Technique for separating cyclopentadiene and methylcyclopentadiene

A technology of methylcyclopentadiene and methylcyclopentadiene dimer, which is applied in the field of separation technology of cyclopentadiene and methylcyclopentadiene, can solve consumption, increase energy consumption, and increase product loss and other problems, to achieve the effect of simple operation process, reduce product loss, and improve pull-out rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

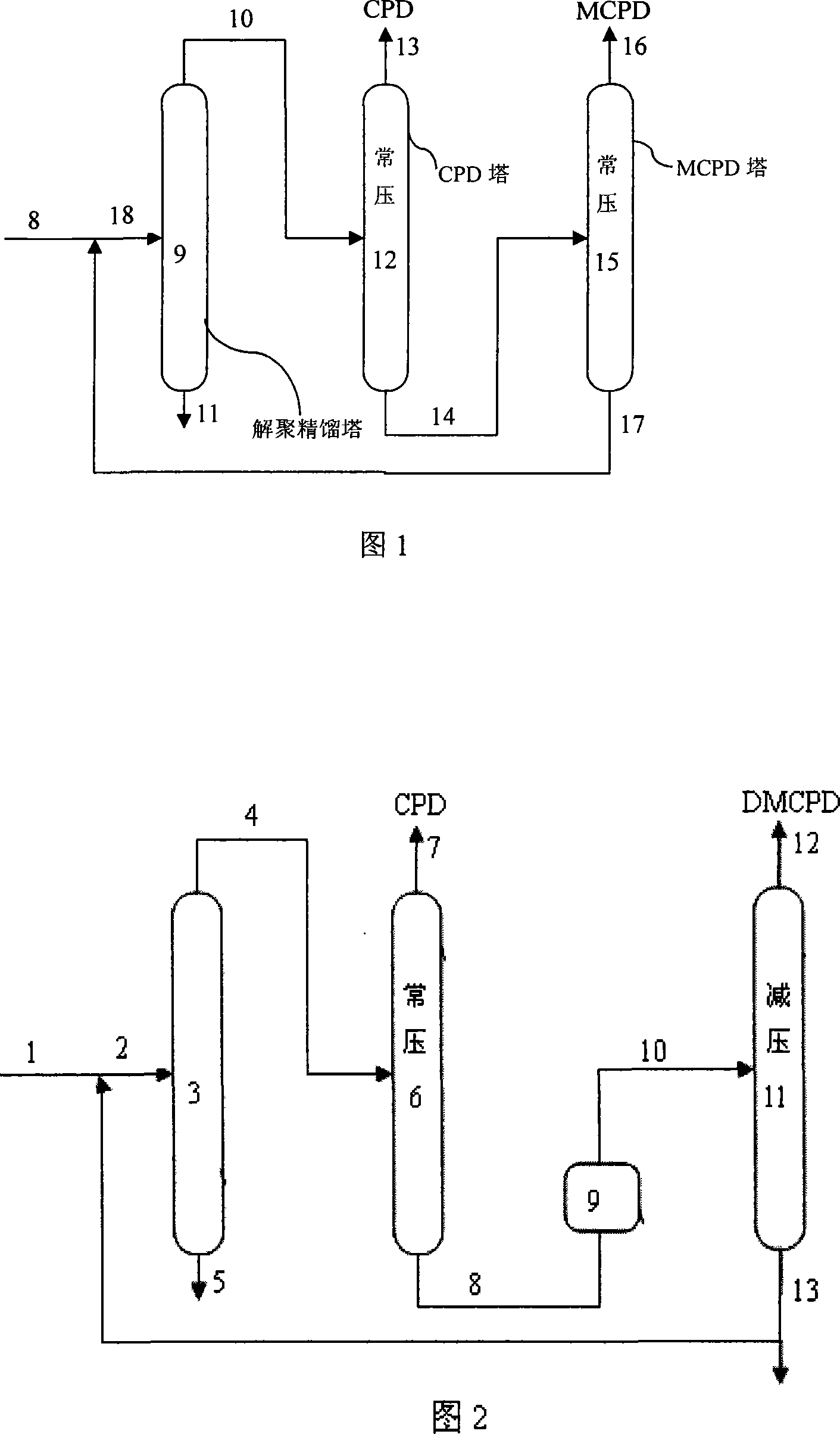

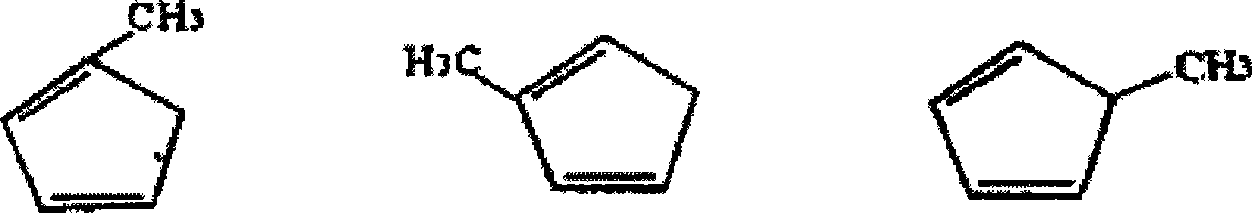

[0031] The working principle of the present invention will be further described below in conjunction with specific examples.

[0032] Referring to Fig. 2, the mixture based on cyclopentadiene and methylcyclopentadiene is a raw material (1 among the figures), and its composition is shown in Table 1.

[0033] Table 1

[0034] component name

[0035] The mixture raw material enters the depolymerization rectification tower (3 in the figure) with the speed of 500kg / h. The diameter of the tower is 800mm, there are 10 trays below the feed inlet, 20 trays above the feed inlet, and heating equipment at the bottom of the tower. The operating conditions are: the pressure at the top of the tower is 0.3MPa, and the temperature at the top of the tower is 170 ° C. The temperature at the bottom of the tower is 220°C.

[0036] Table 2 shows the composition of the top extract material (4 in the figure) of the depolymerization rectification tower.

[0037] Table 2

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com