Process of separating cyclopentadiene and methyl cydopentadiene from ethylene side C9 product

A technology for methylcyclopentadiene and bismethylcyclopentadiene, which is applied in the field of separating cyclopentadiene and methylcyclopentadiene, can solve the difficulty in handling catalysts and cannot simultaneously separate high-purity methylcyclopentadiene Diene, loss of active components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

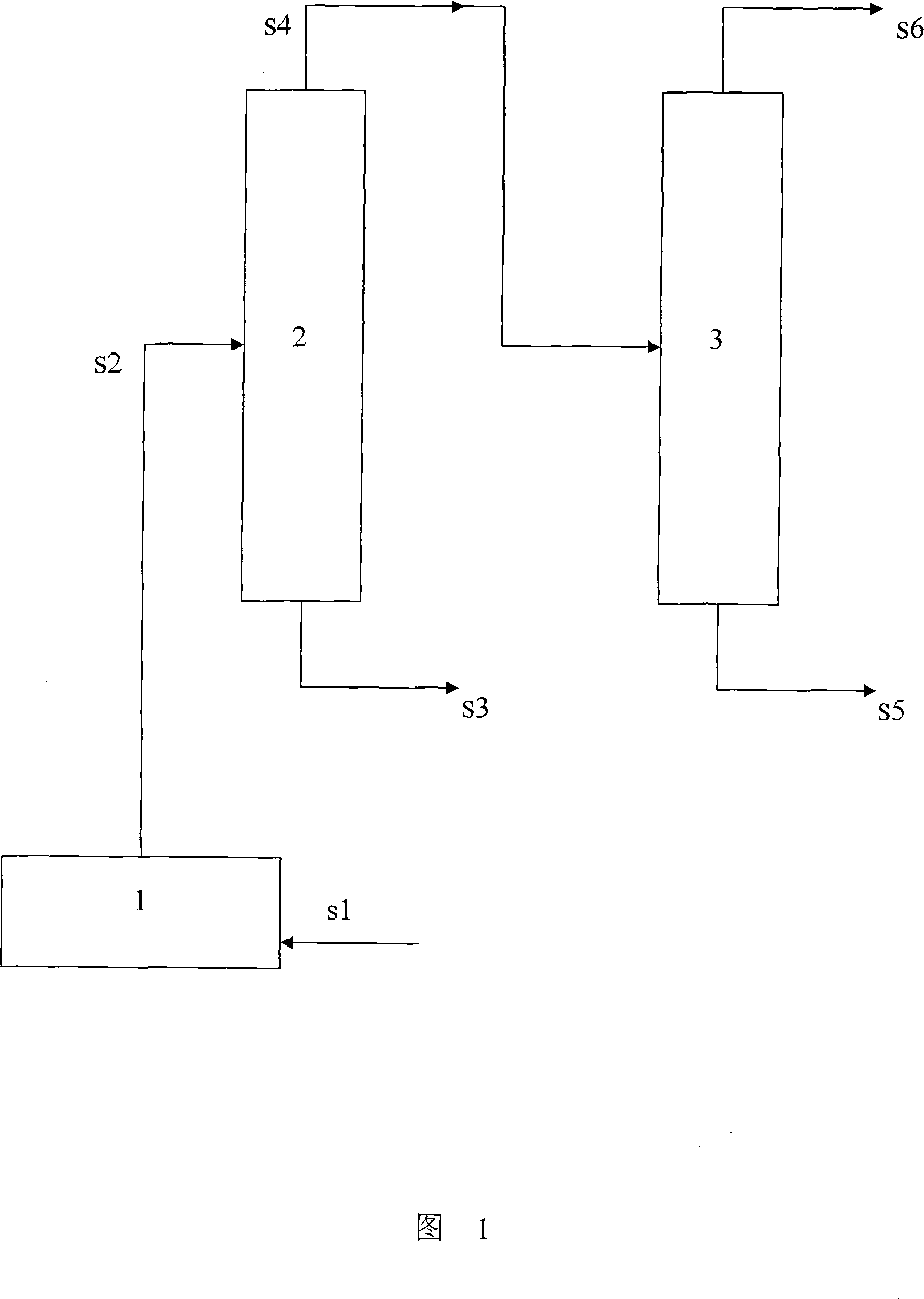

[0028] The ethylene by-product C9 containing 40% of dicyclopentadiene and dimethylcyclopentadiene is passed into the high-temperature cracking reactor, the cracking reaction temperature is 320°C, and the mixed gas after the cracking reaction is passed into the rectification packed with packing Tower 1, the temperature at the bottom of the tower is 260°C, and the temperature at the top of the tower is 80°C. The cuts containing cyclopentadiene and methylcyclopentadiene are extracted at the top of the tower, and the cuts containing cyclopentadiene and methylcyclopentadiene are passed through Enter the rectifying tower 2 filled with fillers, the temperature at the bottom of the tower is 90°C, the temperature at the top of the tower is 45°C, 97% of the cyclopentadiene product is extracted from the tower top, and 95% of the methylcyclopentadiene product is extracted from the bottom of the tower. Both rectification column 1 and rectification column 2 are operated under normal pressure...

Embodiment 2

[0030] The ethylene by-product C9 containing 25% of dicyclopentadiene and dimethylcyclopentadiene is passed into the high-temperature cracking reactor, and the cracking reaction temperature is 380 ° C. The mixed gas after the cracking reaction is passed into the refined Distillation tower 1, the temperature at the bottom of the tower is 280°C, the temperature at the top of the tower is 90°C, and the fraction containing cyclopentadiene and methylcyclopentadiene is extracted at the top of the tower, and the fraction containing cyclopentadiene and methylcyclopentadiene Pass into the rectifying tower 2 that tray is equipped with, tower bottom temperature 100 ℃, tower top temperature 55 ℃, the cyclopentadiene product of tower top extraction 93%, the methyl cyclopentadiene of tower bottom extraction 93% product. Both rectification column 1 and rectification column 2 are operated under normal pressure.

Embodiment 3

[0032]Crude cyclopentadiene containing 65% of dicyclopentadiene and dimethylcyclopentadiene is passed into a high-temperature cracking reactor, the cracking reaction temperature is 280°C, and the mixed gas after the cracking reaction is passed into a tray equipped with Rectification tower 1, the temperature at the bottom of the tower is 160°C, and the temperature at the top of the tower is 35°C. The fraction containing cyclopentadiene and methylcyclopentadiene is extracted at the top of the tower, and the fraction containing cyclopentadiene and methylcyclopentadiene is extracted. The fraction is passed into the rectifying tower 2 equipped with trays, the temperature at the bottom of the tower is 70°C, the temperature at the top of the tower is 35°C, 98% of the cyclopentadiene product is produced at the top of the tower, and 91% of the methylcyclopentadiene is produced at the bottom of the tower olefin products. Both rectification column 1 and rectification column 2 are operate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com