EGR cooler cleaning method and cleaning apparatus

An EGR cooler and cleaning method technology, applied in the field of vehicles, can solve the problems affecting engine performance, carbon deposition and acid liquid cleaning, reducing the amount of exhaust gas recirculation, etc., to ensure performance, solve carbon deposition and corrosion problems, increase cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

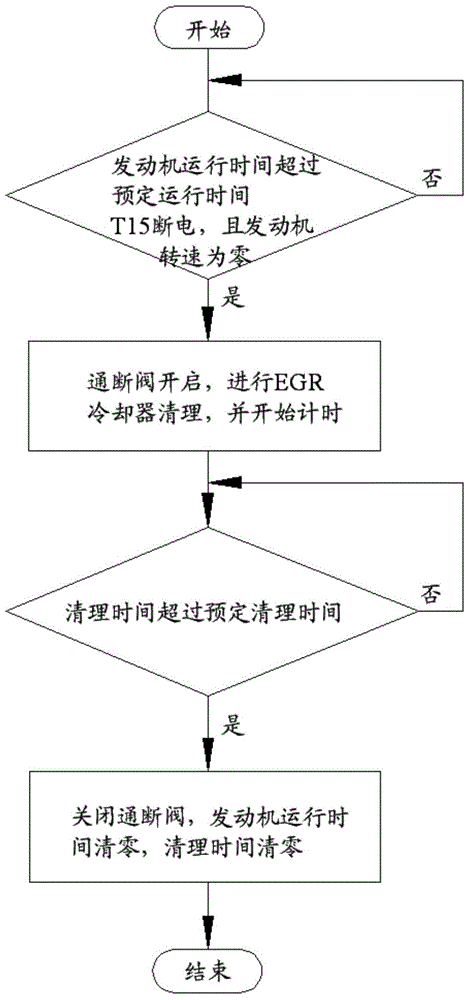

[0037] The core of the present invention is to provide a cleaning method and device for an EGR cooler. The device and method can effectively solve the problems of carbon deposition and corrosion of the EGR cooler without increasing the system cost. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

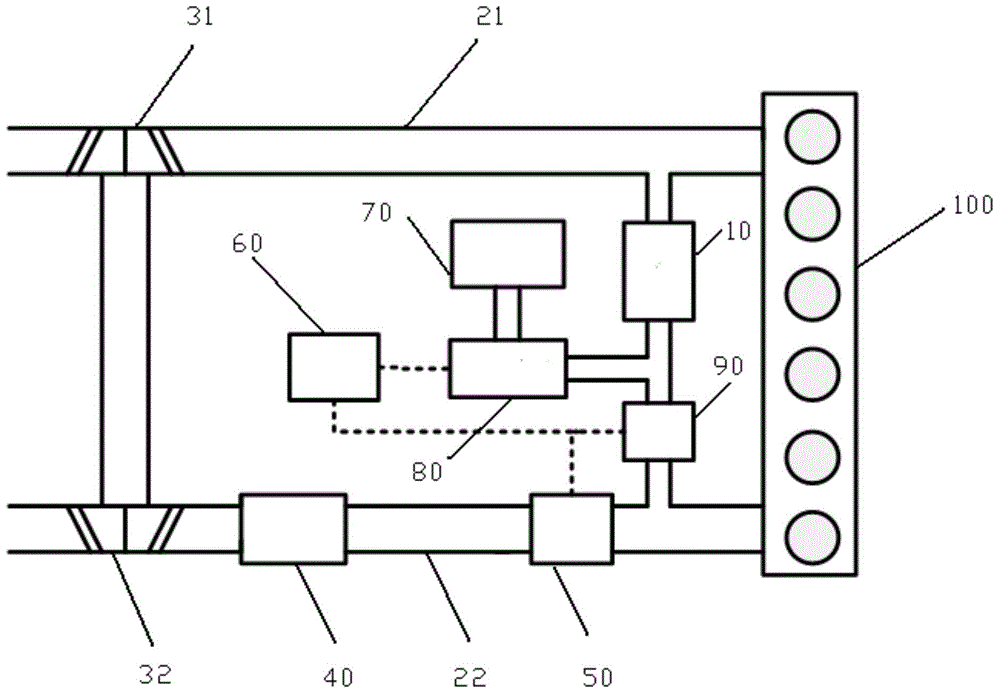

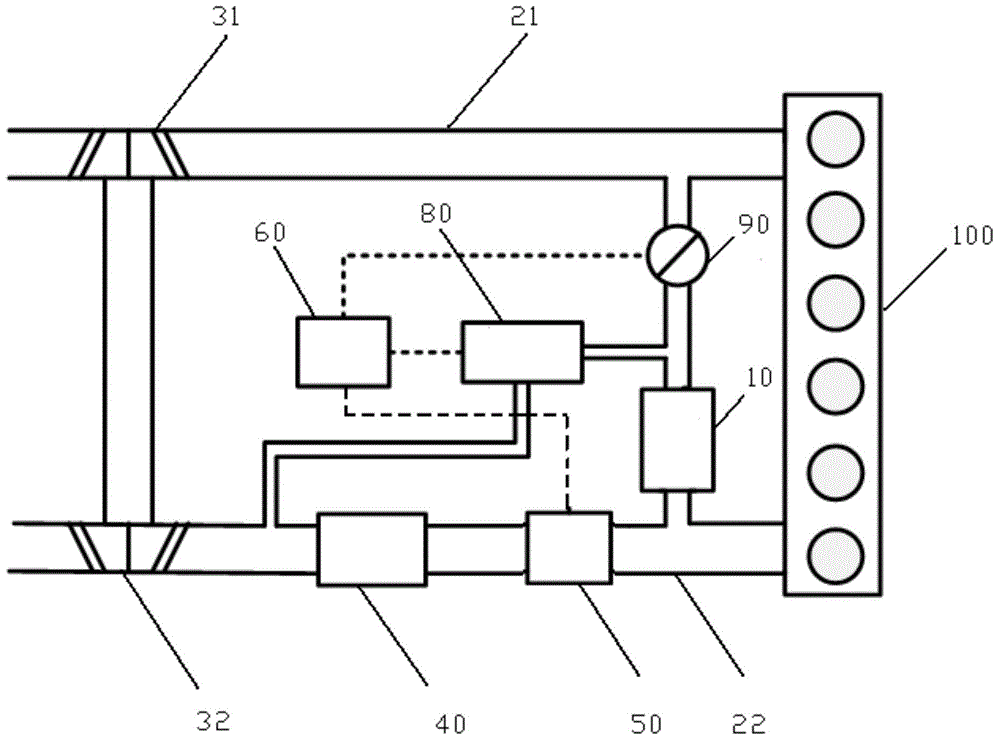

[0038] Please refer to figure 1 , figure 1 It is a structural schematic diagram of Embodiment 1 of the EGR cooler cleaning device provided by the present invention.

[0039] The cleaning device of the EGR cooler 10 in this embodiment includes a high-pressure gas source and an on-off valve 80, and the high-pressure gas source can communicate with the EGR cooler 10 through the on-off valve 80; it also includes a control on-off valve 80. control module. Here, the control module can be specifically integrated into the engine 100 control unit ECU60 of the vehicle, without a separate control unit, which saves the installation space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com