable for purifying and separating the cyclopentadiene and methyl cyclopentadiene from ethylene byproduct C9 or crude cyclopentadiene. Ethylene byproduct C9 or crude dicyclopentadiene that contains dicyclopentadiene and dimethyl cyclopentadiene is put into a high-temperature cracking reactor that is arranged in a tower boiler of a rectifying tower 1; pyrolyzed mixture gas under high temperature runs upwards through the rectifying tower to lead distillate that contains the cyclopentadiene and the methyl cyclopentadiene to be separated at the top of the tower; the mixture distillate of the cyclopentadiene and methyl cyclopentadiene that is extracted at the top of the rectifying tower 1 enters a rectifying tower 2, and the cyclopentadiene is extracted from the top of the tower and the methyl cyclopentadiene is extracted from the bottom of the tower.

Owner:天津天大天海化工新技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound](https://images-eureka.patsnap.com/patent_img/24ba3190-d604-49af-a639-d45bd9ddb998/FDA0002501308420000011.png)

![Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound](https://images-eureka.patsnap.com/patent_img/24ba3190-d604-49af-a639-d45bd9ddb998/BDA0002501308430000021.png)

![Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound Method for selectively synthesizing pyrazolo[1,2-a] pyrazolone or 2-acyl indole compound](https://images-eureka.patsnap.com/patent_img/24ba3190-d604-49af-a639-d45bd9ddb998/BDA0002501308430000031.png)