Method for preparing microporous metal layer on macroporous metal surface

A technology of porous metal and metal layer, which is applied in the production field of porous metal with high gradient pore structure, can solve the problems of reduced corrosion resistance, toughness, and change of metal properties of metal materials, and achieves good film forming effect, quality assurance, and solution The effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

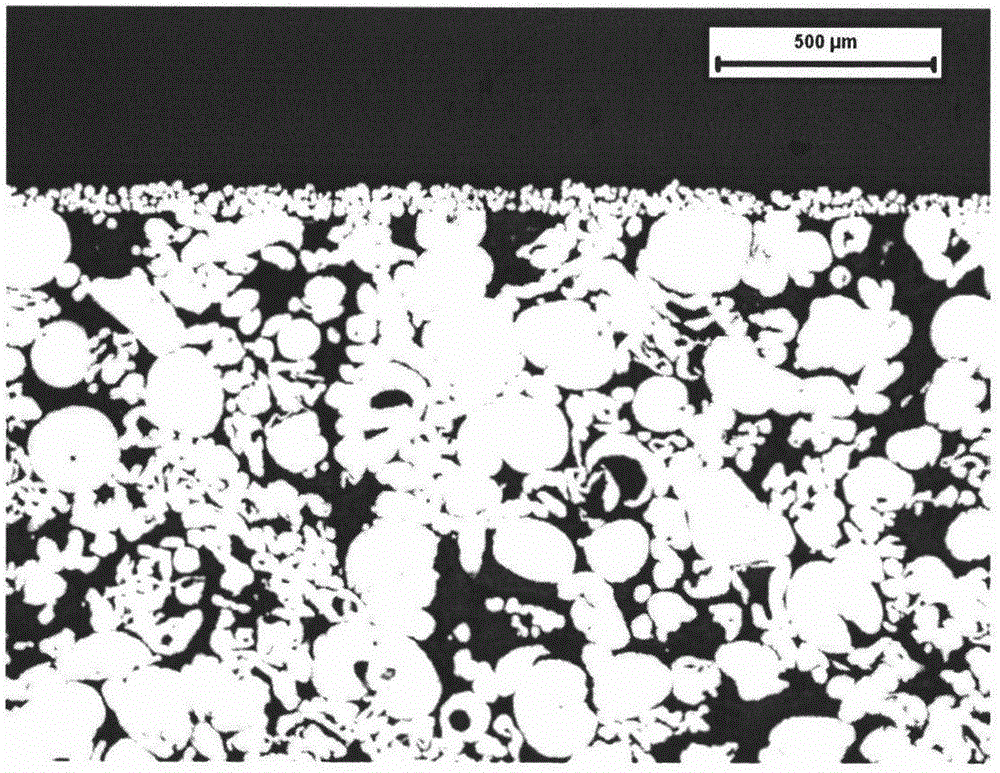

[0017] 1) Select a porous stainless steel disc as the substrate, with a diameter of 200mm, a thickness of 2mm, and a pore size of 150um; mix 50g of calcium oxide and 50g of water to prepare a calcium hydroxide slurry; the raw material for preparing the microporous layer is stainless steel powder with an average particle size of 10μm.

[0018] 2) Brush the above-mentioned slurry on the surface of the stainless steel disc by brushing, scrape off the excess slurry with a scraper, put it into a muffle furnace for drying, and pass in carbon dioxide gas; after drying, use 240 and 600 meshes successively Grind the surface of the substrate with sandpaper, rinse the substrate with clean water and dry it in an oven.

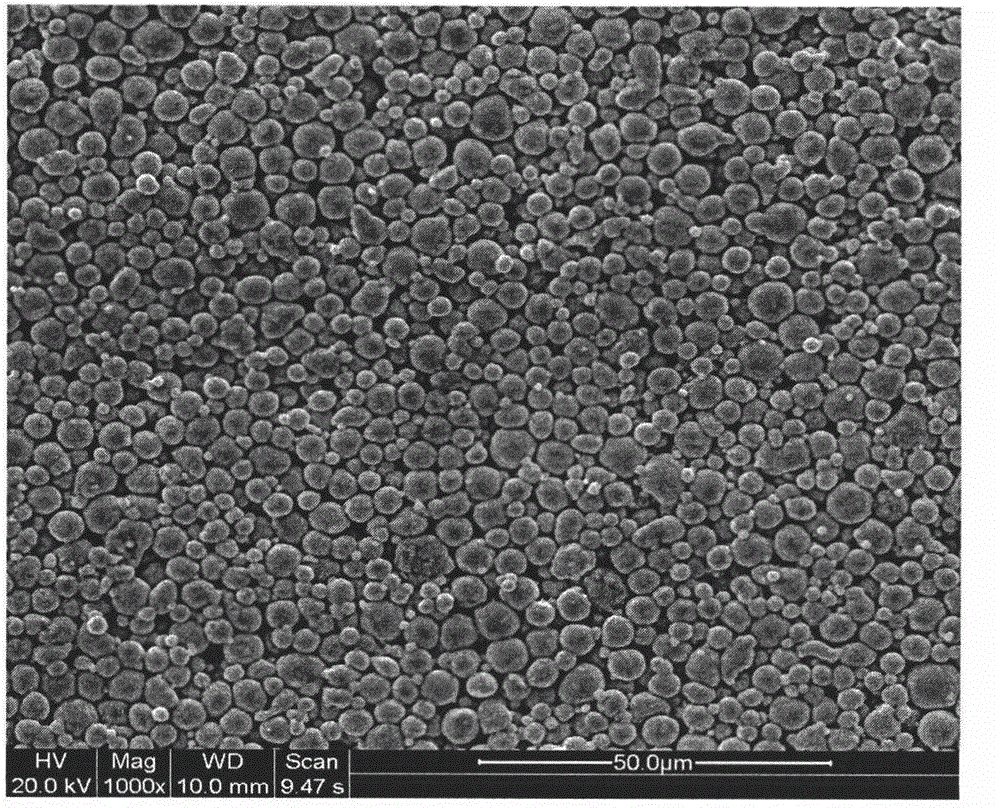

[0019] 3) Mix 20g of SS-316L stainless steel powder with an average particle size of 10μm and 100ml of polyvinyl alcohol (PVA) solution with a mass fraction of 0.5%, and ultrasonically 10min to form a uniformly dispersed slurry, which is brushed onto the surface of the subs...

Embodiment 2

[0024] 1) Select a porous stainless steel tube as the substrate, with an outer diameter of 60mm, an inner diameter of 55mm, a length of 1000mm, and a pore diameter of 50um; mix 50g of magnesium hydroxide with 50g of water to prepare a magnesium hydroxide slurry; the raw material for preparing the microporous layer is an average particle size of 2μm of silver powder.

[0025] 2) with the step (2) of embodiment 1

[0026] 3) Mix 200g of silver powder with an average particle size of 2 μm and 1000ml of polymethylcellulose (MC) solution with a mass fraction of 0.2%, and ultrasonically 10min to form a uniformly dispersed slurry, which is brushed onto the surface of the substrate and dried.

[0027] 4) The green body is sintered under an argon atmosphere. The heating program is: heating to 500°C at a rate of 2°C / min, holding for 1 hour, then heating to 800°C at a rate of 1°C / min, holding for 1.5 hours to obtain a gradient silver / stainless steel composite microfiltration membrane ma...

Embodiment 3

[0031] 1) Select a porous copper tube as the substrate, with an outer diameter of 20mm, an inner diameter of 16mm, a length of 100mm, and a pore diameter of 200um; mix 50g of magnesium hydroxide with 50g of water to prepare a magnesium hydroxide slurry; the raw material for preparing the microporous layer is an average particle size of 2μm of silver powder.

[0032] 2) with the step (2) of embodiment 1

[0033]3) Mix 200g of silver powder with an average particle size of 2 μm and 1000ml of polymethylcellulose (MC) solution with a mass fraction of 0.2%, and ultrasonically 10min to form a uniformly dispersed slurry, which is brushed onto the surface of the substrate and dried.

[0034] 4) The green body is sintered under an argon atmosphere. The heating program is: heating to 400°C at a rate of 2°C / min, holding for 1 hour, then heating to 600°C at a rate of 1°C / min, holding for 1.5 hours to obtain a gradient silver / stainless steel composite microfiltration membrane material con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com