Helicopter oil-water heat exchange device and helicopter

A heat exchange device, a technology for helicopters, applied in the directions of machines/engines, mechanical equipment, engine components, etc., can solve the problems of poor heat dissipation capacity of unmanned helicopters, and achieve the effects of optimized structural arrangement, compact structure and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

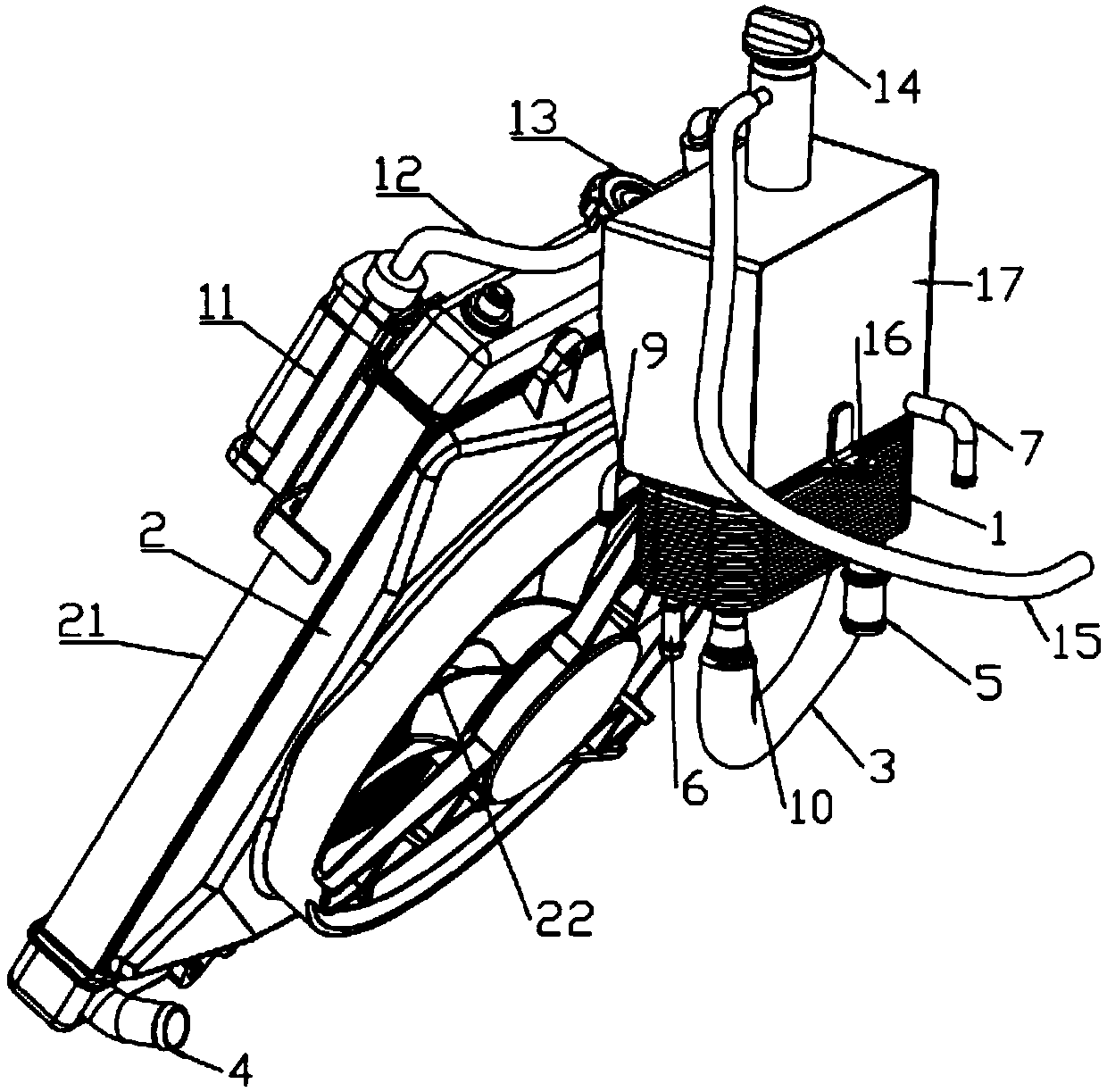

[0017] figure 1 It is a structural schematic diagram of the present invention, a helicopter oil-water heat exchange device, including a heat exchanger 1 connected to the coolant pipeline and the oil pipeline of the engine for mutual heat exchange between the coolant and the engine oil, and also includes a heat exchanger 1 arranged on the coolant The outlet end or inlet end of the pipeline is used for cooling liquid radiator 2 for heat dissipation of the cooling liquid. Here, the outlet of the coolant pipeline refers to the end where the coolant flows out of the engine, and the inlet of the coolant pipeline refers to the end where the coolant enters the engine after cooling cycle. In this embodiment, the coolant and the engine oil in the coolant pipeline and the engine oil pipeline flow out through the engine respectively, and realize mutual heat exchange through the heat exchanger 1, and the engine oil flows back to the engine oil pot 17 and then flows to the engine for lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com