Method for preparing dicyclopentadiene and dimethylcyclopentadiene

A technology of dimethylcyclopentadiene and dicyclopentadiene, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., and can solve problems such as low reflux ratio, separation, and multiple theoretical plates in rectification towers. problem, achieve the effect of reducing dimerization reaction, increasing product yield, and avoiding the formation of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

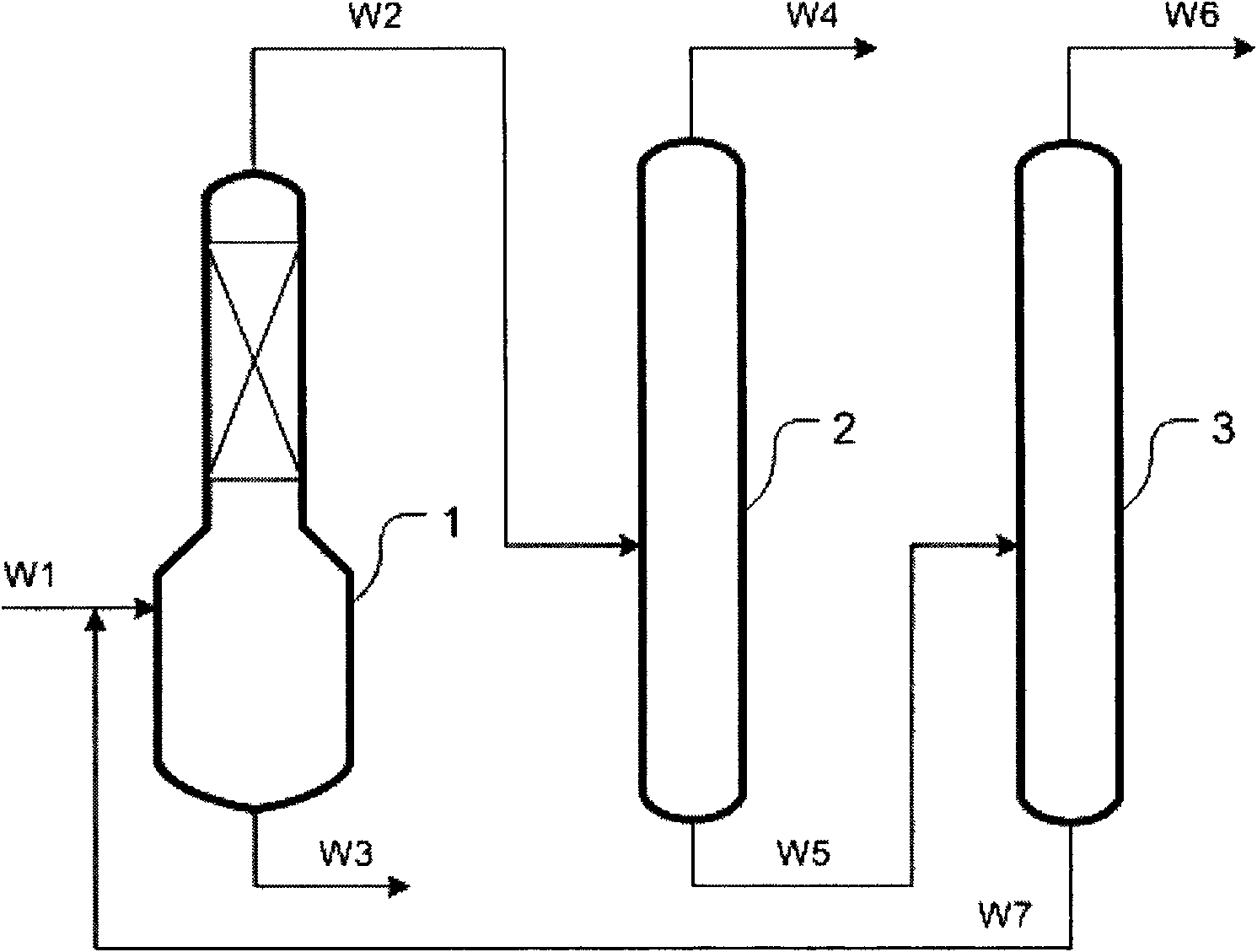

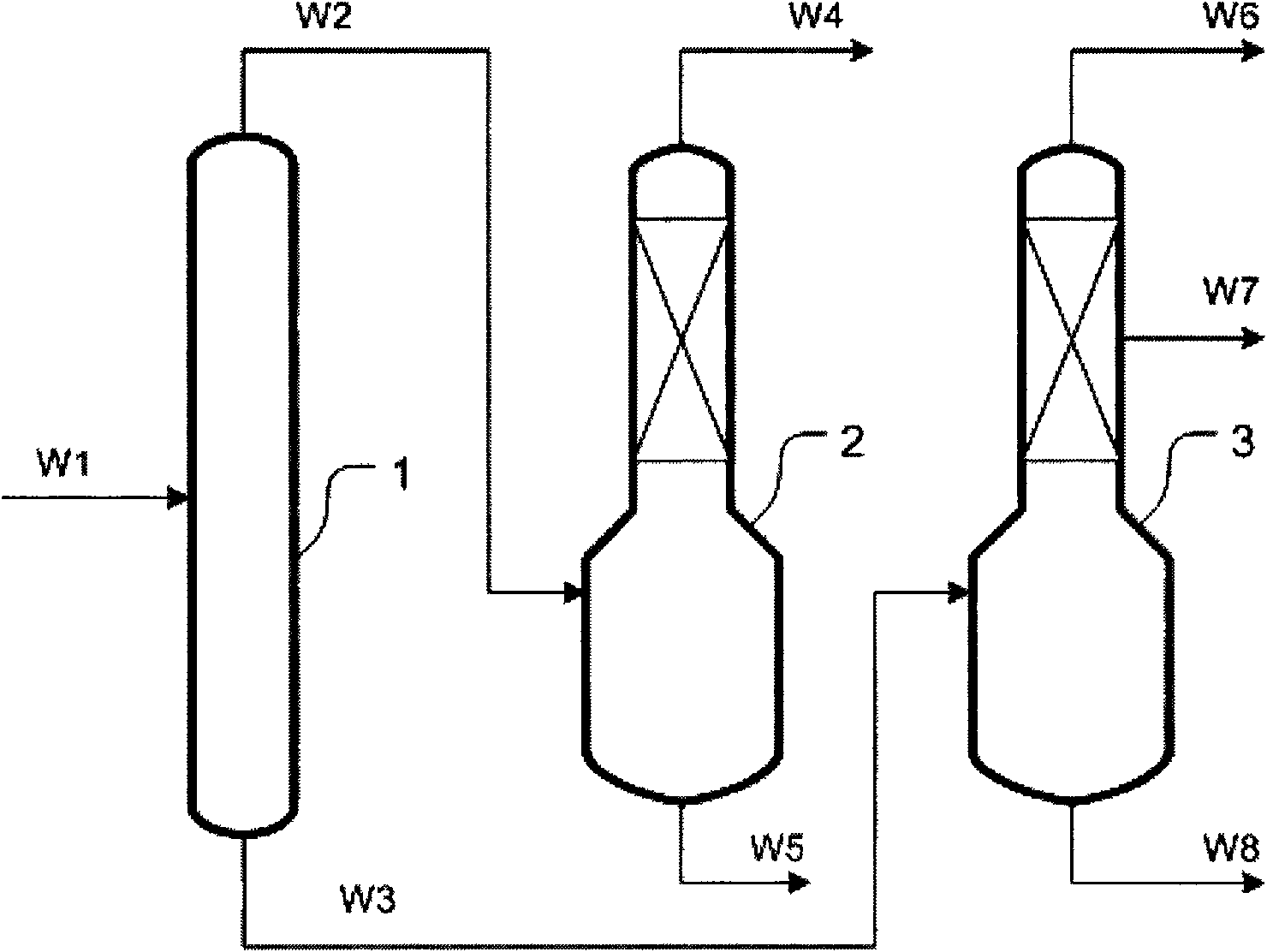

[0024] The technological process of embodiment 1~10 sees attached figure 2 , the raw material C9~C10 fraction W1 first enters the rectification tower 1 for vacuum distillation separation, the theoretical plate number of the rectification tower 1 is 25, the top of the tower is enriched with DCPD material W2, and the bottom of the tower is enriched with DMCPD material W3. The top material W2 of the rectification tower 1 enters the depolymerization rectification tower 2 for depolymerization rectification. The theoretical plate number of the depolymerization rectification tower 2 is 15, and the CPD finished product W4 is obtained at the top of the tower, and the heavy component impurities are regularly discharged from the tower reactor W5. The tower still material W3 of rectification tower 1 enters depolymerization rectification tower 3 to carry out depolymerization rectification, and the theoretical plate number of depolymerization rectification tower 3 is 20, and the CPD finis...

Embodiment 11~16

[0043] Equal amounts of CPD and MCPD obtained in Examples 1 to 10 were mixed respectively to obtain CPD raw materials with a purity of 99.0% and MCPD raw materials with a purity of 98.6%. DCPD and DMCPD were then prepared by thermal dimerization in a batch reactor with an effective volume of 2L using a single-stage reaction batch process. Compared with the multi-stage reaction that is heated step by step, the single-stage reaction requires a longer reaction time, but the process is relatively simple. The raw materials are fed according to 80% of the effective volume of the reactor, and the specific thermal dimerization process operating conditions of each embodiment are shown in Table 6. After the reaction, the product composition was analyzed by gas chromatography, and the thermal dimerization product yield and product composition are shown in Table 7 and Table 8.

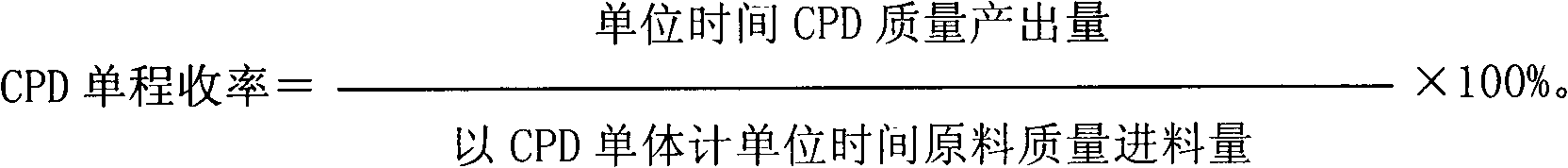

[0044] The product yield of DCPD or DMCPD is defined as:

[0045]

[0046] Table 6.

[0047]

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com