Metallocene catalyst and preparation method thereof, and preparation method of polyethylene nanofiber

A metallocene catalyst and metallocene technology, applied in the direction of single-component polyolefin artificial filaments, etc., can solve the problems of high melting point of polyethylene, cumbersome processing, and increased industrial costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the above-mentioned metallocene catalyst, comprising: mixing porous polymer microspheres, aluminoxane compound and the first organic solvent, heating and stirring to react, then adding metallocene, continuing to heat and stir to react, obtain a metallocene catalyst;

[0041] The porous polymer microsphere contains N element;

[0042] The aluminoxane compound is methylalumoxane and / or modified methylalumoxane;

[0043] Described metallocene is shown in formula (I):

[0044] (Cp) x TiCl y (I);

[0045] Wherein, x is 1 or 2, y is 2 or 3, Cp is a cyclopentadiene group or a cyclopentadiene group derivative, and the cyclopentadiene group derivative is methylcyclopentadienyl group or ethylcyclopentadiene group.

[0046] The porous polymer microspheres are the same as those described above, and will not be repeated here.

[0047] According to the present invention, the porous polymer microspheres are preferab...

Embodiment 1

[0063] 1.1 Store 1 g of porous polymer microspheres (polystyrene, divinylbenzene and acrylonitrile copolymer) with an average pore diameter of 9.05 nm and a size of 3.87 μm in vacuum at 80°C for 15 hours, cool to room temperature, and add to In the 100ml Schlenk type filter reactor treated under water anaerobic conditions, add 20ml toluene with a syringe, then add modified methylalumoxane according to Al / N=7, and stir the reaction at 50°C for 12h Invert the filter for suction filtration, wash with toluene 3 times to remove excess modified methylalumoxane, and then add a certain amount of Cp 2 TiCl 2 Toluene solution (Cp is a cyclopentadiene group; Al / Ti=50), add an appropriate amount of toluene, stir magnetically at 50°C for 12 hours, then invert the reactor for suction filtration, wash 5 times with toluene, and The solid was vacuum-dried and transferred to an ampoule, and the whole operation was carried out under anhydrous and oxygen-free conditions to obtain a metallocene c...

Embodiment 2

[0068] In a 0.1L stainless steel autoclave, nitrogen was replaced 3 times, and then 20ml of n-hexane was added. With the addition of n-hexane, the cocatalyst modified methyl aluminoxane was added, followed by the addition of 6.82μmol1.1 of the metallocene Catalyst, the molar ratio of Al in the modified methylaluminoxane to the Ti of the metallocene catalyst is 5100:1, after the temperature is raised to 50°C, ethylene is introduced into the reaction kettle, the reaction pressure is 3 atm, the reaction time is 30min, and the reaction After the end, the polyethylene particles are collected, filtered, and dried to obtain polyethylene nanofibers.

[0069] The polyethylene nanofibers obtained in Example 2 were analyzed by differential scanning calorimetry, and its secondary melting point was found to be 141.4°C.

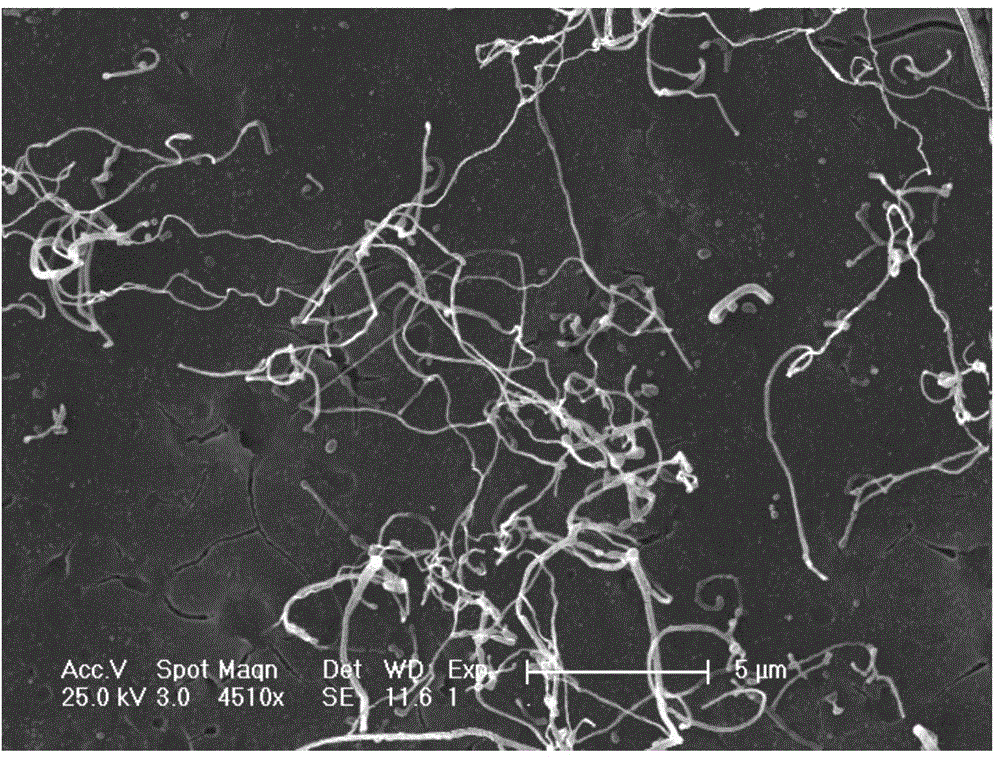

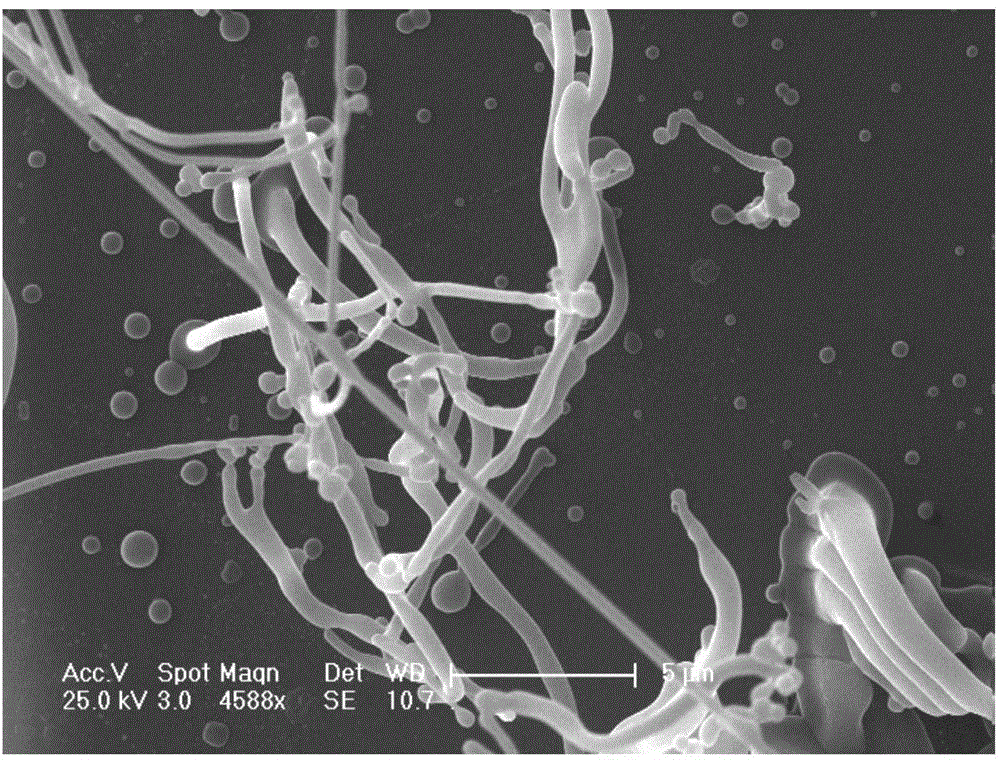

[0070] The polyethylene nanofibers obtained in Example 2 were analyzed using a scanning electron microscope, and it was found that they had independent nanofiber structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com