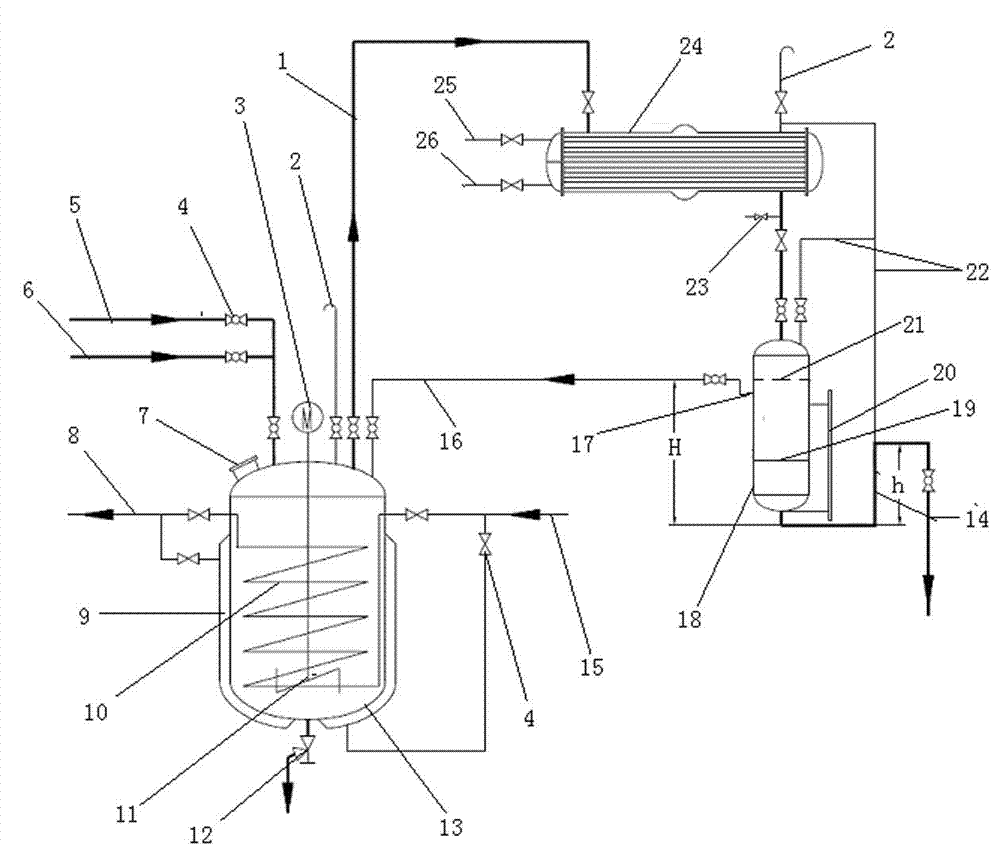

Circulating steam distillation apparatus and process for extracting methylcyclopentadienyl manganese tricarbonyl by aid of apparatus

A methylcyclopentadiene manganese tricarbonyl, steam distillation technology, applied in steam distillation, organic chemistry, chemical instruments and methods, etc. The effect of fully mixing, increasing the return water temperature and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0058] Example 1 Feeding: 2000kg of viscous waste residue of methylcyclopentadiene manganese tricarbonyl, crude salt (industrial sodium chloride) 150kg (3 bags), soda ash 40kg (1 bag), defoamer 6kg, tap water about 3000kg.

[0059] Heating with heat transfer oil, the set temperature of heat transfer oil is 160℃; in normal distillation, the pressure in the kettle is 0.08MPa, the water temperature in the kettle is 110℃, and the total steam distillation time is 20 hours. Obtained product 140kg, product density 1.227 g / cm 3 (20°C).

[0060] Since the product density is less than 1.3 g / cm 3 , When distilling, pay attention to closing the product outlet valve in time, control the oil-water interface, and prevent water from flowing out of the product outlet.

[0061] Chromatographic test: the product contains methylcyclopentadiene manganese tricarbonyl (referred to as MMT) 73.33%, other components CMT 0.73%, D-MMT 0.79%, DMCPD 0.25%, and the heavy component is about 18.8%. Then fi...

example 2

[0064] Example 2 Feeding: 2000kg of viscous waste residue of methylcyclopentadiene manganese tricarbonyl, crude salt (industrial sodium chloride) 250kg (5 bags), soda ash 40kg (1 bag), defoamer 3kg, tap water about 3000kg.

[0065] Heating with heat-conducting oil, the set temperature of heat-conducting oil is 160°C; in normal distillation, the pressure in the kettle is 0.09-0.1MPa, the water temperature in the kettle is 120-125°C, and the total steam distillation time is 20 hours. Obtained product 135kg, product density 1.239g / cm 3 (20°C).

[0066] Chromatographic test: the product contains MMT 75.02%, other components CMT 0.9%, D-MMT 0.73%, DMCPD 0.95%, MCPD 2.48%, heavy components about 18%, water 1053ppm. Then finally get MMT 101.3kg.

[0067] Take distilled water in the kettle to measure its density of 1.069 (20°C).

example 3

[0068] Example 3 Feeding: 1800kg of methylcyclopentadiene manganese tricarbonyl manganese reaction mixture (1400 liters, density 1.28), because the distilled water of Example 2 was left in the kettle, only about 1500kg of water was added, and the total water volume in the kettle reached about 3600 kg, add 3kg of defoamer, omit coarse salt and soda ash.

[0069] Heating with heat-conducting oil, the actual temperature of heat-conducting oil is 156-160℃; in normal distillation, the pressure in the kettle is 0.09-0.15MPa, the water temperature in the kettle is 110-125℃, and the total steam distillation time is 30 hours. Obtained product 1171kg, product density 1.347g / cm 3 (20°C).

[0070] Chromatographic test: the product contains MMT 89.5%, other components CMT 2.19%, D-MMT 0.71%, DMCPD 2.74%, MCPD 0.81%, heavy components about 2.4%, water 483ppm. Then finally get MMT 1048kg.

[0071] The distillation residue in the kettle was tested, and the residue contained about 2.5% of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com