Nitrogen-doped tungsten carbide catalyst, and preparation method and application thereof

A tungsten carbide catalyst and nitrogen doping technology, applied in the field of catalysis, can solve the problems of low selectivity and low conversion rate, and achieve the effects of reducing selectivity, improving conversion rate, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment discloses a nitrogen-doped tungsten carbide catalyst (N-W 2 The specific implementation of C / B) comprises the following steps:

[0041] Add 10mmol ammonium metatungstate and 8mmol hexamethylenediamine into water to mix the solution, impregnate the mixed solution with an equal volume on 5g of HZSM-5 molecular sieve containing B acid sites, let it stand at room temperature for 12h, and then put it in the oven After drying at 100°C for 24 hours, the precursor of nitrogen-doped tungsten carbide catalyst was obtained. The mass fraction of tungsten element in the precursor was measured to be 27%, and the mass fraction of nitrogen element was 0.5%;

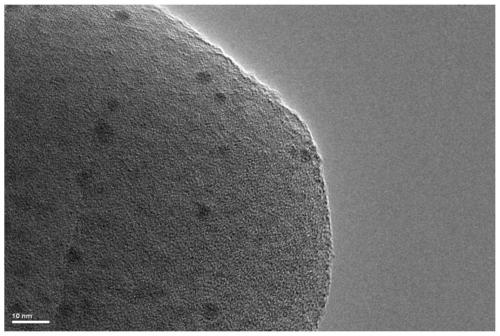

[0042] The precursor was heated to 600°C for carbonization in a mixed gas of hydrogen and nitrogen for 4h, wherein the volume fraction of hydrogen in the mixed gas was 10%, and the rate of temperature increase was 1.5°C / min to obtain a nitrogen-doped tungsten carbide catalyst (N-W 2 C / B), such as figure 1 As show...

Embodiment 2

[0044] This embodiment discloses a nitrogen-doped tungsten carbide catalyst (N-W 2 The specific implementation of C / B) comprises the following steps:

[0045] Add 6.8mmol of ammonium metatungstate and 20.4mmol of hexamethylenediamine into water to mix the solution, impregnate the mixed solution on 5g of H-β molecular sieve containing B acid sites, let it stand at room temperature for 12h, and then put it in the oven After drying at 80°C for 18 hours, the precursor of the nitrogen-doped tungsten carbide catalyst was obtained, and the mass fraction of tungsten element in the precursor was measured to be 20%, and the mass fraction of nitrogen element was 1%;

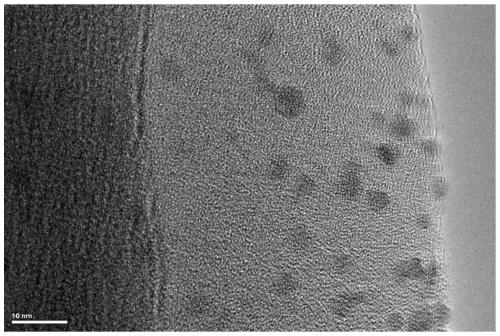

[0046] The precursor was heated to 800°C for carbonization in a mixed gas of hydrogen and helium for 4h, wherein the volume fraction of hydrogen in the mixed gas was 30%, and the rate of temperature increase was 2.0°C / min to obtain a nitrogen-doped tungsten carbide catalyst ( N-W 2 C / B), such as figure 2 As shown, the p...

Embodiment 3

[0048] This embodiment discloses a nitrogen-doped tungsten carbide catalyst (N-W 2 The specific implementation of C / B) comprises the following steps:

[0049] Add 15.3mmol of ammonium metatungstate and 19.2mmol of hexamethylenediamine into water to mix the solution, impregnate the mixed solution on 5g of H-Y molecular sieve containing B acid sites, let it stand at room temperature for 12h, and then place it in an oven at 120°C After drying for 24 hours, the precursor of nitrogen-doped tungsten carbide catalyst was obtained, and the mass fraction of tungsten element in the precursor was measured to be 36%, and the mass fraction of nitrogen element was 0.8%;

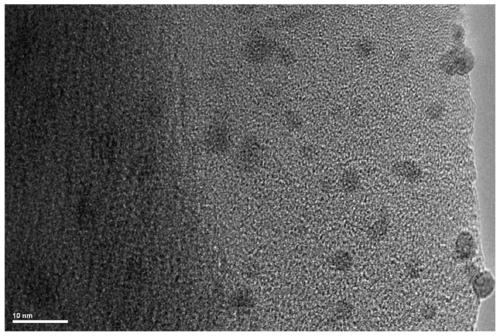

[0050] The precursor was heated to 700°C for carbonization in a mixed gas of hydrogen and nitrogen for 2h, wherein the volume fraction of hydrogen in the mixed gas was 40%, and the rate of temperature increase was 1.0°C / min, to obtain a nitrogen-doped tungsten carbide catalyst (N-W 2 C / B), such as image 3 As shown, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com